Professional Documents

Culture Documents

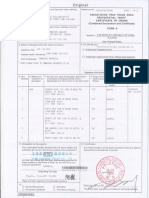

Ar2005 0621 0631 - Soltani Material

Uploaded by

Prankesh YadavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ar2005 0621 0631 - Soltani Material

Uploaded by

Prankesh YadavCopyright:

Available Formats

AN INTELLIGENT TRANSPORTATION SYSTEM IN CONSTRUCTION SITES

Amir R Soltani

School of Engineering, Halton College, Kingsway, Widnes, WA8 7QQ, UK

Site transportation in terms of organising the efficient movement of vehicles, people and materials ensures the efficient use of workforce and production/process time in construction operations. In an attempt to improve productivity from the site transportation perspective, an appropriate IT performance evaluation framework could play an important role in the context of efficient management of construction site layouts and the movement patterns within a site. An efficient path layout of a working site that allows to store, transport, deliver material, plant and equipment in the shortest time is a determinant factor and requirement in a complex project. In addition, risks on construction sites can be reduced if the use of vehicles and mobile plant is properly managed by setting out paths avoiding high risks areas. Provision of safe paths could be used to control high-risk situations on the site. This paper addresses the lack of computer-based support tools for multi-objective optimum path finding applications that can be used interactively to assist site planners with generating alternative path scenarios. This IT tool will support the use of what-if analysis for planners so that they can work out the movements paths for people and vehicles for a given site layout.

Keywords: fuzzy-based multi-objective, genetic algorithm, path finding, site layout.

INTRODUCTION

Movement of materials, plant and site operative from one place to another on construction sites and construction workplaces are of paramount importance to site planners as savings in travel distance can reduce cost and increase productivity. In addition, risks on construction sites can be reduced if the use of vehicles and mobile plant is properly managed by setting out paths avoiding high risks areas. The layout of an efficient working site to store, transport, deliver material, plant and equipment in the safest manner and within the shortest time is a determinant factor and requirement in a complex project (Soltani and Fernando, 2004). In construction sites, a safe working environment is imperative as it brings about a sustained condition in which site operatives work efficiently (Soltani et al., 2002). Perry and Hayes (Perry and Hayes, 1985) have identified risks sources central to construction activities concluding that risk management is most valuable at an early stage in a project where there is still some flexibility in design and planning to consider how the risk might be avoided. Site layouts with site operative and vehicle routes which possess short distance, low risks, and high visibility, can assist site planners to reduce hazards. It is also of great importance to check whether an object in front of an operator can be seenin workplaces or vehicles (Jung and Dohyung, 1996).

Soltani, A R (2005) An intelligent transportation system in construction sites. In: Khosrowshahi, F (Ed.), 21st Annual ARCOM Conference, 7-9 September 2005, SOAS, University of London. Association of Researchers in Construction Management, Vol. 1, 621-31

Soltani

Visibility can be considered to be a safety related measure that allows for better risk perception and avoidance, which could lead to a significant improvement on the site safety management. An IT support tool for the analysis of space on construction site could facilitate the rehearsal of various site planning scenarios taking into consideration several intercorrelated factors including the site layout, location of material storage and temporary facilities, access routes and layout of roads and movement paths. The development of an IT support tools presenting a simulation application for the analysis and planning of movements according to distance and safety-related measures on construction sites can significantly enhance the overall productivity and safety on the site, as the site planning can be integrated with visualisation modelling allowing an automated pathplanning task to be carried out.

AIMS AND OBJECTIVES

This study aims to design a framework for supporting path-planning analysis of construction sites, based on multi-objective evaluation of transport cost and safetyrelated objectives in order to maximise the overall productivity of construction works. This application aims to enable site managers and planners to make strategic decisions regarding the movement of people and vehicles on a construction site, and layout planning that improves travel distance, safety and visibility to allow the examination of path scenarios and the selection of the best possible path. The multi-objective optimisation framework generates a favourable path based on short distance, a userdefined risk minimisation and visibility maximisation. The path-planning IT platform can be applied to a number of instances of site layouts for the evaluation of a dynamic site layout.

