Professional Documents

Culture Documents

Guide Wincc

Uploaded by

จ่า นิก0 ratings0% found this document useful (0 votes)

550 views124 pagessiemens wincc

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsiemens wincc

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

550 views124 pagesGuide Wincc

Uploaded by

จ่า นิกsiemens wincc

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 124

Configuration Guide SIMATIC BATCH

for WinCC V7.1 SP1

___________________

___________________

___________________

___________________

___________________

___________

___________

___________________

___________________

___________________

___________________

___________________

SIMATIC

BATCH

Configuration Guide SIMATIC

BATCH for WinCC V7.1 SP1

Programming and Operating Manual

05/2010

A5E02829586-02

Preface

1

Introduction to the

Configuration Guide

2

Overview of the configuration

tasks

3

Configuration steps in the

SIMATIC Manager

4

Configuration steps in the

WinCC Explorer

5

Configuration tasks in MS

Excel with the WinCC

Configuration Tool

6

Configuration tasks in the

SIMATIC Manager

configuration dialog

7

Process picture for units and

equipment phases

8

Example of a Batch

Configuration

9

Interface description

10

SIMATIC IT Historian

11

Abbreviations

12

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NRNBERG

GERMANY

A5E02829586-02

05/2010

Copyright Siemens AG 2010.

Technical data subject to change

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 3

Table of contents

1 Preface...................................................................................................................................................... 7

2 Introduction to the Configuration Guide ................................................................................................... 11

2.1 Installation of the Software Components.....................................................................................11

2.2 Additional Information for the Configuration Example .................................................................12

0 Basics...........................................................................................................................................13

2.2.1 System Components....................................................................................................................13

2.2.2 PC Configurations........................................................................................................................14

2.2.3 Communication............................................................................................................................15

2.2.4 Time synchronization...................................................................................................................16

3 Overview of the configuration tasks ......................................................................................................... 17

4 Configuration steps in the SIMATIC Manager.......................................................................................... 19

4.1 Basic procedure...........................................................................................................................19

4.2 Standard blocks of the SIMATIC BATCH library .........................................................................20

4.3 User function block for the control of an equipment phase .........................................................21

4.4 User function block for the control of a unit class ........................................................................34

4.5 User instance data block for a unit class .....................................................................................36

4.6 Calling the Blocks ........................................................................................................................36

4.7 Downloading Blocks to the AS.....................................................................................................37

5 Configuration steps in the WinCC Explorer.............................................................................................. 39

5.1 Creating a WinCC project ............................................................................................................39

5.2 Creating message classes and message types ..........................................................................39

5.3 Add channel .................................................................................................................................42

5.4 Create connection........................................................................................................................43

5.5 Set up WinCC user ......................................................................................................................45

6 Configuration tasks in MS Excel with the WinCC Configuration Tool ....................................................... 47

6.1 Introduction ..................................................................................................................................47

6.2 Structure types in WinCC.............................................................................................................48

6.2.1 Structure type for the Batch interface blocks...............................................................................48

6.2.2 Create structure types..................................................................................................................48

6.3 Creating structure tags in WinCC ................................................................................................54

6.3.1 Introduction ..................................................................................................................................54

6.3.2 Organization of the Delivery Table ..............................................................................................55

6.3.3 Naming Convention .....................................................................................................................56

6.3.4 Determining Addresses from the Instance Data Block ................................................................56

6.3.5 Create structure tags ...................................................................................................................58

6.3.6 Creating internal tags for the visualization...................................................................................62

Table of contents

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

4 Programming and Operating Manual, 05/2010, A5E02829586-02

7 Configuration tasks in the SIMATIC Manager configuration dialog .......................................................... 67

7.1 Introduction ................................................................................................................................. 67

7.2 Overview of the configuration tasks............................................................................................ 67

7.3 Step 1 - Configuration of the Batch process cell......................................................................... 68

7.3.1 Configuration of the Batch process cell and importing the process cell instances..................... 68

7.3.2 Create batch types...................................................................................................................... 70

7.3.3 Delivery Table for the Batch Configuration ................................................................................. 72

7.3.3.1 Information about the MS Excel delivery spreadsheet "sb_deliverytable.xls" ............................ 72

7.3.3.2 Organization of the delivery table "sb_DeliveryTable.xls"........................................................... 73

7.4 Step 2 - Configuration of the Batch stations ............................................................................... 75

7.5 Step 3 - Configuration of the WinCC stations ............................................................................. 76

7.6 Step 4 - Distribution of the Batch process cell data.................................................................... 78

7.7 Validation..................................................................................................................................... 79

8 Process picture for units and equipment phases ..................................................................................... 81

8.1 Introduction ................................................................................................................................. 81

8.2 Creating a process picture .......................................................................................................... 81

8.3 Dynamizing a process picture..................................................................................................... 83

8.3.1 Dynamizing a unit........................................................................................................................ 83

8.3.2 Dynamizing an equipment phase................................................................................................ 87

8.4 Operator control and monitoring of the units and equipment phases......................................... 92

9 Example of a Batch Configuration............................................................................................................ 93

10 Interface description ................................................................................................................................ 97

10.1 Information about the SIMATIC BATCH interface blocks V7.1 SP1........................................... 97

10.2 AS interface description for SIMATIC BATCH............................................................................ 97

10.2.1 Principle structure of a user program for a unit with an equipment phase ................................. 97

10.2.2 Unit .............................................................................................................................................. 99

10.2.2.1 Description of functions............................................................................................................... 99

10.2.2.2 Unit interfaces to BATCH and WinCC ...................................................................................... 100

10.2.2.3 Flowchart................................................................................................................................... 101

10.2.3 Equipment phase / equipment operation .................................................................................. 101

10.2.3.1 Description of functions............................................................................................................. 101

10.2.3.2 Function / operation interfaces to BATCH and WinCC............................................................. 102

10.2.3.3 Command parameter ICTRL and status parameter QUSTAT_L.............................................. 103

10.2.3.4 Flow diagrams for the user block of the equipment phase ....................................................... 104

10.2.3.5 Startup flow chart ...................................................................................................................... 104

10.2.3.6 Flow chart for the "START" command...................................................................................... 106

10.2.3.7 Flow chart for the command "HOLD"........................................................................................ 108

10.2.3.8 Flow chart for the "ABORT" command ..................................................................................... 109

10.2.3.9 Flow chart for the "STOP" command........................................................................................ 111

10.2.3.10 Flow chart for the "COMPLETE" command......................................................................... 112

10.2.4 Parameters of the equipment phase......................................................................................... 114

10.2.4.1 Description of functions............................................................................................................. 114

10.2.4.2 Parameter interfaces to BATCH and WinCC............................................................................ 114

10.2.4.3 Flowchart................................................................................................................................... 115

Table of contents

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 5

11 SIMATIC IT Historian............................................................................................................................. 117

11.1 Installation of the Software Components...................................................................................117

11.2 Configuration of SIMATIC IT Historian ......................................................................................117

12 Abbreviations......................................................................................................................................... 119

Index...................................................................................................................................................... 121

Table of contents

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

6 Programming and Operating Manual, 05/2010, A5E02829586-02

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 7

Preface

1

Purpose of the "SIMATIC BATCH Configuration Guide" documentation

What is it about?

