Professional Documents

Culture Documents

Hydrocarbon Crack System

Uploaded by

Lucian Si Silvia PoneaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrocarbon Crack System

Uploaded by

Lucian Si Silvia PoneaCopyright:

Available Formats

Hydrocarbon Crack System (HCS)

This is a simple, home-made system that can be added to any engine in an afternoon by anyone with minimal engine maintenance skills. It uses cheap parts that are readily available and easily bought at local stores. It will increase the efficiency of your engine resulting in more power and torque, reduced engine noise and vibration and reduced exhaust emissions. You should also experience at least 20% mileage increase. Basically; it produces Hydrogen on Demand from regular petrol (gasoline) by cracking Hydrogen from Hydrocarbon vapor using heat alone. Here is a schematic of the system:

As you can see; vapor from an auxiliary bubbler tank (half filled with petrol) flows through a rubber pipe into a heat tube where it is heated to about 300 degrees Celsius by the hottest part of the exhaust pipe. This cracks the hydrocarbon molecules into Hydrogen and Carbon which flows on to the air inlet of the engine. It mixes with the regular fuel/air and greatly increases the burn-efficiency of the engine.

All four stroke engines leak air/fuel mixture past the piston rings into the crankcase. This is known as blow-by and needs to be ventilated (usually to the air filter where it finds its way back into the burn chamber). PCV flows out of the crankcase with sufficient pressure to operate the Hydrocarbon Crack System and is ideal for our purposes for the following reasons: a. It varies in pressure depending on engine speed. This means that the faster the engine speed, the more Hydrogen is delivered to the burn chamber. b. Its destination is the burn chamber anyway so all we are doing is borrowing its variable pressure to operate the HCS. c. It is warm and so helps evaporate the petrol as it flows through the auxiliary bubbler tank. PCV pressure is generally more than is needed by the HCS and so we ventilate it via a screw valve before it reaches the bubbler tank. If the ventilation screw is closed completely; too much PCV pressure will reach the bubbler tank. If the ventilation screw is opened wide; little or no PCV pressure will reach the bubbler tank. An ideal adjustment gives minimal bubbling at engine idle. Aquarium stores sell plastic screw valves at very reasonable prices. A radiator overflow tank makes an ideal bubbler and can be purchased at minimal cost from any auto-parts store. They also sell the rubber fuel pipe that is used to connect the various parts of the system. The 3mm bore copper piping (usually used for brake lines) can also be purchased there. Locate the fuel bubbler anywhere handy for refilling and connecting to the rest of the system. Wind the copper tubing at least three times around the hottest part of the exhaust pipe (closest to the engine block). Allow about 6 inches (15 cm) leading into and out of the coil so that the rubber connection pipe is not too close to the exhaust pipe. The rubber pipe carrying the Hydrogen can be fed directly into the air filter. This system gives similar results to the better known HHO system (or Hydrogen Booster) but it has significant advantages. HHO requires electrical current in order to crack Hydrogen and Oxygen from water and this places a constant drain on the engine. HCS places no such burden on the engine and takes nothing from the engine that wasnt to be discarded anyway. In addition to this; the Browns Gas produced by the HHO system is highly explosive whereas the Hydrogen produced by the HCS contains virtually no oxygen at all and is therefore much safer.

You might also like

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Actyon A0 A06005Document10 pagesActyon A0 A06005Arimbi GembiekNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Detailed Guide: BMW M5 & M6 Launch ControlDocument10 pagesDetailed Guide: BMW M5 & M6 Launch ControldarkalfonNo ratings yet

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideFrom EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideNo ratings yet

- Codigo DTC para Jeep JKDocument11 pagesCodigo DTC para Jeep JKEmiliano Esquinca Ávila100% (1)

- P1449 Fallos de La Batería Del Civic Híbrido.Document4 pagesP1449 Fallos de La Batería Del Civic Híbrido.Norman Valle SáenzNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- 2007 Dodge Caliber ManualDocument360 pages2007 Dodge Caliber ManualJinyuan FangNo ratings yet

