Professional Documents

Culture Documents

Copper Piping

Uploaded by

Noushad P HamsaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copper Piping

Uploaded by

Noushad P HamsaCopyright:

Available Formats

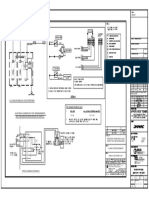

METHOD STATEMENT INSTALLATION OF HOT & COLD WATER COPPER PIPING

1. STORAGE Store all pipes & fittings in manner to avoid ingress of foreign material inside pipes and fittings which may get stuck inside. This can cause deterioration of inner walls or blockage / disruption of water supply. Stack all pipe lengths horizontally with end caps intact and in a manner to avoid intermediate sagging. It should be protected from spilling fluids or spattering of cement and other building material. Protection from falling building material debris is necessary. 2. PREPARATION a. Choose the required pipe and inspect for any visible damage to pipe or polyethylene insulation. Measure required length and mark along the circumference of the pipe. Using a pipe cutter with sharp cutting wheel, grip and start cutting into the tube. Dig the cutting wheel slowly into the tube while rotating it fully along the circumference to achieve a uniform cut. On the end requiring connection, mark approximately 75mm away from the edge. With a sharp knife make a straight cut in the coating of the pipe to reveal the outer surface of the copper pipe. Expand and invert the coating, folding it backward and reveal the copper pipe upto the length of cut in the coating. Using steel wool or soft emery paper clean the bare copper pipe externally and at cutting edge. Ensure proper removal of any oxide on the surface and any burr formed during cutting. Similarly, prepare another piece of pipe for connection to previous pipe. Install the appropriate union or connection as required to be used for making connection. Ensure using closely tight fitting component and connect the pipes inserting the union fully upto the ring. Apply flux as recommended by manufacturer.

b.

c. d.

e.

f.

Wrap wet rags neatly over the pealed and inverted coatings of both pipes to be joined. Allow for proper contact with pipe and adequate moisture in the cloth to withstand heat during brazing process. Slowly and gently heat the joint with blow torch, moving the torch for evenly heating all the joint surface. Concentrating heat at one point can cause overheat at one point resulting in irregular expansion I deformation of joint. For fittings with pre filled solder, heat evenly till a thin bead of solder appears all around the edge. For other fittings apply suitable and correct quantity of solder and spread it evenly by heating and melting it to flow and from a fusion type joint.

g.

During this process, care should be taken to avoid directing the blow torch towards the coating of copper pipe. At the same time check that the rags wrapped at coating I bare pipe have enough moisture to neutralize the conduction of heat that may damage the coating. Allow the joint to cool slowly. Do not sprinkle water etc. to induce cooling deliberate act can cause cracks in the joints or weaken the joint itself. 3. FINISHING When the joint is complete and cooled, fold back the plastic coat to cover bared surface. Wrap suitable adhesive tape (preferably of same colour as coating) to cover the entire length of cut in the coating on both sides including the joint to give it a neat look besides retention of coating at the joint. Install the pipe work using appropriate clamps to avoid undue stress on the pipe or pipe joint. 4. SAMPLE Sample installation shall be carried out and offered for Consultants inspection prior to carrying out majority works

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Search EnginesDocument15 pagesSearch EnginesRam Sagar MouryaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chilled Water Pipe SizingDocument2 pagesChilled Water Pipe SizingLarry Bea77% (13)

- Classification of ComputersDocument2 pagesClassification of Computerseduardo acuniaNo ratings yet

- Access Control GuideDocument69 pagesAccess Control GuideMuhammad AshiqNo ratings yet

- 003-Ansul R-102 System P & I D-P&IDDocument1 page003-Ansul R-102 System P & I D-P&IDNoushad P HamsaNo ratings yet

- Construction Materials E-BookDocument98 pagesConstruction Materials E-BookNoushad P Hamsa100% (1)

- 002 Fire Protection SystemDocument12 pages002 Fire Protection SystemJerome AdduruNo ratings yet

- ME Vs MIIDocument6 pagesME Vs MIIFrancisco Abian GarciaNo ratings yet

- RWV Balancing Valve TrainingDocument33 pagesRWV Balancing Valve TrainingNoushad P HamsaNo ratings yet

- KX SeriesDocument24 pagesKX SeriesNoushad P HamsaNo ratings yet

- A Guide To Air FiltrationDocument50 pagesA Guide To Air FiltrationNoushad P HamsaNo ratings yet