The Configuration Guide provides a structured configuration for a SIMATIC BATCH

project with WinCC and STEP 7.

What is the purpose of this documentation?

The purpose of this documentation is to illustrate the interface mechanisms between

SIMATIC BATCH, WinCC, STEP 7 and an automation system (SIMATIC S7-400). The

Configuration Guide can also be used for SIMATIC S7-300.

What is the result of the configuration?

At the end of the configuration you are able to generate BATCH Control Center recipes

and to start batches. To this purpose a unit with an equipment phase and a parameter is

available to you.

Requirements for the Configuration Guide

What are the software requirements for the configuration?

The software components to be installed are listed in the "Installation of the Software

Components" section.

What additional data is required for the configuration?

All the data required for the configuration and the Configuration Guide itself is available

following installation in the folder "..\\SIEMENS\BATCH\sbscadaexa" and its subfolders.

Notes about the Configuration Guide

For which control systems is the example configuration represented?

The configuration represents the connection of a SIMATIC S7-400. The following is

required for the configuration:

SIMATIC BATCH

SIMATIC WinCC

SIMATIC STEP 7

S7-400 or S7-300 automation systems

What is the procedure for third-party systems?

The configuration of third-party systems is not described in this documentation. However,

given sufficient knowledge about such a third-party system, a controller from another

manufacturer could be used in the SIMATIC environment based on the configuration. In

this case, it is important to read the "Interface description (Page 97)" section.

What is the challenge?

This represents a complex configuration with numerous programs and supplied files. This

documentation will help you maintain an overview.

What are the possible error diagnostics?

Some sections provide information about error diagnostics in addition to procedural

instructions.

Preface

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

8 Programming and Operating Manual, 05/2010, A5E02829586-02

Required Basic knowledge

You should have basic knowledge about the following fields:

SIMATIC STEP 7 configuration or equivalent third-party systems

SIMATIC WinCC configuration

SIMATIC BATCH configuration

Programming knowledge in C++

Structure of the documentation

This documentation is organized in the following chapters:

Preface

Introduction to the Configuration Guide

Overview of the Configuration Tasks

Configuration tasks in the SIMATIC Manager

Configuration tasks in the WinCC Explorer

Configuration tasks in MS Excel with the WinCC Configuration Tool

Configuration tasks in the SIMATIC Manager configuration dialog

Process picture for units and equipment phases

BATCH configuration

Interface description

SIMATIC IT Historian

Abbreviations

Preface

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 9

Additional documentation

The following table lists the documentation that offers additional information for the

configuration guide.

Online Help / Manual Purpose Opened via:

Manual

SIMATIC BATCH PCC API

Only available in English.

Description of the interface functions in

English.

In the SIMATIC BATCH installation

directory under:

..\..\Siemens\BATCH\Examples\BFPcc

API\_doc\bfpccapb.pdf

WinCC Configuration Tool The configuration tool offers options for

easily configuring mass data in WinCC.

Microsoft Excel is used as the user

interface. You have the option of

configuring a WinCC project in Excel

and transferring the data to WinCC or

vice versa.

Online help:

Start > Simatic > WinCC > Tools >

WinCC Configuration Tool

Manual:

Via the Tools menu in the

Configuration Tool WinCC online help.

SIMATIC BATCH

Describes how batch processes can be

automated with SIMATIC BATCH in the

SIMATIC PCS 7 environment.

Online help:

With the "Help" button in the BATCH

configuration dialog "Configure Batch

Process Cell....".

Manual:

Start > Simatic > Documentation >

English > SIMATIC BATCH manual

Online help SIMATIC BATCH

configuration dialog

The configuration dialog guides you

step-by-step through the configuration

of the Batch process cell.

Online help:

With the "Help" button in the plant

editor.

Manual:

Start > Simatic > Documentation >

English > SIMATIC BATCH for WinCC

- Configuration Guide

Note

The process cell configuration on the engineering system described in the online help and

the SIMATIC BATCH manual in the section "Process Cell Configuration in the ES" is based

on SIMATIC PCS 7. It can therefore be ignored.

The SIMATIC BATCH block libraries for the AS S7-400 and the AS S7-300 contain the same

blocks, however no message function is programmed in the blocks for AS S7-300.

Preface

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

10 Programming and Operating Manual, 05/2010, A5E02829586-02

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 11

Introduction to the Configuration Guide

2

2.1 Installation of the Software Components

Overview of software requirements

You must have installed the following software components for the example configuration on

your PC:

One of the following operating systems:

Windows XP Professional with Service Pack 2

Microsoft Windows Server 2003 R2 with Service Pack 2

Microsoft SQL Server 2005 SP2

Microsoft Excel 2003 with Service Pack 2

SIMATIC STEP 7 V5.4 with SP5 HF4

SIMATIC WinCC V7.0 SP1 HF4 with the "Smart Tools" components and the "WinCC

Configuration Tool".

SIMATIC BATCH V7.1 SP1 HF3 with the Automation License Manager V4.0 incl. SP5,

SIMATIC Logon V1.4 SP2 and Acrobat Reader 9.0.

Note

The installation of WinCC incl. hotfix is not carried out during the installation of SIMATIC

BATCH for WinCC V7.1 SP1. The installation files are located in the folders

"WinCC_V70SP1" and "WinCC_V70SP1HF4".

SIMATIC BATCH Installation

1. Insert the SIMATIC BATCH installation DVD in your drive and double-click the

"Setup.exe" file.

2. For this example configuration, select "BATCH Single Station" option in the "Program

Package" setup dialog box.

3. If programs are already installed a blue check mark appears in front of the components.

During the setup you are prompted by a dialog box to specify the security settings for

your firewall.

4. Select an installation path using the "Browse" button or confirm the suggested path.

5. In the next dialog box, enter an installation path for SIMATIC BATCH Backup. Specify a

path using the "Browse" button or confirm the suggested path.