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesFrom EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo ratings yet

- Multipoint Fuel Injection SystemDocument6 pagesMultipoint Fuel Injection Systemalan kurniawanNo ratings yet

- NacelleDocument7 pagesNacellecarlitos232067% (3)

- Fully Autonomous Vehicles: Visions of the future or still reality?From EverandFully Autonomous Vehicles: Visions of the future or still reality?No ratings yet

- System of Gathering of Steams of Fuel BOSCH MEV 17.4Document2 pagesSystem of Gathering of Steams of Fuel BOSCH MEV 17.4Rui MendesNo ratings yet

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Characteristic Map ThermostatDocument3 pagesCharacteristic Map ThermostatJhonTorresRamiresNo ratings yet

- ECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) InformationDocument4 pagesECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) Informationapek1No ratings yet

- WorkDocument17 pagesWorkRam Krishan SharmaNo ratings yet

- Instrument Panel Analog - Nissan Sentra 1993Document8 pagesInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaNo ratings yet

- Apredizaje Aceleración Nissan X-TrailDocument5 pagesApredizaje Aceleración Nissan X-TrailHERNAN DARIO ZAPATA BUSTAMANTENo ratings yet

- 0060035Document7 pages0060035Ydelkadiasmela Dominguezmorel100% (1)

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- Electricalcomponentlocations 131222071900 Phpapp02Document91 pagesElectricalcomponentlocations 131222071900 Phpapp02petcucatalinnNo ratings yet

- Daihatsu Terios 2000-2006 Manual TransmissionDocument7 pagesDaihatsu Terios 2000-2006 Manual TransmissionRock KetphilNo ratings yet

- P2146Document30 pagesP2146Engine Tuning UPNo ratings yet

- sb0341t09 PDFDocument7 pagessb0341t09 PDFZool Car زول كارNo ratings yet

- 2M (256K 8/128K 16) BIT: Flash MemoryDocument49 pages2M (256K 8/128K 16) BIT: Flash MemoryEdson CostaNo ratings yet

- CMP (Phase) MuranoDocument8 pagesCMP (Phase) MuranoGuillermo RojasNo ratings yet

- Sienna SparkPlug RemovalDocument17 pagesSienna SparkPlug Removalazeemm1No ratings yet

- Diagramas Eléctricos VOLVO S40 T5 L5-2.5L TURBO VIN 68 B5254T3 2007Document66 pagesDiagramas Eléctricos VOLVO S40 T5 L5-2.5L TURBO VIN 68 B5254T3 2007Christian Muñoz DuranNo ratings yet

- P 0089Document3 pagesP 0089raisviranNo ratings yet

- HONDA 2007 Civic Sedan Owner's Manual (Unlinked)Document314 pagesHONDA 2007 Civic Sedan Owner's Manual (Unlinked)UndertakerNo ratings yet

- Edc15Vm: Re: Difference - +, EDC15V, EDC15PDocument4 pagesEdc15Vm: Re: Difference - +, EDC15V, EDC15PNicuCatalinNo ratings yet

- AEM Undocumented Settings v1Document13 pagesAEM Undocumented Settings v1Franklyn RamirezNo ratings yet

- DTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Document7 pagesDTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Jehuty88No ratings yet

- PGM Fi PDFDocument36 pagesPGM Fi PDFteja Mudhiraj raj100% (1)

- Manual de Taller Escape y Escape HibridDocument46 pagesManual de Taller Escape y Escape HibridCarlos Sandoval100% (1)

- Power Window Four Windows: Modul ControlsDocument2 pagesPower Window Four Windows: Modul ControlsHery IswantoNo ratings yet

- Daewoo Lanos y NubiraDocument15 pagesDaewoo Lanos y NubiraJøta PerozoNo ratings yet

