Professional Documents

Culture Documents

SUBLOADING SURFACE MODEL IN UNCONVENTIONAL PLASTICITY

Uploaded by

Tonny HoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SUBLOADING SURFACE MODEL IN UNCONVENTIONAL PLASTICITY

Uploaded by

Tonny HoCopyright:

Available Formats

SUBLOADING SURFACE MODEL IN UNCONVENTIONAL PLASTICITY

Department of Ag~c~tural

(Receicd

K. HASHIGUCHI Engineering. Kyushu University. Fukuoka. Japan

19881

6 April 1988 ; in recised form 26 Norentber

Abstract-For engineering problems. the elastoplastic constitutive model has been required. which is applicable to the prediction of cyclic loading behavior for various stress/strain amplitudes. The subioading surface model has been proposed and developed in order to respond to this requirement. The original subloading surface model (or the bounding surface model with a radial mapping) does not assume a yield surface enclosing an elastic domain in which stress rates of any direction do not induce a plastic deformation. Instead. it assumes a normal-yield (or bounding) surface and a subloading surface which always passesthrough a current stress point in not o&y loading but also unloading states retaining a geometrical similarity to the normal-yield surface. Thus. it describesa continuous stress rate-strain rate relation in a loading process, bringing about a smooth elasticplastic transition, and its loading criterion does not require the judgement whether a current stress lies on a yield surface or not. It cannot, however. describe reasonably an induced anisotropy and a hysteresisbehavior for a stresschange within the nodal-yield surface, since the center of similarity of normal-yield and subloading surfaces is fixed or the translation rule is not formulated reasonably. In this paper an exact formulation of this model is presented by deriving a translation rule of the center of similarity and a consistency condition for the subloading surface and by examining the physical meaning of the loading critcriun in terms of a strain rate and the associated flow rule concurrently for materials with an anisotropic h~lrden~ng/~~ftenin~and without an elastic domain. It is capable of dcscrihing an anisotropic hndcning/softcning, a smooth elastic-plastic transition and a hysteresis behavior including Masing e&t. a closed hystcrcsis loop and a mechanical ratchetting cllcct consistently. This model is dcscribcd for metals and is compared with test data of the torsional cyclic tnading behavior of stainless steel,

I, INTROI1UCTION

prediction of inciastic cfcformation of materials subjected to cyclic loadings importmw for pritctktl problems in enginmxing. The conventional theory of plasticity is concerned only with a description of the remarkable plastic deformation in the yield state. ignoring a plastic deformation due to a stress change within the yield surface by assuming its interior to be an elastic domain. The elastic domain is defined as a domain in the stress space, in which stress rates of any direction do not induce plastic deformation, i.e. in which only a purely elastic deformation cm occur. Obviously, the conventional theory is incapitbte of predicting cyclic loading behavior for small stress or strain amplitudes. its extension to the description of plastic deformation induced by the stress change within the yield surface is the inevitable step for the development of plasticity. To this aim. variouselastoplnstic constitutive models have been proposed since Mroz (I 966) proposed the model of a field of hardening moduli. In the meantime, the author proposed the subloading surface model and refined it mathematically (Hashiguchi and Ueno, 1977; Hashiguchi. 1978, 1979. 1980a. 1980b, 1985b). In this extension the state in which a stress lies on the conventional yield surface and the state within the surface are called a normalyietd state and a subyield state, respectively, and the conventional yield surface is called a normal-yield surface, while it was culled a distinct-yield surface in the previous paper (Hashiguchi, 19804. Besides, the bounding surface in series of Dafalias papers (e.g. Dafalias and Popov, 1975; and Dafalias, 1986) is also regarded as the conventional yield surface, since the bounding surface evolves by the isotropic and kinematic hardening rule of the conventional yield surface. The surface in ;I stress space, on which a stress rate causes a remarkable plastic deformation. has been called a yield surface as seen typically in the perfectly plastic body as the simplest classical idealization. Here, one would have to be deliberate in replacing the term yield surface used historically in the theory of plasticity

A rc;tsona&

is of

increasing

by the term bounding one.

surface expressing a geometrical

meaning rather than a physical

The salient feature of the subloading surface model is the assumption of the subloading surface which expands or contracts passing always through a current stress point in not

81s 25:%-Q

917

)I,3 onI> >ield

HASHIM (HI a geometrical modulus Surface. Thus, similarit! to the normalof the Size of the domain does not

loading

surface

but also unloading

and surface to that

states and retaining of a plastic

is the description

by tht: ratio an elastic

subloading

of the normal-yield

exist and the plastic modulus changes continuously. Then, ;1 continuous StrcSS rate-strain rate relation is described in a loading process, bringing about ;1 Smooth el;lstic-plastic transition. and the loading criterion does not require the judgement whether ;L stress lies on

the yield surface Ldkr or not since a stress and Herrmann depends lies always (1980) on the ratio on the Subloading a similar of the magnitude surface. idea of rad1;ll of the current mapping stress to on. Dafalias presented surface

in which :I plastic modulus

that of the conjugate explicitly. subloading surface small yield surface surface. domain stress model. called

on the normal-yield structure call 1975. a plastic surface They

but the loading surface The model

Surface iS not utilized of the original assumes surfucc. the two hardening state. h> ;I ~1s Lvell as the two model Lvhich encloses Then.

Lvhile its mathematical model (Dafalias

is substantially 1976. 1977).

the Same aS that two surface 1981,

it a bounding surface

and Popov. a subyield with relatively 1967)

(Hashiguchi. within

1988). surface.

un elastic kccping surfacc (Mr67. model Mr6/

and moves

deformation

the normal-yield

its size constant model 1966. (1967) (Edclman as well I967 st;ifcd exactly

h;lnd.

to the size of the normal-yield is regarded as an extension 195-l: moduli.

illthO~~~I1 CXpilfldS

as the multi 195

model (model of 3 field of hardening moduli)

of the kinematic 1956) and kinematic Pragcr. to the subyicld hardening the conven!ional it in p:irticular. of the arc the subloading they 2nd Ilcrrm~inn, lhcory surl:icc.

riot bc

; Iwun.

wc

and Druckcr. Ii&l

i ; lshlinski,

the

pcncrali7c

rules of isotropic

hc

introducing yield surf;ice

011 the

the concept ofa

of hardening surface surf;Kc

where hc rcgardcd did not rcnamc with model (IXifalias no1 occur. iliodcl surface n~oilcls mApping ti.;lturc state of Then. or contracts dots

;1S the outcrmosl fllc subloading cvcn when ;I plastic structure

other stress model I~af~ill;is,

;I mcl\cment although

current surf;lcc IM): 011~

point callctl

ilcli~rmn~ion from lhc

has a diIYcrcnt IOSO). The hcl;)rc. nic~ilcls

1kvo surface

occ;i5iori;tllv

h) tllc s;1111clcrrii houndi11g Since

bouritliri~ surface

surface pl;islicily

is [hc yiclil

in the cotircnlional arc liccping niodcl this by the motlcl this and it ~toultl

s;iillc

2s ~3s dc5crihcil

c;iiiii~~t

iiiicorivuritioii~il motlcl

3pccify

by the krm

bounding other.

surface

niotlcl.

rcason;ihlc surlxc cxtcnsion surllicc

to call the two surf:icc slructurcs cxprcsS would

antI the radial the phySici11

term. is an

sincc ~hcy h;1\ctlill.crcnt 1u0&l \vithin

from cxh concisely theory surfa32.

On the other

hand, the term subloading which the subloading Lo

01 the conventional the normal-yield surface olirrcvcrsiblc

to the subyicld mapping

by ;1ssuming

Itic suhl~~~iiling the prctliclion 1978. 1979.

model or fhc r;idial tIcformation 19X4; olsoiis

moilcl

has been appliccl widely 1977; Hnshiguchi, 19X2; I%5 il :~ncl Wroth. I9Y-l; 19x6:

and

(tlashiguchi and Mr6z. :rnd

and IJcno,

19,YOa ; L);~falias itnd tlcrrmann. I( JY 2; Daf;1li:1s. 11 t/l., Hcrrmann 19X6;

I9XO. IM2 ; Aboim

DaL\lii~s,

I;I~~c~c

and fictruszcz:ik. ~1 (I/.. 19x5 1986; Zicnkic\vic/ similarity f%ardct.

Zicnkicwic/ 19X6; (f-ardis

Naylor. Liang howcvcr.

: Pastor

and 1:111. 19x7: I%5 of stress ;I ~CGI~C curve

: Zicnkicwicz

;lnd fastor.

I9815; Anantlr;l.jith

~1 (I/..

19X6

; fktnerjec

Buyuko/turk,

fictruszczak,

(!I..

