Professional Documents

Culture Documents

HT P1200

Uploaded by

vantuyetphamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HT P1200

Uploaded by

vantuyetphamCopyright:

Available Formats

1.

Precautions

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential hazards such as electrical shock and X-rays.

1-1 Safety Precautions

1. Be sure that all of the built-in protective devices are replaced. 2. When reinstalling the chassis and its assemblies, be sure to restore all protective devices, including control knobs and compartment covers. 3. Make sure that there are no cabinet openings through which people-particularly children--might insert fingers and contact dangerous voltages. Such openings include the spacing between the picture tube and the cabinet mask, excessively wide cabinet ventilation slots, and improperly fitted back covers. 4. Design Alteration Warning: Never alter or add to the mechanical or electrical design of the unit. Example: Do not add auxiliary audio or video connectors. Such alterations might create a safety hazard. Also, any design changes or additions will void the manufacturer's warranty. 5. Leakage Current Hot Check (Figure 1-1): Warning: Do not use an isolation transformer during this test. Use a leakagecurrent tester or a metering system that complies with American National Standards Institute (ANSI C101.1, Leakage Current for Appliances), and Underwriters Laboratories (UL Publication UL1410, 59.7). With the unit completely reassembled, plug the AC line cord directly into a 120V AC outlet. With the unit's AC switch first in the ON position and then OFF, measure the current between a known earth ground (metal water pipe, etc.) and all exposed metal parts. Examples: Handle brackets, metal cabinets, screwheads and control shafts. The current measured should not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat.

Fig. 1-2 Insulation Resistance Test

Fig. 1-1 AC Leakage Test

6. Insulation Resistance Cold Check: (1) With the unit's AC plug disconnected from the AC source, connect an electrical jumper across the two AC prongs. (2) Set the power switch to ON. (3) Measure the resistance between the shorted AC plug and any exposed metallic parts. Example: Screwheads, antenna, control shafts or handle brackets. If any of the exposed metallic parts has a return path to the chassis, the measured resistance should be between 1 and 5.2 megohms. If there is no return path, the measured resistance should be "infinite." If the resistance is outside these limits, a shock hazard might exist. See Figure 1-2

Samsung Electronics

1-1

Precautions

1-1 Safety Precautions (Continued)

7. Components, parts and wiring that appear to have overheated or that are otherwise damaged should be replaced with parts that meet the original specifications. Always determine the cause of damage or overheating, and correct any potential hazards 8. Observe the original lead dress, especially near the following areas: Antenna wiring, sharp edges, and especially the AC and high voltage power supplies. Always inspect for pinched, out-of-place, or frayed wiring. Do not change the spacing between components and the printed circuit board. Check the AC power cord for damage. Make sure that no wires or components touch thermally hot parts. 9. Product Safety Notice: Some electrical and mechanical parts have special safety-related characteristics which might not be obvious from visual inspection. These safety features and the protection they give might be lost if the replacement component differs from the original--even if the replacement is rated for higher voltage, wattage, etc. 10 Components that are critical for safety are indicated in the circuit diagram by shading, or . Use replacement components that have the same ratings, especially for flame resistance and dielectric strength specifications. A replacement part that does not have the same safety characteristics as the original might create shock, fire or other hazards.

1-2 Servicing Precautions

Warning1: First read the "Safety Precautions" section of this manual. If some unforeseen circumstance creates a conflict between the servicing and safety precautions, always follow the safety precautions.

1. Servicing precautions are printed on the cabinet. Follow them. 2. Always unplug the unit's AC power cord from the AC power source before attempting to: (a) Remove or reinstall any component or assembly, (b) Disconnect an electrical plug or connector, (c) Connect a test component in parallel with an electrolytic capacitor. 3. Some components are raised above the printed circuit board for safety. An insulation tube or tape is sometimes used. The internal wiring may be clamped to prevent contact with thermally hot components. Reinstall all such elements to their original position. 4. After servicing, always check that the screws, components and wiring have been correctly reinstalled. Make sure that the portion around the serviced part has not been damaged.

5. Check the insulation between the blades of the AC plug and accessible conductive parts (examples: metal panels, input terminals and earphone jacks). 6. Insulation Checking Procedure: Disconnect the power cord from the AC source and turn the power switch ON. Connect an insulation resistance meter (500V) to the blades of the AC plug. The insulation resistance between each blade of the AC plug and accessible conductive parts (see above) should be greater than 1 megohm. 7. Never defeat any of the B+ voltage interlocks. Do not apply AC power to the unit (or any of its assemblies) unless all solid-state heat sinks are correctly installed. 8. Always connect a test instrument's ground lead to the instrument chassis ground before connecting the positive lead; always remove the instrument's ground lead last.

