Professional Documents

Culture Documents

Common Errors in Truss Design PDF

Uploaded by

darkkimiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Common Errors in Truss Design PDF

Uploaded by

darkkimiCopyright:

Available Formats

Common Errors in Truss Design

The following is a list of some of the most common problems MiTek engineers see when reviewing customer truss submittals. Often the trusses need to be changed in order to be sealed and the objective of this document is to avoid truss designs that are sent to engineers to be sealed and then must be changed. The first seven are the most common. After that they are in no particular order of occurrence. Updated 11-29-2012 1. Wrong building or wind codes. Be familiar with what building code your state requires and be sure to use a wind code compatible with the building code you are using. Example: Pennsylvania requires IBC/IRC2009 at the time of this writing which in turn requires ASCE 7-05 for wind and snow. 2. Special connection required to distribute bottom chord loads equally between all plies. Be sure it is possible to transfer loads from one ply to the next on girder trusses. Each ply of a girder is designed to carry an equal amount of load. When load is attached to one face, a portion will have to be transferred to the other plies. If the loads cannot be transferred, the warning Special connection required to distribute bottom chord loads equally between all plies will appear in note #1 on the truss drawing. Try going into design info, nails/screws/bolts, and check the use verticals for load distribution box. This feature will often fix this problem. You can also try changing the type of nail or fastener you are using. Structural screws can transfer more load than nails. In addition, always try to add vertical webs directly above large concentrated loads. If these options do not fix the problem, submit the truss to your MiTek design engineer for help. 3. Bearing undersized. Many times you will come across trusses that give the warning Required bearing size at joint(s) are greater than input bearing size. This is due to the bottom chord and/or top plate crushing from the reaction of the truss. One way to correct this problem is go into Design Info, click on Bearing Design Options, and check any of the options available. These options include upgrading lumber, using a bearing block, or using a truss bearing enhancer. If you have these options checked, the program will attempt to fix the undersized bearing problem. If the bearing is still too small you may need to either increase the actual size of the bearing or add a ply to the truss. If a vertical member comes down directly above a bearing, like a web at an interior bearing or at a raised heel, you may be able to run the vertical through the bottom chord so the end grain of the vertical member is sitting directly on the bearing, which gives a much higher crushing value. Be aware this will fix the crushing on the truss only and not the top plate of the wall. The program assumes you are using the same material on the top plate as the bottom chord of your truss unless set up otherwise. When using the Bearing Block option to fix an undersized bearing, care must be taken on trusses with long scarf cuts at the heel. The Bearing Block ignores the scarf cut when calculating the nailing requirements. The nailing pattern and quantity of nails shown may

be impossible to achieve. Also note bearing blocks are assumed to be the same lumber grade and species as the bottom chord. When in doubt, have these trusses reviewed by an engineer. 4. Gable end trusses run as interior wind zone. If a truss is at the end of the building, be sure the roof zone is set to exterior or gable end zone in the wind loading tab. 5. Corner girders missing load. Many times, on cantilevered corner girders, you will need to make sure additional load for framing and fascia loads are added at the end of the girder or cantilevered section. Since framing is often used instead of trusses, layout does not put this additional load on the end of a corner girder. If a structural fascia is being used, a concentrated load will need to be added at the end of the corner girder and also at the end of the other truss which will be supporting the other end of the fascia. This can be achieved for symmetric corners with Girder loading in the engineering software by checking the cantilevered corner box. 6. . Reducing the spacing on Girder trusses without increasing the dead loads. Do not lower the truss spacing on girder trusses. If you must do this, be sure to check the dead loads on the girder to be sure the truss has been checked for the proper loading. An easy way to do this is to run the truss and preview it to see the weight of the truss. Take the weight and divided it by the span of your truss in feet. Then divide that number by the truss spacing. This number will be the minimum amount of total dead load you will need to have to account for the weight of the truss. You will also need to add any additional loads for material such as sheathing, shingles, drywall, or insulation. Increase your TCDL and BCDL to the appropriate number based on these checks. Again, it is much easier to simply leave the girders at the normal truss spacing. Also, please be aware that the MiTek Engineering software automatically reduces the magnitude of the tie in truss load for the one foot of redundant area when loading from layout is used. 7. Thermal factor needs to be selected correctly Thermal factors should only be set to 1.0 if the roof trusses will be heated and kept above freezing at all times. This may occur in some commercial buildings where a drop ceiling is used. If drywall and/or insulation is being used on the bottom chord of the roof truss (most residential) the thermal factor or Ct factor should be set to 1.1 because the heat from the building will not escape into the enclosed truss area. For unheated agricultural buildings, at Ct factor of 1.2 should be used. 8. Manually changing heel conditions such as wedges or sliders (turning heal solving off). Make all changes to the heel of the truss through Edit Heel Options instead of using Versatruss. If you do make a change in Versatruss, the heel solving will be turned off and the heels may not be checked properly. Instead, make all changes using the Edit Heel Options tool and leave Solve Heels turned on. This will insure the proper size plates, wedges, and sliders at the heels. If you dont use heel options you may get a note saying Heel reinforcement inadequate or the heels simply may not be checked. As an

