Professional Documents

Culture Documents

Te1 Question Paper

Uploaded by

mukesh3021Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Te1 Question Paper

Uploaded by

mukesh3021Copyright:

Available Formats

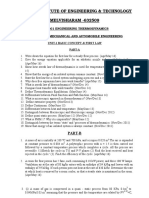

QUESTION BANK THERMAL ENGINEERING 1 (M 506)

Module 1 (Steam Engineering) Short Questions (4 Marks) 1. Explain dryness fraction. 2004 Oct/Nov; 2005 May 2. Explain wet, dry and super heat steam. 2004 Oct/Nov 3. Draw and explain the phase equilibrium diagram for steam on T-S plot with relevant constant property lines. 2007 Jan 4. Describe the applications of Mollier diagram. 2004 Oct/Nov 5. Using Mollier diagram, determine the heat drop and final condition of steam when steam is at 700 K N/m2 at 200 o C is expanded adiabatically to a pressure of 100 K N/ m 2. 2005 May 6. Calculate entropy of 1 Kg of wet steam with dryness fraction 0.9 at a pressure of 840 K N/m 2. 2005 May 7. Calculate the enthalpy of steam at 15 bar and 2500 C. Dec 2007 8. Calculate entropy of 5 kg of steam at a pressure of 15 bar and 250 0 C using steam tables. 2008 May 9. Show that heat supplied is equal to the change in internal energy, when steam is expanded at constant volume. 2005 May 10. Clearly explain the difference between isothermal and hyperbolic processes as applied to wet steam. 2004 Oct/Nov 4 M; 2006 May/Jun 11. Show the following process on T-S and h S diagram of steam; (a) Constant volume cooling. (b). Constant pressure heating and (c) Throttling. 2005 Nov 12. Describe the Rankine cycle and show how it differs from Carnot cycle by sketching both cycles on the same TS diagram. The steam is dry and saturated after evaporation in both cycles. 2006 May/Jun 13. Draw T-S diagram of Rankine cycle for wet, dry saturated and superheated steams. Dec 2007 14. Draw T-S diagram of Rankine cycle using dry saturated steam and develop the equation of cycle efficiency. July/August 2007 ; Nov 2008 15. Distinguish between Water tube and Fire tube boilers and state under what conditions each type would be desirable. 2004 Oct/Nov; 2005 May; 2005 Nov 16. Explain briefly how steam boilers are classified. 2008 17. What are boiler mountings and accessories? Briefly explain any one of them. [2005 May, July/ August 2007]; Nov 2008 18. Explain why safety valves are needed in a boiler. Draw a neat sketch of a spring loaded safety valve and explain its working. 2007 Jan 19. Six Mark (6) Questions 1. A vessel of 0.4 m3 capacity contains 2 Kg of wet steam at 6 bar pressure. Calculate the volume and mass of water and of dry steam. 2005 Nov 2. Steam at 10 bar and 250 o C expands until the pressure becomes 2.75 bar. The dryness fraction of steam at the end of expansion is 0.95 dry. Determine the change in internal energy. 2006 May/Jun 3. Calculate the internal energy of 1 Kg of steam at a pressure of 10 bar when the steam is (i) 0.9 dry and (ii) dry saturated. The volume of water may be neglected. 2005 Nov 4. One Kg of steam at 1.8 MPa and 2800 C undergoes a constant pressure process until the quality becomes 50 %. Find the work done, change in enthalpy and heat transferred if the process is non flow. 2006 May/Jun 5. 12 Marks (12) Questions 1. 0.085 m3 drum contains saturated water and water vapour at 334 0 C. Find the mass of each if there volumes are equal. 2008 May 2. Steam at 18 bar and dryness fraction of 0.9 is heated at constant pressure until dry and saturated. Find the increase in volume, heat supplied and work done per Kg of steam. If the volume is now kept constant find how much heat must be extracted to reduce the pressure to 14 bar. 2005 Nov 3. Two boilers discharge equal amounts of steam. Steam from one is at 18 bar 380 0 C. The other is at 18 bar and 95 % quality. Determine: (a) The equilibrium condition after mixing, (b) Loss of entropy of high temperature steam, (c) Gain in entropy of low temperature steam, and (d) Net increase or decrease of entropy. Dec 2007

