Professional Documents

Culture Documents

04 Vibration

Uploaded by

Nath BoyapatiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Vibration

Uploaded by

Nath BoyapatiCopyright:

Available Formats

Reliability Management Consultant

Vibration Standards

Condition Assessment How much vibration is too much? Published Standards- ISO 2372 Manufacturers Guidelines Comparison Trending

Reliability Management Consultant

ISO2372

(A:Good, B:Rough, C: Still acceptable, D: Unacceptable)

Velocity(mm/s) Peak RMS

1.0 1.58 2.5 4.0 6.4 10.0 15.8 25.0 0.71 1.12 1.8 2.8 4.5 7.1 11.2 18.0

Machine Classes

I A B C C C D D D C D II A B B B III A IV A

Reliability Management Consultant

Vibration Severity Ranges ISO 2372

I A A B B C C D D D D

Still Acceptable Unacceptable

Velocity (mm/s) PEAK RMS 0.40 0.64 1.0 1.58 2.5 4.0 6.4 10.0 15.8 25.0 40.0 64

Good

Machine Classes II III

IV

0.25 0.45 0.71 1.12 1.8 2.8 4.5 7.1 11.2 18.0 28 45

Usable

A A B B C C

Reliability Management Consultant

MACHINERY CLASSIFICATION IN ACCORDANCE WITH ISO2372

: Individual parts of engines and machines , Integrally connected with the complete machine in its normal operating (Production electrical motors of up to 15KW ) CLASS II : Medium sized machines ,( typically electric motors with 15 to 75 KW out put) without special foundations , rigidly mounted engines or machines (up to 300 KW) on special foundations. CLASS III : Large prime movers and other large machines with rotating masses mounted on rigid and heavy foundations which are relatively stiff in the direction of vibration measurement. CLASS IV : Large prime movers and other large machines with rotating masses mounted on foundations which are relatively soft in the direction of vibration measurement (e.g. turbo generator sets, especially those with light weight substructures).

CLASS I

Reliability Management Consultant

RECIPROCATING MACHINES

CLASS V & VI belongs to reciprocating machines on hard & soft foundations. For reciprocating machines ISO have given no standard & indicate that it should be either based on trend or one should be governed by the manufacturer. Reciprocating machines need balancing of rotating as well as reciprocating masses as well. On Diesel Engines 500KW plus it is not unusual to see vibration as high as 2540mm/sec. Trending is normally recommended on reciprocating machines.

Reliability Management Consultant

Reliability Management Consultant

Reliability Management Consultant

Trend Monitoring

Reliability Management Consultant

TRENDING OVERALL READINGS The most efficient and reliable method of evaluating vibration severity is to compare the most recent overall reading against previous readings for the same measurement, to see how the measurements vibration values are changing, trending over time. This trend comparison between present and past readings is easier to analyze when the values are plotted in a trend plot. A trend plot is a line graph that displays current and past overall values plotted over time.

Reliability Management Consultant

TRENDING OVERALL READINGS Past values should include a base-line (known good) reading. The base-line value may be acquired after an overhaul or when other indicators show that the machine is running well. Subsequent measurements are compared to the baseline to determine machinery changes.

Reliability Management Consultant

How do we set the limits?

Warning and Alarm Limits

Baseline = V, G, D Warning = 1.5 x Y mm/s; 10 G; 1.5 D Alarm = 5 to 7 x Y mm/s;30-50G, 4/5D

You might also like

- A 837 eDocument2 pagesA 837 eKhalida MuddasserNo ratings yet

- Control Torsional Vibrations: Highly Flexible CouplingsDocument12 pagesControl Torsional Vibrations: Highly Flexible Couplingscosty_transNo ratings yet

- Satake Multi S Mixer s3-s9Document16 pagesSatake Multi S Mixer s3-s9pppppp5No ratings yet

- ISO 376 Guidance and Uncertainty Measurements Relating To Force EquipmentDocument28 pagesISO 376 Guidance and Uncertainty Measurements Relating To Force EquipmentMark Still DelarnaNo ratings yet