aside, if Multipoint Heel Analog is turned on in design Info, sliders of a predefined length less than of the heel panel may be used in heel options. 9. Raised heel valley trusses. Valley trusses will not have sheathing applied to one of its faces to stabilize it so be sure to add a web and triangulate at least one end of a valley truss with raised heels. If semirigid joints are used, this can typically be ignored. 10. Flat trusses with a parapet. If a truss with a flat top chord is on a structure with a parapet surrounding it, additional loads should be added to the top chord for snow drifting. Also, make sure that either Components and Cladding or Hybrid wind method is used and ensure that the parapet member is defined as a top chord. 11. Large trusses not triangulated at the heels. In order to cut costs, sometimes designers leave out webs that form the triangles which make a truss structurally sound. While these trusses may run, some designs may not be structurally viable and should be avoided or reviewed by an engineer. To avoid this, add webs to triangulate trusses, especially at the heels if the truss span is 20 or longer. Also, make sure you use Semi-Rigid joints anytime you have an un-triangulated truss. 12. Long bearings that end in the middle of a truss panel. If you have a long bearing where the end of that bearing is not located at a joint (i.e. the end of the bearing is in the middle of a panel and there is no joint number associated to the end of the bearing), the program may not be checking the truss for induced shear and bending at that location.

If you see one of these long bearings with no joint number at its end, it may be necessary to add an additional smaller bearing at the end of the larger bearing. This is especially true for girder trusses. An example of how to check this is as follows: If you have a 6-0-0 bearing ending in the middle of a truss panel, you can input a new 03-8 bearing at 6-0-0 and aligned at the end of the longer bearing.

The two bearings will actually overlap as you can see in the second picture. You will notice a new joint number (15) being inserted at the new bearing location and it will now give a reaction at the end of the bearing. An easy way to avoid this is to run a web down to the end of a large bearing.

13. Top chord bearing floor trusses. When using top chord bearing floor trusses, it will usually be required to have a double top chord above the bearing. Be sure the stacked top chord extends far enough into the truss so it can be attached with at least 2 plates. If it does not plate the stacked member with at least two plates, extend it in Versatruss until a second plate is added or simply run it back to the next vertical web. Correct Incorrect

14. No room load on attic trusses. When you create an attic truss be sure to define the truss as an attic under Truss Application in Truss Basics. This will ensure your attic has the required additional load added to the attic room area. If an attic truss is created using Versatruss, you will need to manually add the additional loads to the floor and ceiling area. Also, if you have sloping walls in an attic, the program will not add any load to the room even if it is defined as an attic in Truss Basics. Load will need to be added manually to the floor, ceiling, and walls on these truss types.