6. Follow the instructions provided by the Wizard and close the Setup.

Introduction to the Configuration Guide

2.2 Additional Information for the Configuration Example

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

12 Programming and Operating Manual, 05/2010, A5E02829586-02

2.2 Additional Information for the Configuration Example

Introduction

The data required for the configuration are available in the folder "..\BATCH\SBSCADAEXA"

following the installation from the data medium you have chosen.

Data for the configuration example

You will find the following folders in the installation directory of BATCH:

"SBSCADAEXA" folder

"Examples" subfolder

"Manual" subfolder

"Setup" subfolder

"SBSCADAEXA" folder with the SIMATIC BATCH configuration dialog

This folder contains the configuration dialog with the name "sbfwsbbatchwzrdx.exe". This

folder additionally contains the Configuration Guide in the form of online help. You can call

up the online help from the configuration dialog by using the "Help" button or directly from

this folder.

"Examples" subfolder

The "Examples" folder contains the following files:

sb_deliverytable.xls (delivery spreadsheet)

sb_wincctypes.xls (structure types)

SPOSATemplate.dcf (distribution configuration file for SIMATIC IT)

The Excel files "sb_deliverytable.xls" and "sb_wincctypes" also serve as templates. The

"sb_deliverytable.xls" file contains the data for WinCC and for the configuration dialog. The

"sb_wincctypes.xls" file contains all the necessary structure types for WinCC. For further

information please refer to the sections "Organization of the delivery spreadsheet (Page 73)"

and "Structure types of the batch interface blocks (Page 48)".

The *.dcf file serves as the template for the communication link with SIMATIC IT.

"Manual" subfolder

This folder contains the Configuration Guide in PDF format in German and English with

following names:

projektierungsleitfaden.pdf

engineeringguide.pdf

Print the document in the desired language to perform the configuration.

Introduction to the Configuration Guide

2.2 Additional Information for the Configuration Example

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 13

"Setup" subfolder

This folder contains the readme files in German and English.Basics

2.2.1 System Components

Overview

The system components included in the configuration are shown in the following graphic.

Configuration dialog

Excel file

M

e

s

s

a

g

e

s

Excel file

SlMATlC

BATCH

BATCH

EQM

WinCC

SlMATlC BATCH

PCC APl

S

l

M

A

T

l

C

S

7

sbfwsbbatchwzrdx.exe

SB_WinCCTypes.xls

pcc_batch.eqm

l

n

t

e

r

n

a

l

T

a

g

s

(

S

o

f

t

p

h

a

s

e

s

)

S

l

M

A

T

l

C

P

r

o

t

o

c

o

l

S

u

i

t

e

SB_DeliveryTable.xls

Introduction to the Configuration Guide

2.2 Additional Information for the Configuration Example

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

14 Programming and Operating Manual, 05/2010, A5E02829586-02

SIMATIC WinCC

WinCC in this context is responsible for the communication between SIMATIC BATCH and

the functions of the automation system (AS). In principle, you can establish communication

with any controller (AS) for which there is a communication channel. You can therefore

operate SIMATIC BATCH with a controller other than the Siemens SIMATIC S7 controller

used as an example in this document.

Excel file "SB_WinCCTypes.xls"

The Excel file "SB_WinCCTypes.xls" contains the structure types for WinCC. You can import

the data directly into SIMATIC WinCC.

SIMATIC BATCH

SIMATIC BATCH is the standard SIMATIC BATCH package with the following functions:

Creating recipes

Batch sequence control

Batch data logging

Excel file "SB_DeliveryTable.xls"

The delivery spreadsheet in the form of the Excel file, "SB_DeliveryTable.xls", contains the

structure tags for WinCC and the instances for SIMATIC BATCH.

SIMATIC BATCH configuration dialog

Use the configuration dialog to create the BATCH process model and distribute the data to

the target computers. The internal communication is carried out via the PCC API.

2.2.2 PC Configurations

Single-station configuration

In a single-station configuration, all SIMATIC components such as SIMATIC WinCC,

SIMATIC BATCH and SIMATIC STEP 7 are installed on one PC. You configure, visualize

and operate on this PC.

Multiple-station configuration

In a multiple-station configuration, the various SIMATIC components are installed on several

PCs in a network. This results in a distributed system. The configuration, visualization and

operation are carried out on several PCs in the network.

Introduction to the Configuration Guide

2.2 Additional Information for the Configuration Example

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 15

Redundant configuration

A configuration is considered redundant when there are redundant BATCH servers and/or

WinCC servers in a distributed system. The appropriate redundancy mechanisms are offered

for BATCH and WinCC servers.

2.2.3 Communication

Overview

SlMATlC

BATCH

WinCC

S7

OPC Server

OPC Client

Communication between WinCC and the Controllers

The communication with the controllers takes place via SIMATIC WinCC. WinCC has

special, optimized channel drivers for connection to Siemens controllers such as S7. All

other controllers can be connected via OPC (OLE for Process Control).

Communication between SIMATIC BATCH and WinCC

The communication between SIMATIC BATCH and SIMATIC WinCC takes place through an

integrated Siemens format.

Additional information

You can find additional information about this in the section "Configuration steps in the

WinCC Explorer > add channel". (Page 42)

Introduction to the Configuration Guide

2.2 Additional Information for the Configuration Example

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

16 Programming and Operating Manual, 05/2010, A5E02829586-02

2.2.4 Time synchronization

Synchronization of the time

The time-of-day between the various stations (SIMATIC BATCH Server/Client, WinCC OS)

and the AS needs to be synchronized. You can find additional information on time

synchronization in the "Time Synchronization" section of the online help for WinCC.

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 17

Overview of the configuration tasks

3

Overview

You perform the configuration on a PC that is configured as a single-station system. The

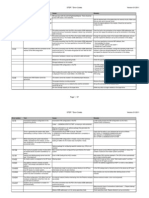

various configuration tasks are listed in the following table.

Step Program Configuration Task

1

SIMATIC Manager

Create S7 program

2

WinCC Explorer

Configure communication channel and

connection. Create message classes and types,

create users and user groups.

3

Microsoft Excel / Configuration Tool

From MS Excel files:

Create structure types (sb_wincc_types.xls,

included in the scope of delivery)

Create structure tags and internal tags in

WinCC (sb_deliverytable.xls, included in the

scope of delivery)

4

SIMATIC BATCH configuration dialog /

Microsoft Excel

Configuration of the BATCH process cell

Create process cell model with batch types

and batch instances

Automatic filling of the delivery spreadsheet

with instances and structure tags from your

S7 project.