4. A large insulated vessel is divided in to two chambers, one containing 6 Kg. of dry saturated steam at 0.2 MPa and the other 12 Kg. of steam, 0.8 quality at 0.5 MPa. If the partition is removed and the steam is mixed thoroughly and allowed to settle, then find the final pressure, steam quality and entropy changes in the process. 2007 Jan 5. Steam at a pressure of 0.5 MPa and a temperature of 200 o C is expanded adiabatically to a pressure of 0.07 MPa. Find the final condition of steam using Mollier diagram. 6. A closed vessel of 1.2 m 3 in capacity contains steam at 3 bar. absolute and 0.85 dryness. Steam at 10 bar and 0.96 dryness is supplied to the vessel until the pressure inside the vessel becomes 5 bar. Calculate the weight of steam supplied to the closed vessel and the final dryness fraction of the steam in the vessel. Neglect the volume of the moisture and thermal capacity of the vessel. 2006 May/Jun 7. A simple Rankine cycle operates between 260 0 C and 950 C. Steam is supplied to the turbine at dry saturated condition. If the expansion is isentropic, determine its efficiency. Show the cycle in h-s and T-s diagrams. 2008 May 8. In a steam power plant working on Rankine cycle, Steam at 100 bar and 500 o C is expanded in a turbine to a condenser pressure of 0.2 bar. The net power out put of the turbine is 140 MW. Determine the thermal efficiency and mass flow rate of steam in Kg/hr. July/August 2007 9. In a Rankine cycle operating on water, superheated vapour enters the turbine at 100 bar, 500 0 C. Condenser pressure is 0.1 bar. The net power output is 150 MW. If the turbine has an isentropic efficiency of 85 % determine (a) the thermal efficiency, and (b) the mass flow rate of steam in kg./hr. Dec 2007 10. Steam at 21 bar and 350 o C is expanded in a steam turbine to 0.08 bar. It then enters a condenser where it is condensed to saturated water. The pump feeds back the water in to the boiler. Assuming the turbine efficiency are 60 %, determine per Kg of steam, the net work, the heat transferred to the working fluid, and the Rankine cycle efficiency. 2007 Jan 11. With the help of neat diagrams, explain the working of various boiler mountings. 12. Module II (Steam Nozzles & Steam Turbines) Short Questions (4 Marks) 1. Explain various types of nozzles and their distinguishing features. 2004 Oct/Nov; 2005 Nov 4 M, 2008 May 2. Explain the effect of friction on the performance of steam nozzles using temperature - entropy and enthalpy entropy diagram. [July/August 2007]; Nov 2008 3. Derive the expressions for velocity and mass flow through the nozzle in terms of initial pressure, initial specific volume, area of cross section, final pressure and index n of frictionless adiabatic expansion. 2004 Oct/Nov 4. Explain physical significance of critical pressure ratio in steam nozzles. 2005 May; 2006 May/Jun 5. Explain the effect of varying the back pressure in a convergent divergent nozzle and state when the maximum flow occurs in the nozzle. 2007 Jan 6. Explain the steady flow energy equation as applied to a steam nozzle. Explain its use in the calculation of steam velocity at the exit of a nozzle. 2006 May/Jun 7. Show the process of expansion of steam in nozzle in T-S diagram: (a) When expansion is isentropic (b) when expansion is irreversible. Dec 2007 8. Explain metastable flow through nozzles. 9. Explain supersaturated flow of steam in nozzle and sketch the process on h S diagram. 2005 May; 2005 Nov; 2007 Jan 10. Steam at 3 bar with 10 o C superheat is passed through a convergent nozzle. The velocity of steam entering the nozzle is 91.5 m/s. The back pressure is 1.5 bar. Assuming nozzle efficiency as 90 %, determine the area of the nozzle at throat. Maximum discharge through the nozzle is limited to 0. 45 Kg/s. Take Cps (superheated steam) = 2.2 KJ/Kg o C. 2004 Oct/Nov 11. Steam expands from 3 bar to 1 bar in a nozzle. The initial velocity is 90 m/s and the initial temperature is 150 o C. The nozzle efficiency is 95 %. Determine the exit velocity. 2005 Nov 12. Steam at a pressure of 700 K N/m2 and 0.9 dry enters a nozzle with throat area 1.4 cm 2. It leaves the nozzle at a pressure of 106 K N/m 2. Calculate the weight of steam discharged per second and the dia. of the exit of the nozzle so that the discharge shall be maximum. 2005 May 13. In a single stage impulse turbine the blade angles are equal and the nozzle angle is 20 o. The velocity coefficient for the blade is 0.83. Find the maximum blade efficiency possible. If the actual blade efficiency is 90 % of maximum blade efficiency, find the possible ratio of blade speed to steam speed. 2004 Oct/Nov