15. Splicing in heel panels and two splices in the same panel. While the program checks all of the following properly, it is still recommended to keep top and bottom chord splices out of the first panel of a truss. Try to move the splices beyond the first web so the chord member will be attached by at least two plates before the splice occurs. It is also recommended to keep from having multiple splices in the same truss panel and to avoid placing multiple splices in an Attic room. Finally, avoid a splice in the top chord of an attic truss in the slopped ceiling area of the room. These rules are not required when the truss is designed with semi-rigid joints. 16. Maximum of one lumber size change at mid panel splices. While the program checks all of the following properly, it is still recommended to avoid splicing a member to another member that is one lumber size larger or smaller than itself in the middle of a panel. For instance, if a splice falls in the middle of a truss panel you can splice a 2x4 to another 2x4 or a 2x6, but not to a member larger than 2x6. A 2x6 may be spliced to a 2x4, 2x6, or a 2x8, but not a 2x10. Better Not so good

If you are required to change more than 1 lumber size at a splice location, move the splice to the next location as shown in the example below. Correct

17. Trusses with a notched bottom chord for ledger bearing. If you have a truss where the bottom chord is cut back to accommodate a ledger type bearing (i.e. the end vertical sits on the ledger bearing), be sure to check the reaction at this location. Many times the bottom chord, end vertical and a web all meet at the raised bearing and if the reaction at that location is more than 500lbs times the duration of loading, you will need to rotate and/or increase the plate so part of the plate is actually above the bearing. This bearing coverage by the plate is to help prevent the end vertical from shearing. This is done automatically in version 7.3.5 SP3 and newer.

18. Valleys and piggy backs with large vertical web spacing. For valley and piggy back trusses, be sure the vertical studs do not exceed a 4-0-0 on center spacing. It is also recommended to add vertical webs at pitch breaks. 19. Tray ceilings near the bearing. When you have a condition where the bottom chord has a step up very close to the heel, sometimes the truss will need to be analyzed as tail bearing. You will find this when the first horizontal section of the bottom chord extends out for a short distance and then steps up to intersect the top chord and upper horizontal section of the bottom chord at the same location. In situations where all three of these members meet at the same location and all three share one joint number, the vertical member will need to be analyzed as a web instead of a bottom chord. This will ensure the truss is being checked properly.

In this situation member 7-10 should be defined as a web. An alternative way to check this truss would be to run members 8-10 and 7-10 as non structural. This is automatically done in version 7.3.5 SP3 and newer.

20. Uplift for first load case exceeds limits. Occasionally you will get this note on trusses due to gravity uplifts that exceed 1000lbs. This is usually caused by having two bearing locations very close together on one end of the truss. The interior bearing acts as a pivot point causing the short end of the truss to want to pull up. You can either connect the truss for the large amount of uplift or you can try to eliminate the uplift by removing the outside bearing and running the truss as a cantilever or using the Release bearing feature on the bearing with the high uplift. If this doesnt solve the problem, submit the truss for review.

21. Allowable Top Chord Reaction Exceeded. This error can occur on floor trusses with a raised bearing. When the bearing is raised, the truss will be analyzed as top chord bearing. If the first diagonal web coming off the bearing starts on the bottom chord, the allowable top chord reaction is very low. Try reversing the first diagonal web so it starts from the top chord and proceeds downward to the next joint. This will greatly increase the allowable reaction limit at that location. This will occasionally happen on roof trusses also. Try reversing the first web in this situation as well. 22. Top chord bearing roof trusses/raised bearing truss. If you have a top chord bearing truss or a truss with a raised bearing sitting on a block, you will have two end verticals. Be sure to define the member sitting on the bearing as a block and define the member stacked next to it as a top chord. This will ensure proper plating.

23. Maximum panel lengths. For roof trusses, use the maximum panel lengths set in the software. The software will give you a warning if you exceed these limits. For floor trusses use a maximum 30 top chord panel length and keep all duct opening to 24 maximum. 24. Insufficient Scab nailing. If you are using the scab feature and get the note special connection required between scab the scab does not work because there is not enough room to nail for the forces. Try extending the scabs length or switching the type of nail used until the program is able to call out a nailing pattern for the scab. If these options do not work, the truss should be reviewed by an engineer. 25. Web bracing does not fit. When using T & I bracing, the program will show a web with the brace on it whether the brace physically fits or not. These trusses must be reviewed and either changed to allow the brace to fit, upgrade the web until a brace is not required, or some sort of alternative bracing will need to be called out by an engineer.