Configure WinCC and BATCH stations

Create batch messages and transfer batch

process cell data to the batch server

5

Graphics Designer / process mode

Configure and dynamize the process picture

with BATCH Controls.

Operator control and monitoring of the units

and equipment phases

6

BATCH Recipe Editor and BCC

Recipe Editor: Create recipes based on the

process cell data

BATCH Control Center: Plan, release and

start batches

Overview of the configuration tasks

1. SIMATIC Manager:

Create the S7 program.

Create new unit and equipment phase FBs including the corresponding BATCH interface

(instance data blocks) based on the BATCH block libraries (S7-400/300). The BATCH

libraries contain the function blocks (FBs) for units (UNITs), equipment phases (EPHs)

and parameters.

Overview of the configuration tasks

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

18 Programming and Operating Manual, 05/2010, A5E02829586-02

2. Configuring in WinCC

Create a new WinCC project.

Configure message classes and message types in the OS Project Editor.

Add a communication connection in the WinCC tag management.

3. Generate the structure types and structure tags

Generate the structure types using the WinCC Configuration Tool implemented in MS

Excel and the supplied "sb_wincc_types.xls" Excel spreadsheet.

Generate the structure tags in WinCC manually using the custom "sb_deliverytable.xls"

file with units, equipment phases and parameters including the associated addresses

from the Batch interface.

4. Configuring in the SIMATIC BATCH configuration dialog

In the configuration dialog the configuration of the BATCH process cell, the process

model with the batch types and batch instances are created, all the BATCH and WinCC

stations of the process cell configured and subsequently distributed to the stations. In

addition the messages in WinCC are generated automatically.

5. A process picture created and dynamized in the Graphics Designer provides the

possibility of manually operating the unit, the equipment phase and a setpoint.

6. Based on the process cell data that was generated and distributed in step 4, you can

create recipes in the BATCH Recipe Editor and generate batches in the BATCH Control

Center.

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 19

Configuration steps in the SIMATIC Manager

4

4.1 Basic procedure

Blocks of the BATCH library

You assemble the user program from the blocks of the installed BATCH block library. All the

function blocks (FBs) required for the configuration are contained in the BATCH block

libraries for an AS S7-400/300.

User blocks can be created in the statement list (STL) based on these blocks. You can freely

choose a structure, block names and the block numbers in STEP 7 from the symbol table.

The following data and logic blocks are created in this documentation:

OB 32

Reactor (FB)

Reactor (DB)

Heating (FB)

Configuration steps in the SIMATIC Manager

4.2 Standard blocks of the SIMATIC BATCH library

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

20 Programming and Operating Manual, 05/2010, A5E02829586-02

The diagram below illustrates the structure of the blocks.

Reactor (FB)

lUNlT_BLOCK (FB)

HEATlNG (FB)

lEPH (FB)

OB32

lUNlT_BLOCK (FB)

HEATlNG (FB)

Reactor001 (DB)

lEPH (FB)

SP_TlME

lEPAR_DlNT (FB)

Legend:

SlMATlC BATCH Blocks

User blocks. The program example

can be used as a template

VAR

END VAR

Block declaration area

VAR

END VAR

VAR

END VAR

VAR

END VAR

4.2 Standard blocks of the SIMATIC BATCH library

Blocks of the installed library SIMATIC BATCH Blocks (S7-400/S7-300)

To create the SIMATIC S7 interface you use the following standard blocks from the installed

SIMATIC BATCH block library.

Source / symbolic name Object name and block

type

Comment

IEOP FB253 Interface Equipment Operation Block (IEOP)

IEPH FB254 Interface Equipment Phase Block (IEPH)

NOTIFY_8P SFB31

IEPAR_DINT FB255 Interface Equipment Parameter Module for Data Type Integer

IEPAR_BOOL FB256 Interface Equipment Parameter Module for Data Type Boolean

IEPAR_REAL FB257 Interface Equipment Parameter Module for Data Type Real

IEPAR_STR FB258 Interface Equipment Parameter Module for Data Type String

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 21

Source / symbolic name Object name and block

type

Comment

IEPAR_ENUM FB259 Interface Equipment Parameter Module for Parameter Type

ENUM

IEPAR_PI FB260 Interface Equipment Parameter Module for Process Input

IEPAR_PO FB261 Interface Equipment Parameter Module for Process Output

IEPAR_SOURCE FB262 Interface Equipment Parameter Module for Data Type

SOURCE

IEPAR_DEST FB263 Interface Equipment Parameter Module for Data Type DEST

IEPAR_VIA FB264 Interface Equipment Parameter Module for Data Type VIA

IEPAR_TKEY FB265 Interface Equipment Parameter Module for Data Type TKEY

IUNIT_BLOCK FB251 Interface IUNIT Block

TAG_COLL FB252 Tag Collection Block

4.3 User function block for the control of an equipment phase

Introduction

A function type is created as a function block. Create a function block for each function type.

It contains the following:

Instance data of the function block IEPH / IEOP

Instances of the IEPAR_DINT parameters (depending on the type)

Handling of the STL source file as a template

You can use the enclosed STL source for the "Heating" equipment phase in order to

implement your equipment phases. To do so, copy the entire program code into the

clipboard using the "Screen selection" function provided in the HTML help. Insert a new

object (STL source) into the "Source" S7 program folder. Open the STL source and insert

the content from the clipboard into the STL source. Save and compile the STL source. The

program parts that you have to adapt to your process are highlighted in bold in the following

template.

Note

Set the mnemonic!

For the translation of the STL source available to you English is required under Settings,

Language tab, for the mnemonic in the SIMATIC Manager.

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

22 Programming and Operating Manual, 05/2010, A5E02829586-02

STL source for the "Heating (FB)" equipment phase

The status transitions implemented in the program code correspond to those in the flow

diagram for the function block "IEPH (Page 104)". The implemented program code

corresponds to the user logic to be executed for the individual command, for example

START, area marked red in the flow diagram for the "START" command (Page 106).

In this template a timer simulates the process. The setpoint of the "SP_Time" equipment

phase controls how long the equipment phase is to remain in a status. The "SELFCOM"

block parameter decides whether the equipment phase is self-terminating or not self-

terminating. For further information refer to Chapter 5.11 in the documentation of SIMATIC

BATCH.

Rule

Take into account when creating the block of the equipment phase that the Batch function

blocks IEPH or IEOP may only be declared once per type.

Note

The symbolic block name assigned by you for the equipment phase as well as the tag name

of the function parameters are used during the automatic WinCC structure tag creation.