RELATED WORK

A large volume of research has been carried out in applying computers in the construction field. Recent research into optimum organisation of construction site layouts (Li et al., 2001), site planning (Tawfiq and Fernando, 2001), site communication (Fernando et al., 2001), has resulted into the development of a number of IT prototypes to aid site-planning tasks, whereas limited research into path finding has been conducted. Brandon et al. (Brandon et al., 1998) described the use of information technology (IT) in the construction industry and reported the rapid advancement in the potenials for practical implementation of advanced information and communications technologies. Zhang et al. (Zhang et al., 2002) used a hybrid intelligence technique (HSSL) by combing an expert system and an artificial neural network to present a construction site management method. Cheung et al. (Cheung et al., 2002) used genetic algorithms to present an efficient site layout arrangement for a pre-cast yard layout. Choo and Tommelein (Choo and Tommelein, 1998) proposed a space scheduling accounting for requirements such as variability in flow speed and paths; the space required needs to represent flows of material, equipment, and labour on layouts. Tommelein (Tommelein, 1999) presented a methodology that took into account the location of the temporary facilities relative to the location of construction workers, in combination with worker travel and customer service time, in order to help identify the best location on site for facilities.

622

An Intelligent Transportation System in Construction Sites

From the path-planning viewpoint, the ability to solve for the optimal path connecting two points in space has been of great importance to industrial (Barraquand et al., 1992), and more recently to architectural, urban and building design communities (Charles et al., 2002). Traditional methods of determining an optimal path to traverse from one point to another have been based on graph exploration techniques. These methods include the Dijkstra (Dijkstra, 1959), A* (Hart et al., 1972) and genetic algorithms (Holland, 1975). Solka et al. (Solka et al., 1995) used highly parallel unconstrained Dijkstra approach in order to develop a new optimal path finding algorithm in which paths are subjected to turning constraints in that the final path solutions will contain no turns greater than 45o. Yu and Yang (Yu and Yang, 1998) adopted a scenario approach in conjunction with Dijkstra algorithm to characterise uncertainties. This approach determines the shortest path by finding among all paths from start to finish the one that, over all scenarios, minimises the maximum deviation of the path length from the optimal path length of the corresponding scenario.

SYSTEM STRUCTURE

The quantitative analysis of a construction site layout requires an evaluation framework that provides problem solutions by applying analytical methods which model site layout representation, distance formulation, hazard zone modelling, and visibility calculations.

Hazard, Distance, and Visibility Information

Visibility data layer Hazard data layer Distance layer

Start & Goal

Optimisation GA Algorithm

Multi-objective Function (Risk Minimisation, Distance Cost Minimisation, and Visibility Maximisation)

Optimum Paths

(a)

(b)

Figure 1 The design conceptualisation using (a) multi-layered grid structure, (b) structure of path finding application The above modelling strategy that leads to an optimal path can be broken into the following key steps: 1) construction site layout representation; 2) path evaluation objectives; 3) path finding algorithms application. These steps are outlined below.

623

Soltani

Construction Site Layout Representation In order to present a site layout for analysis, the site layout is subdivided into cells on a two-dimensional grid. A grid node located at a cells centre-point is allocated to each cell. This method of space mapping generates a set of discrete nodes that cover the entire construction site domain, as shown in Fig. 2 in which dark areas indicate the presence of site objects.

Site objects

Figure 2 A sample of discretised site layout with black shapes highlighting site objects A grid unit area is used to scale down the construction domain size e.g. a grid unit area may represent 1 m2 or 4 m2 of the construction domain size depending on the size of the actual construction domain. The spatial objective of distance, safety, and visibility are presented by a set of numerical values attributed to each node. Path-planning Evaluation Objectives The grid nodes of the discretised site layout hold numerical values corresponding to distance, safety, and visibility. The formulations of these objectives are presented below. Distance Evaluation This is the Euclidean distance between the grid nodes. The distance between two adjacent grid nodes are 1 grid unit for horizontally and vertically aligned grid nodes, and 2 grid unit for diagonally aligned grid nodes. Hazard Zone Modelling The hazard zone modelling part determines the hazard zones associated with the presence of site objects such as cranes, vehicles and equipment, according to their variable degree of risk and dimension. Hazard zones in this application are represented by a number of layers that vary in terms of the size of the hazard area surrounding the object and the distribution of the degree of hazard across the hazard layers. The extent and intensity of hazard from an objects boundary is defined by the hazard length (L) and the hazard level (H), respectively, as shown in Fig. 3. The hazard values are normalised between [0, 1].