26. Incorrect dimension lines All joints and pitch breaks must be properly dimensioned. The engineering program will automatically add the dimensions at the proper locations when creating a truss. However, if joints are moved or added or an attic room size is changed using Versatruss, the dimension lines may no longer reference the proper locations. If any of these design changes are made using Versatruss, you will need to delete the old dimensions and add the new dimensions at the proper locations.

You might also like

- Common Errors in Truss DesignDocument6 pagesCommon Errors in Truss Designduga110% (1)

- Common Errors in Truss DesignDocument9 pagesCommon Errors in Truss Designyyanan1118No ratings yet

- TECH2 - Wyntk - Common Errors in Truss DesignDocument15 pagesTECH2 - Wyntk - Common Errors in Truss DesignMilton Alexander Rivera TorresNo ratings yet

- Lifting LugDocument19 pagesLifting Lugpandiangv100% (2)

- Structural Rules of ThumbDocument11 pagesStructural Rules of Thumbrodriguez.gaytanNo ratings yet

- Risa FoundationDocument14 pagesRisa Foundationpolin27No ratings yet

- Padeye Deign.Document14 pagesPadeye Deign.Bolarinwa100% (3)

- Rules of ThumbDocument14 pagesRules of ThumbAntoniette Samantha Nacion100% (1)

- Innovative Products For Today's Builders.: Site Built Technical ManualDocument26 pagesInnovative Products For Today's Builders.: Site Built Technical ManualMorgan RookNo ratings yet

- Rules of ThumbDocument10 pagesRules of ThumbYazuraPoyoNo ratings yet

- Stepped Crane ColumnDocument14 pagesStepped Crane ColumnFrontlinerEagleNo ratings yet

- STRL Design Rules of Thumb PDFDocument11 pagesSTRL Design Rules of Thumb PDFsakti prasanna sahuNo ratings yet

- Understanding Bearing Size at A Wall or Beam - 1Document4 pagesUnderstanding Bearing Size at A Wall or Beam - 1Alejandra CruzNo ratings yet

- Design of Tail LugDocument34 pagesDesign of Tail LugPrajwal Shetty100% (1)

- Perspectives On Material Handling Practice Perspectives On Material Handling PracticeDocument10 pagesPerspectives On Material Handling Practice Perspectives On Material Handling PracticeMarcos SuarezNo ratings yet

- Advantages and DisadvantagesDocument14 pagesAdvantages and Disadvantagespaul machariaNo ratings yet

- Hexagon Documentation Site Export-3Document100 pagesHexagon Documentation Site Export-3Alberto VELOSA ROANo ratings yet

- Understanding and Installing TrussesDocument45 pagesUnderstanding and Installing TrussesGenesis GarayanalaNo ratings yet

- Design of Tail Lug & Basering Reinforcement-FLUORDocument34 pagesDesign of Tail Lug & Basering Reinforcement-FLUORALONSO GOMEZ100% (1)

- Concrete Rules of ThumbDocument15 pagesConcrete Rules of ThumbNoble Obeng-Ankamah100% (1)

- Plateing Options in MiTekDocument10 pagesPlateing Options in MiTekduga11100% (1)

- SG32 17 Provision of Extended and Telescopic Transoms and Board Brackets 1Document12 pagesSG32 17 Provision of Extended and Telescopic Transoms and Board Brackets 1Nizar MohamedNo ratings yet

- Zamil Steel Buildings Design Manual: Controlling DeflectionsDocument2 pagesZamil Steel Buildings Design Manual: Controlling DeflectionsBang SuccessNo ratings yet

- Trashrack 2021 ManualDocument10 pagesTrashrack 2021 ManualomerscheenNo ratings yet