Note

MSG_EVID_1 and _2 only have to be declared for blocks of the S7-400, not for blocks of the

S7-300.

Program code

FUNCTION_BLOCK "Heating"

TITLE =

VERSION : 0.1

VAR_INPUT

MSG_EVID_1 { S7_server := 'alarm_archiv'; S7_a_type := 'notify_8p' }: DWORD;

MSG_EVID_2 { S7_server := 'alarm_archiv'; S7_a_type := 'notify_8p' }: DWORD;

END_VAR

VAR

IEPH: "IEPH";

SP_Time : "IEPAR_DINT"; //Declaration of Equipment Parameters

SELFCOMP : BOOL ;

SimTimer : DINT ;

END_VAR

VAR_TEMP

IEPHIdle : WORD ;

IEPHRunning : WORD ;

IEPHReady : WORD ;

IEPHCompleting : WORD ;

IEPHCompleted : WORD ;

IEPHResuming : WORD ;

IEPHHolding : WORD ;

IEPHHeld : WORD ;

IEPHStopping : WORD ;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 23

Program code

IEPHStopped : WORD ;

IEPHAborting : WORD ;

IEPHAborted : WORD ;

IEPHUninit : WORD ;

IEPHStarting : WORD ;

END_VAR

BEGIN

NETWORK

TITLE =Initialization of Local Variables

//Idle

L B#16#1;

T #IEPHIdle;

//Starting

L W#16#200;

T #IEPHStarting;

//Runnig

L B#16#2;

T #IEPHRunning;

//Ready

L B#16#20;

T #IEPHReady;

//Completing

L W#16#800;

T #IEPHCompleting;

//Completed

L B#16#4;

T #IEPHCompleted;

//Holding

L W#16#1000;

T #IEPHHolding;

//Held

L B#16#8;

T #IEPHHeld;

//Resuming

L W#16#400;

T #IEPHResuming;

//Aborting

L W#16#2000;

T #IEPHAborting;

//Aborted

L W#16#10;

T #IEPHAborted;

//Stopping

L W#16#4000;

T #IEPHStopping;

//Stopped

L B#16#40;

T #IEPHStopped;

//Uninit

L 0;

T #IEPHUninit;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

24 Programming and Operating Manual, 05/2010, A5E02829586-02

Program code

//Initialize EPH

L #IEPH.QUSTAT_L;

L DW#16#7E7F;

AW ;

L 0;

<>I ;

JC IOK;

L DW#16#60001;

T #IEPH.USTAT_L;

IOK: NOP 0;

NETWORK

TITLE =Initial call of IEPH copies SB commands from block IN to OUT

CALL #IEPH (

MSG_EVID_1 := #MSG_EVID_1,

MSG_EVID_2 := #MSG_EVID_2);

NETWORK

TITLE = Call of IEPAR block copies SP_VAL value written by BCS from IN to OUT

CALL #SP_Time ; //Call all Equipment Parameter blocks here

NETWORK

TITLE =EPH Commands processing

//************Set/Reset Occupy***********

AN #IEPH.Q_OCCUPI;

JC ROCC;

L DW#16#1000000;

L #IEPH.USTAT_L;

OD ;

T #IEPH.USTAT_L;

JU EPHR;

ROCC: L DW#16#FEFFFFFF;

L #IEPH.USTAT_L;

AD ;

T #IEPH.USTAT_L; //Update IEPH status word

EPHR: NOP 0;

//************** START CMD **************

A #IEPH.QSTART;

A( ;

A( ;

L #IEPHIdle;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L DW#16#800000; //Restart in Conti

L #IEPH.QUSTAT_L;

AD ;

L DW#16#800000; //Conti

==D ;

) ;

) ;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 25

Program code

JCN Hcm;

//Delete Conti Flag

L DW#16#FF7FFFFF;

L #IEPH.USTAT_L;

AD ;

T #IEPH.USTAT_L;

//Initialize logic for Starting

L 0;

T #SimTimer;

//Set Running

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

AD ;

L #IEPHStarting;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

//************** HOLD CMD ***************

Hcm: NOP 0;

A #IEPH.QHOLD;

A( ;

A( ;

L #IEPHRunning;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHStarting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

) ;

JCN Scm;

//Initialize logic for Holding

L 0;

T #SimTimer;

//Set Holding

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

AD ;

L #IEPHHolding;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

//************** STOP CMD ***************

Scm: NOP 0;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

26 Programming and Operating Manual, 05/2010, A5E02829586-02

Program code

A #IEPH.QSTOP;

A( ;

A( ;

L #IEPHStarting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHRunning;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHHolding;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHHeld;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHCompleting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

) ;

JCN Acm;

//Initialize logic for Stopping

L 0;

T #SimTimer;

//Set Stopping

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

AD ;

L #IEPHStopping;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

//************** ABORT CMD **************

Acm: NOP 0;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 27

Program code

A #IEPH.QABORT;

A( ;

A( ;

L #IEPHStarting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHRunning;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHHolding;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHHeld;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHCompleting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

) ;

JCN RScm;

//Initialize logic for Aborting

L 0;

T #SimTimer;

//Set Aborting

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

AD ;

L #IEPHAborting;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

//************** RESET CMD **************

RScm: NOP 0;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

28 Programming and Operating Manual, 05/2010, A5E02829586-02

Program code

A #IEPH.QRESET;

A( ;

A( ;

L #IEPHStopped;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHAborted;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

O ;

A( ;

L #IEPHCompleted;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

) ;

JCN Rcm;

//Reset logic for EPH

L 0;

T #SimTimer;

//Set Idle

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

AD ;

L #IEPHIdle;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

//************* RESUME CMD **************

Rcm: NOP 0;

A #IEPH.QSTART;

A( ;

L #IEPHHeld;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN Ccm;

//Initialize logic for Resuming

L 0;

T #SimTimer;

//Set Resuming

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 29

Program code

AD ;

L #IEPHResuming;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

//************ COMPLETE CMD *************

Ccm: NOP 0;

A #IEPH.QTERM;

A( ;

L #IEPHReady;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PROC;

//Initialize logic for Completing

L 0;

T #SimTimer;

//Set Completing

L #IEPH.QUSTAT_L;

L DW#16#FF7F0000; //16#FF7F0000 Delete S88 state and Conti flag

AD ;

L #IEPHCompleting;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Wait in State at least 1 cycle and update #IEPH.QUSTAT_L

NETWORK

TITLE =State Processing

//***************** Starting **********************

PROC: A( ;

L #IEPHStarting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS0;

//Program your conditions for status change from Starting to Running here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC STRT;