- WPL 25 Torque SensorsDocument10 pagesWPL 25 Torque SensorsThịnh Nguyễn vănNo ratings yet

- Basic Understanding of Machinery VibrationDocument48 pagesBasic Understanding of Machinery Vibrationridzim4638100% (1)

- Transformer Services Our Knowledge. Your Experts.: SticsDocument24 pagesTransformer Services Our Knowledge. Your Experts.: SticsknsbNo ratings yet

- AVR Commissioning Rev01Document5 pagesAVR Commissioning Rev01pradeepmv159No ratings yet

- LynwanderDocument8 pagesLynwanderArthanari VaidyanathanNo ratings yet

- Here's The Answer. What's Your Question?: ABB High Power Rectifier ServicesDocument8 pagesHere's The Answer. What's Your Question?: ABB High Power Rectifier Servicesluis_cabrera_49No ratings yet

- A Guide For Choosing The Right Calibration For Torque TransducersDocument6 pagesA Guide For Choosing The Right Calibration For Torque Transducers320338No ratings yet

- BearingDocument22 pagesBearingbbmokshNo ratings yet

- Mazda RX8 Transmission ManualDocument49 pagesMazda RX8 Transmission ManualSpyros Stasinos50% (2)

- VDA Band 05.2 EnglischDocument50 pagesVDA Band 05.2 EnglischManuel NevarezNo ratings yet

- Inspection & Calibration of Torque WrenchesDocument7 pagesInspection & Calibration of Torque WrenchesJellyn Base100% (1)

- Iso 2372 1974Document9 pagesIso 2372 1974HARSHANo ratings yet

- Re17002 CDM1Document12 pagesRe17002 CDM1Kaushik GhoshNo ratings yet

- OX - Solutions Profile 2023Document25 pagesOX - Solutions Profile 2023dove4suppliesNo ratings yet

- Machine Design ElementsDocument75 pagesMachine Design ElementsVaibhav Chauhan 012No ratings yet

- Industrial Torque Brochure UK 2022pdfDocument20 pagesIndustrial Torque Brochure UK 2022pdfotaviofurlannNo ratings yet

- Lesson 01 PDFDocument12 pagesLesson 01 PDFAbuubakr Abdelwhab HassanNo ratings yet

- 7400CT0601 PDFDocument40 pages7400CT0601 PDFFrank HigueraNo ratings yet

- Rexnord Correntes AgriculturaDocument15 pagesRexnord Correntes AgriculturaWilliam BorgesNo ratings yet

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Elmar Product Catalogue PDFDocument258 pagesElmar Product Catalogue PDFbattakopapanteco100% (2)

- TechnicalGuideBook DRIVES ABBDocument442 pagesTechnicalGuideBook DRIVES ABBAngel Dimaria100% (1)

- Dated: 30 April 2012: Commercial-in-ConfidenceDocument20 pagesDated: 30 April 2012: Commercial-in-Confidenceexmstb1No ratings yet

- Parkison Gear TesterDocument4 pagesParkison Gear TesterManoj SinghNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Selecting A Conveyor DriveDocument7 pagesSelecting A Conveyor Drivegopi_ggg20016099No ratings yet

- Why Lin Engineering 2017Document2 pagesWhy Lin Engineering 2017ElectromateNo ratings yet

- Handbook of Mechanical In-Service Inspection-Pressure Systems and Mechanical Plant-Clifford Matthews PDFDocument705 pagesHandbook of Mechanical In-Service Inspection-Pressure Systems and Mechanical Plant-Clifford Matthews PDFVICTOR SEGOVIA100% (5)

- ACE Gas SpringDocument16 pagesACE Gas Springkohyung100% (2)

- Ds RoboticWeldingSolutionsBrochureDocument28 pagesDs RoboticWeldingSolutionsBrochureTalha WahabNo ratings yet