1-2

Samsung Electronics

Precautions

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor ("solid state") devices are easily damaged by static electricity. Such components are called Electrostatically Sensitive Devices (ESDs). Examples include integrated circuits and some field-effect transistors. The following techniques will reduce the occurrence of component damage caused by static electricity. 2. Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device. (Be sure to remove it prior to applying power--this is an electric shock precaution.) 3. After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to prevent accumulation of electrostatic charge. 4. Do not use freon-propelled chemicals. These can generate electrical charges that damage ESDs. 5. Use only a grounded-tip soldering iron when soldering or unsoldering ESDs. 6. Use only an anti-static solder removal device. Many solder removal devices are not rated as "anti-static" (these can accumulate sufficient electrical charge to damage ESDs). 7. Do not remove a replacement ESD from its protective package until you are ready to install it. Most replacement ESDs are packaged with leads that are electrically shorted together by conductive foam, aluminum foil or other conductive materials. 8. Immediately before removing the protective material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed. 9. Minimize body motions when handing unpackaged replacement ESDs. Motions such as brushing clothes together, or lifting a foot from a carpeted floor can generate enough static electricity to damage an ESD.

1-4 Special Precautions and Warning Labels for Laser Products

(UL) This Product Complies with DHHS Rules 21CFR, Sub chapter J.At date of Manufacture (CSA) CERTIFIED ONLY TO CANADIAN ELECTRICAL CODE. CERTIFIE EN VERTU DU CODE CANADIAN DE LELETRICITE SEULEMENT (UL,CSA,EU)

CLASS 1 LASER PRODUCT

Fig. 1-3 Warning Labels (Location: Enclosure Block)

(UL,CSA,SCAN)

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATEO AVOIDEXPOSURE TO BEAM ADVARSEL: USYNLIG LASERSTRLING VED ABNING

NR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION UNDGA UDSAETTELSE FOR STRALING

(EU)

VARO:AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTINA NAKYMATTMALLE LASERSATEILYLLE ALA KATSO SATEESEEN!

UL CSA EU SCAN

VARNING:OSYNLIG LASERSTRLNING NAR DENNA DEL

AR OPPNAD OCH SPARREN AR URKOPPLAD BETRAKTA EJSTRLEN!

: Manufactured for U.S.A. Market. : Manufactured for Canadian Market. : Manufactured for European Market. : Manufactured for Scandinavian Market.

Fig. 1-4 Warning Labels (Location: Disc Clamper, Inner Side of Unit Door or Nearby Unit Chassis )

Samsung Electronics

1-3

Precautions

1-4 Special Precautions and Warning Labels for Laser Products (Continued)

1-4-1 Warnings 1. When servicing, do not approach the LASER exit with the eye too closely. In case it is necessary to confirm LASER beam emission, be sure to observe from a distance of more than 30 cm from the surface of the objective lens on the optical pick-up block. 2. Do not attempt to handle the objective lens when the DISC is not on the tray. 1-4-2 Laser Diode Specifications Material: GaAs+ GaAlAs Wavelength: 760-800 nm Emission Duration: Continuous Laser Output: 0.2 mw (measured at a 1.6 mm distance from the objective lens surface on the optical pick-up block.) 1-4-3 Handling the Optical Pick-up 1. Static electricity from clothing or the body may cause electrostatic breakdown of the laser diode in the Optical Pickup. Follow this procedure: 2. Place a conductive sheet on the work bench (i.e., the black sheet used for wrapping repair parts.) Note: The surface of the work bench should be covered by a copper ground plane, which is grounded. 3. The repair technician must wear a wrist strap which is grounded to the copper sheet. 4. To remove the Optical Pickup block: Place the set on the conductive sheet, and momentarily touch the conductive sheet with both hands. (While working, do not allow any electrostatic sources--such as clothes--to touch the unit.) 5. Ground the "Short Terminal" (located on the PCB, inside the Pickup Assembly) before replacing the Pickup. This terminal should be shorted whenever the Pickup Assembly is lifted or moved. 6. After replacing the Pickup, reopen the Short Terminal. See diagrams below:

1-5 Special Precautions for HDD

* HDD Data Maintenance Step 1. Since the data on the HDD is weak to mechanical shock, place the HDD in a safe location that is free from mechanical shock once it is removed from the main unit. 2. In order to safe keep the data on the HDD, back up the data before the repair or make sure not to place the HDD near any electrical appliance that generates a strong magnetic field. 1-4 Samsung Electronics