14. Steam at 3150 K N/m2 and 370 o C is expanded in a high pressure turbine to 560 K N/m 2 and is reheated to 370 o C and is used in the low pressure turbine. Exhaust is 3.45 K N/m 2. Calculate the gain in efficiency by reheating. 2005 May 15. Give Classifications of Steam Turbines. Briefly explain. 2004 Oct/Nov, Dec 2007 16. Differentiate between impulse and reaction turbines. Nov 2008 17. Define speed ratio, Blade velocity coefficient, blade efficiency and stage efficiency of steam turbines.2004 Oct/Nov 18. Define (a) Blading Efficiency, (b) Stage Efficiency and (c) nozzle Efficiency 2005 May 19. Derrive an expression for maximum blade efficiency in a single stage Impulse Turbine. 2007 Jan 20. Define diagram efficiency. Write down an expression for the same. Dec 2007 21. Draw the inlet and exit velocity diagrams of a Parsons reaction turbine. Dec 2007 22. Draw velocity triangles of moving blades of a reaction turbine. 2008 May 23. Define speed ratio, Blade velocity coefficient, blade efficiency and stage efficiency of steam turbines. 2004 Oct/Nov 24. Define (a) Blading Efficiency, (b) Stage Efficiency and (c) nozzle Efficiency 2005 May 25. Define the term degree of reaction used in a reaction turbine and prove that the moving and fixed blade should have same shape for a 50 % reaction. July/August 2007, Dec 2007 26. Deduce the expression for the work done per stage of a reaction turbine and determine the condition for maximum efficiency. 2005 May 27. Explain the terms throttle governing and nozzle governing. 2006 May/Jun, July/August 2007 28. Why are steam turbines compounded? Explain different methods of compounding. 2007 Jan 29. Six Mark (6) Questions 1. Dry saturated steam at a pressure of 8 bar absolute enters a convergent divergent nozzle and leaves at 1.5 bar absolute. If the flow is isentropic and corresponding expansion index is 1.135, find the ratio of cross sectional area at exit and throat for maximum discharge. 2006 May/Jun 2. Steam at a pressure of 10 bar and 0.98 dry is passed through a convergent divergent nozzle to a back pressure of 0.1 bar. The mass flow rate is 0.55 Kg/s. Find (i) pressure at the throat. (ii) Number of nozzles used if each nozzle has a throat area of 0.5 cm 2. The enthalpy drop used for heating the steam by friction in divergent part is 10% of the overall enthalpy drop. The index of expansion is 1.13. 2007 Jan 3. Dry saturated steam at 5 bar enters a convergent divergent nozzle at a velocity of 160 m/s. The exit pressure is 1.5 bar. The throat and exit atea are 1280 mm 2 and 1600 mm2 respectively. Assuming isentropic flow up to the throat , critical pressure ratio as 0.58 and frictional heating as 10 % of the heat loss in the divergent portion, estimate the mass flow rate and the nozzle efficiency. July/August 2007 4. In a 50 % reaction turbine stage, running at 50 revolutions per second, the exit angles are 30 0 and the inlet angles are 500. The mean diameter is one meter. The steam flow rate is 10 3 Kg/min. and the stage efficiency is 85 %. Determine (i) the power output of the stage; (ii) the specific enthalpy drop in the stage. 2006 May/Jun 5. The data pertaining to an impulse turbine is as follows: Blade speed = 300 m/s, Isentropic enthalpy drop in nozzle = 450 KJ/Kg., Nozzle efficiency = 90 %, Nozzle angle = 20 o , Blade velocity coefficient = 0.85, Blade exit angle = 25 o ,. Draw the velocity diagram and calculate for a steam flow rate of 1 Kg/s, (i) The inlet angle of moving blade. (ii) The axial thrust. (iii) The driving force on the wheel. (iv) Diagram power. (v) Diagram efficiency. (vi) The energy lost in blades due to friction. July/August 2007 6. A single stage impulse turbine has a diameter of 1.2 meter running at 3000 rpm. The nozzle angle is 18o. Blade speed ratio is 0.42. The ratio of relative velocity at outlet to the relative velocity at inlet is 0.9. The outlet angle of the blade is 3 o smaller than the inlet angle. The steam flow rate is 5 Kg/s. Draw the velocity diagram and find: (i) velocity of whirl. (ii) axial thrust on the end bearings. (iii) blade angle. (iv) power developed. 2007 Jan 7. 12 Marks (12) Questions 1. Starting from fundamentals, show that the maximum discharge through a nozzle, the ratio of throat pressure to inlet pressure is given by [2 / (n+1)] n/(n - 1) where n is the index for isentropic expansion through the nozzle. 2005 Nov 2. Steam at 0.9 MPa, 250 0 C and flowing at the rate of 1 Kg/S passes in to a pipe carrying wet steam at 0.8 MPa and 0.95 dry. After adiabatic mixing at 0.8 MPa the flow rate is 2.3 Kg/s. Determine the condition of the steam after mixing. The mixture is then expanded in a friction less nozzle

3.

4. 5.

6.