- Tutorial 06 UnwedgeDocument13 pagesTutorial 06 UnwedgeManuela Alejandra Mollo Flores100% (1)

- Preliminary Design Rules of ThumbDocument11 pagesPreliminary Design Rules of Thumbnimal1234No ratings yet

- Descripción Norma RmiDocument31 pagesDescripción Norma RmiJuan Mauricio Palacios AnzolaNo ratings yet

- Rules of Thumb: Graduate Manual Design TipsDocument10 pagesRules of Thumb: Graduate Manual Design TipsDebendra Dev KhanalNo ratings yet

- Pico Light 1Document32 pagesPico Light 1manolislem100% (3)

- Method of Statement Column and Access With Water MarkDocument11 pagesMethod of Statement Column and Access With Water MarkManu MohanNo ratings yet

- Perform With Precision: Box Culvert TravelerDocument14 pagesPerform With Precision: Box Culvert Traveler魏雨辰No ratings yet

- APEX Ultra PurlinsDocument12 pagesAPEX Ultra PurlinsMohammad Abu Al-ToyourNo ratings yet

- Application Design Manual-CHUTESDocument17 pagesApplication Design Manual-CHUTESZahoor Ahmed100% (1)

- Bridge GuideDocument20 pagesBridge GuideEng. Mahmoud Al shafeyNo ratings yet

- Structural Support Design Guidelines 8-25-16 PDFDocument17 pagesStructural Support Design Guidelines 8-25-16 PDFsbalu12674No ratings yet

- Raft FoundationDocument15 pagesRaft FoundationMuniswamaiah Mohan100% (2)

- PURLINSDocument4 pagesPURLINSFatra FuhlerNo ratings yet

- Concrete Beam and Slab Design Using ProkonDocument34 pagesConcrete Beam and Slab Design Using ProkonChamila Kumara Rankoth100% (3)

- TC Owners ManualDocument28 pagesTC Owners ManualAdrian BernaNo ratings yet

- Transmission Tower Modeling By: George T. Watson PEDocument11 pagesTransmission Tower Modeling By: George T. Watson PEGeorge MainaNo ratings yet

- StAad ModelingDocument18 pagesStAad ModelingVineet Verma0% (1)

- Conveyor Pulley Maintenance and Spares Reduction PlanDocument4 pagesConveyor Pulley Maintenance and Spares Reduction Plangullipalli srinivasa raoNo ratings yet

- STAAD GuideDocument8 pagesSTAAD GuideFerdinand DagaNo ratings yet

- Oil Casing Design PDFDocument11 pagesOil Casing Design PDFAbd EnnacerNo ratings yet

- Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-TipsDocument7 pagesRules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tipsnuwan01100% (1)

- Understanding Wind LoadsDocument7 pagesUnderstanding Wind Loadsduga11No ratings yet

- Compression Springs: Compression Spring Design General ConsiderationsDocument15 pagesCompression Springs: Compression Spring Design General Considerationsblowmeasshole1911100% (1)

- Deck Over TrailerDocument79 pagesDeck Over TrailerGeorge finkle80% (5)

- Methodology For Fabrication and Erection of Penstock PipeDocument8 pagesMethodology For Fabrication and Erection of Penstock Pipemanju100% (1)

- Types of Fits Clearance Fit Transition Fit Interference Fit PDFDocument9 pagesTypes of Fits Clearance Fit Transition Fit Interference Fit PDFTej SwaroopNo ratings yet

- Tips and Tricks For Using STAADDocument13 pagesTips and Tricks For Using STAADAzam Islam KhanNo ratings yet

- Thomas Thomas Thomas Thomas: Type Cmr/AmrDocument4 pagesThomas Thomas Thomas Thomas: Type Cmr/AmrGustavo Espinosa MartinezNo ratings yet

- Traction in ElevatorsDocument3 pagesTraction in ElevatorsПавле Крстевски100% (1)

