Professional Documents

Culture Documents

Guideline For Safe Use & Handling of Mercury & Mercury Compounds

Uploaded by

Alfred E. NewmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guideline For Safe Use & Handling of Mercury & Mercury Compounds

Uploaded by

Alfred E. NewmanCopyright:

Available Formats

A Guideline for the Safe Use & Handling of Mercury And Mercury Compounds

Developed by the Office of Engineering Safety (EH&S)

The Engineering Program Texas Engineering Experiment Station And The Dwight Look College of Engineering Texas A&M University

A Guideline

for the Safe Use & Handling

of Mercury

and Mercury

Compounds

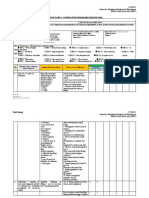

Contents 1.0 Introduction 2.0 Hazards 2.1 Toxicity and Hazards 2.2 Exposure Limits 3.0 Controls for Handling Mercury and Mercury Compounds 3.1 Project Safety Analysis (PSA) 3.2 Engineered Controls 3.3 Administrative Controls 3.3.1 Hazards Assessment 3.3.2 Training 3.3.3 Work Practices 3.3.4 Medical Surveillance 3.3.5 Label and Storage 3.3.6 Packing and Shipping 3.3.7 Mercury Spill Cleanup 3.3.8 Mercury Waste Collection and Disposal 3.3.9 First Aid 3.3.10 Exposure Monitoring 3.3.10.1 Biological Monitoring 3.3.10.2 Area Monitoring 3.3.10.3 Personal Monitoring 4.0 Responsibilities 4.1 Responsible Individual 4.2 Workers 4.3 Hazards Control 5.0 Appendices 5.1 Appendix A: Basic Terms and Definitions 5.2 Appendix B: Guidelines for Cleaning Up Elemental Mercury Spills 5.3 Appendix C: Biological Monitoring & Medical Surveillance for Mercury 5.4 Table B-1: Protective Equipment to be Used for Mercury Spill Cleanup

Safe Handling

of Mercury

and Mercury

Compounds

1.0 Introduction Mercury is a liquid metal that is environmentally persistent and bioaccumulates in the food chain. Mercury is present in both organic and inorganic forms. The inorganic form can be further divided into elemental mercury and mercuric salts. Organomercury consists of long and short alkyl and aryl compounds. Elemental mercury evaporates at room temperature and reacts with many elements to form salts, amalgams, and organomercury compounds (see Appendix A for basic definitions). Elemental mercury, and some mercury compounds, are listed in state and federal regulations as hazardous wastes. This document contains Precautions and controls for safely handling metallic mercury and its compounds. Specific guidance for avoiding or limiting metallic mercury spills. Guidelines for cleaning up mercury spills. All Engineering personnel and students who work with mercury should comply with the controls specified in Section 3.0 of this document, to prevent adverse health effects resulting from mercury use or spills. 2.0 Hazards 2.1 Toxicity and Hazards All forms of mercury are toxic. Mercury poisoning can result from inhalation, ingestion, and injection or absorption through the skin. Elemental mercury poses a health hazard because it is volatile. Elemental mercury, as a vapor, penetrates the central nervous system (CNS), where it is ionized and trapped, resulting in its extreme toxic effects. Elemental mercury is not well absorbed by the gastrointestinal tract; therefore, when ingested, it is only mildly toxic. Mercury metal and mercury compounds are highly hazardous if inhaled, or if they remain on the skin for more than a short period of time. Dimethyl mercury rapidly penetrates intact skin. Depending on the type of mercury and dose, symptoms may appear relatively quickly (acute disease) or take a number of years to appear (chronic disease). Elemental or airborne mercury that is deposited in water bodies becomes methylmercury, which is much more toxic. Additionally, in the ambient environment mercury readily bioaccumulates up the food chain. Listed below are various forms of mercury and their effects and hazards. Mercury vapor (i.e., elemental mercury) is readily absorbed through inhalation and can also pass through intact skin. After absorption, the blood carries elemental mercury to the central nervous system where it is oxidized. The oxidation product produces injury. Persons heavily exposed to elemental mercury will develop characteristic symptoms, including: worsening tremors of the hands, shyness, insomnia, and emotional instability (e.g., the symptoms of the Mad Hatter Alice in in Wonderlan da caricature of hat makers who originally cured felt in pools of mercury.) Mercury vapors can reach very high levels when the liquid is heated. Such levels will cause adverse effects in humans almost immediately if workplace controls are inadequate. Research apparatus and other laboratory equipment such as thermometers, vacuum pumps, manometers, and sphygmomanometers, may contain mercury. Mercury salts (e.g., mercuric nitrate) are highly toxic and corrosive. They accumulate mostly in the kidney, causing renal damage. Organomercury compounds attack the central nervous system causing tremors, impaired vision and hearing, and paralysis. These compounds may also cause birth defects. The effects from exposure to excessive levels of airborne mercury or skin contact with mercury compounds may not be noticeable for months or years. Mercury fulminate, Hg(ONC)2, is a detonator used in explosives.

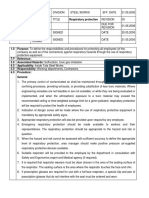

Mercury(II) oxide is an oxidizer. It can cause organic materials to start burning in the same manner as any strong oxidizer. Dimethyl mercury, an extremely toxic material, is a colorless, sweet-smelling liquid. It is a severe fire hazard, with a flash point of 4C. This material rapidly penetrates the skin resulting in severe to fatal exposure from very minor quantities. Extreme caution is required when working with this material and when selecting personal protective equipment (PPE). Contact the vendor, supplier and/or manufacturer for a current material safety data sheet (MSDS). 2.2 Exposure Limits A worker's exposure to mercury should be less than the Threshold Limit Values (TLVs), the exposure limits established by the American Conference of Governmental Industrial Hygienists (ACGIH.) Following are the maximum exposures permitted for an 8-hour, time-weighted average (TWA) concentration:

Substance Mercury metal vapor Mercury salts Aromatic organic compounds Alkyl compounds

Threshold

Limit Value (TLV)

0.025 mg/m 3 0.025 mg/m 3 0.1 mg/m 3 0.01 mg/m 3 ( Ceiling limit is 0.03 mg/m 3 )