- Manual Vivant TacumaDocument76 pagesManual Vivant TacumaLuis Alberto Martinez Tinoco100% (1)

- Super Airflow Converter: Super Air Flow Converter Wiring Diagram by ModelDocument64 pagesSuper Airflow Converter: Super Air Flow Converter Wiring Diagram by ModelOdien SalehNo ratings yet

- Wiring Diagrams PDFDocument35 pagesWiring Diagrams PDFTessa HernandezNo ratings yet

- Ae-Hev Hyundai IoniqDocument107 pagesAe-Hev Hyundai IoniqafboullosaNo ratings yet

- Manual Luv Motor C22neDocument0 pagesManual Luv Motor C22neEfrain ContrerasNo ratings yet

- Installation Instructions 30-5130Document8 pagesInstallation Instructions 30-5130alexcus1539No ratings yet

- MTX-L Digital Air/Fuel Ratio Gauge User ManualDocument16 pagesMTX-L Digital Air/Fuel Ratio Gauge User ManualSebastian Esteban Cordova ToroNo ratings yet

- Clarion DXZ545MP, DXZ546MP (PE-2623) E6131-00Document0 pagesClarion DXZ545MP, DXZ546MP (PE-2623) E6131-00El Mostafa KahlouchNo ratings yet

- 1.1 What Is Obd-I GM Daewoo Scanner?: Dtdauto Technology Team, Hanoi, VietnamDocument15 pages1.1 What Is Obd-I GM Daewoo Scanner?: Dtdauto Technology Team, Hanoi, Vietnamahmad adelNo ratings yet

- Instrument Panel Yaris 2008Document89 pagesInstrument Panel Yaris 2008Pat NeenanNo ratings yet

- DTC P0008 or P0009: Diagnostic InstructionsDocument2 pagesDTC P0008 or P0009: Diagnostic InstructionsJose Luis Velasquez RomeroNo ratings yet

- GEMS SystemsDocument30 pagesGEMS Systemssflynn79100% (1)

- 1985 Honda Accord SE-i - Diagramas ElectricosDocument15 pages1985 Honda Accord SE-i - Diagramas ElectricosRodrigo López100% (1)

- Hyundai H100 PDFDocument10 pagesHyundai H100 PDFSantiago Facunda0% (1)

- Benz - Vehicle NetworkingDocument27 pagesBenz - Vehicle NetworkingAnanthNo ratings yet

- MTX-L PlusDocument14 pagesMTX-L Plusjuanlasserre9444No ratings yet

- 1996 Dodge Grand Caravan Localizacion de ComponentesDocument28 pages1996 Dodge Grand Caravan Localizacion de ComponentesLuis Angel BarajasNo ratings yet

- Toyota Corolla 1.8l 2zr (Body Control Module)Document2 pagesToyota Corolla 1.8l 2zr (Body Control Module)Franz DelgadilloNo ratings yet

- System Wiring Diagrams: Air ConditioningDocument67 pagesSystem Wiring Diagrams: Air ConditioningJose Luis Orozco RobledoNo ratings yet

- F3 Chapter 1 (SOALAN) - RespirationDocument2 pagesF3 Chapter 1 (SOALAN) - Respirationleong cheng liyNo ratings yet

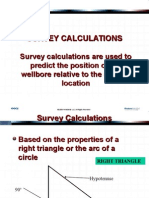

- 02 Survey Calculations - PpsDocument96 pages02 Survey Calculations - PpsLeo Ivan Aviles RicaldiNo ratings yet

- BSIT Nov Dec 2012 2nd CycleDocument59 pagesBSIT Nov Dec 2012 2nd CyclePiyush PriyankNo ratings yet

- Attention Gated Encoder-Decoder For Ultrasonic Signal DenoisingDocument9 pagesAttention Gated Encoder-Decoder For Ultrasonic Signal DenoisingIAES IJAINo ratings yet