//Initialization of Running sequence

L 0;

T #SimTimer;

//RPH status change from Starting to Running

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

L #IEPHRunning;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

30 Programming and Operating Manual, 05/2010, A5E02829586-02

Program code

JU UPSP; //Update Setpoints

//Program your logic for Starting sequence here

STRT: L #SimTimer; //Starting

L L#1;

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Running **********************

PRS0: A( ;

L #IEPHRunning;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS1;

//Program your conditions for status change from Running to Completing or READY here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC RUNT;

SET;

S #SELFCOMP;

A #SELFCOMP;

JC SELF;

//None Self completing EPH. Set Ready and wait for SB cmd Complete

//Initialization of READY sequence

L 0;

T #SimTimer;

L #IEPH.QUSTAT_L;

L DW#16#FFFFFFDF;

AD ;

L #IEPHReady;

OD ;

T #IEPH.USTAT_L; //Update IEPH status word

JU UPSP; //Update Setpoints

//Self completing EPH. EPH can complete itself

//Initialization of Completing sequence

SELF: L 0;

T #SimTimer;

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

L #IEPHCompleting;

OD ;

T #IEPH.USTAT_L;

JU UPSP; //Update Setpoints

//Program your logic for Running sequence here

RUNT: L #SimTimer; //Running

L L#1;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 31

Program code

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Completing *****************

PRS1: A( ;

L #IEPHCompleting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS2;

//Program your conditions for status change from Completing to Completed here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC CMPT;

//Set Completed

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

L #IEPHCompleted;

OD ;

T #IEPH.USTAT_L;

JU UPSP; //Update Setpoints

//Program your logic for Completing sequence here

CMPT: L #SimTimer; //Completing

L 1;

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Holding *****************

PRS2: A( ;

L #IEPHHolding;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS3;

//Program your conditions for status change from Holding to Held here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC HELT;

//Set Held

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

32 Programming and Operating Manual, 05/2010, A5E02829586-02

Program code

L #IEPHHeld;

OD ;

T #IEPH.USTAT_L;

JU UPSP; //Update Setpoints

//Program your logic for Holding sequence here

HELT: L #SimTimer; //Holding

L 1;

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Resuming *****************

PRS3: A( ;

L #IEPHResuming;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS4;

//Program your conditions for status change from Resuming to Running here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC RSUT;

//Set Running

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

L #IEPHRunning;

OD ;

T #IEPH.USTAT_L;

L 0;

T #SimTimer;

JU UPSP; //Update Setpoints

//Program your logic for Resuming sequence here

RSUT: L #SimTimer; //Resuming

L 1;

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Aborting *****************

PRS4: A( ;

L #IEPHAborting;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS5;

Configuration steps in the SIMATIC Manager

4.3 User function block for the control of an equipment phase

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 33

Program code

//Program your conditions for status change from Aborting to Aborted here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC ABRT;

//Set Aborted

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

L #IEPHAborted;

OD ;

T #IEPH.USTAT_L;

JU UPSP; //Update Setpoints

//Program your logic for Aborting sequence here

ABRT: L #SimTimer; //Aborting

L 1;

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Stopping *****************

PRS5: A( ;

L #IEPHStopping;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

JCN PRS6;

//Program your conditions for status change from Stopping to Stopped here

L #SimTimer;

L #SP_Time.Q_SP_VAL; //Read Set Point value of Equipment Parameter

<D ;

JC STPT;

//Set Stopped

L #IEPH.QUSTAT_L;

L DW#16#FFFF0000;

AD ;

L #IEPHStopped;

OD ;

T #IEPH.USTAT_L;

JU UPSP; //Update Setpoints

//Program your logic for Stopping sequence here

STPT: L #SimTimer; //Stopping

L 1;

+D ;

T #SimTimer;

T #SP_Time.ACT_VAL; //Update actual value of Equipment Parameter

JU UPSP; //Update Setpoints

//**********************************************

//***************** Set/Reset Continue *********

Configuration steps in the SIMATIC Manager

4.4 User function block for the control of a unit class

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

34 Programming and Operating Manual, 05/2010, A5E02829586-02

Program code

PRS6: A( ;

L #IEPHReady;

L #IEPH.QUSTAT_L;

AD ;

==D ;

) ;

A #IEPH.QCONT;

JCN PRS7;

L DW#16#800000;

L #IEPH.USTAT_L;

OD ;

T #IEPH.USTAT_L;

JU PRS8;

PRS7: L DW#16#FF7FFFFF;

L #IEPH.USTAT_L;

AD ;

T #IEPH.USTAT_L;

PRS8: NOP 0;

NETWORK

TITLE = Call of IEPAR block updates Equipment ParameterACT_VAL value from IN to OUT

UPSP: NOP 0;

CALL #SP_Time ; //Call here all Equipment Parameter blocks

NETWORK

TITLE =Update QUSTAT_L of IEPH block

CALL #IEPH (

MSG_EVID_1 := #MSG_EVID_1,

MSG_EVID_2 := #MSG_EVID_2);

END_FUNCTION_BLOCK

See also

Flowchart (Page 101)

4.4 User function block for the control of a unit class

Introduction

A unit class is created as a function block. The "IUNIT_BLOCK" function block must be

inserted into the tag declaration. In addition the "Heating" user function block is entered in

the tag list.

Configuration steps in the SIMATIC Manager

4.4 User function block for the control of a unit class

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 35

Handling of the STL source file

You can use the enclosed STL source for the "Reactor" unit class in order to implement your

unit class. To do so, copy the entire program code into the clipboard using the "Program

code" function provided in the HTML help. Insert a new object (STL source) into the "Source"

S7 program folder. Open the STL source and insert the content from the clipboard into the

STL source. Save and compile the STL source. The program parts that you have to adapt to

your process are highlighted in bold.

Note

Set the mnemonic!

For the translation of the STL source available to you English is required under Settings,

Language tab, for the mnemonic in the SIMATIC Manager.

Rule

Take into account when creating the block of the unit class that the Batch function block

IUNIT_BLOCK only has to be declared once.

Note

The symbolic block name assigned by you for the unit class is used during the automatic

WinCC structure tag creation.