You might also like

- Samsung HT-Q9 Re Product or de DVD Manual de ServicioDocument51 pagesSamsung HT-Q9 Re Product or de DVD Manual de ServicionixrinNo ratings yet

- Manual Servico Mini System Samsung Max g55td XazDocument70 pagesManual Servico Mini System Samsung Max g55td XazAntonio CunhaNo ratings yet

- Samsung Max-Dx75!76!79 Kx75 SMDocument41 pagesSamsung Max-Dx75!76!79 Kx75 SMJorch Ramirez Estrada50% (2)

- Samsung Gly26ke Gly32ke Gly37ke Gly40ke Chassis Le26r73bd r74bd Le32r73bd Le37r74bd Le40r73bd LCD TV SMDocument292 pagesSamsung Gly26ke Gly32ke Gly37ke Gly40ke Chassis Le26r73bd r74bd Le32r73bd Le37r74bd Le40r73bd LCD TV SMyomismoNo ratings yet

- 1-1 Safety PrecautionsDocument4 pages1-1 Safety PrecautionsCarlos GonçalvesNo ratings yet

- 1-1 Safety PrecautionsDocument4 pages1-1 Safety PrecautionsChirita ElenaNo ratings yet

- Manual de Servicio Samsung MAX-X55!56!66Document44 pagesManual de Servicio Samsung MAX-X55!56!66Mauro Mangialavori0% (1)

- LE32S71 - Service ManualDocument160 pagesLE32S71 - Service Manualbidule78No ratings yet

- ER-260 265 AU User ManualDocument109 pagesER-260 265 AU User ManualRadu Baciu-NiculescuNo ratings yet

- PrecautionDocument2 pagesPrecautionNita CatalinNo ratings yet

- 1-1 Safety PrecautionsDocument2 pages1-1 Safety Precautionsyo9bmnNo ratings yet

- Samsung hln467 567wx Xaa CH L62a-N Rev.3Document131 pagesSamsung hln467 567wx Xaa CH L62a-N Rev.3uberplasmaNo ratings yet

- Manual Servico Mini System Samsung Max g55td XazDocument70 pagesManual Servico Mini System Samsung Max g55td XazNosdan LemosNo ratings yet

- 01 PrecautionsDocument4 pages01 PrecautionsJorge Fernando de TivantaNo ratings yet

- SRP-350 v2 SVC EngDocument125 pagesSRP-350 v2 SVC EngMichael HanniganNo ratings yet

- Samsung 550VDocument65 pagesSamsung 550VClaudio Hector ArrosaNo ratings yet

- 1-1 Safety PrecautionsDocument4 pages1-1 Safety PrecautionsJonbra CartoNo ratings yet

- Samsung Cft24907x CH Ks2aDocument47 pagesSamsung Cft24907x CH Ks2asupermax900No ratings yet

- Samsung DVD TV Chassis C16ADocument82 pagesSamsung DVD TV Chassis C16Acclodoaldo1577No ratings yet

- Precaution PDFDocument4 pagesPrecaution PDFreis silvaNo ratings yet

- Ps42p2std CH D53aDocument128 pagesPs42p2std CH D53aLuděk CsibaNo ratings yet

- Toshiba 14 - 21r - t01 Ch. Ks1aDocument61 pagesToshiba 14 - 21r - t01 Ch. Ks1aEric NoiretteNo ratings yet

- Samsung Ks3aDocument49 pagesSamsung Ks3aJanel WatsonNo ratings yet

- Samsung Sp42w4hpx, Sp43t7hpx CH J54aDocument78 pagesSamsung Sp42w4hpx, Sp43t7hpx CH J54aDustin McculloughNo ratings yet

- Samsung Pg17n, Pg19n Service ManualDocument85 pagesSamsung Pg17n, Pg19n Service ManualAZAD MATUBBERNo ratings yet

- Samsung S19a300b S19a300n S20a300b S20a300n S22a300b S23a300b S24a300b S24a300bl Chassis wdm1 LCDocument41 pagesSamsung S19a300b S19a300n S20a300b S20a300n S22a300b S23a300b S24a300b S24a300bl Chassis wdm1 LCMocanu RaduNo ratings yet

- SAMSUNG LCD Service Manual (Internal) - ES15UDocument81 pagesSAMSUNG LCD Service Manual (Internal) - ES15Umeng798651No ratings yet

- SAMSUNG LCD Service Manual Internal) - ES15UDocument81 pagesSAMSUNG LCD Service Manual Internal) - ES15Uqwerzwill905560No ratings yet

- 1-1 Safety PrecautionsDocument4 pages1-1 Safety PrecautionsAdriano Alves Do NascimentoNo ratings yet