19X7). concrete

PI t/l., 19X.7 ; Chcn surfaces

Yang 01 II/.. 19115) and metals (tfashiguchi.

of the normal-yield Spi1cc or on the ccn(ral ilftcr the :ldvocation with f9~6) ;IS ~v;ls critici/cJ c;lnn(>t t() mc[:~ls lvhich gcom;itcri;lfs, ~~;~tcri:lls. center Thus. ;1n open hysteresis

19YOa). In thcsc papers. is fixed Surfi1cc. and Ucno. (1984). though

the ccntcr 01

and the subloading

in the origin ;I stress

axis of the normal-yield mocfcl (f-fashiguchi and Zienkicwicz 11 would bnsic loop is predicted

it p:~~~cd alrcatly

of this

1977). Then,

strain

for the partial

unloadin, IT--reloading the Masing model has hardly

cycle of stress clYcct (Masing. hccn applied with the compared it SO that

by MrOz undergo its

and also why this

bc dcscribcd. whcrc;ls

bc the reason

an elastic: deformation concept (Hashiguchi. with a plastic to the uniaxinl I9YOb. loading

in ;I wide IOXSb)

range of stress to ;I wide

Seems available deformation. behavior

CI:ISS of clilstopl:lstic (19x1

the author translates

~:IS tried ofmctal.

to cxtcnd

of similarity

and fkfalias of the subloading condition

) has tried it

model is ~1

for the spcci;tl case limitcd brought singularity to completion

In (his p;1pcr. ;1 m~1thcmatic~1lly by deriving in the Geld of plastic

exact formulation i1 translation und

surface for

rule of the ccntcr of similarity. a consistency

avoiding

moduli.

the: subloading

Subloadmp surface model in unconventional plasticity

919

surface and bk- examining without an elastic domain. fundamental

the physical meaning of the loading criterion in terms of a strain hardening/softening and Its capability for prediction of hysteresis behavior including the ratchetting effect. which are the this model is applied with test data of inevitable

rate and the associated flow rule for materials with an anisotropic Masing effect. a closed hysteresis loop and a mechanical by the analyses of benchmark to metals by determining

properties of cyclic loading behavior in the subyield state, is shown concisely problems in uniaxial loading. Further, functions explicitly material and is compared

the torsional cyclic loading behavior of stainless steel. Finally. shortcomings of the other well-known single surface models are discussed, comparing

mathematically

models, i.e. the multi. the infinite, the two and the with the present model.

2. B.-\SIC CONSTITUTIVE

EQUATIONS

FOR THE NORMAL-YIELD

STATE

Constitutive normal-yield

equations for the normal-yield

state in which a current stress lies on the of conventional surface model in the subsequent and explanation

surface are formulated

below. which belong to the framework to the subloading

theory. and these will be extended

sections. While some of these equations were described in the previous paper (Hashiguchi, IYPSa). they are repeated here since they are necessary for the formulation of the subloading surface model. First. assume that the normal-yield surface is described by the following equation :

/(6)-F(H)

= 0

(1)

ciECT--ai. Ihc scconcl-or&r tensor a is ;I stress. and the scalar il and the second-order

(2

tensor ai arc respcc-

internal state variahlcs for tlcscribing the expansion/contraction tivcly. of the surface. Let J-F

and the translation,

< 0 hold in the interior of the yield surface. For simplicity, retaining a geometrical the function /is to be a homogeneous function which

one ~ssumcs that the surface dcscribcd by cqn (I) expands/contracts similarity in ;I stress spncc. Therefore, whcrc n is thr dcgrrr 01homogcncity

satislics the relations ,/(u.Y,) = u/(.Y,) and Z, i7j/3x, * X, = nf for any real 11and variables x,. of the function /: Let /i, whcrc a supcrposcd dot dcsignatss a material-time derivative. be a function of plastic strain rate 9 (homogeneous of degree one by dimensional invariance of time) and ~mr plastic internal state variables describing a history of plastic deformation. f:urthcr. let ; be given as

where .i and fi arc functions of ip in homogeneity

of degree one and some plastic internal (It can be set that

state variables. and the notation II (I represents a norm (magnitude). ,i =Oand fi= -F/F. resulting in 5 = - FI, for gcomaterials.) f%yditTcrcntiating cqn (I) and substituting the relation

q (6) ^._ = Ai tr (i%)

z.c-i

when

f(d)

(4)

(5)

which results from eqn ( I ). noting the homogeneity of the function f, one has theconsistency condition

K. HASHKXCHI

(6)

Here. assume that the associated flow rule holds for the normal-yield state :

C = Ai

where i is a proportionality By substituting factor.

(i > 0).

(7)

eqn (7) into eqn (6) i is given as follows : tr (I%) ; A= V

D

where

(8)

d=

tr {ii($&+L)}

(9)

(10) Since ii and 1 involve I? in homogeneity of degree enc. one can write Ii = A;. 3i = Ai. /; and li arc scalar and second-order tensor functions to the elastic modulus in ;I uniaxial loading state. Let an elastic strain rate be given as ,j = F2 s where E (fourth-order Substituting or fi = EC (13) (11) (12) of stress and some plastic internal with the similarity

state variables. [j is called ;I plastic (or hardening) modulus in conformity

tensor) is the elastic modulus.

eqn (7) with cqn (8) and eqn (13) into the equation 1_= EC+$,

one obtains i = B-ti+ tr (;lS) --_n

D

or inversely tr (riEC) ._ __ _.._I .___n .

(15)

d_

II + tr (iEii)

(16)

The constitutivc equation (15) or (16) by itself falls within the framework of the conventional theory of clastoplasticity in which the interior of the normal-yield surface is assumed to be an elastic domain. Therefore (1) the discontinuous stress rate-strain rate relation is predicted, which changes abruptly at the moment when the stress reaches the normal-yield surface ;

Subloading surface model in unconventional plasticity (2) the loading criterion

921

requires the judgement whether the current stress lies on the Masing effect

normal-yield surface or not ; (3) obviously. the hysteresis loop for the partial unloading-reloading, and the mechanical ratchetting phenomenon cannot be described. It is inapplicable to the cyclic Loading behavior in the subyield state.

3. FUNDAMENTAL ASSUMPTIONS AND THEIR

which the interior fundamental conventional multi. of the normal-yield

PHYSKAL

W-l-ERPRETATIONS

As was described at the end of Section 2, the elastoplastic constitutive limitations. In the following,

model in

surface is assumed to be an elastic domain has let the models in this structure be called models. and let the extended models (e.g. the

(elastoplastic constitutive)

the infinite.

the two and the subloading surface models) to the subyield state be models in accordance with Drucker (19S8). Prior to extending the model. the are given and their physical interpretations

called unconventional

equations in Section 2 to the subloading surface model as an unconventional fundamental assumptions for new formulations in this section. 3. I . Assrrrrrptinrrs

The following

will be formulated model.

assumptions are incorporated into the subloading surface model which so as to overcome the aforementioned limitations in the conventional

[ItI T/w .st4hltdittg .surfctw is .sitnilitr to the ttorrttrtl-_vidti .surfttw, uncl thiw .sttrfitcc.sIii* iri~~~.siti~jtt.s i~s.s~~~iilitrit~, pr~~.s~~rt~i~t~ rite .scttm* ~jrii~~~tttti~~tt ~~itltc~tii ri*lcttriw rt~tfttit~rt .

By the assumption [II] a center ofsimilarity

configuration of the normal-yield similarity-center

(or similarity-center)

exists for lhc spcciticd vector of [I], the similarity-

and the subloading surfaces. Let the position surface.

be denoted by S. Hcsides. in view of the asstlmption

center must lie inside the normal-yield The similarity-center

of two tigures is characterized by the fact that the straight lines

issuing from it intersect with the corresponding (or conjugate) points on these figures in a constant ratio of distances from the center. provided these figures are not only similar but also are located in positions of similarity. In the case of two surfaces whose geometrical Needless to centers are specified. the above-mentioned straight lines intersect with these surfaces and with their centers in a constant ratio of distances from the similarity-center. say, the geometrical centres of these surfaces are different diffcrcnt from the similarity-center in general. from each other and also are

In the state that the similarity-center coincides with similarity~cntcr becomes indefinite

lies on the normal-yield surface. the subloading the aforementioned ratio of the distances Thus, the

and the normal-yield surfaces contact with each other in their different sizes. If the stress in this situation, so that a subioading surface is not determined uniquely.

contact point, i.e. the similarity-center, becomes the singular point of a field of elasticplastic moduli which causes a discontinuity of stress rate-strain rate relation, while the subloading surface plays as a loading surface as will be described later as to the assumption [Iv]. This is physically inadmissible in general, although it has been widely assumed following the first proposition of this model (Hashiguchi and Ucno. 1977) for soils in such a way that the similarity-center is fixed in the origin of stress space and the nodal-yield surface passes through it. Eventually, this assumption is required to guarantee that the subloading surface is always uniquely determined and thus a continuous stress rate-strain

Y7__

IL HASHKCCHI

rate is always described for the non-zero strain rate. (The indifferentiability of a stress rate with respect to a strain rate in the neighborhood of the null strain rate is the fundamental property of the irreversible deformation elastic equation.) although Truesdell (1955) excluded it in the hypo-

[III] The similuritwenter rno~es (more e.wutl?.. cm more ml!) during (elustopiustic) process hut does not moie during an unloutiiny (&.rtic) process. In view of this assumption the similarity-center

~1 ionding

can be regarded as a plastic internal model. On the other hand, the geo-

state variable as well as F and i in the conventional

metrical center of the subloading surface, denoted by 1, is not a plastic internal variable as it evolves even during an unloading (elastic) process in accordance with the assumption [I]. Whereas. 6 is determined from the geometrical relations of u. F. $ and S since the subloading surface is similar and is located in a position of similarity to the normal-yield surface. Now. one introduces the ratio of the size of the subloading surface to that of the normal-yield surface. Let it be called a NS-surface size ratio (abbreviated as NSR) and let it be denoted by R. Needless to say. NSR ranges from zero to unity. Hence.