Reactor example

Program code

FUNCTION_BLOCK "Reactor"

TITLE =

VERSION : 0.1

VAR_INPUT

Reactor_MSG_EVID_1 { S7_server := 'alarm_archiv'; S7_a_type := 'notify_8p' }: DWORD;

Heating_MSG_EVID_1 { S7_server := 'alarm_archiv'; S7_a_type := 'notify_8p' }: DWORD;

Heating_MSG_EVID_2 { S7_server := 'alarm_archiv'; S7_a_type := 'notify_8p' }: DWORD;

END_VAR

VAR

Heating : "Heating"; //Declaration all user defined Equipment Phases

IUNIT : "IUNIT_BLOCK";

END_VAR

BEGIN

NETWORK

TITLE =

CALL #IUNIT (

MSG_EVID_1 := #Reactor_MSG_EVID_1);

CALL #Heating (

MSG_EVID_1 := #Heating_MSG_EVID_1,

MSG_EVID_2 := #Heating_MSG_EVID_2); //Call all Equipment Phase blocks here

END_FUNCTION_BLOCK

Configuration steps in the SIMATIC Manager

4.5 User instance data block for a unit class

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

36 Programming and Operating Manual, 05/2010, A5E02829586-02

4.5 User instance data block for a unit class

Instance block for the unit class

You can now create the unit instance as an instance data block for the unit class in the

SIMATIC Manager.

To do so, select Insert new object > Data block in the block container of your project. Enter

the symbolic name "Reactor001" and select "Instance DB" as the type. Select the FB

number of the corresponding unit class IUNIT_BLOCK (FB).

Note

The symbolic data block name assigned by you for the unit class instance is used during the

automatic WinCC structure tag creation.

4.6 Calling the Blocks

Call

In order for the one unit instance to process a controlling function block in the AS, you must

position a call in a cyclic block, e.g. in the OB32. The unit block must not be called cyclically

in less than 1 second intervals

Note

Set the mnemonic!

For the translation of the STL source available to you English is required under Settings,

Language tab, for the mnemonic in the SIMATIC Manager.

OB32 example

Program code

ORGANIZATION_BLOCK OB 32

TITLE = "Main Program Sweep (1-sec cycle)"

VERSION : 0.1

VAR_TEMP

EV_CLASS : BYTE ; //Bits 0-3 = 1 (Coming event), Bits

//4-7 = 1 (Event class 1)

SCAN_1 : BYTE ; //1 (Cold restart scan 1 of OB 32), 3

//(Scan 2-n of OB 32)

PRIORITY : BYTE ; //Priority of OB Execution

OB_NUMBR : BYTE ; //32 (Organization block 32, OB32)

RESERVED_1 : BYTE ; //Reserved for system

Configuration steps in the SIMATIC Manager

4.7 Downloading Blocks to the AS

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 37

Program code

RESERVED_2 : BYTE ; //Reserved for system

PREV_CYCLE : INT ; //Cycle time of previous OB32 scan

//(milliseconds)

MIN_CYCLE : INT ; //Minimum cycle time of OB32

//(milliseconds)

MAX_CYCLE : INT ; //Maximum cycle time of OB32

//(milliseconds)

DATE_TIME : DATE_AND_TIME ; //Date and time OB32 started

END_VAR

BEGIN

NETWORK

TITLE = Call of UNIT control block

//Call of UNIT control block must not happen faster than 1 sec

CALL #Reactor , "Reactor001" ; //Call all Unit instances here

END_ORGANIZATION_BLOCK

4.7 Downloading Blocks to the AS

Compile the block sources and download the blocks generated from this to your AS via the

"Download" command in the SIMATIC Manager.

Configuration steps in the SIMATIC Manager

4.7 Downloading Blocks to the AS

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

38 Programming and Operating Manual, 05/2010, A5E02829586-02

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 39

Configuration steps in the WinCC Explorer

5

5.1 Creating a WinCC project

Introduction

The WinCC project is created in WinCC Explorer. In this configuration, you will create a

multi-user project.

Requirement

SIMATIC WinCC is installed with options (BPC=Basic Process Control).

Procedure

1. Open the WinCC Explorer.

2. Select the menu command File > New.

3. Select the option button "Multi-User Project" and click "OK" to close the dialog box.

4. In the next dialog box enter the desired project name, select the project path and the

desired destination drive, and click the "Create" button.

Result

The multi-user project is created and displayed in the WinCC Explorer.

Further information

You can find further information about this in the "WinCC Information System" online help

under Start > SIMATIC > WinCC.

5.2 Creating message classes and message types

Introduction

The OS Project Editor configures the WinCC message system and creates message classes

and message types. To begin, open the OS Project Editor in the WinCC Explorer. Then

check the message configuration for SIMATIC BATCH in the Alarm Logging.

Configuration steps in the WinCC Explorer

5.2 Creating message classes and message types

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

40 Programming and Operating Manual, 05/2010, A5E02829586-02

Requirements

WinCC Setup is installed with the "Options" and the "Basic Process Control" components

are selected.

The WinCC Explorer is open.

Procedure

1. Double-click on "OS Project Editor" in the tree of the WinCC Explorer.

The Project Editor opens.

2. Change to the "Message Configuration" tab.

3. Leave the standard settings unchanged and click on the "OK" button to close the

message configuration in the OS Project Editor.

4. Double-click on "Alarm Logging" in the tree of the WinCC Explorer.

5. In the tree view double-click on the "Message Classes" data folder and double-click on

the object "OS Control Messages".

6. Double-click on the "Batch" object in the detail window to check the message type of the

"Batch" message class in the "Type" dialog box.

The "Type 80" message type must be created in the OS Project Editor.

7. Close the dialog box.

8. Close the Alarm Logging.

Configuration steps in the WinCC Explorer

5.2 Creating message classes and message types

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 41

Result

The following figures show the important configuration tasks.

Configuration steps in the WinCC Explorer

5.3 Add channel

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

42 Programming and Operating Manual, 05/2010, A5E02829586-02

Additional information

You can find additional information about this in the "Add Channel" section and in the WinCC

Information System online help.

5.3 Add channel

Introduction

Add the "SIMATIC S7 Protocol Suite" communication driver in the tag management of

WinCC for the connection between WinCC and the AS (S7) .

Requirement

The WinCC project is open.

Procedure

1. Mark the "Tag Management" object in the tree and select the shortcut menu command

Add New Driver....

Configuration steps in the WinCC Explorer

5.4 Create connection

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 43

2. Select the "SIMATIC S7 Protocol Suite.chn" driver by expanding it or double-clicking.

Result

The communication channel is created.

Additional information

You can find additional information about this in the "Create Connection" section and in the

WinCC Information System online help.

5.4 Create connection

Introduction

Create one or more connections for the respective connection route depending on the

number of automation systems involved. Configure these connections in the WinCC tag

management.

Requirement

A new driver is added.