- Samsung CL29K3W Chassis KS3ADocument92 pagesSamsung CL29K3W Chassis KS3AHernan Ortiz EnamoradoNo ratings yet

- Samsung Cl29k3w8x STR CH Ks3aDocument53 pagesSamsung Cl29k3w8x STR CH Ks3aHugo G.No ratings yet

- Samsung LE26S81BHX Chassis GJA26TSADocument159 pagesSamsung LE26S81BHX Chassis GJA26TSANina SeimeniNo ratings yet

- Samsung Chassis S51aDocument49 pagesSamsung Chassis S51aAlan BurnNo ratings yet

- 1 Precautio: Ns 1-1 Safety PrecautionsDocument4 pages1 Precautio: Ns 1-1 Safety PrecautionslvmottaNo ratings yet

- CN565BW CN765DWC Kct57aDocument49 pagesCN565BW CN765DWC Kct57aEduardo AlanisNo ratings yet

- Samsung 540, 740, 940 Service ManualDocument98 pagesSamsung 540, 740, 940 Service Manualike4546No ratings yet

- FilesDocument97 pagesFilessyamsuddin semNo ratings yet

- Service: ManualDocument31 pagesService: ManualsumidinNo ratings yet

- TV Samsung - Le27s73bd - Le32s73bd - Le37s73bd - Le40s73bd - Chassis - Gsd27-32-37-40se - LCD - TVDocument203 pagesTV Samsung - Le27s73bd - Le32s73bd - Le37s73bd - Le40s73bd - Chassis - Gsd27-32-37-40se - LCD - TVpepenasaNo ratings yet

- Samsung Sync Master 955DF AQ19LS AQ19JSDocument62 pagesSamsung Sync Master 955DF AQ19LS AQ19JSClaudio Hector ArrosaNo ratings yet

- Chassis KS2A-N Manual de Servicio PDFDocument56 pagesChassis KS2A-N Manual de Servicio PDFRamonAlbertoFernandezNo ratings yet

- Cl-29a5w8x Cl29a6p Ks3aDocument79 pagesCl-29a5w8x Cl29a6p Ks3aaerodomoNo ratings yet

- Cs 767amtrx - BWT CH - Sct55a (SM)Document62 pagesCs 767amtrx - BWT CH - Sct55a (SM)Roberd MihailovNo ratings yet

- Le40 - 46n87bcx Chassis GTUxxDocument204 pagesLe40 - 46n87bcx Chassis GTUxxDarcio DarNo ratings yet

- Samsung p2770hd Chassis Lem27dsDocument65 pagesSamsung p2770hd Chassis Lem27dsboroda2410100% (2)

- Color Television Receiver: Chassis: S15A Model: CS3339Z6X/TAW CS3366Z6X/AWE CS5039Z6X/AWEDocument66 pagesColor Television Receiver: Chassis: S15A Model: CS3339Z6X/TAW CS3366Z6X/AWE CS5039Z6X/AWEمحمد حشيشNo ratings yet

- CW 29 M 064 VpxxecDocument75 pagesCW 29 M 064 VpxxecAnonymous hOHi6TZTnNo ratings yet

- Samsung ck6202x3s, ck6202x3x Chassis S51a Service Manual PDFDocument50 pagesSamsung ck6202x3s, ck6202x3x Chassis S51a Service Manual PDFMohammad MousavikNo ratings yet

- TV-LED - Samsung - UN32EH4000 - Chasis U71A - B PDFDocument108 pagesTV-LED - Samsung - UN32EH4000 - Chasis U71A - B PDFJorge Clavel20% (5)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- HT P1200Document3 pagesHT P1200vantuyetphamNo ratings yet

- HT P1200Document10 pagesHT P1200vantuyetphamNo ratings yet

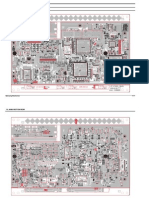

- PCB Diagram: 1-1. Main (Top View)Document5 pagesPCB Diagram: 1-1. Main (Top View)vantuyetphamNo ratings yet

- HT P1200Document16 pagesHT P1200vantuyetphamNo ratings yet

- Block Diagram: 9-1 MAIN PartDocument1 pageBlock Diagram: 9-1 MAIN PartvantuyetphamNo ratings yet

- Wiring Diagram: Samsung Electronics 10-1Document1 pageWiring Diagram: Samsung Electronics 10-1vantuyetphamNo ratings yet

- HT P1200Document4 pagesHT P1200vantuyetphamNo ratings yet

- Entertaining The Costco WayDocument276 pagesEntertaining The Costco Wayhwmaw100% (1)

