Professional Documents

Culture Documents

Selecting TEMA Heat Exchangers - 07.10 PDF

Uploaded by

konazoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selecting TEMA Heat Exchangers - 07.10 PDF

Uploaded by

konazoiCopyright:

Available Formats

Selecting TEMA Type Heat Exchangers

Tubular Exchange Manufacturers Association

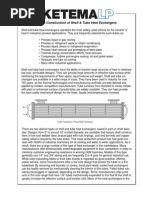

TEMA is a set of standards developed by leading heat exchanger manufacturers that define the heat exchanger style and the machining and assembly tolerances to be employed in the manufacturing of a given unit. TEMA stands for Tubular Exchanger Manufacturers Association. An advantage of TEMA standards is that end customers recognize that the specifications set forth comprise industry standards that directly relate to recognized quality practices for manufacturing. Vendors who build to TEMA standards can be competitively compared because tolerances and construction methods should be very similar for a given design. The general descriptions of the three major TEMA classes are: TEMA C - General Service TEMA B - Chemical Service TEMA R - Refinery Service TEMA R is the most restrictive and TEMA C is the least stringent. TEMA B and TEMA R are very similar in scope. TEMA R includes the requirement for confined joints where recesses must be machined in the flanges and tubesheets. A spiral wound gasket with a ring construction also meets this TEMA R requirement. TEMA R also requires a greater minimum thickness for some components. This section has the purpose of defining the major TEMA constructions and identifies the advantages, limitations and applications suitable for each type. TEMA designations refer to the front head design, the shell design and the rear head design. For example, a TEMA type BEM has a type B front head, a type E shell and a type M rear head design. There are conditions such as with high vapor flows, high pressure and temperature crossing where a combination of special TEMA features is advantageous. For example, K type shells allow for proper vapor disengagement for reboilers and J and H type shells accommodate high vapor flow. Straight Tube, Fixed Tubesheet, Type BEM, AEM, NEN, Etc. - This TEMA type is the simplest design and is constructed without packed or gasketed joints on the shell side. The tubesheet is welded to the shell and the heads are bolted to the tubesheet. On the NEN heat exchanger, the shell and the head is welded to the tubesheet. Typically, a cover plate design is provided to facilitate tube cleaning. This TEMA category, especially the NEN, it is the lowest cost TEMA design per square foot of heat transfer surface. Advantages Less costly than removable bundle designs Provides maximum amount of surface for a given shell and tube diameter Provides for single and multiple tube passes to assure proper velocity May be interchangeable with other manufacturers of the same TEMA type Limitations Shell side can be cleaned only by chemical methods No provision to allow for differential thermal expansion, must use an expansion joint Applications Oil Coolers, Liquid to Liquid, Vapor condensers, reboilers, gas coolers Generally, more viscous and warmer fluids flow through the shell Corrosive or high fouling fluids should flow inside the tubes Removable Bundle, Externally Sealed Floating Tubesheet, Type OP, AEW, BEW This design allows for the removal, inspection and cleaning of the shell circuit and shell interior. Special floating tubesheet prevents intermixing of fluids. In most cases, straight tube design is more economical than U-tube designs. Advantages Floating tubesheet allows for differential thermal expansion between the Shell and the tube bundle. Shell circuit can be inspected and steam or mechanically cleaned The tube bundle can be repaired or replaced without disturbing shell pipe Less costly than TEMA type BEP or BES which has internal floating head Maximum surface for a given shell diameter for removable bundle design Tubes can be cleaned in AEW models without removing piping. Limitations Fluids in both the shell and tube circuits must be nonvolatile, non-toxic Tube side passes limited to single or two pass design All tubes are attached to two tubesheets. Tubes cannot expand independently so that large thermal shock applications should be avoided Packing materials produce limits on design pressure and temperature Applications Intercoolers and aftercoolers, air inside the tubes Coolers with water inside the tubes Jacket water coolers or other high differential temperature duty Place hot side fluid through the shell with entry nearest the front end