By this assumption

mation

NSR

dccrcascs or dots not chnngc kvhcn ;I purely elastic dcfora purely elastic deformation only can occur when NSR

occurs, and inversely

dccrcascs or dots not change. Thus. the subloading surface plays a role of loading surface. This is a physical background of the term subloading surface. ksirlcs. it is not rcquircct to judge whcthcr a stress lies on the loading surface or not in a loading criterion since ;I stress always lies on it by the assumption [I]. while the judgcmcnt whothcr the yield surface or not is rciluircd in convcnlional models.

;I

stress lies on

Now, note that the null NSR

state (K = 0: cr = 5 = S) is the minimum [IV], only

;I

state

of

NSK

since R 2 0. Then, by the assumption

purely elastic tlcform;~tion

ti)r /i < 0 L;III

occur to reach the null NSR state, and after that an clastoplastic deformation for /i :, 0 occurs. Now, if ;I plastic deformation occurs linitcly in the null NSR state. a stress rate strain rate relation bccomcs discontinuous deformation singular cvcn if

;I

in this state by the abrupt occurrcncc In other words, the null NSR moduli.

ofplastic

:I anti

stress path is smooth.

state becomes

point of the field of elastic-plastic

In order to avoid this physical

mathematical shortcoming, tion [IV]. Thus,

the assumption [Iv] is accompanied with the subsidiary assumpi.e. I?, to that of the magnitude a purely elastic dclbrmalion state. Eventually.

it results that the ratio of the rate of NSR,

ofplastic

strain rate is infinite in the null NSR

occurs substantially in the null NSR &sides, by the assumptions [Iv

state. and [IV], the state in which ;I purely elastic cleforma-

tion occurs for stress rates of any direction is realized in the null NSR state. In other word>. an elastic domain exists merely as a point and only in the position of similarity-center. [V] CVhn NSR is unilv, i.e. in the nomtal-yield state. N stress rut+strtrirt is girrn h 18 tlrr c.orwerltiorrcd cq~riltions tl~~scrihrrl in Sectiorl 7.

rutc rdtrtir~tr

Iatcr is the all

This assumption

loads to that the subloading

surface model formulated

extension of the conventional

model and thus it dots not Icap from it. Conscqucntly.

the equations dcscribcd in Section 2 hold in the normal-yield state. 3.2. Ph,ssical inlerpretations of assumpti0n.s In the initial subloading model (Hashiguchi

and Ucno.

1977;

Hashiguchi.

197s.

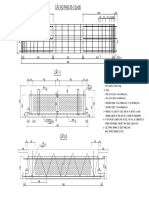

19SOa) or the bounding surface model with a radial mapping (Dafalias and Hcrrmann. 19540). the similarity-center is fixed in the origin of stress spact or in a certain point within the normal-yield surface. As the simplest case one considers the uniaxial loading behavior of the idealized material with the nonhardcning Mises normal-yicid surface and with an initial isotropy as shown in Fig. I in which c and 6 arc axial components of d and ri.

Subloading

surface model in unconventional

phstidty surface model with

973 a radial

respectively.

By the initial

subloading

or the bounding

mapping, all the shapes of initial loading. reverse loading and reloading

curves are predicted to be the same and only an elastic deformation is predicted in an unloading process since the subloading surface shrinks as a stress decreases. Therefore, the Masing effect is not

are caused by the as shown

described and an open hysteresis loop is predicted. These shortcomings

structure of this model in which the similarity-center is fixed. On the other hand. let the similarity-center move with a plastic deformation in Fig. 2 in which S and 9 are axial components of the simila~ty-center the subloading surface. 1. respectively. By the premise of initial isotropy.

S and the center of the similarity-

center lies at the origin of stress space and the subloading surface is merely a point without a size at the onset of initial loading as shown in Fig. 2(a) and it expands gradually as the stress increases so that a plastic deformation is generated and therefore the similarity-center also moves up following a stress as shown in Fig. 2(b). On the other hand. in the unloading state shown in Fig. 2(c), the subloading surface shrinks when the stress decreases to the position deformation gradually and reduces to a point so that only an elastic the subloading surface does not move in this process. is generated gradually. and of the similarity-center

is generated and therefore the similarity-center

But after the stress passed through the position of similarity-center expands again from the point so that a plastic deformation therefore the sinlil;lrity-center rncjves iIs shown in Fig, deformation

2(d). In other words, a plastic

begins bcforc 3 stress vanishes so that the Masing rule can be described to some oxutcnt. Further. in the reloading process shown in Fig. 2(c), the subloading surface shrinks similarity gradually and rcduccs to the point when a stress increases to the position of fhc ccrttcr so that only an elastic deformation is gcncratcd and the similarity-ccntcr to the initial stage of unloading mcntionct! ahovc.

in Fig. prior Z?(f). A rfcscription alttx to its rlccrcns~ ot

dots not move in this process similarly Suhscqucntly,

closctl Iiystcrais

the subloading surface cxpantis so that ;I plastic dcforma~ion prococtls and

loop is ;ltt;linud in this loop. nunnor, (ix. whuruas, oin Lhc r&atling ;I small to S in

the similarity-cc~~tcr moves up ~~)ltl~wi~~~ ttx stress as shown

unloading in ;i purely elastic tMi)rni;ition ttic: incrcisc

t?g. Z(c)) caiiscs an open hystcrcsis

I/r~*.si~~~rl trlc*ruriqq I!/ si/,~i/~rrir~*c*rnlcr. The

Bauschinger

clfcct means that the yiclcl

stress in the rcvcrsc loading bccomcs smalfcr than that in the initial loading. inducing ;I plastic dc!~)rnl~Iti(~n. It gives rise to the induced ;inisotropy of plastic def~)rI~~~l(i~)r~ behavior in the normal-yicid state. This ell&t is described concisely by the kinematic hardening in surface moves with a plastic deformation. Hcrc, i is which the ccntcr oi of normal-yield rcgardcd to be a geometrical center

of elastic

domain. On ihe other hand, the Masing rule

is characterized by the fact that a curvature of the reverse loading curve becomes smalfcr than that ofthc initial loadingcurvc. Further. a closed hysteresis loop during fhc unloadingreloading process is caused by a smail plastic deformation in the unloading process prior to a purcty elastic deformation

to

at the onset ofrctoilding.

These phcnomen~t arc interpreted

bc caused by the fact that fhe stress state. in which materials deform most elastically. is S cxprcsscs this

not fixed in its null state but moves following a current stress during 3 plastic deformation. As was described as to the assumptions [IV] and [IV], the similarity-center

Fig. I. A schematic diagram nf uniaxial loading behavior predictedby the initial subloading surface

model (bounding surface model with a radial mapping).

K.

HASHIGUCHI

ICI Fig. 2. A xhcmak dugram ol uni:txi;il loading behavior prcdtckd by the subloading surfxc model : (;I) a beginning stale of an initial lading (a = S = i = 0, K = 0) ; (h) an initial loading prcxxss(6 > 0. S > 0. R > 0) ; (c) an unloading proccss until 0 dccrcascs to S (ci < 0, S = 0. k < 0: cl&c &formation); (d) an unloading rcvcrsc loading proccss after CTpassed through S(ci < 0. 3 < 0, R > 0); (c) 3 reloading process unlil n incrcaws to S (ri z 0. S = 0. d < 0: cldc dcformarion); (f) a rchxdiny prows after n p;~sd through S (d a. 0. .$ z 0. k > 0).

stress state, called the most elastic stress , and its movcmcnt gives rise to the induced

anisotropy Thus, which affects a response for a small plastic deformation in the subyirld state. while the center of normal-yield surface, oi, can be called a gcomrtrical center of sense) or a normal-yield back stress or a normal-

elastic domain (in the conventional

yield kinematic hardening parameter, the similarity-ccntcr S can be called the most elastic stress or a subyirld back stress or a subyield kinematic hardening parameter. Also, F can be called a size of elastic domain hardening paramctcr. The conventional isotropic/kinematic (in the conventional hardening sense) or an isotropic

model involves only two internal

variables, i.e. F and 2. On the other hand, the extended subloading surface model involves three internal variables, i.c. F, cliand S. Then, the formulation of the evolution equation of the similarity-ccntcr S is to bc the main problem in the extension of the conventional model to the unconventional Physical nreaniy deformation enc. mtl role of NSR.

It seems plausible to assume that the plastic

surface expands. During ;L softening process.

occurs when a subloading

Subloading swfaa model in uncoaventioaal plasticity

92s

(f)

Fig. 2. (continuity.

however, the normal-yield surface itself shrinks and thus the subloading surface also shrinks when they approach closely one to the other. Therefore, it cannot be assumed in general that a plastic deformation does not occur when the subloading surface shrinks. This is the physical background of the assumption [fvJ which is described by the NSR (not by the expansion/contraction of the subloading surface itself). Besides, this assumption should be incorporated into the formulation of constitutive equation. If not, it is not guaranteed that a stress approaches the normal-yield surface even when a plastic deformation proceeds infinitely. fts incorporation wiff be done in a formulation of the extended consistency condition for this model in which a stress does not lie generally on the normal-yield surface, while in all other models including the multi, the infinite. the two and the bounding surface models, their plastic strain rate equations have been assumed u priori by using some infcrpolution rule for plastic modufi between the elastic and the normal-yield states. As was described as to the assumptions [IVl and [IV], this model involves an elastic domain as a point. However, almost purely elastic behavior can be described in the sobyiefd state by selecting the high plastic modulus as a function of R. In other words, it can be reduced to the conventional model.

4. FORMU~~ON OF SUBLOA~IN~ SURFACE MODEL

Based on the assumptions described in Section 3, let the subloading surface model be formulated in this section.