3.0 Controls for Handling Mercury and Mercury Compounds Planning and documentation are required for all Engineering operations, research and teaching, which involve the use of mercury. This section contains controls for preventing unnecessary exposure and minimizing the likelihood and extent of mercury spills. Guidelines for cleaning up a mercury spill can be found in Appendix B. 3.1 Project Safety Analysis Project Safety Analysis (PSA) is a procedure to increase the knowledge of hazards in a project or operation, by identifying the potential for loss and risk early in the project planning process. The Engineering Safety Policy (established February 1996) requires Project Safety Analysis for all new projects, and for on going projects where potentially harmful or dangerous conditions present an unacceptable risk. The PSA defines the proposed project; the facilities, apparatus, equipment and chemicals to be used; the hazards and risks of each stage of the project; the necessary controls for preventing potential harmful exposures and/or releases; standardized safe work practices and procedures; the ultimate disposition of apparatus, equipment, materials and chemicals; and clean up and decontamination of facilities. The faculty/PI responsible for the individual project or operation is required to initiate a PSA to the Office of Engineering Safety for evaluation. 3.2 Engineered Controls The following controls should be available for activities involving the use of mercury: Adequate ventilation or vapor-containment systems. Mercury Spill-Control Kits. These should be in all work areas where >1.0 ml of mercury is used (except for small sealed items, such as thermometers and sphygmomanometers). Spill control kits should be replaced or restocked following each use. Employees shall contain and control spills, and summon the TAMU Hazardous Materials Emergency Response Team for clean up and disposal (From a TAMU telephone, dial 9-9-1-1, for emergency response assistance). Catch basins and pans made of smooth impervious material (e.g., plastic or smooth-finish paint) and with edge lips. Note: Steep edge lips are more effective than gentle rises in trapping spilled mercury. Catch basins should be large enough to contain the greatest amount of mercury that could spill, and be positioned to catch mercury droplets escaping from any plausible direction. (It may be useful to place absorptive mats on seamless plastic sheets in or under catch pans to capture mercury leaks from the equipment. Droplets of mercury can then be collected by simply wrapping up the plastic with the mat still inside and disposing of it as mercury waste.) Section 3.2.8 contains more information on the disposition of hazardous materials.

Removable plastic shields, mercury traps, and blowout valves. Concrete floors should be sealed with epoxy. Impervious working surfaces with few crevices are preferred for work involving mercury. Carpeted and tiled areas shall not be used. 3.3 Administrative Controls The administrative controls listed in this section should be implemented when mercury and its compounds are involved in operations. 3.3.1 Hazards Assessment Before beginning any Engineering project or operation involving the use of metallic mercury, mercury compounds, mercury apparatus or equipment containing mercury, the Responsible Faculty/PI should: Prepare an Integration Work Sheet (IWS) for the operation. Become familiar with the hazards associated with the materials for the particular operation and implement all necessary controls. The current MSDS must be obtained for each hazardous material, including mercury and mercury compounds, describing its hazards and controls. Determine if the worker's current training is adequate for the activity. All affected personnel shall complete training in Laboratory Safety, Hazard Communication, operation of specific apparatus and equipment, and safe work practices and procedures. All training shall be documented and records maintained as specified in the TAMU Hazard Communication Program, the TAMU Safety Manual, and the Engineering Safety Policy. Notify the Office of Engineering Safety and the TAMU Environmental Health & Safety Department (EHSD) of each new use of mercury, except for sealed items such as thermometers. A Project Safety Analysis (PSA) is required for all new projects and for on-going projects when significant changes occur or when hazardous conditions warrant. The Office of Engineering Safety Office should: Provide guidance on the selection of controls and job-specific training. Determine the required workplace monitoring for mercury, as needed. Determine if a written safety plan is necessary for operations that involve heating or using large quantities of mercury or its compounds. The Safety Office may waive the requirement for a written safety plan, if the quantity is small (so that one/half of the vapor limits in Section 2.2 are not exceeded) or for totally enclosed systems using quantities >1.0 ml. NOTE: Operational An Safety Plan (OSP) is ALWAYS required when using dimethyl mercury. TAMU-EHSD should: Evaluate the operation(s) to determine if air permits are required and/or the appropriate TNRCC and/or EPA documentation has been prepared and approved. 3.3.2 Training Employees and students who potentially may be exposed to mercury should be trained in the hazards and controls before initial assignment, as described in the TAMU Hazard Communication Program. The required training should include at least the following areas: Safe use of mercury. Mercury hazards. Cleanup of small spills. (Appendix B discusses mercury cleanup guidelines.) Proper use of mercury vacuum cleaners. Workers who use breakable or open equipment containing >1.0 ml of metallic mercury shall receive training in the proper use of mercury vacuum cleaners and other spill cleanup procedures. Use of PPE, including respirator training. Procedures for summoning emergency response services, and for incident notification/reporting. Hazard Communication, Laboratory Safety, Prudent Laboratory Practice, PPE Site, project and/or laboratory specific safe work practices and procedures

Training in basic laboratory safety and chemical hazard communication is provided without charge by TAMU. Registration information is available at: Laboratory Safety Training http://ehsd-online.tamu.edu/training/lab.htm Hazard Communication Training http://ehsd-online.tamu.edu/training/hazcom.htm

3.3.3 Work Practices Mercury users should be aware of and follow work practices listed below: Dimethyl mercury. This chemical is so toxic that its use always requires OSP. an Additionally, inner (silver shield, 4H, or other brand laminate-style gloves) and outer gloves (heavy-duty nitrile or neoprene, with long cuffs) are required as a minimum when handling, using, or working with dimethyl mercury. 3.3.3.1 For all forms of mercury, the following work practices apply:

Avoid using mercury whenever possible. Use alternative equipment and/or instruments that have no mercury to measure temperature or pressure. Where alternative materials or methods are available, prudent laboratory practice requires choosing the less hazardous alternative. Depending on the type and concentration of mercury involved and the work to be done, additional PPE may be required, above the minimum. Contact the Office of Engineering Safety or the TAMUEHSD industrial hygienist for assistance. Do not eat, drink, or smoke; or store food, drinks, smoking materials, or cosmetics in any area where mercury is in use. Avoid skin and eye contact. Use appropriate protective gloves when handling metallic mercury. DO NOT use lightweight disposable gloves for heavier jobs, as these can tear easily and allow mercury to lodge under the fingernails or contact other parts of the skin. When the operation may result in exposure to the face, wear splash-proof goggles AND a face shield, unless full-face respiratory protection is being used.Note: Quantitative permeation or penetration information is scarce on the type of gloves or protective clothing that offer protection from exposure to mercury compounds. Wash hands and face after handling mercury, before lunch or breaks, and at the end of each work period. Do not work with mercury on surfaces with cracks (e.g., tile seams, spaces between wood boards, baseboards, wall coving, gaps between table legs and floors), crevices, and hard-to-reach spaces; porous surfaces (e.g., carpets, wood, and crinkle-texture paint), and false floors. Do not store or handle mercury near sinks or drains. Spilled mercury could run into the sink, lodge in the trap, ruin the pipe by amalgamating with and weakening the metal, and then be released into the environment or a retention tank system designed only for dilute solutions in rinse water. Mercury in the plumbing and drains may result in unnecessary and potentially adverse exposure to maintenance workers and others. Avoid using mercury or mercury compounds in operations that could generate mercury waste streams contaminated with radionuclides, as it is expensive and often impossible to dispose of this type of mixed waste stream. Where the project necessitates the generation of a mercury waste stream with radionuclides, the responsible Faculty/PI is required to document appropriate arrangements for proper waste disposal or long-term storage of the waste, as a component of the PSA. Transfer of liquid mercury between containers should be carried out in a fume hood over a tray or pan to confine any spills.

Conduct weekly self-inspections of all PPE, controls, equipment, and apparatus. Inspection findings and corrective action(s) should be documented. 3.3.4 Medical Surveillance An occupational medicine physician should determine the need for biological monitoring or medical surveillance examinations of workers with potential mercury exposure. The requisite biological monitoring or medical surveillance examinations should be determined based on an evaluation of the operation, workplace controls, and relevant human factors as well as input received from the Faculty/PI, affected workers, and safety officers. At a minimum, all affected persons should be monitored for mercury in blood and urine BEFORE working with mercury to establish a baseline for evaluation, and at least every three months for project duration. (Refer to Appendix C for additional information on biological monitoring and medical surveillance). 3.3.5 Labeling and Storage The following controls apply to the labeling and storage of mercury and its compounds: Label all containers of metallic mercury and its compounds. Label all mercury containers and storage as follows:

WARNING: CONTAINS MERCURY VAPOR HARMFUL AT ROOM TEMPERTURE MAY BE FATAL IF HEATED IN THE OPEN DO NOT BREATHE VAPOR USE WITH ADEQUATE VENTILATION AVOID SKIN CONTACT

Do not store mercury near chemicals that can create explosive mixtures with mercury (e.g., acetylene, ammonia, boron phosphodiiodide, chlorine dioxide, methyl azide, ground sodium carbide, and others) or with radioactive materials. Keep mercury compounds that are oxidizers separate from organic materials and other combustibles. Additionally, all chemical storage is required to be segregated by Hazard Class. Minimize the amount of mercury in use or in storage. Mercury storage should have inherent spill containment/control. Store mercury in a cool, separate and secure location. Use containers made of impact-resistant material, or place them in sturdy secondary containers. Keep all mercury containers tightly closed when not in use. Avoid cutting cartons that contain plastic bottles filled with mercury. A plastic bottle could be cut or torn open and result in a mercury spill. 3.3.6 Packing and Shipping TM, or bubble pack, for all mercury Use appropriate packing materials for mercury containers, such as Kimpak containers and objects/devices containing mercury. 3.3.7 Mercury Spill Cleanup Elemental mercury is typically easy to work with under normal conditions (e.g., in a fume hood). However, spills involving elemental mercury that are ignored or improperly addressed can cause serious problems because: Mercury is dense (specific gravity ~13.5). Large drops shatter into numerous small droplets that can move at great speed across long distances.

Droplets and vapors tend to congregate in crevices. Porous materials can become contaminated and may have to be disposed of as mercury waste (see Section 3.2.8) because they are too difficult to decontaminate. Mercury amalgamates with other metals. Metal objects are weaker after contamination with mercury, and may be unsuitable for further use. Items soiled by spilled mercury often cannot be decontaminated and, therefore, should be disposed of as mercury contaminated hazardous waste (see Section 3.2.8). Microorganisms convert metallic mercury to organomercury compounds, which are more hazardous in some species than the metallic form. This may result in significant environmental problems, particularly when mercury enters into the aquatic food chain. Mercury will bioaccumulate in the environment and, thus, be passed up the food chain. If a mercury spill occurs, immediately: 1. Block off any area where droplets of spilled mercury are visible using tape or rope, and post signs (such as example below) made of any available material.

MERCURY SPILL

Keep Out!

2. Avoid walking on or touching any surface contaminated with mercury. 3. Promptly notify the TAMU Hazardous Materials Emergency Response Team at 845-2132, or dial 99-1-1 to summon TAMU emergency services. The HazMat Team will survey the affected area to determine the airborne concentration of mercury, adjust the boundaries of the blocked-off area as needed, conduct cleanup and disposal of spilled mercury, and provide technical support. Costs of emergency response, cleanup and waste disposal may be billed to the responsible Faculty/PI, laboratory, department or TEES research center. 4. Notify the Office of Engineering Safety. 5. Personal protective equipment (PPE) and clothing specifically designed for use with mercury must be readily available for unusual situations and for spill cleanup. If a mercury spill is too large to clean up safely or workers are injured or contaminated, dial 9-9-1-1, to summon TAMU emergency response and medical services. 6. Small spills of metallic mercury may be cleaned up safely by the personnel involved if they have had the proper training and equipment. 7. Mercury Spill Kits must be available in each work area where mercury is present. Use of vacuum cleaners/shop vacuums for mercury spills is prohibited. Use only specially designed and dedicated mercury vacuum cleaners. Guidance for cleaning up mercury spills is in Appendix B. 3.3.8 Mercury Waste Collection and Disposal Generators of mercury-contaminated wastes should evaluate the waste to determine if any applicable hazardous-waste criteria have been exceeded. All generators must be in compliance with TAMU rules and other applicable regulations. Equipment or objects containing mercury, but no longer needed by a program, should be evaluated in accordance with the TAMU Hazardous Waste Management Program. Equipment or objects characterized as hazardous waste should be tagged and prepared for transport and disposal through the TAMU-EHSD Hazardous Waste Management Program.