7. 8. Module III (Gas Turbine Plants) Short Questions (4 Marks) 1. Explain advantages and disadvantages of a closed cycle gas turbine. 2004 Oct/Nov; 2006 May/Jun; 2007 Jan 2. Differentiate between closed loop and open loop gas turbines. Dec 2007 3. What are the advantages and disadvantages of gas turbine over I C engines? What are the fields of applications of gas turbine power plants? 2005 Nov, July/August 2007 4. Describe a gas turbine combustion chamber with the help of a neat sketch. 2004 Oct/Nov 5. Explain factors which affect the combustion efficiency of gas turbine power plant. 2007 Jan 6. Define Combustion intensity. Dec 2007 7. Define isentropic efficiency of a gas turbine. 2005 May; Dec 2007 8. Draw T-S diagram of a gas turbine showing inter-cooling, reheating and regenerative heating. Dec 2007 9. What are the advantages of reheating in a gas turbine? Nov 2008 10. Discuss means of improving the specific output and thermal efficiency of the simple open cycle gas turbine plant. 2005 May ; 2005 Nov; 2007 Jan ; Dec 2007 11. Derive an expression for thermal efficiency of standard gas turbine plant working on closed Braytons cycle. 2008 May 12. What are the uses of compressed air? 2005 May 13. Explain the phenomenon of surging and choking in centrifugal compressors. 2006 May/Jun, July/August 2007 14. Differentiate between rotary and centrifugal compressors. Explain any one type of rotary compressor. 2008 May 15. Discuss various classifications of rotary air compressors. 2008 16. What are the special advantages of axial compressors? Nov 2008 17. Six Mark (6) Questions 1. Derive the expression for optimum pressure ratio for maximum specific work output in a closed cycle gas turbine plant. 2004 Oct/Nov; 2005 May 2. In an open cycle constant pressure gas turbine, air enters the compressor at 1.02 bar and 20 o C. The pressure of air rises to 4.08 bar. The isentropic efficiencies of compressor and turbine are 80 % and 85 % respectively. The air Fuel ratio is 80:1. Find the thermal efficiency of the cycle if the flow rate of air is 2.5 Kg/S. Take Cp = 1 k J/kg. o K and = 1.4 for air and gas. C V of fuel used to 41720 kJ/kg. 2004Oct/Nov 3. With the help of neat sketches, explain the working of centrifugal air compressor. 2008 May 4. 12 Marks (12) Questions 1. What problems are encountered in the design of gas turbine combustion chamber? Draw a neat sketch of a combustion chamber used for an open cycle plant and name the parts.

isentropically to a pressure of 0.4 MPa. Determine the velocity of the steam leaving the nozzle. Neglect the velocity of steam in the pipeline. July/August 2007 12 M Dry saturated steam at a pressure of 0.6 MPa flows through nozzles at the rate of 4.5 kg./sec. and discharges at a pressure of 0.16 MPa. The loss due to friction in the diverging portion of the nozzle is 15% of the total isentropic enthalpy drop. Taking isentropic expansion index as 1.135, determine the cross-sectional area of the throat and exit of the nozzle. 2008 May Dry saturated steam enters a steam nozzle at a pressure of 12 bar and is discharged at a pressure of 1.5 bar. If the dryness fraction of discharged steam is 0.95, what will be the final velocity of steam? Nov 2008 Steam at a pressure of 10 bar and dryness fraction of 0.98 is discharged through a convergent divergent nozzle to a back pressure of 0.1 bar. The mass flow rate is 10 kg/kW-Hr. If the power developed is 200 kw, determine (a) the Pressure at the throat, and (b) Number of nozzles required if each nozzle has a throat of rectangular cross section 5 mm x 10 mm, if 10 % of overall isentropic enthalpy drop reheats by friction in the divergent portion. Dec 2007 In a stage of an impulse turbine, with single row wheel, the mean dia of the blades is 1m. It runs at 3000 rpm. The steam issues from the nozzle at a velocity of 350 m/sec and the nozzle angle is 200. The rotor blades are equiangular. The blade friction factor is 0.86. Determine the power developed if axial thrust on the end bearing of rotor is 120 N. 2008 May Discuss on Velocity and pressure compounding of steam turbines. Nov 2008