- Troubleshooting: 1. No PowerDocument2 pagesTroubleshooting: 1. No PowervantuyetphamNo ratings yet

- HT P1200Document4 pagesHT P1200vantuyetphamNo ratings yet

- Cryomed CRF Model 7452Document120 pagesCryomed CRF Model 7452vantuyetphamNo ratings yet

- Personality Theories - George BoereDocument284 pagesPersonality Theories - George BoerePascaru Adela-cosminaNo ratings yet

- Table of ContentsDocument4 pagesTable of ContentsvantuyetphamNo ratings yet

- Diagrama Motor c15 CATDocument4 pagesDiagrama Motor c15 CATEduardo Rels TGNo ratings yet

- Network Blu-Ray Disc / DVD Home Theater System: Service ManualDocument151 pagesNetwork Blu-Ray Disc / DVD Home Theater System: Service ManualAlexNo ratings yet

- Manual DibalDocument61 pagesManual DibalYldemar PerezNo ratings yet

- Manual de Diagnostico S 1.6Document28 pagesManual de Diagnostico S 1.6Kaique Mello100% (1)

- Multi Panel Meter MT4Y/MT4W SeriesDocument11 pagesMulti Panel Meter MT4Y/MT4W SeriesRicky HardiansyahNo ratings yet

- Manual Lippke4500Document40 pagesManual Lippke4500Arkhano Jhoss Gio0% (1)

- DSG ValvesDocument17 pagesDSG ValvesChris RoederNo ratings yet

- Installation Manual Heavy Duty Submersible Effluent/Dewatering PumpsDocument30 pagesInstallation Manual Heavy Duty Submersible Effluent/Dewatering PumpsJULY151989No ratings yet

- Acsr Conductors AccessoriesDocument7 pagesAcsr Conductors Accessoriesashok10577No ratings yet

- Rru 3804Document16 pagesRru 3804Miguel Angel Lara RochaNo ratings yet

- SN09031510A HV Termination Plug For No Load KV TroubleshootingDocument19 pagesSN09031510A HV Termination Plug For No Load KV TroubleshootingJavier PayáNo ratings yet

- Eco 2888Document3 pagesEco 2888Jonathan SuarezNo ratings yet

- Accessories PDFDocument20 pagesAccessories PDFcmct0819No ratings yet

- Samsung HLT 6156 Service ManualDocument142 pagesSamsung HLT 6156 Service ManualWilliam Redick100% (1)

- Partida 5. TT-10415D Ensamble RTD-Termopozo SOR SSI Temperature Sensors BrochureDocument44 pagesPartida 5. TT-10415D Ensamble RTD-Termopozo SOR SSI Temperature Sensors BrochureAndree' WsNo ratings yet

- S5 Uj08e10aDocument339 pagesS5 Uj08e10aGeorge Patrick100% (1)

- Sony Anycast Station Aws-G500e OpmDocument313 pagesSony Anycast Station Aws-G500e OpmanselmocassianoNo ratings yet

- Presostato PM1Document30 pagesPresostato PM1tunradotNo ratings yet

- EHV Cable Accessories: The Complete Range For All 300-550 KV High-Voltage CablesDocument4 pagesEHV Cable Accessories: The Complete Range For All 300-550 KV High-Voltage CablesdeltaNo ratings yet

- Service Manual: 20010915-18000 Hamamatsu, JapanDocument19 pagesService Manual: 20010915-18000 Hamamatsu, JapanTvbox 15No ratings yet

- TECHNICAL RERORT of IptDocument18 pagesTECHNICAL RERORT of IptBihinda Rashidi0% (1)

- TopFlite Components - Tinel - Lock® RingDocument1 pageTopFlite Components - Tinel - Lock® Ringbruce774No ratings yet

- Neoclassic300bpre Manual 10 08 PDFDocument12 pagesNeoclassic300bpre Manual 10 08 PDFandree wNo ratings yet

- ULP (Universal Logic Plug) System User GuideDocument148 pagesULP (Universal Logic Plug) System User GuideNebojsa DelibasicNo ratings yet

- Flash ProDocument143 pagesFlash ProDavid WalkerNo ratings yet

- Fluiddrawp6enus PDFDocument395 pagesFluiddrawp6enus PDFWilfredo AchoNo ratings yet

- Si210 Wiring and ConnectionsDocument30 pagesSi210 Wiring and ConnectionsFERNS0% (1)

- Chapter 8 Air Bag SystemDocument11 pagesChapter 8 Air Bag Systemjhon greigNo ratings yet

- Service Manual LK14M42 LT0661Document893 pagesService Manual LK14M42 LT0661KHALED ALINo ratings yet