The responsible Faculty/PI should document a plan for the ultimate disposition of hazardous materials & hazardous waste, and the clean up & decontamination of apparatus, equipment and facilities. The disposition plan should be finalized before purchasing materials or initiating project activity. 3.3.9 First Aid Personnel contaminated with dimethyl mercury should immediately: 1. 2. Wash the affected area using either an eyewash station or safety shower, as appropriate. Report to TAMU Emergency Medical Services (dial 9-9-1-1). Be sure to inform the medical responders or physicians of the quantity of mercury involved.

Personnel contaminated with mercury metal or other mercury compounds should exercise the following precautions: 1. 2. Immediately wash the affected area using either an eyewash station or safety shower, as appropriate. Report to TAMU Emergency Medical Services (dial 9-9-1-1). Be sure to inform the medical responders or physicians of the type, quantity, and physical state of mercury involved. Use a mercury vapor monitor to make sure there is no mercury on the skin or in the space under the fingernails. If necessary, clean the area with soap, water, and a scrub brush; then, recheck with the instrument to ensure that all of the mercury is removed . Do not use the solutions that come with mercury cleanup sponges or powders for PERSONAL decontamination some are corrosive! Remove and place all contaminated clothing in a plastic bag. Personnel who are not contaminated should handle spill cleanup only if they are trained and equipped. Immediately notify TAMU-EHSD if any cleaning water is discharged into a sink, drain, retention tank, or sanitary sewer system.

3.

4.

4.0 Responsibilities General responsibilities for all faculty, staff and students, are described in the Engineering Safety Policy. 4.1 Responsible Individual The responsible faculty/PI, department head, or designee, should ensure that all persons who might handle mercury are trained in accordance with the provisions of this document and the TAMU Hazard Communication Program (HazCom), prudent laboratory practice, and established project-specific procedures. 4.2 Personnel All faculty/PI, staff, students and other affected persons should: Follow the precautions for mercury specified in this document, in the Engineering Safety Policy, and in procedures cited or included as part of the TAMU Safety Manual and the TAMU Hazard Communication Program. Additional guidance on the safe handling and disposition of mercury is available from the Office of Engineering Safety and from TAMU-EHSD. 4.3 Hazards Control The responsible faculty/PI, department head, or designee should: Provide support and training to anyone who handles mercury or cleans up mercury spills. Provide appropriate controls, personal protective equipment (PPE) and protective clothing. Provide mercury spill kits and other equipment as necessary to safely contain and collect spilled mercury. Ensure that mercury vacuum cleaners are maintained in good working condition. Provide the appropriate respiratory protection and training to all affected persons. Ensure that all mercury is properly stored and secured.

Ensure that all apparatus, equipment and facilities are cleaned and decontaminated at project closure. Ensure that all small, sealed mercury-containing items (such as thermometers) are securely stored. Non-mercury alternatives are recommended as prudent practice, to reduce risk of spill and exposure.

5.0 Appendices 5.1 Appendix A: Basic Terms and Definitions

Absorption Amalgam

- method whereby a substance can pass through intact, unbroken skin. - mixture or alloy of mercury with other metals. - a secondary container used to collect minor spills. System (CNS) - Parts of the nervous system, including the brain

Catch pan/basin Central Nervous and spinal cord.

Manometer - An instrument used to measure gas and vapor pressure. Mercury salts - Inorganic mercury compounds. Mercury vacuum - specially designed type of vacuum cleaner used to safely collect spilled mercury. Metallic mercury - Mercury in its elemental state. Organomercury mercury atom. compounds - Mercury compounds that include carbon atoms, bonding directly to the

Sphygmomanometer

- An instrument used for monitoring blood pressure.

5.2 Appendix

B: Guidelines

for Cleaning

Up Elemental

Mercury

Spills

Respond promptly to all spills and accidents involving any hazardous chemical. Contact the TAMU Hazardous Materials Emergency Response (dial 9-9-1-1 or 845-2132) for assistance in cleaning up a chemical spill. A small spill is a release that meets ALL of the following criteria: Nature and potential hazard of material is known. The incident results in no injury to people or damage to facilities. Release presents no actual or potential threat to human health, the environment, or property. Any spill that exceeds any of the above criteria is considered a large spill. For large spills, immediately call 9-9-1-1 to summon emergency response services. The following guidelines apply when cleaning up mercury spills: Use sufficient PPE and protective clothing (see Table B-1) to keep mercury droplets off personal clothing and skin. This includes plastic or rubber gloves, disposable foot covers (whenever mercury is on the floor), and additional protective clothing when in doubt of the proper clothing to use. All protective equipment and clothing shall be rated for use with mercury. Never use thin disposable gloves, as these can tear and allow mercury to lodge under the fingernails. Use the buddy system when respirators are required. Watch the color of the end-of-service indicators on the faces of the other people's cartridges, and have them replaced when the indicators change color. Use only respirator cartridges rated for mercury use. Be careful not to drag airline respirator hoses through mercury. Check the hoses and equipment with a mercury vapor monitor for contamination before storing. Spread plastic sheets over surfaces onto which mercury could drop or run during spill cleanup. Tape the sides of the sheets to the floor. NOTE: such plastic sheets, and other clean up items, must be disposed of as mercury contaminated hazardous waste. Remove any dust or oil which may have become contaminated with mercury during spill and cleanup. Use detergent or a solvent to remove oil or grime, or use a vacuum, to remove dust. Be certain to adhere to all appropriate controls during spill cleanup. Dip rags in cleaning solutions once. Never dip a dirty rag in a clean solution, as this will contaminate the solution and the container. Minimize the amount of mercury-contaminated material generated during cleanup, as it is expensive to dispose of mercury contaminated liquid wastes. Clean up materials must be contained and disposed of as hazardous waste. Use mercury kits with hand-powered miniature vacuums or sponges to clean up spills whenever practical. Replace mercury kit items after use. To avoid the spread of contamination, never sweep mercury contaminated material or blow it off of surfaces with compressed-air nozzles. Instead, vacuum or seal it off in place. Trapped mercury inside equipment, instruments and building components can be a health hazard to those who work on affected surfaces in the future. A sign indicating that trapped or sealed mercury is present may be needed. Avoid trapping or sealing any mercury in place. Clean and decontaminate all apparatus, equipment and facilities following use, or dispose of as hazardous waste. Notify TAMUEHSD of any suspected trapped mercury. Use a specially designed and dedicated vacuum for cleaning up large mercury spills. Check the vacuum's exhaust with a mercury vapor monitor before using it and remove as much mercury as possible from inside the vacuum after using ittoo much residual mercury can ruin the mercury absorber. Do not use a regular or HEPA vacuum cleaner to clean up mercury spills because mercury