2006 May/Jun; 2007 Jan 2. What are the effects on the thermal efficiency and specific output of the gas turbine power plant of the following factors. (a) load on the plant, (b) pressure ratio, (c) turbine inlet temperature, (d) compressor inlet temperature, (e) regenerator. July/August 2007 3. Prove that for a two stage gas turbine plant with perfect inter-cooling and perfect reheating the intermediate pressure for maximum work output is given by the geometric mean of the initial suction pressure and the final delivery pressure. 2006 May/Jun 12 M, 2008 May 4. Explain the working of a closed cycle gas turbine. Nov 2008 5. In a gas turbine plant, air is compressed from 1 bar and 15 oC to 5.6 bar. It is then heated to 650 oC in a combustion chamber and expanded back to 1 bar. Calculate the cycle efficiency. Nov 2008 6. In a gas turbine plant air is compressed from 1 bar, 15 o C through a pressure ratio of 4:1. It is then heated to 650 o C in a combustion chamber and expanded back to atmospheric pressure of 1 bar in a turbine. Calculate the cycle efficiency and work ratio if a perfect heat exchanger is used. The isentropic efficiencies of the turbine and compressor are 85 % and 80 % respectively. 2005 Nov; Dec 2007 7. Explain the ideal energy transfer in a centrifugal compressor and how does axial flow compressor differ from centrifugal compressor. 2005 Nov 8. Module IV (Solar Energy) Short Questions (4 Marks) 1. Define optical efficiency? How optical losses can be minimized? 2005 Nov 2. Define the term overall loss coefficient with respect to a solar collector. Nov 2008 3. What are the various thermal losses in a solar collector? Explain. 2005 May 4. Define the term instantaneous collection efficiency. 2008 May 5. Explain the concept of Zero Energy house July/August 2007 6. Write short notes on solar pond. 2004 Oct/Nov 4 M; 2006 May/Jun 4 M; 2005 Nov 7. Explain various types of solar thermal collectors. 2004 Oct/Nov 4 M, 2008 May 8. Explain mean flat plate temperature as applied to solar energy. 2004 Oct/Nov, 2008 May 9. Explain working of a cylindrical parabolic concentrating collector. July/August 2007 10. Explain liquid flat plate collector. 2005 May 11. Explain with a neat sketch the working of Flat plate collector 2007 Jan 12. Explain focusing type solar collector. 2005 May; Nov 2008 13. Explain the working of concentrator type of collector. Dec 2007 14. Describe the subtracting system. 2005 May 15. Explain the concept of Satellite solar power station. 2007 Jan 16. Explain the functioning of a solar water heater. 2004 Oct/Nov 17. With the sketch explain working of a solar air heater. 2006 May/Jun 18. Six Mark (6) Questions 1. Write down an energy balance equation of a liquid flat plate collector. Explain various terms in this equation. 2008 May 2. 12 Marks (12) Questions 1. What is the importance of Solar Power in the present energy crises in world? Also discuss recent developments in power generation using solar energy. 2007 Jan, 2. Explain the working of a solar heater. Nov 2008 3. Explain working of a cylindrical parabolic concentrating collector. What are its advantages over a solar air heater? 2005 Nov 4. Explain with the help of a neat sketch the solar thermal power generation system. 2004 Oct/Nov; 2005 May; Dec 2007 5. Explain the working of a solar power generation cycle using flat plate collectors. Nov 2008 6. Describe the basic principle of photovoltaic conversion and list out the merits over other systems? What are the basis hurdles in the development of this mode of power generation? [2007 Jul/Aug] 7. Explain the low temperature Rankine cycle used for solar power generation. 2006 May/Jun 12 M; 2008 May 8. Explain any four thermal applications of solar energy with the help of neat sketches. Dec 2007 9. How many types of solar water collectors are generally used? Describe any two of them. Discuss the selective coating used. 2005 Nov 10. Describe in detail the different energy storage systems used in connection with solar power. Also state their advantages and disadvantages. 2007 Jan

11. Module V Thermal Power Plants Short Questions (4 Marks) 1. Draw layout of a diesel power plant. 2004 Oct/Nov; 2005 May 2. Discuss various arrangements of feed water heaters in steam power plants. Dec 2007 3. What are the functions of a condenser in a steam power plant? 2006 May/Jun 4. What are the different types of condensers? Nov 2008 5. What is the function of evaporators in a thermal power plant? Nov 2008 6. Discuss about the ash handling system in a power plant. 2004 Oct/Nov; 2005 May; 2007 Jan, July/August 2007 7. Briefly explain the advantages of forced draft over induced draft. 2004 Oct/Nov 8. Describe various stages of coal handling, preparation delivery. 2004 Oct/Nov; 2005 May; 2005 May; Dec 2007 9. Discuss various types of fuels used in thermal power plants. 2008 May 10. List operations in ash handling. Dec 2007 11. Explain necessity of dust collection system. 2008 May 12. Why mechanical handling of fuel is necessary in power plants? Dec 2007 13. Describe the different types of overfeed stockers and discuss the merits and demerits of each over the other. 2007 Jan 14. What are the merits of mechanical draft system? 2004 Oct/Nov; 2005 May 15. Distinguish between Forced draught and Induced draught. Dec 2007 16. What is natural draught cooling tower? What is the reason for its hyperbolic shape? 2005 Nov; 2004 Oct/Nov; 2005 Nov 17. What are cross flow and counter flow cooling towers. 2006 May/Jun 18. Six Mark (6) Questions 1. Give advantages and disadvantages of steam power plants. Dec 2007 2. Distinguish between forced and induced draft system. Why the balanced draft is preferred over the forced or induced draft? 2007 Jan 3. Discuss the emitting and collecting mechanisms in Electrostatic precipitators. 2007 Jul/Aug 4. Explain the functions of a cooling tower in a modern power plant. Describe with a neat sketch the working of a mechanical draft cooling tower. 2006 May/Jun, July/August 2007 5. Explain the working of two pass surface condenser with a schematic diagram. 2007 Jan 6. Explain the working of two pass surface condenser with a schematic diagram. 2007 Jul/Aug 7. 12 Marks (12) Questions 1. Draw and explain the layout of a typical Steam power plant. 2005 May; 2006 May/Jun 2. What are the various types of condensers used in thermal power stations? Nov 2008 3. Briefly explain the emissions from thermal power plant and their effect on atmosphere and environment. 2007 Jan, 2007 Jul/Aug 4. What are cyclone separators? Explain the principle of gas solid separator in cyclone. 2005 Nov 5. With the help of a T S diagram explain the working of a direct contact spray condenser. 2005 Nov 6. Explain the operation of an electrostatic precipitator. 2006 May/Jun 6 M; 2008 May 7. Explain the working of forced draft cooling tower. Nov 2008

You might also like

- ATD QB Session 2018 2019Document6 pagesATD QB Session 2018 2019Utkarsh Kumar SrivastavNo ratings yet