Removable Bundle, Outside Packed Head, Type BEP, AEP, Etc - This design allows for the easy removal, inspection and cleaning of the shell circuit and shell interior without removing the floating head cover. Special floating tubesheet prevents intermixing of fluids. In most cases, straight tube removable design is more costly than U-tube designs. Advantages Floating tubesheet allows for differential thermal expansion between the shell and the tube bundle. Shell circuit can be inspected and steam cleaned. If the tube bundle has a square tube pitch, tubes can be mechanically cleaned by passing a brush between rows of tubes. The tube bundle can be repaired or replaced without disturbing shell piping On AEP design, tubes can be serviced without disturbing tubeside piping Less costly than TEMA type BES or BET designs Only shell fluids are exposed to packing. Toxic or volatile fluids can be cooled in the tubeside circuit Provides large bundle entrance area, reducing the need for entrance domes for proper fluid distribution Limitations Shell fluids limited to non volatile, non toxic materials Packing limits shell side design temperature and pressure All tubes are attached to two tubesheets. Tubes cannot expand independently so that large thermal shock applications should be avoided Less surface per given shell and tube diameter than AEW or BEW Applications Flammable or toxic liquids in the tube circuit Good for high fouling liquids in the tube circuit Removable Bundle, Internal Split Ring Floating Head, Type AES, BES, Etc. - Ideal for applications requiring frequent tube bundle removal for inspection and cleaning. Uses straight-tube design suitable for large differential temperatures between the shell and tube fluids. More forgiving to thermal shock than AEW or BEW designs. Suitable for cooling volatile or toxic fluids. Advantages Floating head design allows for differential thermal expansion between the shell and the tube bundle. Shell circuit can be inspected and steam cleaned. If it has a square tube layout, tubes can be mechanically cleaned Higher surface per given shell and tube diameter than pull-through designs such as AET, BET, etc. Provides multi-pass tube circuit arrangement.

Limitations Shell cover, split ring and floating head cover must be removed to remove the tube bundle, results in higher maintenance cost than pull-through More costly per square foot of surface than fixed tube sheet or U-tube designs Applications Chemical processing applications for toxic fluids Special intercoolers and aftercoolers General industrial applications Removable Bundle, Pull-Through Floating Head, Type AET, BET, etc. - Ideal for applications requiring frequent tube bundle removal for inspection and cleaning as the floating head is bolted directly to the floating tubesheet. This prevents having to remove the floating head in order to pull the tube bundle. Advantages Floating head design allows for differential thermal expansion between the shell and the tube bundle. Shell circuit can be inspected and steam or mechanically cleaned Provides large bundle entrance area for proper fluid distribution Provides multi-pass tube circuit arrangement. Suitable for toxic or volatile fluid cooling Limitations For a given set of conditions, this TEMA style is the most expensive design Less surface per given shell and tube diameter than other removable designs Applications Chemical processing applications for toxic fluids Hydrocarbon fluid condensers General industrial applications requiring frequent cleaning Removable Bundle, U-Tube, Type BEU, AEU, Etc. Especially suitable for severe performance requirements with maximum thermal expansion capability. Because each tube can expand and contract independently, this design is suitable for larger thermal shock applications. While the AEM and AEW are the least expensive, U-tube bundles are an economical TEMA design.

Advantages U-tube design allows for differential thermal expansion between the shell and the tube bundle as well as for individual tubes. Shell circuit can be inspected and steam or mechanically cleaned Less costly than floating head or packed floating head designs Provides multi-pass tube circuit arrangement. Capable of withstanding thermal shock applications. Bundle can be removed from one end for cleaning or replacement Limitations Because of u-bend, tubes can be cleaned only by chemical means Because of U-tube nesting, individual tubes are difficult to replace No single tube pass or true countercurrent flow is possible Tube wall thickness at the U-bend is thinner than at straight portion of tubes Draining of tube circuit is difficult when mounted with the vertical position With the head side up. Applications Oil, chemical and water heating applications Excellent in steam to liquid applications