916

K.

HASHIGIXHI

The subloading surface is described by the assumption [II] on similarity of the subloading surface to the normal-yield surface as f(5) = RF in setting (17)

where the function f(cS) has the same form as the homogeneous function f(s) R is described by current values of u. 2 and F as

in eqn (I).

(19) Also. by the assumption [II] on similarity. the following geometrical relations hold

(20) (21)

(22)

(23) where (24) (25) W) (27) CW

Fig. 3. Configurations

of u. S, i nnd 5. (a) Normal-yield

surface; (b) subloading

surfkce.

Subloading surface model in unconventional plasticity

927

(29)

(30)

u, denotes the conjugate stress on the normal-yield subloading surface. while the outward same direction.

surface for the current stress u on the

normals at these stresses on the surfaces have the

F. a?.S, R. E. and u.. There exist four R and 1 by the basic variables. i.e. the current stress u and the plastic internal state variables F. ai and S be

In the above, there appear the variables u. variables among them. Now, independent let the expressions of explained below. which is required in calculation Substituting the relation of stress rate-strain rate.

tf=t?+Rs

which is obtained from eqn (21). into eqn (17). one has

(31)

/(a+ RS) = RF

(32)

from which one can determine R substituting the current stress u and internal variables F. ci and S. Further. substituting ci and S and the already determined R into the equation

s=S--R$

which is obtained from eqn (3 I), OS is determined. Now. let the cxtcndcd evolution equation of ai to the subyicld state be formulated. :Iccord;mce with the assumptions [II] and [VI. assume that the translation normal-yield stress 6,. Hence, noting the relation (22), eqn (3) becomes

(33)

In

rule (3) of the

surface holds even in the subyield state, regarding u in eqn (3) as a conjugate

(33)

Next. consider the evolution assumptions [I]. [II] and [II] that

equation

of the similarity-center.

It must hold by the

or

R, < x

whcrc

(36)

(37)

~(0 < x < I) is a material constant. The surface described by /(s) the dashed line in Fig. 3. Equation (35) is rewritten as

R:F is depicted by

928

K. HASHIGUCHI

tr{fi,(k-fs)}<0

whenR,=X

(38)

in a differential

form. using the relation

f?f (3 ss

where

tqF =-----T-n

tr(&S)

when R, = x

(39)

Equations center.

(35) or (36) and (38) wit! be called an enclosing condition

of simitarity-

In order to satisfy eqn (38), referring to Fig. 3. assume that

when R, = x

(41)

and the straight line

where S, designates the intersecting point of the norn~~~l-y~~l~i surf&c issuing from tho point oi and passing through

the point S in the stress space, ix.

C( 20)

is a material constant which controls the rate of translation

of the similarity-ccntcr.

On the other hand, for R, = 0, i.e. S = ii. one assumts that

s-;;;s = CllfY[[(ur-Gi)

when R, = 0.

(43)

In Fig. 3, i,, is the outward normal of the normal-yield

surface at the point S,, i.e.

(44)

setting s,. 5 s,.-ri. For eqns (41) and (43) to be satisfied, one assumes the following (45) linear equation of R,

as the simplest one

(46)

which is rewritten

as

(47)

noting eqns (22) and (42).

Subloading surface model in unconventional

plasticity

929

Eventually. the translation rule of S is given from eqn (47) as follows :

(48) which reduces to $ = f ,,iPIld = CIICPlld, whenk=O. $=O, X= 1.

(49)

The evolution equation of i given by eqn (3) conforms to Zieglers (1959) modification of Pragers (1956) kinematic hardening rule due to a mathematical convenience that the components of ai in the directions of null stress condition vanish throughout a deformation for initially isotropic materials. However. it does not differ from Pragers rule in the case of metals with von Mises yield surface. Equation (34) is the extension of eqn (3) to the subyield state. Further, the evolution equation of the similarity-center given by eqn (48) also involves this mathematical convenience eventually. Then, all the components of ai, S and 07[see eqn (33)] in the directions of null stress condition vanish consistently throughout a deformation, while a more due consideration is required to clarify whether it has a physically inevitable reason too. Next, one formulates a consistency condition for this model in which a current stress does not lit on the normal-yield surface in general. Ditlcrcntiating cqn (32) and noting the relation

v (4 --=

dd one has

nRF _ G-@-i)n*

(r

{(

fi

d+RA-

nF

-d-

R

R

-$

~0.

(51)

In ordsr to obtain from eqn (51) a consistency condition by which a plastic strain rate will be formulated, let an evolution equation of R, i.e. R, be assumed. In accordance with the assumptions [IV] and [IV], one introduces the equation R = CI]]ipI( fordP # 0 (52)

where U is a monotonically decreasing function with respect to R satisfying the conditions I/= +co U=O forR=O forR= I. (53)

The Masing rule and a closed hysteresis loop arc described to some extent by the movement of the most elastic stress S. Howcvcr. note that if U is a function of R alone, eqn (52) results in R-R0 = /(t?-f:) for R = R,: E -p = f$ where .Cpis the accumulated plastic strain. i.e. zp = j IIipI]dr (t, time). Therefore. the accumulated plastic strain Cp gcneratcd until R rcachcs a certain value from a certain state (R,,, tT{) in a loading (elastoplastic) process is the same independent ofan initial loading, reverse loadings and reloadings after unloadings of various magnitudes. This would not be realistic as known from the fact, for example, that the plastic strain generated during the reloading process after a small unloading is to be far smaller than that during the initial loading process. Then. assume that the function U depends not only on R but also on a distance from the current stress Q to the conjugate stress u,,_As a measure of this distance, one introduces the non-dimensional parameter

K. HASHICCCHI

which is rewritten

by eqn (20) as

R,.=

(A-l >

R

(5%

where

(56)

Thus.

the function

Uis

given as

U =

l?(R.Ry)

or U = o(R.

I?).

with rcspcct to

(57)

Obviously C must be a monotonically Enamplcs of the function U are

decreasing function

R,. or il too.

I!,; = u,(l

- R)/I? In

(58)

U =

w hcrc II,

-u2

R/I?

(59)

, II: and IPI arc material constants.

Suhslituting cqns (4X) and (SZ) into cqn (51), one obtains the consistency condition for this extended model :

ttcrc, assume that the associated flow rule holds also for the subloading surface :

ep = hi.

By substituting eqn (61) into (60). the proportionality tr (iici) i A= D where factor iis given as

(()I)

b=tr

[i

ii $L=+i+C(,

-I$

- F)+

$+}I.

(63)

Since fi and d involve 3 in homogeneity of degree one. one can write them as k = i/i. oi = ix /; and ri are scalar and second-order tensor functions (64) (65) of stress and some plastic internal

Subloading surface model in unconventional plasticity

931

variables. The loading criterion and the physical interpretation of the associated flow rule for this extended model are given in the next section. It should be noted that eqns (61)-(63) lead to b + rx) (i -+ 0) for R < I and b = b + ok or u2 -, co in eqn (58) or (59)]. In other forR=lbyselectingLi+coforRcl[u, words. this model reduces to the classical constitutive equation by the selection of material parameters, the interior of the normal-yield surface becoming an elastic domain substantially. For the special case of S = dr = d. the function B of eqn (63) reduces to

b = tr [l{($I;+

$+ij].

(66)

Further, for S = d = d = 0 with P = 0 and C = 0, the function b reduces to

b =

FFE+ p> tr(iia). (

(67)

In the above, the plastic modulus b was derived logically by formulating the consistency condition on the premise d > 0 for i. # 0. while the plastic modulus has been assumed a priori in the past formulations by interpolation rules (Hashiguchi and Ueno, 1977; Hashiguchi, 1978. 1979. I980a ; Dafalias and Herrmann. I980 ; Oafalias, 1986 ; Zicnkiewicz and Mrbz. 1984. etc. for S = ai = 07= 0 and Hashiguchi, 1980b. 1985b for $ # 0). Combining elastic and plastic strain rate equations (13) and (61) with cqn (62). one obtains

i = E i+ tr (iii)

-j-n

or invcrscly tr (iiEi)

B+ tr (iiEii)

(69)

5. A LOADING

CRITERION

AND

THE

ASSOCIATED

FLOW

RULE

A loading criterion formulated in terms of a strain rate instead of a stress rate with the outward normal of plastic potential surface and the elastic modulus was induced by Hill (1958). premising on a hardening process. This criterion seems applicable to generalized elastoplastic materials with hardening/softening behavior. Later on, Hill (1967) formulated it on the postulate that a strain rate space is divided by a hyperplane into the two domains which cause a loading and an unloading, rcspcctivcly. Besides, Mrbz and Zienkiewicz (1984) formulated it on the postulate that a strain space is divided by a yield surface into the two domains which cause a loading and an unloading, respectively. It does not belong to the ordinary stress space formulation but falls within the so-called strain space formulation in which the constitutive relation of a stress rate and a strain rate is formulated by a strain (not a stress) and plastic internal variables. Both of them are not straightforward formulations from the postulate on the ordinary loading surface in the stress space. Whereas, the strain space formulation premises at present that the interior of yield surface is an elastic domain and that the yield surface includes a null stress state, because of the decomposition of strain into elastic and plastic components. Thus, the existing strain space formulation is regarded as the untraditional representation or interpretation of the classical elnstoplasticity.