- Rankine Cycle 2marksgDocument7 pagesRankine Cycle 2marksgEric CookNo ratings yet

- ETD Important QuestionsDocument6 pagesETD Important QuestionsRavi KîshôreNo ratings yet

- Etd QB 2021Document11 pagesEtd QB 2021KEERTHIVASAN R MechNo ratings yet

- Tutorial 4Document2 pagesTutorial 4Diego Cuarenta JaureguiNo ratings yet

- Me 6301 Good QPDocument13 pagesMe 6301 Good QPMohanraj SubramaniNo ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Pset 1 CombustionDocument13 pagesPset 1 CombustionMicaella Jaime De LeonNo ratings yet

- Important QuestionsDocument5 pagesImportant Questionstamilselvan nNo ratings yet

- STUCOR - ME8595-TJ (1) - WatermarkDocument14 pagesSTUCOR - ME8595-TJ (1) - WatermarkMr PerfectNo ratings yet

- ChE 204 HW-4 and HW-5 Together, Spring 2014, See Changes!Document5 pagesChE 204 HW-4 and HW-5 Together, Spring 2014, See Changes!Irene Kaye AceroNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument2 pagesOur Official Android App - REJINPAUL NETWORK FromPradeep KumarNo ratings yet

- Compiled 1 PDFDocument33 pagesCompiled 1 PDFJuneNeilBalacuitNo ratings yet

- Sheet #7Document4 pagesSheet #7AHMED BAKRNo ratings yet

- Homework SteamDocument6 pagesHomework SteamCherry May Basinang-RamosNo ratings yet

- Applied Thermodynamics Question Bank Unit - 1Document7 pagesApplied Thermodynamics Question Bank Unit - 1Shivansh SudhaNo ratings yet

- MEC1405 - Thermodynamics I (2009Document3 pagesMEC1405 - Thermodynamics I (2009Maria CutajarNo ratings yet

- eNGINEERING THERMODYNAMICS QUESTION PAPERDocument11 pageseNGINEERING THERMODYNAMICS QUESTION PAPERAbubakkar Siddiq100% (3)

- 8.assignment Tutorial QPDocument13 pages8.assignment Tutorial QPvsureshkannanmsecNo ratings yet

- EI6403-Applied Thermodynamics and Fluid Dynamics PDFDocument13 pagesEI6403-Applied Thermodynamics and Fluid Dynamics PDFHarish prajenNo ratings yet

- Assignment Basics ATDocument2 pagesAssignment Basics ATXerox WorldNo ratings yet

- Thermodynamics QuestionsDocument4 pagesThermodynamics Questionsprateek vyasNo ratings yet

- TD QP UPTO Nov 2012 18092012Document31 pagesTD QP UPTO Nov 2012 18092012Narayanan Srinivasan100% (1)

- National Examinations - December 2011: NotesDocument26 pagesNational Examinations - December 2011: NotesNiko Garcia MeythalerNo ratings yet

- Cpp-Gaseous State - RGVDocument2 pagesCpp-Gaseous State - RGVGauri KabraNo ratings yet

- Me2202 - EtDocument7 pagesMe2202 - EtAnonymous mRBbdopMKfNo ratings yet

- Feb 04Document2 pagesFeb 04Kiran NaikNo ratings yet

- Thermodynamic Question BankDocument10 pagesThermodynamic Question BankRaj PratyushNo ratings yet

- Thermal Engg II - Important QuestionsDocument18 pagesThermal Engg II - Important Questions6039 ASHWINNo ratings yet

- Tutorial Questions 1111Document6 pagesTutorial Questions 1111Fahmy Muhd100% (1)

- Tutorial Sheet No2Document7 pagesTutorial Sheet No2عبدالله عمرNo ratings yet

- Taller 2 2023-1Document8 pagesTaller 2 2023-1anderson ortizNo ratings yet

- Assignment 1 First Law 2016Document8 pagesAssignment 1 First Law 2016PabitraBadhuk0% (1)

- 2013Document31 pages2013Narayanan SrinivasanNo ratings yet

- QUESTION BANK ThermodynamicsDocument6 pagesQUESTION BANK Thermodynamicsvikas_1989No ratings yet

- Thermodynamics Important QuestionsDocument4 pagesThermodynamics Important QuestionsMaha LakshmiNo ratings yet

- Rtmnu Q Paper Engineering Thermodynamics W 19Document4 pagesRtmnu Q Paper Engineering Thermodynamics W 19Zaky MuzaffarNo ratings yet

- Borgnakke's Fundamentals of Thermodynamics: Global EditionDocument94 pagesBorgnakke's Fundamentals of Thermodynamics: Global Edition정윤서No ratings yet

- Question Bank-Thermal EngineeringDocument4 pagesQuestion Bank-Thermal EngineeringIrfan ShaikhNo ratings yet

- ME6301-Engineering Thermodynamics 2013 RegulationDocument12 pagesME6301-Engineering Thermodynamics 2013 RegulationLogesh LoganNo ratings yet

- Thermodynamics Review ProblemsDocument3 pagesThermodynamics Review ProblemssayanNo ratings yet

