Professional Documents

Culture Documents

Factory-Made Wrought Buttwelding Fittings: Unit: U1 Textfile: B16P9$0001

Uploaded by

Panchal ShaileshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factory-Made Wrought Buttwelding Fittings: Unit: U1 Textfile: B16P9$0001

Uploaded by

Panchal ShaileshCopyright:

Available Formats

ASME B16.

9-2001

FACTORY-MADE WROUGHT BUTTWELDING FITTINGS

1 SCOPE 1.1 General This Standard covers overall dimensions, tolerances, ratings, testing, and markings for wrought factory-made buttwelding ttings in sizes NPS 12 through 48 (DN 15 through 1200). 1.2 Special Fittings Fittings may be made to special dimensions, sizes, shapes, and tolerances by agreement between the manufacturer and the purchaser. 1.3 Fabricated Fittings Fabricated laterals and other ttings employing circumferential or intersection welds are considered pipe fabrication, and are not within the scope of this Standard. 1.4 Standard Units The values stated in either metric or U.S. Customary units are to be regarded separately as standard. Within the text, the U.S. Customary units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this Standard. The designations for pressure rating and size are Class and NPS for both metric and customary dimensioned ttings. The designations PN and DN used in international standards are shown for reference convenience. 1.5 References 1.5.1 Referenced Standards. Standards and specications adopted by reference in this Standard are shown in Mandatory Appendix II. It is not considered practical to identify the specic edition of each standard and specication in the individual references. Instead, the specic edition reference is identied in Mandatory Appendix II. A product made in conformance with a prior edition of reference standards and in all other respects conforming to this Standard will be considered to be in conformance.

1

1.5.2 Codes and Regulations. A tting used under the jurisdiction of the ASME Boiler and Pressure Vessel Code, the ASME Code for Pressure Piping, or a governmental regulation is subject to any limitation of that code or regulation. This includes any maximum temperature limitation, or rule governing the use of a material at low temperature. 1.6 Service Conditions Criteria for selection of tting types and materials suitable for particular uid service are not within the scope of this Standard. 1.7 Welding Installation welding requirements are outside the scope of this Standard. 1.8 Quality Systems Nonmandatory requirements relating to the tting manufacturers Quality System Program are described in Nonmandatory Appendix A. 1.9 Convention For the purpose of determining conformance with this Standard, the convention for xing signicant digits where limits, maximum or minimum values, are specied shall be rounded off as dened in ASTM E 29. This requires that an observed or calculated value shall be rounded off to the nearest unit in the last righthand digit used in expressing the limit. Decimal value in the last and tolerances do not imply a particular method of measurement. 2 PRESSURE RATINGS 2.1 Basis of Ratings The allowable pressure ratings for ttings designed in accordance with this Standard may be calculated as for straight seamless pipe of equivalent material (as shown by comparison of composition and mechanical properties in the respective material specications) in accordance with the rules established in the applicable

You might also like

- Astm A53-18Document23 pagesAstm A53-18Cyd He82% (11)

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- Astm A27Document4 pagesAstm A27Rafael Elles100% (2)

- F439Document7 pagesF439cenkunal100% (1)

- Astm A370 - 18Document50 pagesAstm A370 - 18Ărash Âmirķhansarie78% (9)

- Astm A105Document5 pagesAstm A105ahmad0% (1)

- Astm A27 (2013) PDFDocument4 pagesAstm A27 (2013) PDFStuar TencioNo ratings yet

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument13 pagesSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipesdgkmurti100% (1)

- Manual CTI Technical Manual PDFDocument39 pagesManual CTI Technical Manual PDFaricomen43% (7)

- Astm A105 2021Document5 pagesAstm A105 2021Pedrito Calapucha100% (2)

- Crumb RubberDocument30 pagesCrumb RubberAjinkya Mali100% (1)

- Astm A105-A105m-21Document5 pagesAstm A105-A105m-21Nicolas CgNo ratings yet

- A 249 - A 249M - 16a PDFDocument10 pagesA 249 - A 249M - 16a PDFأسامة وحيد الدين رمضانNo ratings yet