- Whd-qsm-002 Maintenance Manual Rev4Document121 pagesWhd-qsm-002 Maintenance Manual Rev4aymenmoatazNo ratings yet

- 08 Vibrotech Full CatalogueDocument12 pages08 Vibrotech Full Catalogueadnan khanNo ratings yet

- Dynamic Stiffness Ratio Diagram and ISO Standards for Vibration MeasurementsDocument3 pagesDynamic Stiffness Ratio Diagram and ISO Standards for Vibration MeasurementsAnonymous DKv8vpNo ratings yet

- Resolvers HaroweDocument8 pagesResolvers Harowemcantraks17No ratings yet

- GR00000700 00Document36 pagesGR00000700 00Van GAPNo ratings yet

- ABBDrives TechnicalGuideBook PDFDocument446 pagesABBDrives TechnicalGuideBook PDFDoDuyBacNo ratings yet

- B Me 297 PresentationDocument51 pagesB Me 297 PresentationmajidNo ratings yet

- P25539 ElectricactuatorsDocument52 pagesP25539 ElectricactuatorsDiego Fernando Avendano RodriguezNo ratings yet

- VDA Band 03.1 Eng 2000 Ensuring ReliabilityDocument82 pagesVDA Band 03.1 Eng 2000 Ensuring ReliabilityMarcin CałusNo ratings yet

- Merlin Gerin SwitchgearsDocument28 pagesMerlin Gerin SwitchgearsJean HicuburundiNo ratings yet

- RAVENOL AHC Fluid for Active Suspension SystemsDocument2 pagesRAVENOL AHC Fluid for Active Suspension Systemsabdull rehmanNo ratings yet

- E-Guide Linear Actuators v3Document21 pagesE-Guide Linear Actuators v3ptyfuentesNo ratings yet

- IMEKO-WC-2000-QM-P568Document10 pagesIMEKO-WC-2000-QM-P568Marco LopezNo ratings yet

- SIL Products & Services: Redefining Flow ControlDocument16 pagesSIL Products & Services: Redefining Flow ControlsantoshjayantiNo ratings yet

- Reciprocating Compressor Condition MonitoringDocument7 pagesReciprocating Compressor Condition MonitoringSantos Arauz Menacho100% (1)

- Condition Monitoring EssentialsDocument44 pagesCondition Monitoring Essentials4358213100% (2)

- Group 00 General Manual PrecautionsDocument28 pagesGroup 00 General Manual PrecautionsGPRNo ratings yet

- Company Profile KsiDocument10 pagesCompany Profile KsiarieprachmanNo ratings yet

- Lifting Anchor System Civil Engineering: Technical Product InformationDocument56 pagesLifting Anchor System Civil Engineering: Technical Product InformationNISHANTH SNo ratings yet

- Schenk Balancingnews 0212Document8 pagesSchenk Balancingnews 0212Raphael LemosNo ratings yet

- Internshipreportvvc1 161115150040 PDFDocument87 pagesInternshipreportvvc1 161115150040 PDFHemanth Kumar PVNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- 1la8 SeimennDocument8 pages1la8 SeimennNath BoyapatiNo ratings yet

- ADocument1 pageANath BoyapatiNo ratings yet

- Fastener Handouts (Screw)Document34 pagesFastener Handouts (Screw)cluchavezNo ratings yet

- Measurement of Bearing Clearance - Turbomachinery MagazineDocument3 pagesMeasurement of Bearing Clearance - Turbomachinery MagazineNath BoyapatiNo ratings yet

- Comparison-R407c and R410aDocument5 pagesComparison-R407c and R410aKartik PrabhakarNo ratings yet

- Instruction ScreenDocument1 pageInstruction ScreenNath BoyapatiNo ratings yet

- Capacitor Bank ProtectionDocument17 pagesCapacitor Bank ProtectionskisakNo ratings yet

- Motor Spare 2Document2 pagesMotor Spare 2Nath BoyapatiNo ratings yet

- Second Amendment On CSS OrderDocument2 pagesSecond Amendment On CSS OrderNath BoyapatiNo ratings yet