- User's Manual HEIDENHAIN Conversational Format ITNC 530Document747 pagesUser's Manual HEIDENHAIN Conversational Format ITNC 530Mohamed Essam Mohamed100% (2)

- Mechanism of Muscle ContractionDocument24 pagesMechanism of Muscle Contractionfisika100% (1)

- Aluminum: DR 900 Analytical ProcedureDocument4 pagesAluminum: DR 900 Analytical Procedurewulalan wulanNo ratings yet

- Sentinel Visualizer 6 User GuideDocument227 pagesSentinel Visualizer 6 User GuideTaniaNo ratings yet

- SC Perthub Single Cell OmicsDocument34 pagesSC Perthub Single Cell OmicsGANYA U 2022 Batch,PES UniversityNo ratings yet

- Fiber SyllabusDocument1 pageFiber SyllabusPaurav NayakNo ratings yet

- HydrocarbonsDocument5 pagesHydrocarbonsClaire Danes Tabamo DagalaNo ratings yet

- PHYSICSDocument24 pagesPHYSICS21SO204 AnvithaNo ratings yet

- Review Problems Chapter 4 Solutions PDFDocument4 pagesReview Problems Chapter 4 Solutions PDFAntoninoNo ratings yet

- DA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFDocument329 pagesDA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFrindy_bilhaniNo ratings yet

- More Practice Multiple ChoiceDocument3 pagesMore Practice Multiple ChoiceHiNo ratings yet

- Fitting Fundamentals: For SewersDocument21 pagesFitting Fundamentals: For SewersLM_S_S60% (5)

- Faculty: Geology Exploration Specialty: Geology Engineering Group: 123.6 Student: Asef Sadiqov Teacher: Afet Israfilova Theme: The EarthDocument16 pagesFaculty: Geology Exploration Specialty: Geology Engineering Group: 123.6 Student: Asef Sadiqov Teacher: Afet Israfilova Theme: The EarthKenan RehmanNo ratings yet

- Redox TitrationDocument5 pagesRedox TitrationchristinaNo ratings yet

- 7625-300 Vitamin B12 AccuBind ELISA Rev 6Document2 pages7625-300 Vitamin B12 AccuBind ELISA Rev 6carlosalfredorivasNo ratings yet

- T0000598REFTRGiDX 33RevG01052017 PDFDocument286 pagesT0000598REFTRGiDX 33RevG01052017 PDFThanhNo ratings yet

- Harmony XB4 - XB4BD53Document5 pagesHarmony XB4 - XB4BD53vNo ratings yet

- EP 1110-1-8 Vo2 PDFDocument501 pagesEP 1110-1-8 Vo2 PDFyodiumhchltNo ratings yet

- A Comparative Study On The Academic Performance ofDocument18 pagesA Comparative Study On The Academic Performance ofDiether Allen L. YnionNo ratings yet

- Silicon Controlled RectifierDocument38 pagesSilicon Controlled RectifierPaoNo ratings yet

- PRD Doc Pro 3201-00001 Sen Ain V31Document10 pagesPRD Doc Pro 3201-00001 Sen Ain V31rudybestyjNo ratings yet

- KVS - Regional Office, JAIPUR - Session 2021-22Document24 pagesKVS - Regional Office, JAIPUR - Session 2021-22ABDUL RAHMAN 11BNo ratings yet

- Fractal Cities - A Geometry of Form and Function PDFDocument432 pagesFractal Cities - A Geometry of Form and Function PDFDavid Diaz100% (1)

- Pipe Clamp For Sway Bracing TOLCODocument1 pagePipe Clamp For Sway Bracing TOLCOEdwin G Garcia ChNo ratings yet

- Ss e (Bocr) ManualDocument2 pagesSs e (Bocr) ManualNaveen GuptaNo ratings yet

- 9Y011-02704 KubotaDocument143 pages9Y011-02704 KubotaZaqi SatchNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)