L L Site Object H

Site Object

H Hmin L Site Object

Hmin

Minimum Risk Level Hmin

Maximum Risk Level Hmax

624

An Intelligent Transportation System in Construction Sites

(a)

(b)

(c)

Figure 3 Hazard zone with (a) constant hazard distribution, (b) linear hazard distribution, (c) non-linear hazard distribution Visibility Calculation This objective determines the visibility value from a fixed position in the site. The visibility model consists of a set of lines of sight, by which objects in the construction sites can be seen. The lines of sights which are referred to as isovists lines (Benedikt, 1979), can be defined as the geometry obtained by casting light rays in all directions from a fixed position in space. Figures 4(a) and 4(b) show the results of applying visibility analysis using isovists to a single point on two different locations within a site layout.

Site Objects Ray casting from a point producing isovist lines of high visibility value Ray casting from a point producing isovist lines of low visibility value

(a)

(b)

Figure 4 Visibility analysis of spatial layouts using isovists lines for (a) a high visibility point (b) a low visibility point Path finding algorithm application The path-planning evaluation objectives create a set of solutions that consist of those solutions satisfying desirable design requirements. The goal is to find these solutions that contain the highest (optimum) performance with regard to a certain measure, such as safety. Therefore, the path-planning framework is an optimisation problem that entails an optimisation algorithm. Genetic Algorithms (GA) which is a probabilistic optimisation algorithm that mimics natural evolution and genetics was used in this study. The GA chromosome representation is first introduced. Chromosome Representation The GA chromosome was selected to be an integer string that encodes the twodimensional geometrical coordinates of a number of grid nodes of the discrete site

625

Soltani

layout, which correspond to intermediate points between the start and the goal locations, defining a segment sequence that forms the path.

Start node 2D co-ordinates of the intermediate path

Construction site

Goal node

y x

x1

S

y1 x2 y2 x3 y3

points

Genes forming a chromosome

g1

g2

g3

g4

g5

g6

Integer chromosome representation

Intermediate Path Points

Figure 5 GA solution representation of a site path

For a path consisting of three intermediate points, the corresponding GA chromosomes representation can be shown in Fig. 5. S and G are the start and goal nodes, respectively. The co-ordinates of the intermediate path points are given by x and y, which map into chromosome genes denoted by g. Fuzzy Based Multi-objective Evaluation Fuzzy logic and fuzzy sets were first introduced by L. A. Zadeh (Zadeh, 1965) as a mathematical theory of vagueness. Fuzzy based multi-objective evaluation is used to combine these path-planning objectives. A heuristic safety model requires some qualitative description of safety level and safety design requirements. In an ideal world, the safety level should prevent risks to the extent that the corresponding cost measures are no longer relevant. From a practical design point of view this safety level is neither achievable and nor is feasible. Therefore, two safety levels are presented as: a) maximum normalised level of achievement for safety, designated by Us; b) minimum normalised level of achievement for safety, designated by Ls. The difference between these two levels gives the safety threshold, Ts. A heuristic function describing the safety membership function at a grid node, S(Pk), can be mathematically expressed as:

if S (Pk ) US 1 if LS < S (Pk) < US S(Pk) = 1 (( U S S ( Pk )) / TS ) 0 if S (Pk) LS where Pk is a grid node and S(Pk) is the safety value at the grid node Pk. In the above equation, the minimum normalised level of safety achievement, LS, is presented as a percentage of the maximum normalised level of safety achievement, US, where US is assigned to 1 and accordingly LS can vary from 0 to 1. In a similar manner, the visibility membership function v(Pk) is also defined. Intersection, also known as T-norm, is the most basic operations on fuzzy sets, which is represented by using an algebraic product of S(Pk) and v(Pk), i.e. A (x) B (x). The distance

626

An Intelligent Transportation System in Construction Sites

weighting is either 0 or 1, since the fuzziness evaluation of distance cannot be conceptualised. Objective Function A heuristic safety model requires a composite objective value of a grid node Pk on the site layout, C(Pk, Pk+1), is obtained by adding the normalised values of distance to the T-norm product of safety and visibility member functions, given by C(Pk, Pk+1) = dCd(Pk, Pk+1) + s(Pk). v(Pk) where Pk and Pk+1 are a pair of adjacent nodes, Cd(Pk, Pk+1) is the binary distance function and d is the distance weight.

RESULTS AND DISCUSSIONS

Two-dimensional approximation of the construction site layout of a real cable tunnel project in Singapore was considered in this study. The issues in the selection of this construction site layout could be related to: the existence of various routes for site operatives and material delivery allowing the study of surface transport in terms of cost, safety, convenience and mode of transport; the allocation of sources of hazard during the construction programme in order to demonstrate the safety factors restricting movements on the site; and the availability and ease of access to the site layout information. The layout representation uses a 100 by 100 unit grid size.

