Professional Documents

Culture Documents

BSL Resume

Uploaded by

kjha5095Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BSL Resume

Uploaded by

kjha5095Copyright:

Available Formats

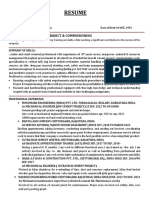

KAUSHLENDRA K JHA Mobile:9438774009

E-Mail:kjha5095@gmail.com

Seeking assignments in Production Management / Operations & Maintenance with an organization of high reputed in Iron and Steel Manufacturing Industry CAREER PRCIS A dynamic professional with more than 09 years of experience in the areas of: Production Management Tool Room Operations Operations & Maintenance Process Enhancement Spare Part Management Team Management Expertise in managing operations using Operators & Manpower with key focus on top line and bottom line profitability by ensuring optimal utilization of resources. Experience of working in conveyor line errection & circuit activities & Machine Maintenance. Proficient in handling production operations for manufacturing Direct reduced Iron(DRI) . An effective communicator with excellent relationship management skills and strong analytical, leadership, decision-making, problem solving & organizational abilities. COMPETENCIES OVERVIEW

Formulating & executing production and manpower schedules / plans for smooth execution of projects at the circuit floor within time. Coordinating with production & PPC for ensuring fulfilment of daily / monthly production targets. Maintenance planning & execution of circuit & Equipments on basis of zero breakdown concepts. Analyzing the observations of the condition monitoring with the help of scheduling of preventive, predictive and shutdown maintenance. Daily rejection analysis & taking counter measures for ensuring adherence to the pre-set technical specifications and attending meeting of zero manufacturing defects (ZMD). Leading, mentoring & monitoring the performance of team members to ensure efficiency in process operations and meeting of individual & group targets. Creating and sustaining a dynamic environment that fosters development opportunities and motivates high performance amongst team members. Improving bottom lines with the help of CIT (Continuous improvement team) and training them in various fields.

EMPLOYMENT SCAN Since june08 to till date :Working with Bhushan Steel Ltd. Angul(odisha) as engineer Operation & Maintenance, Raw Material Handling System Bhushan Steel Ltd Meramandali Odisha

Bhushan Steel Ltd. Formerly known as Bhushan Steel & Strips Ltd. Is a globally renowned one of the leading prominent player in steel industry .Backed by more than decades, of experience is steel rd making , Bhushan Steel is now Indias 3 largest secondary steel producer company with an existing steel production cap. Of 2 MTPA(approx.)

Raw Material Handling Department: Working as an engineer Operation & Maintenance : Control of RMHS through P.L.C which is feeding to DRI, Blast Furnace, Sinter Plant & Coke Oven Plant. For inward Raw Material, Material Stacking and equipment utilisation. For feeding to Ore Primary Bunker & Coal Primary Bunker. Implementing of Yard Management System. Maintenance of Material Handling Equipment (Stacker cum Reclaimer)Man & L&T made. Responsible for Shift Activities. 100% Schedule Adherence for Preventive & Predictive Maintenance for all the Equipments. Maintenance planning & execution of machines & Equipments on basis of zero breakdown concepts. Reducing cost of maintenance [Fixed & variable]. Implementation of special activities. Execution of Engineering changes in process, layout or machines as & when required.

Maintaining Operational safety in plant Maintaining DAILY WORK MANAGEMENT formats Identification of Spare part requirement. Job safety analysis for ensuring operational safety. Maintaining discipline in Department, analyzing performance of team & team members. Determining & improving skill level of new comers. Identifying and implementing the project related to power saving. Highlights: I was the part of team who had synchronised series of conveyors slat and overhead) with each other which include feeding material through conveyor . 425 TPH Coal Washery is attached to the RMHS plant supplying Washed Coal to DRI Plant and

Meddling to Power Plants. Power Plant feeding too is the responsibility of this department. The 425 TPH Sandvik Iron Ore and 600 TPH Humboldt Coal processing plant is fed by Stock Yard having 4 Truck Tipplers ,Two Wagon Tipplers , 4 Stacker cum Reclaimers and a series of Conveyor Belts. Total Raw Material Processing plant ( Iron Ore & Coal ) involving Truck Tipplers, StackerReclaimers,Screens, Cone Crushers, Conveyor Belts,Vibro-Feeders and allied equipments feeding to 6 Kilns of 500 TPD capacity.