You might also like

- Selection of Shell & Tube Heat Exchangers - TEMA TypesDocument6 pagesSelection of Shell & Tube Heat Exchangers - TEMA TypesCelestine OzokechiNo ratings yet

- Excerpt From: Heat ExchangersDocument12 pagesExcerpt From: Heat ExchangersHabib Ben FredjNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- TEMA Type Heat Exchangers PDFDocument4 pagesTEMA Type Heat Exchangers PDFkinjalpatel123450% (1)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Tema HexDocument7 pagesTema HexPrashanthMNairNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- 4 - TEMA StandardDocument16 pages4 - TEMA StandardM.H vafaeiNo ratings yet

- Selecting The Proper TEMA TypeDocument3 pagesSelecting The Proper TEMA TypeMubarik AliNo ratings yet

- Shell and Tube Heat ExchangersDocument36 pagesShell and Tube Heat ExchangersMumahmmad Rizwan RNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Heat Exchanger As Per TEMA Design PPT by Rakesh Mishra 31.03.2020Document34 pagesHeat Exchanger As Per TEMA Design PPT by Rakesh Mishra 31.03.2020Rakesh Mishra100% (1)

- Shell-and-Tube Heat Exchanger: Pick The Right Side: Allocating Fluids in A Tubular Exchanger Demands CareDocument4 pagesShell-and-Tube Heat Exchanger: Pick The Right Side: Allocating Fluids in A Tubular Exchanger Demands CareOvaisNo ratings yet

- Shell and Tube Heat Exchanger Design ConsiderationsDocument55 pagesShell and Tube Heat Exchanger Design ConsiderationsCc12 22tNo ratings yet

- Advantage and Dis-AnvantagertfDocument3 pagesAdvantage and Dis-Anvantagertfhukbalahap_q1No ratings yet

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Document38 pagesBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- Heat Transfer by Heat ExchangersDocument7 pagesHeat Transfer by Heat ExchangerssugiantobarusNo ratings yet

- Shell and Tube Heat Exchanger Design GuideDocument7 pagesShell and Tube Heat Exchanger Design GuideGaurav SharmaNo ratings yet

- Tema Designations of Heat ExchangersDocument6 pagesTema Designations of Heat ExchangersNikunj KNo ratings yet

- Hairpin heat exchanger design delivers high performance in a compact footprintDocument1 pageHairpin heat exchanger design delivers high performance in a compact footprint7761430No ratings yet

- TEMA Designations: Understanding Heat Exchanger NomenclatureDocument12 pagesTEMA Designations: Understanding Heat Exchanger NomenclatureSyeda Khaliqa HamidNo ratings yet

- Type of Heat ExchangersDocument46 pagesType of Heat ExchangersguravdrNo ratings yet

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- Heat Exchanger - StudyDocument22 pagesHeat Exchanger - StudyDedy WindiyantoNo ratings yet

- Lect 3Document43 pagesLect 3Mahesh KumarNo ratings yet

- Unit-5 - ST HEsDocument25 pagesUnit-5 - ST HEsDr. M. Mohan Jagadeesh kumarNo ratings yet

- Shell and Tube Heat ExhangerDocument31 pagesShell and Tube Heat ExhangerKailash UpretiNo ratings yet

- Classificazione TEMADocument9 pagesClassificazione TEMASami TalmoudiNo ratings yet

- Shell-And-Tube Heat ExchangersDocument29 pagesShell-And-Tube Heat Exchangersparagmishra1986No ratings yet

- Sthe SSDocument43 pagesSthe SSNathanianNo ratings yet

- Perpindahan Panas: Endah SulistiawatiDocument19 pagesPerpindahan Panas: Endah SulistiawatiEmi LestariNo ratings yet

- Heat Exchanger ClasificationDocument55 pagesHeat Exchanger ClasificationNikhil Sawant100% (1)

- Shell and Tube Heat ExchangersDocument69 pagesShell and Tube Heat ExchangersVenkitaraj K PNo ratings yet