- Astm A578Document5 pagesAstm A578amein kaidNo ratings yet

- Seamless Carbon Steel Pipe For High-Temperature ServiceDocument8 pagesSeamless Carbon Steel Pipe For High-Temperature Servicejose moralesNo ratings yet

- Astm A 312-2021Document13 pagesAstm A 312-2021Mohammed AliNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- ASTM A924 - A924M - 22aDocument14 pagesASTM A924 - A924M - 22aOS LaboratoryNo ratings yet

- Mos GRPDocument53 pagesMos GRPslxanto100% (3)

- A312a312m 24057 PDFDocument13 pagesA312a312m 24057 PDFIra Roni YudaNo ratings yet

- A962a962m 18Document13 pagesA962a962m 18AFQBAVQ2EFCQF31FNo ratings yet

- ASTM A312 - A312M - 22aDocument13 pagesASTM A312 - A312M - 22aDjaffar Salahoui100% (2)

- Astm A53-A53m 2018Document23 pagesAstm A53-A53m 2018Lewis M. Nixon100% (4)

- Astm A530 A530m-18Document9 pagesAstm A530 A530m-18Rafa Pontón RNo ratings yet

- ASTM A370-18 Mechanical Testing of Steel ProductsDocument50 pagesASTM A370-18 Mechanical Testing of Steel ProductsMaria Paulina Holguin PatiñoNo ratings yet

- Industrial Automation and Control SyllabusDocument3 pagesIndustrial Automation and Control Syllabusyr48No ratings yet

- Astm A 182-2021Document17 pagesAstm A 182-2021Mohammed Ali100% (1)

- Info Gas StationsDocument70 pagesInfo Gas StationsGuillermo CorderoNo ratings yet

- Pipe Flanges and Flanged Fittings: NPS Through Nps 24 Metric/Inch StandardDocument1 pagePipe Flanges and Flanged Fittings: NPS Through Nps 24 Metric/Inch StandardPanchal ShaileshNo ratings yet

- Pipe Flanges and FittingsDocument12 pagesPipe Flanges and FittingsBangun KartaNo ratings yet

- MDC19 PS Asm 01Document27 pagesMDC19 PS Asm 01abdul0rohiminNo ratings yet

- Public Review Draft 2145Document21 pagesPublic Review Draft 2145AmeliaPrisiliaNo ratings yet

- Astm A105 A105m 21Document5 pagesAstm A105 A105m 21miraclemj35No ratings yet

- 1 Scope PDFDocument1 page1 Scope PDFedisjdavNo ratings yet

- MSS SP-88 (1993)Document15 pagesMSS SP-88 (1993)jothishNo ratings yet

- Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution SystemsDocument5 pagesManually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution SystemsRichard PNo ratings yet

- 1 - Introductoin To Non-Newtonian Fluid Time IndependentDocument13 pages1 - Introductoin To Non-Newtonian Fluid Time Independentsuruchi shrivastavaNo ratings yet

- A312a312m 24800Document13 pagesA312a312m 24800Med Ali SmaouiNo ratings yet

- Astm A53 A53m 20Document23 pagesAstm A53 A53m 20alvin dueyNo ratings yet

- Astm A249Document5 pagesAstm A249TeoTyJayNo ratings yet

- Astm A182 A182m 22Document7 pagesAstm A182 A182m 22Adco forge & fittings pvt ltdNo ratings yet

- Common Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeDocument13 pagesCommon Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeradziNo ratings yet

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 pagesSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesHugo IgrejaNo ratings yet

- Standard Specification For Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and SeamlessDocument23 pagesStandard Specification For Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and SeamlessPriya DharshiniNo ratings yet

- Mechanical Testing of Steel Products: Standard Test Methods and Definitions ForDocument50 pagesMechanical Testing of Steel Products: Standard Test Methods and Definitions ForMohammad Zaki UsmanNo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument13 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessOS LaboratoryNo ratings yet