93

K. HASHIGUCHI

The physical interpretations of the associated flow rule were given by Drucker (1951) and by Ilyushin (1961). The former belongs to the stress space formulation but premises the existence of the yield surface enclosing an elastic domain and the latter belongs substantially to the strain space formulation. The present model does not premise the existence of an elastic domain and also does not use a strain belonging to the stress space formulation. In this section. a physical interpretation of the above-mentioned loading criterion by Hill is given from the postulate on the loading surface in a stress space within the framework of the stress space formulation for the generalized materials without an elastic domain but with hardening,softening behavior. while the formulation of this loading criterion was discussed briefly by the author (Hashiguchi. 1988) on the premise of the associated flow rule. Further. the associated flow rule is derived from this loading criterion and from Ilyushins hypothesis of a non-negative work done during a strain cycle. In this section let a loading and an unloading mean the processes during which a plastic deformation occurs and does not occur, respectively. Now, one introduces a loading surface :

f(a,ff,)=O

(i=l.2

. . . . . n)

(70) and / < 0 for the

where scalar or tensors H,denote collectively plastic internal variables, interior of the loading surface. Ditiercntiation of eqn (70) leads to the consistency condition

+c

c7f

,.., (JH,

: Q,=o.

(71)

Here

Ict it bc assumed

that a plastic strain d=IEm

rate P is expressed Ilrnll = I)

as

(A>O,

(72) second-order

where Ais a proportionality factor dctcrmined below, and m is a normalized tensor which is a function of stress and some plastic internal variables. fi, can be expressed by eqn (72) as

r-i, = ,ih,

where scalars or tensors h, are functions of stress and some plastic internal Substituting eqn (73) into eqn (71). we have variables.

(73)

(>O

for ip # 0)

(74)

or tr (nti)

=x-

(~0

forCP ZO).

(75)

where

Subloading surface model in unconventional plasticity

933

(76)

(77)

Substitutions of eqns (13). (14) and (72) into eqn (75) lead to rl < = tr {nE(i-im)j r) (78)

from which one obtains the expression for ; by the strain rate instead of a stress rate. Let it be denoted as A:

A = Ftr~r(~~m)

by which eqn (72) is rewritten as

(>O

for ip # 0)

(79)

i = Am.

(80)

Now, one dcrivcs a loading criterion for the constitutive equation which satisfies the following assumptions.

The assumption [VI] is described as tP # 0 when tr(nci) > 0

nt&ient

(81)

which means that the inequality tr (nci) > 0 is a Thus, it must hold that tr (nci) < 0

condition Ji)r u loading.

when ip = 0

(82)

which means that the inequality tr (II&) G 0 is a nrcasury condition for un unloadiry. This condition is not, however, a sufficient condition for this state. (lt holds also in the loading with a softening.) Since it holds that B = lG in an unloading (i = 6). the necessary condition (82) for an unloading is rewritten as tr (nE2) < 0 when 2 = 0 (83)

by a strain rate instead ofa stress rate. As known from the relation tr [nE( -d)] = - tr (nEi), the strain rate space is divided into half spaces by the sign of tr (nEi). Now, it can be stated from eqn (79) that (i) if D + tr (nEm) c 0, a loading cannot occur for tr (nEi) > 0 ; (ii) if I! + tr (nEm) = 0, a loading cannot occur except for the special process tr (nEi) = 0, while an unloading also cannot occur in the deformation process tr(nG) > 0 by the necessary condition (83). The admissible strain rate and stress rate with the signs of 3 and tr (nEm) under the condition A > 0 were examined by Mair and Hueckel (1979) in detail.

934

K. HLSHICIXHI

Accordingly.

a deformation

bringing about tr (nE.$ > 0 cannot occur at all in both a (nEm) < 0. This contradicts the assumption VII].

loading and an unloading Thus. it must hold that

if >+tr

?+tr(nEm)

> 0

(8J)

in order to satisfy the assumptions the subsidiary condition

[VI] and lJ41], and by taking account of eqn (g4) into

A > 0. it must hold that

tr (nEC) > 0

when Cp # 0

(85)

which means that the inequality The necessary conditions

tr (nEi)

> 0 is a necessar_r concfition fur a loading. and a loading. respectively. tr (nEC) from each other. while only either of these a loading criterion is given as

(83) and (85) for an unloading

exhibit different ranges of the quantity conditions for each process. Eventually,

processes can be taken. Then, it results that they are not only necessary but also sullicient

t? # 0: tr (nEC) > 0. dP = 0: tr (nEti) < 0 (S(J)

which was shown by Hill (1958). presupposing T\ > 0. Whereas. i: in cqn (75) is not applicable to hardcning/softcning holds not only in a loading but also in an unloading

materials, since d > 0

for the state I! < 0 [for which a

soltuning tr (nci) < 0 proceeds if a loading takes place]. Ilyushin (1961) postulated that the work done during a strain cycle is non-negative. i.c.

tr (a dc) 3 0.

6: ip

For an infinitesimal strain cycle, cqn (87) is written as

(87)

tr (da de) 2 0

whcrc ti is a plastic relaxation

or tr (tipi) >,

when

(8Y)

stress rate. i.e.

d dU

Fig. 4. A non-negative

work done during 3 strain

Subloadingsurfaa

modelin uncoaventionalplasticity

&P=EILp,

935

(89)

referring to Fig. 4 in which the elastic lines ab and cd are regarded as parallel since one considers the infinitesimal strain cycle. Substituting eqn (SO) into eqn (88). one has

tr (mU) Z 0

when & # 0,

(90)

while the strain rate satisfying this inequality occupies a half of strain rate space, In order that eqn (90) is fulfilled for an arbitrary strain rate in the loading process, i.e. eqn (86) ,, it must hold that

m = n.

(91)

Equations (72) or (SO) with eqn (91) is the associated flow rule.

6. QUANTITATIVE DESCRIPTIONS OF BENCHMARK PROBLEMS IN UNIAXIAL LOADING

Let the basic characteristics of the present model be examined by the quantitative descriptions of some benchmark problems in uniaxial loading. In order to do it concisely, one adopts the nonhardenin~ von Mises normal-yield surface. Thus, for a uniaxial loading the normal-yield state is described by

Ial = F

(92)

with P=Oo. and eyn (32) is written as l(s+RSI = RF from which R is given as

Z=O,

n=l

(93)

(94)

R=&

hF-S CT where ais the axial component of d. And 6 is given from eqns (33) and (95) as

(95)

a=S(I-R)=S-.

ZF--O lol

(96)

hF--S

Let the function I/ be given as

u = u( 1 -

R)/W,

(97)

where U, 3~ and 9 are material constants. If one adopts a value close lo unity for the material constant x, the evolution equation of the similarity-center is given from eqn (49) by

936 Sk f

K.

HASHIGWHI

tan- (=CF)

-F

Fig. 5. Relation of S versus cp (x =

I) in unluxial

loading.

s = CJj(FTS)iP (x

Integration of eqn (98) leads to

z I).

(98)

s-s, =

F-T s,,

for the initial condition

+[I

-cxp

(CJ&--E$)ll

S = So : cP = 4. In these equations the upper and lower cases stand curves described by eqn (99) have a unique shape arc asymmetric to each

for 2 > 0 and i < 0, rcspcctivcly. S-cP

as shown in Fig. 5, while the curves for tension and compression other. The axial plastic strain rate is given from cqns (6l)-(63) as

Although dimensional

the equations numerical

for the uniaxial

loading are given above in order to exhibit were performed by the sixin Section 4 and eqn (97).

the fcaturcs of the prcscnt model concisely, the calculations program based on the exact equations

The calculated results are shown in Fig. 6 in which material constants are selected as

I; =

100 MPa,

II

5,

HI

5.

tl

7,

c = 700,

X =

0.99

which causes a large plastic deformation

compared

with usual metals, in order to exhibit a curves are shown in Fig. 6(a) in which

hysteresis and ratchetting behavior clearly. The initial loading and the unloading-reloading a closed loop is observed. (0)

I 1

I 0

I l?I%l Fig. 6(a).

I a2

Fig. 6. Uniaxial loading behavior calculated by the subloading surface model : (a) the initial loading, the unloading and the reloading curves; (b) the hysteresis loop for 161 G 99.5 MPa: (c) the cyclic loading curve for a large stress amplitude (a = 0 -90 MPa) : (d) the cyclic loading curve for a small ---S. -----i. stress amplitude (n = 50 -90 MPa). ----IT.

Subloading surface model in unconvmtional plasticity

937

(b)

xx

a.s.ti

IMPal

---..----

-lOOI I I

-(12

0 Fig. 6(b).

EP1)6)

9: z

(cl

u, s.b

IMPa)

EP(%l

Fig. 6(c).

Q2

(d)

101

I

U,S.G

IMPa)

Fig. 6(d).