- Problem Set (10 Questions) of First-Second Law of ThermodynamicsDocument4 pagesProblem Set (10 Questions) of First-Second Law of Thermodynamicscoolcool2167No ratings yet

- PHYS1B28: Thermal Physics Department of Physics and Astronomy, University College London. Problem Sheet 5 (2005)Document1 pagePHYS1B28: Thermal Physics Department of Physics and Astronomy, University College London. Problem Sheet 5 (2005)ShootingStarPhotonsNo ratings yet

- Question Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhDocument5 pagesQuestion Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhSAJU UTHUPPANNo ratings yet

- Me6301 Engineering Thermodynamics - Uq - Nov Dec 2015Document3 pagesMe6301 Engineering Thermodynamics - Uq - Nov Dec 2015BIBIN CHIDAMBARANATHANNo ratings yet

- Thermodynamics Assignment SheetDocument3 pagesThermodynamics Assignment SheetSatwikMohantyNo ratings yet

- EMCDocument1 pageEMCAditya GurunathanNo ratings yet

- ETD - Question BankDocument6 pagesETD - Question BankGopinath VNo ratings yet

- Me3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsDocument10 pagesMe3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsRamakrishnan NNo ratings yet

- Me2202 Engineering Thermodynamics - Uq - Nov Dec 2010Document4 pagesMe2202 Engineering Thermodynamics - Uq - Nov Dec 2010BIBIN CHIDAMBARANATHANNo ratings yet

- ThermoDocument4 pagesThermowong zhi chengNo ratings yet

- ETD Model IV QPDocument2 pagesETD Model IV QPtagoreboopathyNo ratings yet

- Tut 3Document4 pagesTut 3SamarthNo ratings yet

- ME2202 ENGINEERING THERMODYNAMICS Nov-Dec 2012 Important Question V+ EditionDocument2 pagesME2202 ENGINEERING THERMODYNAMICS Nov-Dec 2012 Important Question V+ EditionPrasobh ShamohanNo ratings yet

- KF 1Document19 pagesKF 1Diana Fitriani SurtikaNo ratings yet

- MPD 2012 - Sheet 3 - Binary and Combined CyclesDocument3 pagesMPD 2012 - Sheet 3 - Binary and Combined CyclesPeter Raouf100% (1)

- ElementsDocument10 pagesElementsNur Amira Mardiana ZulkifliNo ratings yet

- 00107Document9 pages00107mukesh3021No ratings yet

- StabilityDocument5 pagesStabilityJenelia Jojo50% (2)

- Safety HandbookDocument17 pagesSafety HandbookRakesh JunnurNo ratings yet

- Shop Safety PolicyDocument21 pagesShop Safety Policymukesh3021No ratings yet

- Laboratory Manual Physics - 1: AGH University of Science and Technology in Cracow Department of ElectronicsDocument3 pagesLaboratory Manual Physics - 1: AGH University of Science and Technology in Cracow Department of Electronicsmukesh3021No ratings yet

- Strength of MaerialsDocument45 pagesStrength of MaerialsShivakumar PatilNo ratings yet

- CNC Programming - PdfdsfdsDocument27 pagesCNC Programming - PdfdsfdsArie JuliantoNo ratings yet

- Impact of A Jet: Experiment 4Document6 pagesImpact of A Jet: Experiment 4Eye IqbalNo ratings yet

- Convocation Adv Sept 13Document1 pageConvocation Adv Sept 13mukesh3021No ratings yet

- Types of Boilers PDFDocument5 pagesTypes of Boilers PDFJosé RubioNo ratings yet

- LM FluidMechanicsLabDocument0 pagesLM FluidMechanicsLabmukesh3021No ratings yet

- Boilers and Thermic Fluid HeatersDocument54 pagesBoilers and Thermic Fluid HeatersParin PatelNo ratings yet

- Experiment - 08 - Determination of Meta-Centric HeightDocument3 pagesExperiment - 08 - Determination of Meta-Centric HeightAshish YadavNo ratings yet

- Fluids Lab ManualDocument67 pagesFluids Lab Manualkalyan_aubeNo ratings yet

- Fluids Lab Venturi Meter - 4Document5 pagesFluids Lab Venturi Meter - 4augur886No ratings yet

- PublicationsDocument11 pagesPublicationsmukesh3021No ratings yet

- Anleitung Ir1 eDocument16 pagesAnleitung Ir1 emukesh3021No ratings yet

- Advt ES2 03 2013EDocument1 pageAdvt ES2 03 2013Emukesh3021No ratings yet

- Mechanics of Fluids Laboratory: A Manual For TheDocument52 pagesMechanics of Fluids Laboratory: A Manual For Theturnip331100% (1)

- EAS361 LabManual Fall2004 r3Document41 pagesEAS361 LabManual Fall2004 r3mukesh3021No ratings yet

- Fluid Mechanics Ans Machinery - Lab ManualDocument76 pagesFluid Mechanics Ans Machinery - Lab ManualVikram Puttenahalli Nagesh GowdaNo ratings yet