- PHT Unit-5 (THEORY)Document81 pagesPHT Unit-5 (THEORY)521 Balaji ONo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger Designcoldness_13No ratings yet

- IIT Delhi Heat ExchangerDocument19 pagesIIT Delhi Heat ExchangersunilNo ratings yet

- Heat Operation ExchangersDocument67 pagesHeat Operation ExchangersAkankshya MishraNo ratings yet

- Heat ExchangersDocument44 pagesHeat Exchangersanthony tiensunNo ratings yet

- Shell and tube heat exchangers constructionDocument8 pagesShell and tube heat exchangers constructionZeeshan SajidNo ratings yet

- Presentation On Shell & Tube ExchangerDocument32 pagesPresentation On Shell & Tube Exchangersaurabhmeshram88No ratings yet

- TEMA Type BEU or AEU Heat Exchanger GuideDocument15 pagesTEMA Type BEU or AEU Heat Exchanger GuidemaruthigabbitaNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument27 pagesShell and Tube Heat Exchanger DesignAnkit ChandelkarNo ratings yet

- SeminarDocument9 pagesSeminardfgfdfggdfNo ratings yet

- TEMA designation heat exchanger typesDocument12 pagesTEMA designation heat exchanger typesmohammadazrai0% (1)

- Basic Construction of Shell & Tube Heat ExchangersDocument12 pagesBasic Construction of Shell & Tube Heat ExchangerslatshareNo ratings yet

- Heat Exchanger: Department of Chemical Engineering, University of Engineering & Technology LahoreDocument31 pagesHeat Exchanger: Department of Chemical Engineering, University of Engineering & Technology LahoreDINESHRAMANUJAMNo ratings yet

- Fluid Allocation in Shell and Tube Heat ExchangersDocument7 pagesFluid Allocation in Shell and Tube Heat Exchangerssyed omerNo ratings yet

- A Crisis of More Area Than The Required Heat Exchanging Surface AreaDocument28 pagesA Crisis of More Area Than The Required Heat Exchanging Surface Areaavula43100% (1)

- Ped CB208 P8 1Document57 pagesPed CB208 P8 1Siddhant SoymonNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat ExchangerShivanand YadavNo ratings yet

- Geothermal Power Stations PDFDocument12 pagesGeothermal Power Stations PDFDavitxu1No ratings yet

- Pitting and CreviceDocument36 pagesPitting and CreviceDavitxu1No ratings yet

- Manual For Investigation and Correction FWH FailuresDocument0 pagesManual For Investigation and Correction FWH FailuresDavitxu1No ratings yet

- Steam Source Book 2Document108 pagesSteam Source Book 2joe_pulaskiNo ratings yet

- Steam Source Book 2Document108 pagesSteam Source Book 2joe_pulaskiNo ratings yet

- Pitting and CreviceDocument36 pagesPitting and CreviceDavitxu1No ratings yet

- Manual For Investigation and Correction FWH FailuresDocument0 pagesManual For Investigation and Correction FWH FailuresDavitxu1No ratings yet

- Corrosion IntroductionDocument95 pagesCorrosion IntroductionDavitxu1No ratings yet

- Boiler CirculationDocument76 pagesBoiler CirculationDavitxu1No ratings yet

- Steam Source Book 2Document108 pagesSteam Source Book 2joe_pulaskiNo ratings yet

- Failure of Boiler TubesDocument16 pagesFailure of Boiler TubesvtbkNo ratings yet

- Nrel Production Cost ModelDocument49 pagesNrel Production Cost ModelDavitxu1No ratings yet

- Cspa Report Dec 2012 Ver1.0Document132 pagesCspa Report Dec 2012 Ver1.0Davitxu1No ratings yet

- Maklumat Vaksinasi: Vaccination DetailsDocument1 pageMaklumat Vaksinasi: Vaccination Detailsaccung manNo ratings yet