- Structural Design of Hangar For AirportDocument18 pagesStructural Design of Hangar For Airportsanusi69100% (3)

- Family Handyman Ultimate Organizing SolutionsFrom EverandFamily Handyman Ultimate Organizing SolutionsRating: 5 out of 5 stars5/5 (2)

- Build Your Own Garage Manual: More Than 175 PlansFrom EverandBuild Your Own Garage Manual: More Than 175 PlansRating: 4 out of 5 stars4/5 (2)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- B I o G R A P H yDocument17 pagesB I o G R A P H yRizqia FitriNo ratings yet

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionDocument10 pagesMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyNo ratings yet

- Biblical World ViewDocument15 pagesBiblical World ViewHARI KRISHAN PALNo ratings yet

- Rifle May 2015 USADocument72 pagesRifle May 2015 USAhanshcNo ratings yet

- Standard Answers For The MSC ProgrammeDocument17 pagesStandard Answers For The MSC ProgrammeTiwiNo ratings yet

- Cloud Comp PPT 1Document12 pagesCloud Comp PPT 1Kanishk MehtaNo ratings yet

- 8051 NotesDocument61 pages8051 Notessubramanyam62No ratings yet

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorDocument21 pagesLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimNo ratings yet

- Radon-222 Exhalation From Danish Building Material PDFDocument63 pagesRadon-222 Exhalation From Danish Building Material PDFdanpalaciosNo ratings yet

- IEC TC 56 Dependability PDFDocument8 pagesIEC TC 56 Dependability PDFsaospieNo ratings yet

- 15 Day Detox ChallengeDocument84 pages15 Day Detox ChallengeDanii Supergirl Bailey100% (4)

- 6GK74435DX040XE0 Datasheet enDocument3 pages6GK74435DX040XE0 Datasheet enLuis CortezNo ratings yet

- Shakespeare Sonnet EssayDocument3 pagesShakespeare Sonnet Essayapi-5058594660% (1)

- How To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7Document20 pagesHow To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7kukaNo ratings yet

- rp10 PDFDocument77 pagesrp10 PDFRobson DiasNo ratings yet

- BSC HTM - TourismDocument4 pagesBSC HTM - Tourismjaydaman08No ratings yet

- Lecture 2 Effects of Operating Conditions in VCCDocument9 pagesLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezNo ratings yet

- ASHRAE Journal - Absorption RefrigerationDocument11 pagesASHRAE Journal - Absorption Refrigerationhonisme0% (1)

- Model 255 Aerosol Generator (Metone)Document20 pagesModel 255 Aerosol Generator (Metone)Ali RizviNo ratings yet

- Journal of Biology EducationDocument13 pagesJournal of Biology EducationFarah ArrumyNo ratings yet

- ISO 27001 Introduction Course (05 IT01)Document56 pagesISO 27001 Introduction Course (05 IT01)Sheik MohaideenNo ratings yet

- Advanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsDocument74 pagesAdvanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsetayhailuNo ratings yet

- Guyana and The Islamic WorldDocument21 pagesGuyana and The Islamic WorldshuaibahmadkhanNo ratings yet

- 7TH Maths F.a-1Document1 page7TH Maths F.a-1Marrivada SuryanarayanaNo ratings yet

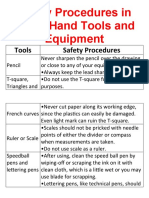

- Safety Procedures in Using Hand Tools and EquipmentDocument12 pagesSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezNo ratings yet

- Physics Education Thesis TopicsDocument4 pagesPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)

- Subject Manual Tle 7-8Document11 pagesSubject Manual Tle 7-8Rhayan Dela Cruz DaquizNo ratings yet

- Canoe Matlab 001Document58 pagesCanoe Matlab 001Coolboy RoadsterNo ratings yet

- Test 51Document7 pagesTest 51Nguyễn Hiền Giang AnhNo ratings yet

- Science 4 Diagnostic/Achievement TestDocument5 pagesScience 4 Diagnostic/Achievement TestGe PebresNo ratings yet