- Astm A249a249m-16Document10 pagesAstm A249a249m-16Eugene DerkachNo ratings yet

- Astm A194 A194m 23Document7 pagesAstm A194 A194m 23Kalanithi GKNo ratings yet

- Seamless Carbon Steel Pipe For High-Temperature ServiceDocument9 pagesSeamless Carbon Steel Pipe For High-Temperature ServicePetrusTampubolonNo ratings yet

- Astm A234-23Document10 pagesAstm A234-23fadfadg2No ratings yet

- This Study Resource Was Shared Via: Carbon Steel Forgings For Piping ApplicationsDocument5 pagesThis Study Resource Was Shared Via: Carbon Steel Forgings For Piping ApplicationsMuñes santiagoNo ratings yet

- Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser TubesDocument11 pagesWelded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubesist93993No ratings yet

- Hot Isostatically-Pressed Alloy Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDocument8 pagesHot Isostatically-Pressed Alloy Steel Flanges, Fittings, Valves, and Parts For High Temperature Servicesfinal_1No ratings yet

- Astm A312 A312m 19Document6 pagesAstm A312 A312m 19Weijin LeowNo ratings yet

- Astm A1014 A1014m 16 2021Document3 pagesAstm A1014 A1014m 16 2021Milady OyuelaNo ratings yet

- Common Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeDocument13 pagesCommon Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep Rangesafak kahramanNo ratings yet

- SP 97 2006Document15 pagesSP 97 2006Miteshshinde17No ratings yet

- Metal-Arc-Welded Carbon or High-Strength Low-Alloy Steel Pipe For Use With High-Pressure Transmission SystemsDocument4 pagesMetal-Arc-Welded Carbon or High-Strength Low-Alloy Steel Pipe For Use With High-Pressure Transmission Systemsist93993No ratings yet

- Your Reliable Supplier of Ferrous & Nonferrous Piping Materials!Document48 pagesYour Reliable Supplier of Ferrous & Nonferrous Piping Materials!Heru HermansyahNo ratings yet

- 14 Astm A312 A312m-2017Document13 pages14 Astm A312 A312m-2017FYNo ratings yet

- A1014 A1014m - 2010Document4 pagesA1014 A1014m - 2010hugo_siqueira_11No ratings yet

- D 1527 - 99 - Rde1mjctukve PDFDocument11 pagesD 1527 - 99 - Rde1mjctukve PDFKhoai Sai GonNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Sec-I 136Document1 pageSec-I 136Panchal ShaileshNo ratings yet

- Sec-I 133Document1 pageSec-I 133Panchal ShaileshNo ratings yet

- Sec-I 138Document1 pageSec-I 138Panchal ShaileshNo ratings yet

- Sec-I 140Document1 pageSec-I 140Panchal ShaileshNo ratings yet

- Sec-I 139Document1 pageSec-I 139Panchal ShaileshNo ratings yet

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 pageTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNo ratings yet

- Sec-I 132Document1 pageSec-I 132Panchal ShaileshNo ratings yet

- Sec-I 131Document1 pageSec-I 131Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNo ratings yet

- Sec-I 128Document1 pageSec-I 128Panchal ShaileshNo ratings yet

- Sec-I 121Document1 pageSec-I 121Panchal ShaileshNo ratings yet

- Sec-I 127Document1 pageSec-I 127Panchal ShaileshNo ratings yet

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshNo ratings yet

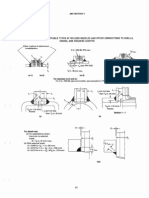

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Sec-I 129Document1 pageSec-I 129Panchal ShaileshNo ratings yet

- Sec-I 130Document1 pageSec-I 130Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNo ratings yet

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 pageFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNo ratings yet

- Sec-I 119Document1 pageSec-I 119Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Sec-I 117Document1 pageSec-I 117Panchal ShaileshNo ratings yet

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 pageFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNo ratings yet

- Design: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessDocument1 pageDesign: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessPanchal ShaileshNo ratings yet