amalgamates with copper in the motor, and the vacuum will exhaust high concentrations of mercury vapor into the air. The vacuum then becomes dangerous to use or decontaminate and ultimately must be disposed of as hazardous waste. Use Resisorb to eliminate mercury vapors near surfaces, particularly after removing liquid mercury from those surfaces. Contact TAMU-EHSD for assistance in cleanup operations and/or to determine the appropriate packaging requirements for bulky items that may be contaminated with mercury. Place used rags, cleaning materials, protective gear, and mercury-contaminated gear into plastic bags. Cut up mops and other large tools before placing them into the bags. Gently squeeze excess air from the bags, then place the sealed bags into drums and affix a completely filled out TAMU Hazardous Waste Tag to the drum. Contact TAMU-EHSD or the Office of Engineering Safety for training and/or assistance in completing the Waste Tag form. TAMU-EHSD will transfer the drum to the designated Waste Accumulation Area. Have the Hazardous Materials Emergency Response Team conduct a clearance survey before removing any access barriers. The spill area shall not be returned to normal use until this survey is completed. Notify TAMU-EHSD if mercury-contaminated water enters into a drain, retention tank or sanitary sewer, so that appropriate action can be initiated.

5.3 Appendix

C: Biological

Monitoring

& Medical

Surveillance

for Mercury

5.3.1. All affected personnel, faculty/PI and students, should be tested by approved biological monitoring procedures prior to starting work on any project using significant amounts of mercury, to establish a baseline for future comparison. All personnel should be tested periodically over the course of the project, and results compared to the established baseline to determine if potentially harmful exposure has occurred. An occupational medicine physician should determine frequency of the periodic tests. 5.3.2. BIOLOGICAL MONITORING FOR MERCURY

Total Inorganic Mercury in Urine Monitor pre-shift BIE = 35 micrograms per gram creatinine Total Inorganic Mercury in Blood BIE =15 micrograms per gram NOTE: Mercury may be present in biological specimens collected from subjects who have not been occupationally exposed, at a concentration that could affect interpretation of the result. Such background concentrations are incorporated into the BEI value. Biological monitoring provides one means to assess exposure had health risk to workers. It entails measurement of the concentration of a chemical determinant in the blood, fluids and tissues of those with potential exposure; it is an indicator of the uptake of a substance. Biological monitoring indirectly reflects the dose to a worker from exposure to the substance of interest. In most cases, the specimen used for biological monitoring is urine, blood, or exhaled air. Biological Exposure Indices (BEI) are values for assessing biological monitoring results. BEI's represent the levels of determinants which are most likely to be observed in specimens collected from healthy workers who have been exposed to potentially harmful substances to the same extent as workers with inhalation exposure at the Threshold Limit Value (TLV). The BEI indicates a concentration below which nearly all workers should not experience adverse health effects. The BEI determinant can be the chemical itself, one or more metabolites, or a characteristic, biochemical change induced by the chemical. BEI's are not intended for use as a measure of adverse effects or for diagnosis of occupational illness. Biological monitoring provides assistance to the occupational health professional and/or physician to: 1. detect and determine absorption via the skin or gastrointestinal system, or via inhalation 2. assess body burden 3. determine PAST exposure(s) 4. detect occupational and/or non-occupational exposures among workers 5. test the efficiency of engineering controls and PPE 6. monitor work practices BEIs are intended as guidelines to be used in the evaluation of potential health hazards. BEIs apply to 8-hour exposures, 5 days per week. Although modified work schedules are sometimes used in various occupations, the ACGIH BEI committee does not recommend that any adjustment or correction factor be applied to the BEI', i.e., the BEI' should be used as listed, regardless of the work schedule. The Threshold Limit Value (TLV) for inorganic mercury is 0.025 mg/g of air. The primary route of exposure is cutaneous; either by contact with vapors or, more likely, by direct contact with the skin. 5.3.3. SOURCE OF BIOLOGICAL MONITORING CRITERIA

The detailed scientific criteria and justification for each BEI can be found in Documentation the of the Threshold Limit Values and Biological Exposure Indices , published annually by the American Association of Governmental Industrial Hygienists (ACGIH).

Appendix 5.4. Table B-1: Protective

Equipment

to be Used for Mercury

Spill Cleanup

Item Impervious gloves Shoe covers, disposable Booties, heavy soled Apron, laboratory Apron, laboratory Disposable coveralls without hood Disposable coveralls with hood Respirator, cartridge a Respirator, airline a, b NOTES:

a- Use of this respirator shall be approved in advance by an industrial hygienist. Respirators shall be issued only to persons who are trained in its use, medically qualified, and who have no facial hair that will interfere the respirator's effectiveness. b- Airline hoses and equipment shall be monitored for mercury contamination before they are returned to the approved storage location.

Description Left and right Sizes: medium Standard Standard heavy-duty light-duty (Sizes: small, (Sizes: small, hand; and large

medium, and large) medium, and large)

You might also like

- Hazmat Guide MercuryDocument3 pagesHazmat Guide MercuryJoaquim Sabino PessoaNo ratings yet

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryFrom EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryNo ratings yet

- Mercury Spill Cleanup Procedures: Department of Environmental Health & SafetyDocument6 pagesMercury Spill Cleanup Procedures: Department of Environmental Health & SafetymeekleavesNo ratings yet

- OSHA Safety - ElectroplatingDocument35 pagesOSHA Safety - Electroplatingvinithgandhi90No ratings yet

- Safety Book-RevisedDocument12 pagesSafety Book-RevisedFardeen KhanNo ratings yet

- Management of Depleted Uranium Used as Shielding in Disused Radiation DevicesFrom EverandManagement of Depleted Uranium Used as Shielding in Disused Radiation DevicesNo ratings yet

- Thermal Metal SprayingDocument4 pagesThermal Metal SprayingArlen NurlanNo ratings yet

- OshaDocument14 pagesOsha12035safyaabdulmalik100% (2)