- Carbon SteelDocument1 pageCarbon SteeldexterNo ratings yet

- 2 Acceleration Questions and AnswersDocument2 pages2 Acceleration Questions and Answersapi-272986951100% (2)

- Zeal Institute of Manangement and Computer ApplicationDocument4 pagesZeal Institute of Manangement and Computer ApplicationSONAL UTTARKARNo ratings yet

- IC-V80 V80E ManualDocument64 pagesIC-V80 V80E Manualrzkyln100% (1)

- Influence of Social Studies Education On Ethnic and Religious Tolerance Among National Certificate of Education Students in Kaduna State.Document104 pagesInfluence of Social Studies Education On Ethnic and Religious Tolerance Among National Certificate of Education Students in Kaduna State.Tsauri Sule SalehNo ratings yet

- Chapter 1 Optical Fiber Transmission Media PDFDocument46 pagesChapter 1 Optical Fiber Transmission Media PDFGilang AnandaNo ratings yet

- As Biology Revision L3 Cells Microscopes and IAM PPQ 2Document7 pagesAs Biology Revision L3 Cells Microscopes and IAM PPQ 2Anonymous fFKqcYNo ratings yet

- Trends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeDocument53 pagesTrends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeNarasimhaReddy PangaNo ratings yet

- Graffiti Model Lesson PlanDocument9 pagesGraffiti Model Lesson Planapi-286619177100% (1)

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksNo ratings yet

- Planning Dirty FrameworkDocument62 pagesPlanning Dirty FrameworkHoàng Hoa Dương100% (1)

- The Scientific MethodDocument4 pagesThe Scientific MethodRob LovNo ratings yet

- SECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSDocument2 pagesSECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSMuhammad Tahir QamarNo ratings yet

- Delhi University SEC Exam Date Sheet March 2023Document2 pagesDelhi University SEC Exam Date Sheet March 2023aamir9ali-42No ratings yet

- Arduino - Decision Making StatementsDocument20 pagesArduino - Decision Making StatementsJohn Clifford Ambaic JayomaNo ratings yet

- 8.9 Basic Maths For Well PlanningDocument9 pages8.9 Basic Maths For Well PlanningKhanh Pham MinhNo ratings yet

- Risk Assissment 1Document12 pagesRisk Assissment 1Ibrahim BouzinaNo ratings yet

- Basf Masteremaco Application GuideDocument15 pagesBasf Masteremaco Application GuideSolomon AhimbisibweNo ratings yet

- DVOR Principle 코이카 양식Document71 pagesDVOR Principle 코이카 양식Undral Batbayar100% (1)

- AI Berkeley Solution PDFDocument9 pagesAI Berkeley Solution PDFPrathamGuptaNo ratings yet

- God in The Quran A Metaphysical StudyDocument133 pagesGod in The Quran A Metaphysical StudyFaisal Ali Haider LahotiNo ratings yet

- Hardware Devices Used in Virtual Reality TechnologiesDocument6 pagesHardware Devices Used in Virtual Reality TechnologiesTheMoon LightNo ratings yet

- Bicycle Repair ManualDocument162 pagesBicycle Repair Manualrazvancc89% (9)

- Anie Altamirano Learning For Life HandoutDocument4 pagesAnie Altamirano Learning For Life HandoutAnnapurna VNo ratings yet

- Adiabatic Production of Acetic AnhydrideDocument7 pagesAdiabatic Production of Acetic AnhydrideSunilParjapatiNo ratings yet

- The Champion Legal Ads: 11-02-23Document58 pagesThe Champion Legal Ads: 11-02-23Donna S. SeayNo ratings yet

- 2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoDocument15 pages2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoIdongesit EtukudoNo ratings yet

- Lesson Plan 2 Sine Rule and Cosine RuleDocument8 pagesLesson Plan 2 Sine Rule and Cosine Ruleapi-280114661No ratings yet

- Methanol Technical Data Sheet FactsDocument1 pageMethanol Technical Data Sheet FactsmkgmotleyNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)