- Energy Planning A Guide To PractitionersDocument75 pagesEnergy Planning A Guide To PractitionersNoushad P HamsaNo ratings yet

- Ventilation Systems Equal Friction Method Date ProjectDocument2 pagesVentilation Systems Equal Friction Method Date ProjectNoushad P HamsaNo ratings yet

- Copper Tube DesignDocument34 pagesCopper Tube DesignNoushad P HamsaNo ratings yet

- Energy Planning A Guide To PractitionersDocument75 pagesEnergy Planning A Guide To PractitionersNoushad P HamsaNo ratings yet

- Mechanical Draft Cooling TowerDocument6 pagesMechanical Draft Cooling TowerNoushad P HamsaNo ratings yet

- Gombrich - EstiloDocument6 pagesGombrich - EstiloRoxana CortésNo ratings yet

- Release Notes GLD Editor V1.51 2Document3 pagesRelease Notes GLD Editor V1.51 2Papa ConfiNo ratings yet

- Floor PlansDocument26 pagesFloor PlansXiaobinn Y OcaNo ratings yet

- 20 Useful Terminal Commands and Tools That You May Need in Ubuntu-Linux MintDocument7 pages20 Useful Terminal Commands and Tools That You May Need in Ubuntu-Linux Mintoral_cuNo ratings yet

- GGA - Pressure Independent Terminal UnitsDocument10 pagesGGA - Pressure Independent Terminal UnitsInventor SolidworksNo ratings yet

- Leaflet Packo Open TanksDocument4 pagesLeaflet Packo Open TanksRicky Okwir Okello100% (1)

- SOAP Web SecurityDocument0 pagesSOAP Web SecurityRei ChelNo ratings yet

- Term Exam 2 - QuestionsDocument4 pagesTerm Exam 2 - Questionsamadeus135No ratings yet

- Automatic Irrigation Calculation SheetDocument38 pagesAutomatic Irrigation Calculation Sheetكرم عمروNo ratings yet

- Ms Powerpoint Quiz2016Document2 pagesMs Powerpoint Quiz2016api-2610280400% (2)

- ULTIMATE STRESS DESIGN Sample OnlyDocument2 pagesULTIMATE STRESS DESIGN Sample OnlyE SNo ratings yet

- Fluid Control ProductsDocument42 pagesFluid Control Productskb_pramodNo ratings yet

- Spring Boot ReferenceDocument251 pagesSpring Boot ReferenceShishir RoyNo ratings yet

- Dwnload Full World of Art 8th Edition Sayre Test Bank PDFDocument35 pagesDwnload Full World of Art 8th Edition Sayre Test Bank PDFoctopodatomjohnnh73100% (7)

- Wpa Cli SecretsDocument7 pagesWpa Cli SecretsJulian MelendezNo ratings yet

- Specsheet Etile19m-Fw I5 CpuDocument2 pagesSpecsheet Etile19m-Fw I5 CpuMarisagarcia2014No ratings yet

- San Luis Reservoir State Recreaion Area Campground MapDocument2 pagesSan Luis Reservoir State Recreaion Area Campground MapCalifornia State ParksNo ratings yet

- As NZS 7000 Programme ConfDocument3 pagesAs NZS 7000 Programme ConfnitinatpNo ratings yet

- Analyze Training GuideDocument158 pagesAnalyze Training GuideBaharehSianatiNo ratings yet

- 2 Bedroom Carport and Deck PDFDocument14 pages2 Bedroom Carport and Deck PDFAnonymous tLrDSTaFINo ratings yet

- Foundation & Column DesignDocument6 pagesFoundation & Column DesignAlbert LuckyNo ratings yet

- 1.2 Principles of Pavement EngineeringDocument22 pages1.2 Principles of Pavement EngineeringRyan ChristopherNo ratings yet

- ChartDocument4 pagesChartVenkates Waran GNo ratings yet

- IRMCK341: Sensorless Motor Control IC For AppliancesDocument36 pagesIRMCK341: Sensorless Motor Control IC For AppliancesMeselao Meselao MeselaoNo ratings yet

- Oral Presentation Guidelines: 1. Audio/Visual & Equipment AvailableDocument2 pagesOral Presentation Guidelines: 1. Audio/Visual & Equipment AvailableNanda SafiraNo ratings yet