938

K. HASHI~CHI

The hysteresis loop for the range of stress +99..5 MPa is shown in Fig. 6(b) in which the Masing rule is expressed to some extent. The Masing rule is described as (Xl&. When one represents the initial loading curve as c = f(c). 1966) : the reverse loading curve is

described as (o,, - a) 2 = f((~~~--&)?) where u,, and E,, are values of c and axial strain E at the onset of reverse loading. On the other hand, the reverse loading curve in real materials is described as (a,,--~) coefficient, and

L = ~((E,~-E)/L)

where L( I < L < 2) can be called a roundins a Masing effect referring to the

this phenomenon

can be called

Baushinger effect. For L = I the shapes of an initial and a reverse loading curves coincide with each other. On the contrary, loading for L = 2 the stress and the strain generated in a reverse loading process, i.e. the Masing rule itself. process are twice those in an initial

It is observed in Fig. 6(b) that L = 1.5. while L is controllable in the range I 6 f. < 2 bq the selection of the material parameter C: L = I for C = 0. i.e. the initial subloading surface model. and L approaches curve shown in Fig. 5. The cyclic loading stress amplitude behavior for the large stress amplitude O-90 MPa and the small 5(r-90 MPa (50 cycles) is shown in Fig. 6(c and d) in which mechanical phenomena are observed. while for a small stress amplitude is not attained 9 for C x c for which the c--,+ curve approaches the S-Y

ratchetting and its shake-down completely down

open loops are rcpcated until S reaches the range of CJ.The shake-down smaller for a smaller stress amplitude. by making the function accumulated A modification to R and

and finally tho cycle proceeds in a constant interval of plastic strain which is is required to attain a stronger shakcequation of R be a function of an that a deformation bccomcs purely /I in the evolution

plastic strain r? in addition with the incrcasc of 2.

Rso

elastic gradually bc conccivablc

As shown above by sonic basic examinations that the subloading surface mod4

though they arc the simple casts, it would has a basic structure applicahlc to the but also subyicld states.

prediction of cyclic loading behavior in not only normal-yield

7. CONSTITUTIVI: EQUATIONS 01: METALS AND 7lii:IK COMPAKISONS Wl.l.11 AN I:XlI:KIMI:.NT IN SIMPLI: TOKSIONAI. CYCLIC LOAI)ING

The basic formulation in the form applicable

of the subloading

surface model was given in the prcccding equations of metals bc formulated below

sections. Based on it, let the explicit constitutivc Let the normal-yield surface be given as /(d) F(H) = Js/3 jib /I

to the analysis of cyclic loading behavior.

(lOI)

= F,,[l +/I,;

I -cxp

(-II,fl)j]

( IO)

(103)

/i = \/I/3

R y I/i /I

( 10-I)

where F,, is an initial value of F, and II,, h2, k,, kz and Y arc material constants. and dzb-ftrdl. f? will be explained The nonlinear (I 966) and refined d = k,2--kk:IIiP/Ii. later. kinematic by Equation hardening (1979: (103) Marquis rule proposed by Armstrong and Fredcrickson see also Benailna and Marquis, 1987) is as a modification obcyinp Zicglcrs (105)

is regarded

(1959) proposal for mathematical cqn (103) is integrated as

convcniencc which was dcscribcd in Section 3; whereas.

- = +[I k, _ _

k, for the initial condition + Xl)

. . 3--r,

-cxp

(~k:\l~(EP-f$,;.]

(106)

d = si,, : cP = cc in uniaxial loading. whcrc the upper and the lower

Subloading surface model in uoconvcotional phsticity cases

939

stand for tension and compression, respectively. Here, it is worthwhile to notice that all the equations (99), (102) and (106) of the internal variables S, F and d reduce to the same exponential form of plastic strain in the uniaxial loading. Besides, eqn (99) and (106) describe concisely the gradual saturations of translations of S and d during a monotonic loading and the abrupt recovery of translations at the onset of stress reversal, which are typical properties of irreversible deformation. The hardening of metals is interpreted to be caused by the accumulated plastic strain. For a certain accumulated plastic strain, the expansion of the yield surface, i.e. the so-called isotropic hardening during a cyclic loading is far more weakened than that during a monotonic loading and it saturates for a rather small accumulated plastic strain. In order to describe a cyclic loading behavior of metals, Chaboche er al. (1979) proposed the concept of (isotropically) nonhardening domain which means that the isotropic hardening does not occur when a plastic strain lies inside a certain surface in a plastic strain space, Let this surface be called a hardening surface. It is similar to the conventional yield surface in a stress space, for which it is assumed that a plastic deformation occurs only when a stress lies on the surface. Based on this idea. they described the hardening surface by the equation

J2/3IlPll-K=

where

(107)

c BP--5.

(108)

Let the rate of translation and expansion of the hardening surface be given as & = (I-h)@tr(iu?)i (109) (110)

R s Jtij31R~ tr (iriP)

where h and c are material constants and

R E J2/311PII/K.

(112)

Equations (109) and (I IO) satisfy eqn (107) when fi = 1. Equations (107)-( 11I) for i?; = f were proposed by Chaboche et ul. (1979) as b = l/2 and modified by Ohno (1982) as h # l/2, where f is defined as l-= I f=O whenJ2/311Pll-K=0 when,/!$ll?(l-K<O and or tr(iu?)>O tr(ii$),<O.

However. this hardening criterion falls within the framework of conventional plasticity, postulating that the interior of the hardening surface is a purely nonhardcning domain. Thus, it would not be applicable to the cyclic loading behavior for plastic strain amplitudes which change within the hardening surface. Further, a discontinuous stress rate-strain rate relation is described with an abrupt occurrence of hardening when a plastic strain reaches this surface. In order to extend the concept of nonhardening domain to the unconventional plasticity framework, the new variable fi is here incorporated into eqn (104) so that a hardening occurs depending on the value of R even when a plastic strain lies inside the hardening surface. and thus the continuous hardening rate is described always. Besides, the judgement whether the current plastic strain lies on the hardening surface or not is not required. By this extension or its refinement. a cyclic loading behavior of metals will be predicted properly for various stress or strain amplitudes.

940

K. HASHKXCHI

$. d and ip are given by eqns (48). (52) with eqn (58) and (61)-(63) themselves. The subloading surface for the normal-yield surface (101) is expressed in the form of eqn (32) as

\&&i+ where

RS[I = RF

(113)

Solving

eqn (113) for

R,one obtains the analytical

solution (I IS)

fz= (J+G(J:+Qila'~lz)i/~

where J 3 tr (as). Q 3 jF/1!!$(1.

(116)

Equation (115) is the expression of R by the current stress u and internal variables F, 2 and S. Further, substituting cqn (I 15) into eqn (33). one has the expression for 37by them. Let an elastic constitutive equation be given by Hookes law :

where E and G arc Youngs modulus and a shear modulus, respectively. Figure 7 shows a relationship bctwecn fir and y/,,/3 in a simple torsional cyclic loading mcasurcd by Tanaka ct ul. (1985). whcrc T and 7 are the shear stress and twice the plastic shear strnin, rcspcctively (the cquivalcnt stress J3/2llaII and the equivalent plastic strain rate J2/311dP([ reduce to $1~1 and lipI/,/ for a simple torsion and to 1~1 and lCpl for a uniaxial loading. rcspcctively, whcrc u and ip arc a deviatoric stress and a deviatoric plastic strain rate). The thin-walled tubular specimen (21 i mm diameter, I~~ mm thickness and 60 mm Icngth) of type 316 stainless steel was subjected to cyclic loadings of plastic strain amplitudes of y/,/3 = +_0. I, +_0.2 and +0.4%. The cyclic loading in each stage -in each specified value of amplitudewas continued until the stabilized behavior was almost attained ; the corresponding equivalent plastic strain jldyPljfi was more than 30%. The theoretical curves calculated by the present model are depicted in Fig. 8(a) where material constants and initial values are selected as follows : 11, = 1.5, /I: = 25, k, = 15,000 MPa, kz = 200

c = 700, x = 0.9. u, = 6,000. 1~ = 0.1 \' = 5, < = 5, h = 0.1 E = 199,000 MPa, F. = 250MPa. where Ko, ai,. S, and ai,) are initial G = 77.000 MPa &,=S,,=Ci,,=O of K, dr, S and ci. respectively. Variations of

&=O. values

fi&, fi(4+ F;ip/ljpl) (normal-yield state) and ,/3S, and S, are shear components of ci and S. The smooth effect and the saturation of hardening are shown in Fig. A good agreement between experiment and theory

5. DISCUSSIONS

are depicted in Fig. 8(b). where oi, elastic-plastic transition, Masing 8. is observed in Figs 7 and 8(a).

The multi surface model proposed by Mroz (1966. 1967) and Iwan (1967) as an extension of the kinematic hardening model to the subyield state and the two surface model

Subloading surface model in unconventional plasticity

941

(MPa)

-400 -03

-0.4

-0.2

0.2

YP/JF

0.4

WJ)

0.6

Fig. 7. Measured relationship of ,/jr versus 4/d for simple torsional cyclic loadings of various plastic strain amplitudes (Tanaka et al.. 1985).

proposed by Dafalias and Popov (1975) and Krieg (1975) as a simplification of the multi surface model are well known and have been widely used as well as the initial subloading surface model or the bounding surface model with a radial mapping. The unconventional models as the extention of the kinematic hardening model to the subyield state, i.e. the multi and the two surface models premise on the contact of loading surfaces. which is avoided exactly in the present models by the assumption [Il]. It leads to the singularity of the field of hardening moduli in the contact point which is a similaritycenter of the surfaces. Thus, a discontinuous stress rate-strain rate reIation is described when a stress passes through the contact point after it left once from this point (in a

-4001 -0.6

I

-0.4

I

-0.2

I

0

I

0.2 YP/fi

1

0.4 I%)

1

0.6

tm ii,+ ,F+q)

.P

400 (b) 200-

fisr fis, WPI) -ZOO0,

-400 -0.6

-0.4

-0.2

0.2

7

0.4 (%)

0.6

P/z3

Fig. 8. Calculated relationship for simple torsional cyclic loadings of various plastic strain amplitudes: (a) fi r versus yV$; (h) $d, (---). &J,+FiicIIYI) (-) and AS, (-----) versus r*/JT.