- Fluid Mechanics Hydraulics Lab ManualDocument24 pagesFluid Mechanics Hydraulics Lab Manualsawmag123No ratings yet

- Fluid Mechanics (2003)Document6 pagesFluid Mechanics (2003)mukesh3021No ratings yet

- Laboratory ManualDocument10 pagesLaboratory Manualmukesh3021100% (1)

- Flued Mechanics & MachineryDocument4 pagesFlued Mechanics & Machinerymukesh3021No ratings yet

- Centrifugal Pump Test Rig: Fluid Mechanics and Hydraulics LabDocument6 pagesCentrifugal Pump Test Rig: Fluid Mechanics and Hydraulics Labmukesh3021No ratings yet

- 1373090220Document14 pages1373090220mukesh3021No ratings yet

- Pert Time/ Cost: An Aid To Agribusiness ManagementDocument62 pagesPert Time/ Cost: An Aid To Agribusiness ManagementPangga TolentinoNo ratings yet

- CPMDocument15 pagesCPMViktor AnastasovskiNo ratings yet

- Syllabus DBATUDocument88 pagesSyllabus DBATUShivanand ArwatNo ratings yet

- Lecture 1: Entropy and Mutual Information: 2.1 ExampleDocument8 pagesLecture 1: Entropy and Mutual Information: 2.1 ExampleLokesh SinghNo ratings yet

- Bachelor of Science: Subject: Chemistry Semester IDocument30 pagesBachelor of Science: Subject: Chemistry Semester Isameer samNo ratings yet

- Thermo 20 YrDocument54 pagesThermo 20 Yrraman50% (2)

- Institute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)Document1 pageInstitute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)Rohan NewaskarNo ratings yet

- Stage - A Thermodynamics & Thermochemistry: Mother's Public School, Unit - 1, BhubaneswarDocument8 pagesStage - A Thermodynamics & Thermochemistry: Mother's Public School, Unit - 1, BhubaneswarAman9692No ratings yet

- Chapter 06 PDFDocument281 pagesChapter 06 PDFalejaNo ratings yet

- 5 Steps To A 5 Physics Christopher Bruhn PDFDocument422 pages5 Steps To A 5 Physics Christopher Bruhn PDFAmogh Ayalasomayajula100% (1)

- Page 1 of 40Document61 pagesPage 1 of 40Garima KapoorNo ratings yet

- Renewable Energy SourcesDocument141 pagesRenewable Energy SourcesHasan Hüseyin ÖzkanNo ratings yet

- EntropyDocument14 pagesEntropySMCNo ratings yet

- Phys340 Lec1-10 EqnsDocument8 pagesPhys340 Lec1-10 Eqnsapi-547379030No ratings yet

- A Textbook of Physical Chemistry A Textbook of Physical Chemistry PDFDocument483 pagesA Textbook of Physical Chemistry A Textbook of Physical Chemistry PDFEstanislao Amadeo Avogadro100% (1)

- Planetary DysphoriaDocument7 pagesPlanetary Dysphoriatantalus11No ratings yet

- The Philosophy of Quantum TheoryDocument11 pagesThe Philosophy of Quantum TheorySumbul ZehraNo ratings yet

- Physics 8.821: Problem Set 1 SolutionsDocument9 pagesPhysics 8.821: Problem Set 1 SolutionsBobNo ratings yet

- Me 433 BookDocument511 pagesMe 433 BookpizzweNo ratings yet

- Lesson Plan EtdDocument3 pagesLesson Plan EtdJoe Kamal RajNo ratings yet

- Fiziks: Second Law of Thermodynamics and EntropyDocument34 pagesFiziks: Second Law of Thermodynamics and EntropySURAJ PRATAP SINGHNo ratings yet

- Chapter 17 KeyDocument16 pagesChapter 17 KeyAriny ZaqiyahNo ratings yet

- Stanciu PDFDocument18 pagesStanciu PDFprashant_salima6377No ratings yet

- Me 6301 Engineering Thermodynamics Short Questions and AnswersDocument43 pagesMe 6301 Engineering Thermodynamics Short Questions and AnswersBIBIN CHIDAMBARANATHAN83% (29)

- Application Thermo MetallDocument415 pagesApplication Thermo Metalltopomono2No ratings yet

- IB Chemistry HL Internal AssessmentDocument14 pagesIB Chemistry HL Internal AssessmentZinzan Gurney100% (1)

- FGDGBDocument1 pageFGDGBAlireza PourmokhtarNo ratings yet

- Three-Pressure-Level Combined CycleDocument41 pagesThree-Pressure-Level Combined CycleGianluca Castoldi QuintanoNo ratings yet

- Melvin Vopson - Second Law of Information DynamicsDocument6 pagesMelvin Vopson - Second Law of Information DynamicsjohnparamolNo ratings yet

- The Myth of Energy StealingDocument4 pagesThe Myth of Energy Stealingautodidact144No ratings yet

- DTU Automotive Engineering SyllabusDocument63 pagesDTU Automotive Engineering SyllabusVinay TripathiNo ratings yet