1 2 3 10 8 9 11 4

23 6 5 22 32 7

33

12

24

25

14 14 14

13

20 21 34 Manuallygenerated site path directions 19 16 31 18 28 17 30 29 27 26

15 28 16 16

Figure 6 Site layout of the construction site under investigation The description of site objects on Fig. 6 are as follows: 1) East bore tunnel; 2) West bore tunnel; 3) Drive shaft; 4)Rear service tunnel; 5) Tunnel segments (consumption 100 segments per day 20 rings); 6) Tunnel lining grouting plant (bentonite, sodium silicate, sodium bicarbonate, cement, water, pumping equipment, computer system, labarotary); 7) Sedimentation tank; 8) Muck pit; 9) Temporary sub-station for tunnel boring machine; 10) Tower crane; 11) Muck

627

Soltani

disposal truck; 12) Grantry lane; 13) Labour accommodation; 14) Spare parts; 15) Canteen; 16) Tunnel boring machine parts; 17) Site consultants office; 18) Contractors office; 19) Security control; 20) Chiller units; 21) Truck wheel wash; 22) Grantry crane; 23) Boring machine back up assembly rails; 24) Boring machine cutter disks, drive motors, etc.; 25) Tunnel segment curved bolts, nuts, washers, etc.; 26) Emergency deliveries, stand by area for immediate storage; 276) Spare segment cars, muck cars; 28) Car park; 29) Formwork & construction materials; 30) Tunnel service pipes (water, grouting lines, California switch rails & parts); 31) Motor cycle parking; 32) Work shop; 33) Grouting equipment, test samples, etc.; 34) Gate. The muck pit (site object number 8) is considered to be a source of hazard that is represented by the non-linear hazard distribution model, as shown in Fig. 7(a) and the visibility distribution around the site is given by Fig. 7(b). A detailed path planning is used to simulate routes that have been used during this construction project.

No risk area A site object

Risk source

A site object

Low Risk

High Risk

High Vis.

Low Vis.

(a)

(b)

Figure 7 Graphical representations of (a) safety, and (b) visibility distribution Figure 8(a) shows the shortest distance for the sites consultant to get to the workspace containing site objects (5), (6) and (32) from their office. This path could also be considered as the safest path since this region of the site is not exposed to a great risk.

(a) containing site objects (5), (6) and (32)

(b)

Figure 8 The shortest path from the site consultants office (17) to the workspace The use of vehicles by the consultants for either travelling or transporting small goods and materials to the workspace requires routes that do not create danger to the pedestrian traffic. The path shown in Fig. 8(b) can be used for the vehicles but it seems to be uneconomical for such transit movements because of small turning circle,

628

An Intelligent Transportation System in Construction Sites

a limited area which may be used by the site operatives and other vehicles as shown in Figs. 9 and 10, and the transportation of equipment from the boring machine cutter disks, drive motors (24) and tunnel segment curved bolts, nuts, washers (25) to the drive shaft (3). In fact, the vehicle routes shown in Figs. 8(b), 9(b) and 10(b) can be used as the segments of a route for delivering the tunnel materials to the drive shaft (3), the formwork and construction material workspace (29), and the tunnel service pipes (30).

(a)

(b)

Figure 9 The safest and the most visible path from the car park (28) to the drive shaft

(a)

(b)

Figure 10 50% safe and 50% visible path from the site contractors office (18) to the workspace containing site objects (5), (6) and (32) Figures 8(b), 9(b) and 10(b) demonstrate the use of large trucks may present danger to the site operatives and it is more appropriate to use articulated trucks with interchangeable carrier sections that can be parked near to the activity areas. Forklift trucks and powered barrows are the other mode of transports that can be used for the delivery of loose materials to the drive shaft. It is, however, important that a driver adhere strictly to the allocated routes. Figure 9(a) shows the safest and the most visible path for travelling between the car park (28) and the drive shaft (3) allocated for the site visitors. This path goes through the most visible areas of the site and simultaneously satisfies the safety measure by staying away from the hazard source. This route can also be used by the site operatives to reach several other areas of the site such as the muck pit (8) and the spare parts workspace (14). The path shown in Fig. 10(a) can also be used for a variety of purposes by the site operatives, such as transporting manually spare parts from the spare part workplaces (14) to the workspace containing site objects (5), (6) and (32) using a hand barrow, as well as to be used by the site contractors officers. The vehicle path shown in Fig. 10(b) can also be used as a route for transporting the site visitors from the car park (28) to the workspace containing site objects (5), (6) and (32). The paths in all the above cases provided an opportunity for the site planner to use the corresponding path segments according to an appropriate construction scheduling that could vary and resulting in re-allocation of paths and movement patterns on the site.