YJ;!

K. HASHIGCCHI

reloading after a partial unloading). Accordingly. these models are incapable of describing a smooth stress-strain curve in general. Further. the two surface model assumes the subyield surface enclosing an elastic domain. Then. even if there does not exist a contact ofsurfaces, a discontinuity of stress rate-strain rate relation occurs when a stress reaches the subyield surface. Further. consider the uniaxial loading behavior of the material with the nonhardening von Mises normal-yield surface. The multi surface model predicts asymmetric unloadingreloading curves where the ending point of hysteresis loop coincides with its beginning point since the movements of nesting surfaces in the reloading state are just the inverse of those in the unloading state. Then, an unrealistically large hysteresis loop is predicted with the rounding coefficient L = 2 (Masing rule) and a mechanical ratchetting effect cannot be described tracing a fixed hysteresis loop cyclically. On the other hand. in the two surface model a plastic modulus is prescribed by the distance from a current stress point on the subyield surface to a conjugate stress on the normal-yield surface. Then. ail the stress-strain curves are of same shape except for elastic parts. Accordingly. the Masing effect cannot be described by the two surface model, i.e. L = I. The multi surface model was mathematically refined to the inlinito surface model by Mrt3z et ctl. (1981) assuming an infinite number of surfaces. It also involves. however, the above-mentioned shortcomings. Recently. in order to avoid them. Klisinski (1988) and Kiisinski and Mritz (1988) proposed a method to remove a contact of the active loading and the stress reversal surfaces by combining a restrained translation of the former to the center of the latter and its expansion rcfcrring to the concept of the subloading surface mod& However, this moditication [cads to a more peculiar prabtcm that the two special lines arc gcncrated in the domain encfoscd by the stress rcvcrsal surface, along which a stress rate inducts a purely elastic deformation. The two surface model was further simplilicd to the single surface model by Dufalias and Popov (1977) making the inner yield surface shrink to a point so that an elastic domain

vanishes, and it was appiicd to met;tl by Dafr4i;ts (IM). (1977) and to concrctc by Fardis ct trl.

This model has the ~~~lv~~~i~~~gc to tfcscribc the mutual ~lcpcn~icncy bctwecn the directions of ;I stress rate and it plastic strain rate, whik it is obviously incupablc ol describing the plastic dcform;ltion due to the stress change along lhc normal-yield surface.

However, ratchctting it is not applicable to the cyclic lontling with :tn open hystcrcsis loop ;IS well as tfw behavior predicting an cxcessivc

initial subloading surttcc model.

Also, it is incapable of dcscribin~ a softening behavior at feast by the existing fortnul~ltion ;IS was indicated by Hashiguchi f 1%&t, IMY). Furthcrmorc, this model is accompnnird with the mathemtltical inconvcniencc requiring analyses of nonlinear sirnultancous equaIions in stress rate-strain rate ilIl:llysiS in general. The subloading surface model dots not assume :L purely elastic domain.

Also. when the normal-yield and [he subloading surfaces come into contact. their sizes coincide with each other, i.e. R = I, while the plastic modulus ntonotonic~illy depends on NSR. Thus. a continuous stress rate-strain rate relation is described in a loading state. bringing about a smooth elastic-plastic transition. Further, the extended subloading surface model formulated in this paper is capable of describing fundamental plastic deformation behavior. i.e. ;gn anisotropic h~Ird~nin~/softenin~ and a hysteresis bthavior including the Masing

cfrcct, ;i c&cd hystcr& loop and :1 mechanical ratchctting effect oonsistcntly by tuking account of the movement of the similarity-ccntcr, i.e. the most elastic stress. Thus, it is to bc :tpplicablc to the prediction of cyclic loading behavior in the subyicld state, which has been rcyuircd ;1s Ihc unconvcntionai elastoplasticity. The r:idial mapping mo&l dots not utilize the subloading surfacc and thus it uscs the

ratio of the magnitude of the current stress to that of the conjugate stress instead of NSR for the formulation ofpI&c strain rate equation by an interpolation method. These ratios arc, howcvcr, mathcmaticiilly the s;m~c when the subloading surface is similar to the normalyield surf;lcc ;ls is postul;itcd

in the initial

or the prcscnt subloading

surface model.

projection-center is not formulated in :I useful form and thus it is actually fixed. Dafalitls (1986) and Klisinski (1988) assumed cz priori the evolution equation of the similarity (projection or homology)-center which is the special

Besides, the evolution

equation of the

Subloading

surface model in unconventional

plasticity

form (isotropically and kinematically nonhardening nodal-yield surface) of the equation proposed by the author (Hashiguchi. 1985b) and is inapplicable to deformation analysis of real materials with a hardening/softening. Thus, the concrete formulation of the radial mapping is regarded to lie in the stage of that of the initial subloading surface model. Besides, as was described in Section 4. the incorporation of the subloading surface is inevitable in order to formulate the extended consistency condition from which a plastic strain rate equation is derived reasonably. taking account of the physical requirement that NSR increases with a plastic defo~ation without the use of ad hoc method such as an interpolation. Further. the incorporation of the subloading surface would be unavoidable for further extension to a more generalized model which does not assume the similarity and to the tangential plasticity (Hashiguchi. 1989). The subloading surface model as well as the other elastoplastic constitutive models without an adoption of such an atf hoc method as the intersection or the corner of plastic potential surfaces is incapable of describing the mutual dependency between the directions of a stress rate and a plastic strain rate and also the plastic defo~ation due to the stress change along the loading surface. however. Hereinafter. we should extend models so as to describe these behaviors also. Dafalias (1986) advocated the hypoplasticity referring to the hypoelasticity of Truesdell (1955). His definition of hypoplasticity or the naming of this term is not clear but he states that the hypoplastic constitutive equation includes a stress rate direction tensor. i.e. ti/llSjl so that it becomes an incrementally nonlinear equation. while the hypoclasticity does not premise on the existence of a potential surface but excludes the nonlincilrity. Thus, it rcquircs the analysis of nonlinear sirn~~ltaneotls equations of stress rate strain rate. Obviously, it Icads to a serious disadvantage to the analysis of boundary value problems. Howcvcr. thcrc does not exist the incvitablc reason that one has to introduce the stress rate tiircction tensor Jircctly in or&r to dcscribs the mutual dcpcndcncy hctwccn the rlircctions of it stress rate and a plastic strain rate as is easily seen by the fact that cvcn I lookcs law, the sirnplcst litlcar equation, can dcscribc ;I strain rate for any stress rata. and r+c~ wr.w, their ciirections atfccting citch other. The further extension of the subloading surtitcc n~odcl within the framework of the ordinary bilinear equation so as to dcscribc the ahovc-mer~ti~~r1cJ mutu;~I dcpcnrlcncy and the plastic deformation by the stress change along the loading surface will bc cxposcd in a subscqucnt paper.

REFERENCES Aboim. C. A. and Wrath. C. P. (19X2). Bounding-surname-pf~sticity theory applied to cyclic loading of sand. Proc. I.rr ItIf. S,nrp. ?Iufttcr. Jl&*/.r Cconrc*ctr.. Zurich. p. 65. An;lndraj;th. A. and Dafalias. Y. F. (1986). Bounding surface plasticity. Ill. Applica&m IO anisotropic cohcsivc soils. J. /&ug ,\I&. ASCE 112, 1292. Armstrony. P. J. and f:rcdcric. C. 0. f 1966). A rn~~h~~li~~l rcprcscntatioa of the multiaxial f~~lushin~~r rt&~l. G.E.C.H. Report RD B.N, p. 731. Hancrjcu. S. and Pan. Y.-W. (1986). Transient yielding model for clays. 1. B~gng ,%~ech.ASCE 112. 170. U;trds[. J. P. (1986). A bounding surface plasticity model for wnds. /. Enyng M&I. ASCE 112. 119X. Rcnalla. A. and Marquis, D. (1987). Constitutivc equations for nonproportional cyclic elastopiastic viscoplasticity. 1. &rg,,g Trchd. ASME IO!& 326. Chahochc. J. L.. Dang-Van, K. and Cordicr. G. (1979). Modclizttion of the strain memory cffcct on the cyclic hardening of 3 I6 stainless steel. Trun.v. 5rh Inr. Con/. SNiRT, Berlin. Division L. Chen. E.-S. and Ruyukozturk. 0. (198.5). Constitutivc model for concrete in cyclic compression. J. Eitgng. dlrch. ASCE I I I. 797. Dablios. F. Y. ( 1% I ). A novel hounding surfrtcc constitu;ive law for the monotonic and cyclic hardening rcsponsc of mct;tls. Trcras. hrh hf. Cortl: SXliRT. Paris. L3/J. D;ilXas. Y. F. (198-I). Modclling cyclic plasticity: simplicity versus sophistication. ~lc*c/umicnl Engincrring Muwbrb, p. 153. John Wiley. Dahlias, Y. F. (1986). Bounding surface plastic&y. 1. Mathematical foundzttion and hypopiasticity. J. Engng itfr*&. zlSCE In. 966. Dafzlias. Y. F. and Herrmann. L. R. (1980). A hounding surface soil plasticiiy. Prac. fnr. Smp. &its Cyclic Trms. tnod.. Swansca. p. 335.

K.

HASHIG~~I~ of soil plasticity II ftrii .i~eech.-Fruns. to tsotroptc cohesive

Y. F. and Herrmann. L. R. (1982). Bounding surface fo~u~tion Lou& p. 253. John Wiley, New York.

Dafalias. Y. F. and Hemann.

soils. /. Engng .Uech. ASCE Dafak. Y. F. and ;Mrch. tt. 173.