- CFBCDocument1 pageCFBCNath BoyapatiNo ratings yet

- 6000 en 06 SRBDocument84 pages6000 en 06 SRBSuphi YükselNo ratings yet

- Moody's Friction Factor Chart Represented by Cole Brook EquationDocument1 pageMoody's Friction Factor Chart Represented by Cole Brook EquationNath BoyapatiNo ratings yet

- BRGDocument2 pagesBRGNath BoyapatiNo ratings yet

- Supp Screen (IC)Document2 pagesSupp Screen (IC)Nath BoyapatiNo ratings yet

- Belt ConveyorDocument12 pagesBelt ConveyorNath Boyapati100% (1)

- Dunlop Technical ManualDocument41 pagesDunlop Technical ManualGonzalo AriasNo ratings yet

- 155-MW Natural-Gas-Fired Gas Turbine Featuring A Dry Low NO Combustor (Power)Document1 page155-MW Natural-Gas-Fired Gas Turbine Featuring A Dry Low NO Combustor (Power)Nath BoyapatiNo ratings yet

- STD UploadDocument1 pageSTD UploadNath BoyapatiNo ratings yet

- Sources of Textile Fibers: Solar Energy Is The Basis of LifeDocument1 pageSources of Textile Fibers: Solar Energy Is The Basis of LifeNath BoyapatiNo ratings yet

- NOTIS - Basic Theory: Basic Types of ScalesDocument1 pageNOTIS - Basic Theory: Basic Types of ScalesNath BoyapatiNo ratings yet

- Ideal Gas-Turbine Cycle T-S Diagram With The Same Processes As in Fig. 6 Complete-Cycle Gas Turbine Shown Below The T-S DiagramDocument1 pageIdeal Gas-Turbine Cycle T-S Diagram With The Same Processes As in Fig. 6 Complete-Cycle Gas Turbine Shown Below The T-S DiagramNath BoyapatiNo ratings yet

- Energy Loss When Moving Water Between Copper TubesDocument1 pageEnergy Loss When Moving Water Between Copper TubesNath BoyapatiNo ratings yet

- Gas PowerDocument1 pageGas PowerNath BoyapatiNo ratings yet

- Claim FormDocument3 pagesClaim FormMorgan ThomasNo ratings yet

- Inspect and Repair Desuperheater Nozzle AssemblyDocument1 pageInspect and Repair Desuperheater Nozzle AssemblyNath BoyapatiNo ratings yet

- 27 Nakshatra PadasDocument13 pages27 Nakshatra PadasAstrologer in Dubai Call 0586846501No ratings yet

- Ì Iêv Êãõ Ià I Ìiàê Vviàãê Ià Ì Êv Iý L Ìþê 'Ê V Ê I Ê Àiûi Ìê' ) Iêì Êãõ Ià I ÌiàêìõliãDocument1 pageÌ Iêv Êãõ Ià I Ìiàê Vviàãê Ià Ì Êv Iý L Ìþê 'Ê V Ê I Ê Àiûi Ìê' ) Iêì Êãõ Ià I ÌiàêìõliãNath BoyapatiNo ratings yet

- PPG Loss CalDocument1 pagePPG Loss CalNath BoyapatiNo ratings yet

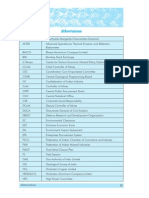

- Abbreviations Abbreviations Abbreviations Abbreviations AbbreviationsDocument3 pagesAbbreviations Abbreviations Abbreviations Abbreviations AbbreviationsNath BoyapatiNo ratings yet

- Recommended Fluid Velocities in Piping: Determine The Pipe Schedule NumberDocument1 pageRecommended Fluid Velocities in Piping: Determine The Pipe Schedule NumberNath BoyapatiNo ratings yet

- Guide to Cross-Subject Area ReportsDocument19 pagesGuide to Cross-Subject Area Reportssatyanarayana NVSNo ratings yet