- Working With MercuryDocument2 pagesWorking With MercuryDarius DsouzaNo ratings yet

- Msds Stainless SteelDocument11 pagesMsds Stainless Steelrakesh marwahNo ratings yet

- Radiation Health Series #5Document17 pagesRadiation Health Series #5Rads53No ratings yet

- Chemical Spill Procedure: 1. PurposeDocument2 pagesChemical Spill Procedure: 1. PurposeWalter A. Mustafa Takeo100% (1)

- Chemical SafetyDocument46 pagesChemical Safetyjefry2002No ratings yet

- Aemsc Precursor Code of Practice Ed 1 1999Document37 pagesAemsc Precursor Code of Practice Ed 1 1999SabariyantoNo ratings yet

- Norma Astm E407.1093127-1Document22 pagesNorma Astm E407.1093127-1Gabriela AlmeidaNo ratings yet

- ASTM E407-07 Standard Practice For Microetching Metals and AlloysDocument22 pagesASTM E407-07 Standard Practice For Microetching Metals and AlloysRifqiMahendraPutra100% (3)

- Chem Lab Safety IS.4209.1987Document25 pagesChem Lab Safety IS.4209.1987DEE TOTLVJANo ratings yet

- MSDS Brugal 4413Document8 pagesMSDS Brugal 4413curtisvaleroNo ratings yet

- Material Safety Datasheet - Cs-137 Eckert ZieglerDocument4 pagesMaterial Safety Datasheet - Cs-137 Eckert ZieglerArif100% (1)

- Assignment of Control TechniquesDocument15 pagesAssignment of Control TechniquesAnanda NairNo ratings yet

- Chemical Spill Management GuidelinesDocument7 pagesChemical Spill Management GuidelinesAvyan KelanNo ratings yet

- Safety Precautions in The LaboratoryDocument6 pagesSafety Precautions in The LaboratoryDennis MuneneNo ratings yet

- hsg94 PDFDocument40 pageshsg94 PDFbtjajadiNo ratings yet

- Managing Mercury: Household Hazardous WasteDocument5 pagesManaging Mercury: Household Hazardous WasteWaseem AhmadNo ratings yet

- Material Safety Data Sheet: Gouging Carbon ElectrodesDocument5 pagesMaterial Safety Data Sheet: Gouging Carbon Electrodesranesh rajanNo ratings yet

- Notes For Chapter 10 - Safety ManagementDocument5 pagesNotes For Chapter 10 - Safety ManagementAlexis OngNo ratings yet

- Environmental and Safety Aspects in Process IndustriesDocument6 pagesEnvironmental and Safety Aspects in Process Industriesyadavsuyash007No ratings yet

- Radiation Safety ProcedureDocument14 pagesRadiation Safety Proceduremdd omanNo ratings yet

- Occupational Health and Saefty 15Cv564Document26 pagesOccupational Health and Saefty 15Cv564Sunilkumar M SNo ratings yet

- LEMTEK45E English Version Rev1Document35 pagesLEMTEK45E English Version Rev1ambiya086114No ratings yet

- Qcs 2010 Section 11 Part 2.3.02 SHE Procedures - COSHH (CONTROL OF SU PDFDocument16 pagesQcs 2010 Section 11 Part 2.3.02 SHE Procedures - COSHH (CONTROL OF SU PDFbryanpastor106No ratings yet

- Environmental Risk AssessmentDocument15 pagesEnvironmental Risk AssessmentRitah ApolotNo ratings yet

- Protocol For Storage and Handling of Hazardous Chemicals (Qh-ptl-275!3!1)Document23 pagesProtocol For Storage and Handling of Hazardous Chemicals (Qh-ptl-275!3!1)kanakarao1100% (1)

- INDUSTRIAL HAZARDS AND THEIR SAFETY NotesDocument15 pagesINDUSTRIAL HAZARDS AND THEIR SAFETY NotesSimna RamesanNo ratings yet

- Radiation Protection: Name: D.K.D.M UdayanganiDocument10 pagesRadiation Protection: Name: D.K.D.M UdayanganidharmapriyaussNo ratings yet

- Chlorine ManualDocument26 pagesChlorine ManualsuguchemNo ratings yet

- Guide To DSEAR Risk AssessmentDocument25 pagesGuide To DSEAR Risk Assessmentkanakarao10% (1)

- OSUlaser Safety ManualDocument14 pagesOSUlaser Safety ManualUrología GinecológicaNo ratings yet

- 12.environmental Aspects and SafetyDocument4 pages12.environmental Aspects and SafetyBhuneshwar ChelakNo ratings yet

- Decontamination PreDocument31 pagesDecontamination Presch203No ratings yet

- Canadian Association of Petroleum Producers - CAPP - NORM GuideDocument12 pagesCanadian Association of Petroleum Producers - CAPP - NORM GuideBob SmithNo ratings yet

- QU EHSMS Standard Operating Procedure 04 - Hazardous Waste DisposalDocument25 pagesQU EHSMS Standard Operating Procedure 04 - Hazardous Waste DisposalsampathdtNo ratings yet

- Radiation Leak TestingDocument3 pagesRadiation Leak TestingTika Putri KecilNo ratings yet

- Circular: Guidelines On The Use of Chlorine Containing Chemicals For Disinfection of Swimming PoolsDocument4 pagesCircular: Guidelines On The Use of Chlorine Containing Chemicals For Disinfection of Swimming PoolsAhmed MuhammadNo ratings yet

- Fluid Flow Manual PDFDocument201 pagesFluid Flow Manual PDFHajra AamirNo ratings yet

- 1-TG01 - Chemical Safety Vers 1.1 PDFDocument62 pages1-TG01 - Chemical Safety Vers 1.1 PDFRichard Seke KinkelaNo ratings yet

- ENGN4625 Lab Exp Risk Assessment - 2012Document11 pagesENGN4625 Lab Exp Risk Assessment - 2012Chuah Chian YeongNo ratings yet

- Report-0.45699700 1700076717Document3 pagesReport-0.45699700 1700076717Amr TarekNo ratings yet

- Msds Standard Weld Metal Domestic InternationalDocument8 pagesMsds Standard Weld Metal Domestic InternationalKate HowardNo ratings yet

- Rep 810 INTERVENTION IN THE SITUATION OF CHRONIC AND EMERGENCY EXPOSURE - 063116Document18 pagesRep 810 INTERVENTION IN THE SITUATION OF CHRONIC AND EMERGENCY EXPOSURE - 063116ISHAQNo ratings yet