L: R.

I I&

(1986). 1263.

Bounding

surface plastxity. hardening

: Application

Po~v.

E. P. t 1979. A

model of nonlinearly variables

materials

for complex loading. 4ctu

Dafalias. Y. F. and Pupov. E. P. (lY76).

Plastic Internal

formalism

of cyclic plastictty. J.

.dppl.,\fr&.

.-mfEJ3.645.

Dafalias. Y. F. and Popov. E. P. (1977). Cyclic loading for materials with a vanishing elastic domain. iVu&ar E%Jng Design 4;. 293. Drucker. D. C. (1951). A more fundamental approach IO plastic stress-strain relations. Prttc. Isr L:.S. &ut/. Conqr. Appl. Me& AS.\fE I. 487. Druckrr. D. C. (1988). Conventional and unconventional plastic response and representation. .-lpp/.Mech. Rw. AS.~fE41. 151. Dunear. R. (19X7). A viscoplastic bounding surface model for concrete under compressive and tensile condittons and its application to arch dam analysis. Prcx. 2ntI Inr. C& on Con.rrirtrrirc L~n~.r fi,r Enyinccrinq .tf~ler. Thror_r and Application. Tucson, p. 849. Edelman. F. and Drucker. D. C. (lY51). Some extensions of elemrntally plasticity theory. /. ~runklin Inr;. 251. 581. Fardis. M. N.. Al&e, B. and Tassoulas. L. (1983). Monotonic and cyclic constitutive htws for concrete. f. &qnq Afceh. ASCE 109, 516. Hashiguchi. K. and Ueno, hl. (1977). Elastoplastic constitutivc laws of soils. Constitutive Equations of Soils: Proc. 9th fC.SSIF&, Special Session 9. Tokyo, p. 73. Hashiguchi. K. ( 1978). Plastic cnnstitutive tyuatinns of granular materials. Prw. US-Jqwn Smrintrr Cmtmirttctrrrt MwIr. Sftttisk-d ~~pp?t~it~~t~..s in &fcrh. Grm. dfutrriuls.. Sendai. p. 32 I. Iiashipuchi, K. (197Y). Constitutrve cquaItons of granular mcdra uIth an antsotroptc hardcnmg. PWC-. 3rd Inr. Con/. Nwwr. Mcrh. Gconrdr., Aachcn, p. -IX. Hashiguchi. K. (19XOa). Cnnstitutive equations ofelastoplastic materials with elastic-plnsfic transition. J. .4ppl, ~ft*rh. ASAIE 47, 266. I Iashiguchi. K. ( IYXOh). AnIsotropic hardcnmp model for granular nxxha. f%-rnt.III I. S.rmp. .S<ioilr C,r& Trcms. l.wrd.. Swansca. p. 469. Ilashiguchi, K. (19X I). Constitutivc equations of elastopl;Istic materials with xuxotropic hardcmng and elastic plastx transition. J. ;tppl. ,Wech. .4SdlE Jx, 297. I LtshiguchI, K. (19x&). M~Icrt)ftlctric appmachcs -static intrinsically tirslc-indcFndcil1. Cvn~titutivo Laws of Soils: Prw. t 1 r/t IC:\MFf~.Discussion Session IA. San Francisco, p. 7.5. I Iashiguchi. K. (IYXSh). Sublading surfxc model of plasticity. fhd.. p, 117. I Iashiguchi. K. (198X). A mathcm;~Iical modilication of two surface model formulation in plasticity. Int. J. 5Xd.v Structurfs 24, 9x7.

L. R.. K;Ili;Ikin, V. A. M., Shen. C. K., Mush, K. D. and Zhu. Z.-Y. (19X6). Numcrtcal implcmcntation of plastici1y motlcl for cohcsivc soil\. J. fGiqny .tlc~<~lr. rl.SLE 113,500. flill. R. (195X). A grncd theory ol uniqucncss and sIahiJiIy in clasnc-plastic solids. J. ,tfwh. Phvv. Solids. 6. 236. t Iill. R. (1967). On the classical constiiutivc relations for elasliciplastic solids. Xecenf lroqtrcss in .4ppli~f~ .Meck., p. ?-II. Ilyushin, A. A. (1961). 0 postulate plastichnosti (On the postulate of plasticity). Prrk. ~bforh. .\frk. 25, 503 Ishlinski. 1. U. (195-I). Ceneralircd theorv of plasticity with linear srrnin hardcnina. Ukr. ~\fcrr. Z/I. 6. 31-I. Iwan. W. D. (15167). On ;I class of modcls~for ;hc yielding behavior ofcontinuous aid composite systems. J. A@. dfd. AS.\fE 34, 611. Klisinski. M. (19XX). Plasticity theory based on furzy set. J. Er)yuy .Ut*ctr. ,lSCE 114, 563. Klisimki, Xl. and Mror. Z. ( IYYY). Dcscrtption olinclastic drformaIIon ;tnd drgradalion ofconcrete. Inr. J. Solrtls .Sfnrcrurt*~ 24. 3Y I Kricg. R. D. ( lY75). A praciicai two surface plasticity theory. J. dp$. rClech. 4S,\IE42, Ml. Liung. R. K. K.. Sobhsnir. Xl. and Timmcrmann. D. if, (1987). A bounding surface plas1icity model for the stress -sIrain time behavior of clays. Proc. ?rrd fut. Ccm$ Consrirulire Imw Etl.qrig bfutw. : Thrur~ rrnd .Appficcttirm.v. Tucson, p. 699. Mair, G. and Ifuccksl. T. (1979). Non.IssociatcJ and coupled Bow rules of clastoplasticity for rock-like materials. int, J. Rod ,H&. Sfitr. &I. Gennrtd. Ah.st~. 16, 77. Marums, D. (1079).Sur un mod& Jc plsstioitti redant cornptc du comporIcmun1 cytliqtrc. 3Pnrr Cortyr. Fmnccri~ Masing. G. (lY26). Eigcnspannungcn und Vcrfcstigung bcim Messing. Proc. 2nd Iut. Cqyr. Appl. Much.. Zurich, i, 332. hlri,~, Z. ( lWk5). On forms of constituliie laws for elastic--plasttc s&Ids. ifrchii~rtt~1 ~~f~~fi~I~l~~i Sto.wwunt$ IH, 3. Mrhr. Z. 11967). On the dcscrintion of anisotropic workhardcninp. J. .Sfrdr. Phw Sdidv iS. 163. hl&. L. and Norris. V. A. (l&Z). Elas~oplast~c and viscoplastic constilutivc models for sds with anisotropic Trturx C)rlic Lode. p, 305. John Wilcv. SSH York. loadmg. Soil .\fdl.-Mrbt. 2.. Norris. V. A. and Zirnkicwicz. 0. C. (1481). An antsotropic, critical state mod& for soils subject to cyclic loading. Gcnrc&riqtrc 31, 45 I. hfroz. 2. xtd Zicnkicwtcz. 0. C. (lY84). Uniform forrnalitatiun of constiIut~vc cqu;ttions fur clays and sands. .\fdmic-cd Enyinwrrmt .M~r~cricrls.p. J 15. John Wiley. New York. Naylor. D. J. {1985). A continuous plasticity vcrsioin of the critical state model. (111.J. Ntrmrr. ,Cfcfh. Enyng 21, 1187.

I Icrrnuinn.

Subloading

surface model in unconventional

plasticity

945

Pande. G. N. and Pietruszczak, St. (1982). Reflecting surface model for soils. Proc. Isf Inf. Symp. Numer. MO&/S Geomech.. Zurich. p. 50. Pastor. M.. Zienkiewin, 0. C. and Leung. K. H. (1985). Simple model for transient soil loading in earthquake analysis. II. Non-associated models for sands. InI. 1. Ywner. Anal. Merho& Geomech. 9,471. Pietruszczak. St. (1986). A flow theory of soil : Concept of multiple neutral loading surface. hr. J. Compur.

Georech. 2. 185.

Prager. W. (1956). Recent development in the mathematical theory of plasticity. J. Appl. Mech. ASME 20,235. Tanaka. E.. Murakami. S. and Ooka. M. (1985). Effects of strain path shapes on nonproportional cyclic plasticity.

J. Mech. Phys. &lids 33.559.

Truesdell, C. (1955). Hypo-elasticity. J. Rutl. .Vech. Anal. 4. 83. Yang. B.-L.. Dafalias. Y. F. and Herrmann. L. R. (1985). A bounding

Eng. Mech. ASCE I Il. 359.

surface

plasticity

model for concrete.

J.

Ziegler. H. (1959). A modification of Pragers hardening rule. Q. Appl. Phy. 17, 55. Zienkiewicz. 0. C.. Leung. K. H. and Pastor. M. (1985). Simple model for transient soil loading in earthquake analysis. 1. Basic model and its application. fnr. J. Numrr. Anal. Melhoidr Geomech. 9.453. Zienkiewicz. 0. C. and Mr&. Z. (1984). Generalized plasticity formulation and application to geomechanics. Mech. Engineering Maferiuls. p. 655. John Wiley. New York. Zienkiewicz, 0. C. and Pastor, M. (1987). A general model for sand/soil behavior. Proc. 2nd fnr. Co& Constiturice L..aws Engng Mater. : Theor! and Applicarions. Tucson. p. 26 I.

You might also like