629

Soltani

CONCLUSIONS

In this paper, a detail analysis of results extracted from a real case study was presented validating the applicability of the path-planning framework. The evaluation of path planning on the above site layout provided an in-depth analysis of transport operation that proved to be one of the major operations that can greatly influence the overall construction cost in terms of safety management, time, productivity, and travelling distance. In general, this multi-objective site path planning approach has been capable of producing strategic paths for potentially complex site layouts, as well as providing the flexibility of tuning various path-planning criteria, in order to offer useful and complementary option to manually defined site path.

REFERENCES

Barraquand, J., Langlois, B., and Latombe J. (1992). Numerical potential field techniques for robot path planning. IEEE Trans. Systems Man Cybernet, 22(2): 224-241. Benedikt, M. L. (1979). To take hold of space: isovists and isovists fields. Environment and Planning, B(6): 47-65. Brandon, P., Betts, M., and Wamelink, H. (1998). Information technology support to construction design and production. Computers in Industry, 35:1-12. Charles, S. H., Kincho, H. L., Latombe, J., and Kunz J. (2002). A performance-based approach to wheelchair accessible route analysis. Advanced Engineering Informatics, 36: 53-75. Cheung, S.O., Tong, T., and Tam, C. M. (2002). Site pre-cast layout arrangement through genetic algorithm. Automation in Construction, 11(1): 35-46. Choo, H. J. and Tommelein, M. D. (1998). Space scheduling using flow analysis. Proceedings IGLC-7, Berkeley, CA, pages 229-311. Dijkstra, E. W. (1959). A note on two problems in connection with graphs. Numeriche Mathematik, 1: 269-271. Fernando, T., Kahkonen, K., Leinonen, J., Murray, N., and Tawfik, H. (2001). Facilitation of collaborative communication for building construction with virtual reality technology. Conference on Applied Virtual Reality in Engineering and Construction Application, AVR II & CONVR. Gothenburg, pages 1-17. Hart, P. E., Nilsson, N. J., and Raphael, B. (1972). Correction to A formal basis for the heuristic determination of minimum cost paths. SIGART Newsletter, 37:28-39. Holland, J. (1975). Adaptation in natural and artificial systems. Ann Arbor: University of Michigan Press. Jung, E. S. and Dohyung, K. (1996). A man-machine interface model with improved visibility and reach functions. Computers Ind. Engineering, 30(3): 475-486. Li, Z., Anson, M., and Li., G. (2001). A procedure for quantitatively evaluating site layout alternatives. Construction Management and Economics, 19: 459-467. Perry J. G. and Hayes R. W. (1985). Risk and its management in construction projects. Proceedings of Institution of Civil Engineers, 7891): 499-521. Solka, J. L., Perry, J. C., Poellinger, B. R., and Rogers, G. W. (1995). Fast computation of optimal paths using a parallel Dijkstra algorithm with embedded constraints. Neurocomputing, 8: 195-212. Soltani, A. R. and Fernando, T. (2004). A fuzzy based multi-objective path planning of construction sites. Automation in Construction, 13(6): 717-734.

630

An Intelligent Transportation System in Construction Sites

Soltani, A. R., Tawfik, H., and Fernando, T. (2002). Evaluating paths in construction sites using multiple objectives. Third International Conference on Decision Making in Urban and Civil Engineering, pages 893-900. Tawfik, H. and Fernando, T. (2001). A simulation environment for construction site planning. Fifth International Conference on Information Visualisation, pages 199-205. Yu, G. and Yang, J. (1998). On the robust shortest path Problem. Computer Operations Research, 25(6): 457-468. Zadeh, L. A. (1965). Fuzzy sets. Information Control, 8: 338-353. Zhang, J. P., Liu, L. H., and Coble, R. J. (2002). Hybrid intelligence utilisation for construction site layout. Automation in Construction, 11: 511-519.