Since june04 to June08 :Working with ESSAR STEEL Limited Hazira Surat Gujarat as a Jr.Engineer, Operations and taking care of Material Hanling dept.

EBTL & ELL is fully owned subsidiary of ESPLL (part of Essar Global Limited) carry out the business of logistics management, transhipment and port services. The Company specialises in the Jetty handling, storage distribution and movement of cargo by sea, road and rail.

Material Handling Department: Working as a Operation & Maintenance junior engineer in material Handling Department : Material Handling Equipments like Fork Lift, Pallet Trucks and Conveyers. Having target to achieving zero breakdowns. Jetty handling for in ward raw material like Iron Ore, Lime Stone, Coke, HBI DRI and Project Cargo. Material Stacking and Yard Planning. Jetty Handling for outward finish material likes Hot Rolled Coil, Cold Rolled Coil, Slab, Sheet, Plate and HBI.

SCHOLASTICS 3 years Diploma in Mechanical Engineering from New Govt. Polytechnic Patna in 2002. Won prize in Sub divisional officers club Sports & cultural Organization.

IT SKILLS: MS Word, MS Excel, Basics, PowerPoint and Internet Applications. PERSONAL DOSSIER th 28 July 1979 414, Bhushan Housing colony,Narendrapur Odisha At Sarisab Pariwar tola, Madhubani Bihar K0288918 09/10/2022 09692419476

D.O.B Present Address Permanent Address Passport No. Passport expiry Contact No. home

: : : : : :

You might also like

- Advanced Gear Manufacturing and Finishing: Classical and Modern ProcessesFrom EverandAdvanced Gear Manufacturing and Finishing: Classical and Modern ProcessesRating: 3.5 out of 5 stars3.5/5 (2)

- Naukri HimanshuSukhralia (17y 0m)Document3 pagesNaukri HimanshuSukhralia (17y 0m)Amit SinhaNo ratings yet

- Resume-Rahul Srivastava KGDocument4 pagesResume-Rahul Srivastava KGrahul srivastavaNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- Application: Correspondence Address Permanent AddressDocument5 pagesApplication: Correspondence Address Permanent AddressmanojtechNo ratings yet

- Design of High-Speed Railway Turnouts: Theory and ApplicationsFrom EverandDesign of High-Speed Railway Turnouts: Theory and ApplicationsRating: 4.5 out of 5 stars4.5/5 (4)

- Power Mech BroucherDocument25 pagesPower Mech BroucherKunal TambeNo ratings yet

- Saravanan M - Resume NewDocument3 pagesSaravanan M - Resume NewjillNo ratings yet

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesFrom EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesRating: 4.5 out of 5 stars4.5/5 (13)

- Vijay Pal: GB ProjectDocument4 pagesVijay Pal: GB ProjectpalvjNo ratings yet

- HK CV VBDocument5 pagesHK CV VBVijayBharati100% (2)

- Saurav Resume PDFDocument5 pagesSaurav Resume PDFMine FollowerNo ratings yet

- Rsume - Production EngineerDocument4 pagesRsume - Production Engineerdayashankar dubeyNo ratings yet

- Maintenance Engineer Sample ResumeDocument4 pagesMaintenance Engineer Sample ResumeÄbdur Ráhmán100% (1)

- Praveen Balaji.RDocument3 pagesPraveen Balaji.RPraveen Balaji RamachandranNo ratings yet

- Venkata Ajay Kumar Talla: Personal SummaryDocument3 pagesVenkata Ajay Kumar Talla: Personal SummaryVenkata Ajay Kumar TallaNo ratings yet

- Project Report in JSWDocument44 pagesProject Report in JSWmohd arif khan71% (14)

- Naukri RishiRawat (14y 0m)Document5 pagesNaukri RishiRawat (14y 0m)Amit SinhaNo ratings yet