- OSRAM LEDriving XENARC Headlamp Brochure For Audi A4 B7Document8 pagesOSRAM LEDriving XENARC Headlamp Brochure For Audi A4 B7Fourtitude.comNo ratings yet

- mf8240 160824142620 PDFDocument698 pagesmf8240 160824142620 PDFArgopartsNo ratings yet

- Building Resilience Philippines Urban PoorDocument16 pagesBuilding Resilience Philippines Urban PoorYasmin Pheebie BeltranNo ratings yet

- Stepper Motor Interface Board: Application ManualDocument43 pagesStepper Motor Interface Board: Application ManualMohamed Ismail100% (1)

- METRO Otherscape PlaytestDocument101 pagesMETRO Otherscape PlaytestthomasNo ratings yet

- Sample Quiz OM Chapter2Document2 pagesSample Quiz OM Chapter2Patleen Monica MicuaNo ratings yet

- Philips 170v7fbDocument95 pagesPhilips 170v7fbaposticaaNo ratings yet

- H07RN-F, Enhanced Version: Product InformationDocument5 pagesH07RN-F, Enhanced Version: Product InformationDarwin YupaNo ratings yet

- This Study Resource Was: Practice Questions and Answers Inventory Management: EOQ ModelDocument7 pagesThis Study Resource Was: Practice Questions and Answers Inventory Management: EOQ Modelwasif ahmedNo ratings yet

- AS-9100-Rev-D Internal-Audit-Checklist SampleDocument4 pagesAS-9100-Rev-D Internal-Audit-Checklist Samplesaifulramli69No ratings yet

- FormatCARS KAAUH Alqahtani 106Document8 pagesFormatCARS KAAUH Alqahtani 106ZEYNONo ratings yet

- Languages and CommunicationDocument17 pagesLanguages and CommunicationDERICK REBAYNo ratings yet

- A Review of Solar Parabolic Trough CollectorDocument7 pagesA Review of Solar Parabolic Trough Collectoraxel_oscNo ratings yet

- ZF 4hp14 - 2Document9 pagesZF 4hp14 - 2Miguel BentoNo ratings yet

- MMA Electrode ClassificationDocument3 pagesMMA Electrode ClassificationRathnakrajaNo ratings yet

- Series Portable Oscilloscopes: Keysight DSO1000A/BDocument15 pagesSeries Portable Oscilloscopes: Keysight DSO1000A/BNestor CardenasNo ratings yet

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Document62 pagesIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- Map Book 4Document58 pagesMap Book 4executive engineerNo ratings yet

- Piccolo: Operating and Maintenance Instructions For The Deck OvenDocument44 pagesPiccolo: Operating and Maintenance Instructions For The Deck OvenAdam B100% (1)

- Hwids - 2012 05 22 - 19 04 00Document9 pagesHwids - 2012 05 22 - 19 04 00RONAL DAMIANO PAREJANo ratings yet

- A Simple Method To Transfer The SelectedDocument2 pagesA Simple Method To Transfer The SelectedrekabiNo ratings yet

- Installation Procedure for Castwel Supercast-II CastableDocument3 pagesInstallation Procedure for Castwel Supercast-II CastableRAJKUMARNo ratings yet

- Legal Opinion WritingDocument53 pagesLegal Opinion WritingBenedict AnicetNo ratings yet

- List of British StandardsDocument6 pagesList of British StandardsPankajNo ratings yet

- SAPA Presentation - 8-31-18Document34 pagesSAPA Presentation - 8-31-18Roi AlcaideNo ratings yet

- T5N 630 PR221DS-LS/I in 630 3p F FDocument3 pagesT5N 630 PR221DS-LS/I in 630 3p F FDkalestNo ratings yet

- Fop 2.1Document11 pagesFop 2.1Paramita HalderNo ratings yet

- Memory Slim CBLT PDFDocument4 pagesMemory Slim CBLT PDFMichell ben ManikNo ratings yet