631

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aspen Tutorial #4: Design Specs & Sensitivity Analysis: OutlineDocument11 pagesAspen Tutorial #4: Design Specs & Sensitivity Analysis: OutlineWonda 005No ratings yet

- Brunei 2Document16 pagesBrunei 2Eva PurnamasariNo ratings yet

- Ultrasonic Inspection of Welds in Tubes & Pipes: Educational NoteDocument13 pagesUltrasonic Inspection of Welds in Tubes & Pipes: Educational NoteleonciomavarezNo ratings yet

- Y-7 Yoke: AC/DC Electromagnetic YokeDocument2 pagesY-7 Yoke: AC/DC Electromagnetic YokeImmanuel RajNo ratings yet

- Street Design Manual NYCDocument312 pagesStreet Design Manual NYCgonleoNo ratings yet

- DSE MC G11 G12 Equations Straight Lines 2023Document6 pagesDSE MC G11 G12 Equations Straight Lines 2023ernestchan501No ratings yet

- Fire AlarmDocument18 pagesFire AlarmgauriNo ratings yet

- A MCQ: Si - No Sub Topics NameDocument2 pagesA MCQ: Si - No Sub Topics NameInzamamul Haque ShihabNo ratings yet

- Aljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossDocument3 pagesAljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossT. LimNo ratings yet

- Accesorios Del Lamborghini VenenoDocument31 pagesAccesorios Del Lamborghini VenenoVicente Gil PalopNo ratings yet

- STAN Statistika 12 PDFDocument25 pagesSTAN Statistika 12 PDFPembelajaran Jarak JauhNo ratings yet

- 9trffi&hpr.! Ni-: Use E EDocument2 pages9trffi&hpr.! Ni-: Use E ERafi ZulfiNo ratings yet

- Ref Manual - Additives For MA Spinel PDFDocument5 pagesRef Manual - Additives For MA Spinel PDFRITWIK SARKARNo ratings yet

- Who Has Allergies & Why: Allergies, Also Known As Allergic Diseases, Are A Number of Conditions Caused byDocument6 pagesWho Has Allergies & Why: Allergies, Also Known As Allergic Diseases, Are A Number of Conditions Caused byJun Dl CrzNo ratings yet

- Factorisation PDFDocument3 pagesFactorisation PDFRaj Kumar0% (1)

- Taiwan API Manufacturer ListDocument4 pagesTaiwan API Manufacturer Listkalyani dynamicsNo ratings yet

- EPTT5100 - Pressure - Temperature Sensor - 1308 - GDocument2 pagesEPTT5100 - Pressure - Temperature Sensor - 1308 - GHendry Putra RahadiNo ratings yet

- Type of TrucksDocument8 pagesType of TrucksYojhan VelezNo ratings yet

- Introduction To ProbabilityDocument50 pagesIntroduction To ProbabilityJohn StephensNo ratings yet

- ELK-3 550 1HC0000742AFEnDocument20 pagesELK-3 550 1HC0000742AFEnOnur FişekNo ratings yet

- DEVISER S7200 - ManualDocument326 pagesDEVISER S7200 - ManualNicolas Maldonado BenitezNo ratings yet

- Bearing Solutions and Service For Wind TurbinesDocument16 pagesBearing Solutions and Service For Wind TurbinesDrZEIDINo ratings yet

- Rig 166 Data SheetDocument2 pagesRig 166 Data SheetEstuardo OlanNo ratings yet

- Approved Reading List Editions 2019ff As of 01 19 2023 2Document9 pagesApproved Reading List Editions 2019ff As of 01 19 2023 2nikolNo ratings yet

- Tugas Topic 4 Devi PermatasariDocument8 pagesTugas Topic 4 Devi PermatasariMartinaNo ratings yet

- Testo-Flue Gas in Industry 3-27-2008Document149 pagesTesto-Flue Gas in Industry 3-27-2008leruaitesNo ratings yet

- Required Obstacle ClearanceDocument14 pagesRequired Obstacle ClearancePero PericNo ratings yet

- BTS "Whalien 52" Lyrics Romanization, English and Indonesian TranslationDocument11 pagesBTS "Whalien 52" Lyrics Romanization, English and Indonesian TranslationEmaFediFeniNo ratings yet

- HLN Applications enDocument27 pagesHLN Applications enClint TcNo ratings yet

- Renal New Growth - NCM 103 - or CaseDocument19 pagesRenal New Growth - NCM 103 - or CasePat EnriquezNo ratings yet