- Thermit PortionsDocument9 pagesThermit PortionsMix MiscevicNo ratings yet

- Environmental, Health, and Safety OverviewDocument11 pagesEnvironmental, Health, and Safety OverviewBradSiefkerNo ratings yet

- Operational Radiation Safety: Guide ST 1.6 / 10 D 2009Document22 pagesOperational Radiation Safety: Guide ST 1.6 / 10 D 2009LoffeguttNo ratings yet

- Innovative Sensor Technology For Emergency DetectiDocument26 pagesInnovative Sensor Technology For Emergency Detectirevanthrithika69No ratings yet

- Industrial Hygiene Assignment 1Document13 pagesIndustrial Hygiene Assignment 1ParanthamanNo ratings yet

- Saftyguide - Laser - e Amada JapanDocument11 pagesSaftyguide - Laser - e Amada JapanHLNo ratings yet

- How Car Engines WorkDocument11 pagesHow Car Engines WorkAlfred E. NewmanNo ratings yet

- Carburetor Cleaning - Small Engine RepairDocument1 pageCarburetor Cleaning - Small Engine RepairAlfred E. NewmanNo ratings yet

- Small Engines: Step 1: Intake StrokeDocument4 pagesSmall Engines: Step 1: Intake StrokeAlfred E. NewmanNo ratings yet

- How To Test and Repair Small Engine Ignition System ProblemsDocument5 pagesHow To Test and Repair Small Engine Ignition System ProblemsAlfred E. NewmanNo ratings yet

- Gas Mixture TableDocument1 pageGas Mixture TableAlfred E. NewmanNo ratings yet

- How To Repair Briggs & Stratton EnginesDocument179 pagesHow To Repair Briggs & Stratton EnginesChuck Achberger95% (22)

- Two Stroke Piston DiagnosisDocument1 pageTwo Stroke Piston DiagnosisAlfred E. NewmanNo ratings yet

- EnginesDocument5 pagesEnginesAlfred E. NewmanNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunAlfred E. NewmanNo ratings yet

- Tecumseh 2 Cycle Engines ManualDocument68 pagesTecumseh 2 Cycle Engines Manualpaul20000100% (2)

- Tecumseh - Carburetor.identification - Troubleshooting.and - ServiceDocument41 pagesTecumseh - Carburetor.identification - Troubleshooting.and - ServicePooch_the_Cat100% (5)

- Briggs Stratton Service Manual 70076881Document234 pagesBriggs Stratton Service Manual 70076881Alfred E. NewmanNo ratings yet

- Top 7 Common Riding Mower Problems & Solutions 2008Document3 pagesTop 7 Common Riding Mower Problems & Solutions 2008Alfred E. NewmanNo ratings yet

- Two Stroke EnginesDocument4 pagesTwo Stroke EnginesRajesh KumarNo ratings yet

- Tecumseh 2 Cycle Engines ManualDocument68 pagesTecumseh 2 Cycle Engines Manualpaul20000100% (2)

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunAlfred E. NewmanNo ratings yet

- How To Repair Briggs & Stratton EnginesDocument179 pagesHow To Repair Briggs & Stratton EnginesChuck Achberger95% (22)

- How To Repair Small Engines PDFDocument4 pagesHow To Repair Small Engines PDFStephane Durel MbidaNo ratings yet

- Two Stroke Tuning GuideDocument171 pagesTwo Stroke Tuning Guideavista123100% (1)

- Tecumseh - Carburetor.identification - Troubleshooting.and - ServiceDocument41 pagesTecumseh - Carburetor.identification - Troubleshooting.and - ServicePooch_the_Cat100% (5)

- The Art of Drawing DragonsDocument145 pagesThe Art of Drawing DragonsMademoiselleBovary100% (3)

- Top 7 Common Riding Mower Problems & Solutions 2008Document3 pagesTop 7 Common Riding Mower Problems & Solutions 2008Alfred E. NewmanNo ratings yet

- Two Stroke EnginesDocument4 pagesTwo Stroke EnginesRajesh KumarNo ratings yet

- Seal of History Our Inheritance in The Great Seal of USDocument207 pagesSeal of History Our Inheritance in The Great Seal of USAlfred E. NewmanNo ratings yet

- Traveling Along Butch Cassidy's Outlaw TrailDocument7 pagesTraveling Along Butch Cassidy's Outlaw TrailAlfred E. NewmanNo ratings yet

- How To Repair Small Engines PDFDocument4 pagesHow To Repair Small Engines PDFStephane Durel MbidaNo ratings yet

- Emergency Preparedness GuidebookDocument46 pagesEmergency Preparedness Guidebookallen_holly100% (1)

- The Complete Guide To Wiring, 5th EditionDocument353 pagesThe Complete Guide To Wiring, 5th Editiontsofiarocha100% (3)

- Traveling Along Butch Cassidy's Outlaw TrailDocument7 pagesTraveling Along Butch Cassidy's Outlaw TrailAlfred E. NewmanNo ratings yet

- Popular Science FYIDocument18 pagesPopular Science FYIAlfred E. Newman100% (1)

- SDS For GasolineDocument13 pagesSDS For GasolineJeff MNo ratings yet

- MSDS CobraDocument3 pagesMSDS CobraRegita Audia FebrianiNo ratings yet

- Asbestos Home Renovators Trades GuideDocument28 pagesAsbestos Home Renovators Trades GuideShibushi DuibuduiNo ratings yet

- Material Safety Data Sheet: Product Name: Cat Natural Gas Engine Oil (Ngeo) Sae 40Document9 pagesMaterial Safety Data Sheet: Product Name: Cat Natural Gas Engine Oil (Ngeo) Sae 40jose favaNo ratings yet

- Matrix Cladding Installation Guide May2019 Rev1Document12 pagesMatrix Cladding Installation Guide May2019 Rev1Anna MainneNo ratings yet

- SS - PRO02 - Respiratory ProtectionDocument9 pagesSS - PRO02 - Respiratory ProtectionmadhulikaNo ratings yet

- Lactic Acid MsdsDocument6 pagesLactic Acid MsdsBlue Ofo-ob TJNo ratings yet

- Scott Air-Pak X3 SCBA, 2013 CompliantDocument48 pagesScott Air-Pak X3 SCBA, 2013 CompliantForum Pompierii100% (1)