- Sec-I 116Document1 pageSec-I 116Panchal ShaileshNo ratings yet

- Manufacturer'S Data Report Forms: 2007 Section IDocument1 pageManufacturer'S Data Report Forms: 2007 Section IPanchal ShaileshNo ratings yet

- Sec-I 113Document1 pageSec-I 113Panchal ShaileshNo ratings yet

- Sec-I 112Document1 pageSec-I 112Panchal ShaileshNo ratings yet

- Sec-I 114Document1 pageSec-I 114Panchal ShaileshNo ratings yet

- BismuthDocument16 pagesBismuthlostgrailNo ratings yet

- Semiconductor Memories Semiconductor Memories Semiconductor Memories Semiconductor MemoriesDocument37 pagesSemiconductor Memories Semiconductor Memories Semiconductor Memories Semiconductor MemoriesPriyank DevpuraNo ratings yet

- Density AltitudeDocument4 pagesDensity AltitudesubhashcbNo ratings yet

- Brochure Lievers HollandDocument8 pagesBrochure Lievers HollandAKHILNo ratings yet

- Radio Electronics 1963 12 PDFDocument118 pagesRadio Electronics 1963 12 PDFkachappilly2012100% (1)

- Chapter 5 QS015 2017 18 Nota Pelajar 1Document220 pagesChapter 5 QS015 2017 18 Nota Pelajar 1Ahmad MutqmaNo ratings yet

- Sci NotesDocument4 pagesSci NotesnidhiyourmomNo ratings yet

- FLY231GBDocument8 pagesFLY231GBIon VasileNo ratings yet

- 2006 01 0884Document38 pages2006 01 0884Yosra RamadhanNo ratings yet

- Data Compression TechniquesDocument20 pagesData Compression TechniquesAbhishek kumar singh100% (2)

- Radiation QuestionsDocument27 pagesRadiation QuestionsSteve BishopNo ratings yet

- Method Development and Validation For Estimation of Dosulepin in Pure and Dosage Form by Using HPLCDocument8 pagesMethod Development and Validation For Estimation of Dosulepin in Pure and Dosage Form by Using HPLCBaru Chandrasekhar RaoNo ratings yet

- An Elementary Proof For Fermat's Last Theorem Using An Euler's EquationDocument9 pagesAn Elementary Proof For Fermat's Last Theorem Using An Euler's EquationGagan DeepNo ratings yet

- Solid Solution StrengtheningDocument23 pagesSolid Solution StrengtheningAdivadewanggaNo ratings yet

- Desen Tehnic Note de Curs Si Aplicatii - Macarie Si Olaru - 2007Document432 pagesDesen Tehnic Note de Curs Si Aplicatii - Macarie Si Olaru - 2007alexNo ratings yet

- Force Table: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-9447Document18 pagesForce Table: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-9447joanally bagoyoNo ratings yet

- Molecules 18 02328Document48 pagesMolecules 18 02328Yamid OrtizNo ratings yet

- Hooke's Law (4Document30 pagesHooke's Law (4Clark Harold Balido50% (2)

- Franc3D V6 Nastran TutorialDocument52 pagesFranc3D V6 Nastran TutorialSandeep BhatiaNo ratings yet

- Ordering PrinciplesDocument40 pagesOrdering PrinciplesriyamNo ratings yet

- Energy Guide Midea - Mrc07m6aww Mrc07m6ewwDocument1 pageEnergy Guide Midea - Mrc07m6aww Mrc07m6ewwharry HendersonNo ratings yet

- An Alternative Method For The Removal of Surfactants From WaterDocument7 pagesAn Alternative Method For The Removal of Surfactants From WatervahidNo ratings yet

- Luisa 1Document20 pagesLuisa 1Walenty JanowiczNo ratings yet

- Sci 202 - Course GuideDocument8 pagesSci 202 - Course GuideRicardo VelozNo ratings yet

- DM Water Tank SpecificationDocument9 pagesDM Water Tank SpecificationManish PatelNo ratings yet

- Skema Kertas 3Document13 pagesSkema Kertas 3rhimalinyNo ratings yet