Configuration steps in the WinCC Explorer

5.4 Create connection

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

44 Programming and Operating Manual, 05/2010, A5E02829586-02

Procedure

1. In the "SIMATIC S7 PROTOCOL SUITE" communication driver, mark the communication

route through which you wish to communicate with the AS and open the shortcut menu.

Example: MPI or Industrial Ethernet.

2. In the shortcut menu, select "New connection".

3. Enter a name for the connection in the "Connection Properties" dialog and click on the

"Properties" button.

4. In the "Connection Parameters" dialog box, assign the parameters for the connection

between WinCC and the AS.

Enter the Ethernet address of the AS, the rack number and the slot number of the CPU

and click on the "OK" button.

5. Mark the communication route in your communication driver once again and open the

shortcut menu.

Select "System parameter" from the shortcut menu.

6. Open the "Unit" tab. In the drop-down list, select the "Logical device name" that was

assigned during the installation of the communication tab.

Result

The connection from WinCC to the AS is established.

Configuration steps in the WinCC Explorer

5.5 Set up WinCC user

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 45

Additional information

You can find additional information about this in the WinCC Information System online help.

5.5 Set up WinCC user

Introduction

Create a new user in the User Administrator for process mode logon.

It is also possible to authenticate the user via the SIMATIC logon. You can find additional

information about this in the SIMATIC logon or WinCC Information System online help.

Requirement

The WinCC Explorer is open.

Procedure

1. Mark the "User Administrator" object in the tree view and select the shortcut menu

command Open.

2. In the User Administrator, open the shortcut menu for the "Administrator Group" and

select the menu command New User.

Configuration steps in the WinCC Explorer

5.5 Set up WinCC user

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

46 Programming and Operating Manual, 05/2010, A5E02829586-02

3. Enter the logon and password in the "Create New User" dialog box and then enter the

password again.

Activate the "Copy group settings also" check box.

All authorizations for this user are set.

4. Click on the "OK" button.

Result

You have created a new user for runtime logon.

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 47

Configuration tasks in MS Excel with the WinCC

Configuration Tool

6

6.1 Introduction

Creating structure types in WinCC

An MS Excel spreadsheet with the data of the created units, equipment phase and their

parameters with the addresses is required for the configuration of the structure types in

WinCC. Create the structure types in your WinCC project by using the WinCC configuration

tool implemented in MS Excel and the supplied MS Excel spreadsheet "sb_wincctypes.xls".

Creating structure tags in WinCC

An MS Excel spreadsheet with the WinCC structure tags is also required for the

configuration of the structure tags in WinCC. The empty MS Excel spreadsheet

"sb_deliverytable.xls" is provided to this purpose. This spreadsheet can be filled manually or

automatically. The following section describes both variants. The aim of both procedures is a

worksheet "STRUCTURE_TAGS_FOR_WINCC" filled with the WinCC tag names. Create

the structure tags in your WinCC project using the WinCC Configuration Tool implemented in

MS Excel and the filled out MS Excel "sb_deliverytable.xls" spreadsheet.

Manual filling of the MS Excel delivery spreadsheet

The data for the MS Excel delivery spreadsheet result from the S7 program.

Note

Copy both MS Excel files from the installation folder

..\SIEMENS\BATCH\sbsadaexa\examples into the Batch folder of your WinCC project.

If the "Batch" subfolder was not created by the SIMATIC BATCH configuration dialog, you

need to create this folder manually.

Configuration tasks in MS Excel with the WinCC Configuration Tool

6.2 Structure types in WinCC

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

48 Programming and Operating Manual, 05/2010, A5E02829586-02

6.2 Structure types in WinCC

6.2.1 Structure type for the Batch interface blocks

Introduction

The "sb_wincctypes.xls" Excel spreadsheet is located in the "Batch" WinCC project folder. All

structure types required for the Batch interface are listed in the "Structure types" worksheet.

Structure types for the configuration

The structure types required for the Batch interface in the configuration are listed in the

"Name" column.

The following structure types are shown in the supplied delivery spreadsheet:

Name Description Structure in STEP 7

IUNIT_BLOCK Structure type for the unit interface IUNIT_BLOCK

IEPH Structure type for the equipment phase interface IEPH

IEPAR_DINT Structure type for a "32-bit integer" type parameter IEPAR_DINT

IEPAR_BOOL Structure type for a "Boolean" type parameter IEPAR_BOOL

IEPAR_STR Structure type for "String" type parameter IEPAR_STR

IEPAR_PI Structure type for a parameter of the "Process Input"

type

IEPAR_PI

IEPAR_REAL Structure type for a "Real" type parameter IEPAR_REAL

IEPAR_PO Structure type for a parameter of the "Process Output"

type

IEPAR_PO

IEPAR_ENUM Structure type for a parameter of the "Enumeration"

type

IEPAR_ENUM

IEPAR_SOURCE Structure type for a parameter of the "Source" type IEPAR_SOURCE

IEPAR_VIA Structure type for a parameter of the "Via" type IEPAR_VIA

IEPAR_DEST Structure type for a parameter of the "Destination"

type

IEPAR_DEST

6.2.2 Create structure types

Introduction

The structure types used in your STEP 7 project must have been created in the WinCC

Explorer using the WinCC Configuration Tool implemented in Microsoft Excel.

Configuration tasks in MS Excel with the WinCC Configuration Tool

6.2 Structure types in WinCC

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

Programming and Operating Manual, 05/2010, A5E02829586-02 49

Requirements

Microsoft Excel is installed.

The project language of the WinCC Explorer has been set to English. WinCC Explorer >

Options > Language.

The WinCC project is closed.

Procedure

1. Start Microsoft Excel and open the file, "sb_wincctypes.xls".

2. Click on the "Create Project Worksheet" icon.

3. Activate "Establish connection to existing project" check box in the "New Project

Worksheet" dialog box.

Click on the "Next" button.

4. In the final dialog, enter the absolute path to your WinCC project as shown in the figure

under item 5.

Click on the "Finish" button.

Configuration tasks in MS Excel with the WinCC Configuration Tool

6.2 Structure types in WinCC

Configuration Guide SIMATIC BATCH for WinCC V7.1 SP1

50 Programming and Operating Manual, 05/2010, A5E02829586-02

5. In the "Project Properties" worksheet of the newly created project folder, select "No" to

"Use Default Values" in the drop-down list in the "Data Entry" group. Double-click on the

corresponding cell for this. A selection menu is then shown to the right of the cell. Click

on the icon and select "No". After selecting "No", click again in any cell to apply the

selection.

Note

The "No" option for the "Use default value" setting is important because otherwise the