- Draeger Panorama Standard P enDocument2 pagesDraeger Panorama Standard P enForum PompieriiNo ratings yet

- Barite SDS March 2016 (Qmax)Document4 pagesBarite SDS March 2016 (Qmax)Baher SaidNo ratings yet

- Coshh Assessment: Hi-Stick Spray Paint Contract Number:: Substance Properties and Hazards LabelsDocument4 pagesCoshh Assessment: Hi-Stick Spray Paint Contract Number:: Substance Properties and Hazards LabelsSafety ExpertNo ratings yet

- Nynas - Nytro Izar IiDocument42 pagesNynas - Nytro Izar IiWillmar Curillo - G&CNo ratings yet

- Msds CPD Intraplast N UsDocument10 pagesMsds CPD Intraplast N UsJose David CastroNo ratings yet

- 3M - Marine Compound & Finishing Material - EXP Nov 2021Document13 pages3M - Marine Compound & Finishing Material - EXP Nov 2021brianNo ratings yet

- h2s SafetyDocument7 pagesh2s Safetydurga273No ratings yet

- Jha (Eat#1) PRF 75047Document7 pagesJha (Eat#1) PRF 75047L O V ENo ratings yet

- 2 Simulants PDFDocument73 pages2 Simulants PDFPrema SathishNo ratings yet

- Miller Dialarc 250 Ac-DcDocument28 pagesMiller Dialarc 250 Ac-Dcdavid caraoNo ratings yet

- SDS - Astm P 127 02Document7 pagesSDS - Astm P 127 02Omar SaaedNo ratings yet

- 3M 3000 Sales SheetDocument2 pages3M 3000 Sales SheetMichael TadrosNo ratings yet

- MSDS For Rheliant Drilling MudDocument6 pagesMSDS For Rheliant Drilling MudjendlouhyNo ratings yet

- Msds MurexideDocument5 pagesMsds MurexideD'the QuiintLy MaskatNo ratings yet

- Complement Super: Safety Data SheetDocument7 pagesComplement Super: Safety Data SheetANDRE AURELLIONo ratings yet

- Piperazine Hexahydrate PDFDocument5 pagesPiperazine Hexahydrate PDFAnonymous T32l1RNo ratings yet

- Material Safety Data Sheet Salt: 1. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet Salt: 1. Chemical Product and Company IdentificationkhurramNo ratings yet

- Dmso, Safety Data SheetDocument7 pagesDmso, Safety Data Sheetalvaro_cruzNo ratings yet

- Specifications Welding Rectifier MillerDocument76 pagesSpecifications Welding Rectifier Millerjumansyahamid1988No ratings yet

- Losurf-300 Nonionic SurfactantDocument6 pagesLosurf-300 Nonionic SurfactantBoualam BouNo ratings yet

- MSDS - Europe - 907 - 02 - en - 30315 - UK HbsAg UltraDocument15 pagesMSDS - Europe - 907 - 02 - en - 30315 - UK HbsAg UltraJermain BarbadosNo ratings yet

- PPE Inspection ChecklistDocument5 pagesPPE Inspection ChecklistBalasubramaniamkamarajNo ratings yet

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 4 out of 5 stars4/5 (6)

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (28)

- By the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsFrom EverandBy the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsNo ratings yet

- Think This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeFrom EverandThink This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeRating: 2 out of 5 stars2/5 (1)

- ADHD is Awesome: A Guide to (Mostly) Thriving with ADHDFrom EverandADHD is Awesome: A Guide to (Mostly) Thriving with ADHDRating: 5 out of 5 stars5/5 (2)

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionFrom EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionRating: 4 out of 5 stars4/5 (404)

- Raising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsFrom EverandRaising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsRating: 5 out of 5 stars5/5 (1)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisFrom EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisRating: 4.5 out of 5 stars4.5/5 (42)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedRating: 5 out of 5 stars5/5 (81)

- The Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsFrom EverandThe Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsRating: 3.5 out of 5 stars3.5/5 (3)

- Outlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisFrom EverandOutlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (1)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (3)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaFrom EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaRating: 4.5 out of 5 stars4.5/5 (266)

- Sleep Stories for Adults: Overcome Insomnia and Find a Peaceful AwakeningFrom EverandSleep Stories for Adults: Overcome Insomnia and Find a Peaceful AwakeningRating: 4 out of 5 stars4/5 (3)

- Love Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)From EverandLove Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)No ratings yet

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- Gut: the new and revised Sunday Times bestsellerFrom EverandGut: the new and revised Sunday Times bestsellerRating: 4 out of 5 stars4/5 (393)

- Cult, A Love Story: Ten Years Inside a Canadian Cult and the Subsequent Long Road of RecoveryFrom EverandCult, A Love Story: Ten Years Inside a Canadian Cult and the Subsequent Long Road of RecoveryRating: 4 out of 5 stars4/5 (44)

- Dark Psychology & Manipulation: Discover How To Analyze People and Master Human Behaviour Using Emotional Influence Techniques, Body Language Secrets, Covert NLP, Speed Reading, and Hypnosis.From EverandDark Psychology & Manipulation: Discover How To Analyze People and Master Human Behaviour Using Emotional Influence Techniques, Body Language Secrets, Covert NLP, Speed Reading, and Hypnosis.Rating: 4.5 out of 5 stars4.5/5 (110)

- The Marshmallow Test: Mastering Self-ControlFrom EverandThe Marshmallow Test: Mastering Self-ControlRating: 4.5 out of 5 stars4.5/5 (58)

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessFrom EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessRating: 4.5 out of 5 stars4.5/5 (328)

- Dark Psychology: Learn To Influence Anyone Using Mind Control, Manipulation And Deception With Secret Techniques Of Dark Persuasion, Undetected Mind Control, Mind Games, Hypnotism And BrainwashingFrom EverandDark Psychology: Learn To Influence Anyone Using Mind Control, Manipulation And Deception With Secret Techniques Of Dark Persuasion, Undetected Mind Control, Mind Games, Hypnotism And BrainwashingRating: 4 out of 5 stars4/5 (1138)

- Troubled: A Memoir of Foster Care, Family, and Social ClassFrom EverandTroubled: A Memoir of Foster Care, Family, and Social ClassRating: 4.5 out of 5 stars4.5/5 (27)