- Sibabrata DasDocument4 pagesSibabrata DasjaydiphajraNo ratings yet

- My Resume PDFDocument3 pagesMy Resume PDFAbdullah SheikhNo ratings yet

- 18, Sukumar Roy Path, SAIL Co-Operative Housing Society, City CentreDocument2 pages18, Sukumar Roy Path, SAIL Co-Operative Housing Society, City CentrenishantsukumaranNo ratings yet

- 01 VKT - 2012 JanDocument6 pages01 VKT - 2012 JanVinod Kumar TurkiNo ratings yet

- MazharDocument4 pagesMazharMohammed SultanNo ratings yet

- Steel Authority of India Limited (SAIL) - Human Resource Information System - 240154100Document113 pagesSteel Authority of India Limited (SAIL) - Human Resource Information System - 240154100simran kumari100% (1)

- Mechanical Engineer Seeks New ChallengeDocument3 pagesMechanical Engineer Seeks New ChallengeMuhammadKashifChaudharyNo ratings yet

- Mechanical Engineer ResumeDocument6 pagesMechanical Engineer Resumearshad shahNo ratings yet

- Curriculum Vitae: Personal InformationDocument8 pagesCurriculum Vitae: Personal InformationArun PrasadNo ratings yet

- Profile Summary:: Nationality: Pakistani City: Karachi Religion: Islam Residence.: Gulistan-e-Johar, KarachiDocument2 pagesProfile Summary:: Nationality: Pakistani City: Karachi Religion: Islam Residence.: Gulistan-e-Johar, KarachiFarhan SaghirNo ratings yet

- Vuthpala. Chaitanya Krishna: Engineering Manager - Operation & Maintenance - Power / Desalination PlantDocument2 pagesVuthpala. Chaitanya Krishna: Engineering Manager - Operation & Maintenance - Power / Desalination PlantVuthpalachaitanya KrishnaNo ratings yet

- CV Rahul K - MH2 A - 035417Document4 pagesCV Rahul K - MH2 A - 035417Rahul KumarNo ratings yet

- Sarvesh InternshipDocument58 pagesSarvesh InternshipSarvesh GuptaNo ratings yet

- Industrial Report Akshay SirDocument25 pagesIndustrial Report Akshay SirAditya SharmaNo ratings yet

- Sibaram Pattanaik: Senior Engineer at SANVIRA IndustriesDocument3 pagesSibaram Pattanaik: Senior Engineer at SANVIRA IndustriesSibaram PattanaikNo ratings yet

- Summer Training Project (Anshul)Document63 pagesSummer Training Project (Anshul)Anshul PandeyNo ratings yet

- Mechanical Engineer Hamza Nouman1Document5 pagesMechanical Engineer Hamza Nouman1Hamza NoumanNo ratings yet

- CV - ThiraviyamDocument4 pagesCV - ThiraviyamRamasamy ThiraviyamNo ratings yet

- Baboolal VishwakarmaDocument2 pagesBaboolal VishwakarmababoolalvishwakarmaNo ratings yet

- ResumeDocument4 pagesResumerenison86No ratings yet

- Pallab Roy Chowdhury: Sr. Plant EngineerDocument2 pagesPallab Roy Chowdhury: Sr. Plant EngineerAlokeNo ratings yet

- Mazhar 1Document4 pagesMazhar 1Mohammed SultanNo ratings yet

- CV - SamBen Jose 2023Document4 pagesCV - SamBen Jose 2023MECH SAMNo ratings yet

- Sujith Mohandas: Career ObjectiveDocument2 pagesSujith Mohandas: Career Objectivesunil601No ratings yet

- Company ProfileDocument16 pagesCompany ProfileAyisha Ammu86% (7)

- Project Report On Trainig and Development of Employees In: Amalgam Steel Power Limited Amalgam Steel Private LimitedDocument40 pagesProject Report On Trainig and Development of Employees In: Amalgam Steel Power Limited Amalgam Steel Private LimitedSHIVANG SINGHNo ratings yet

- BSL ReportDocument80 pagesBSL Reportbhatia_nikhil100% (1)

- Resume - Bryce ShawDocument2 pagesResume - Bryce ShawBryce ShawNo ratings yet

- Ricky Resume SDocument3 pagesRicky Resume SSrinivas MangipudiNo ratings yet

- Ram Raj YadavDocument2 pagesRam Raj YadavRam Raj YadavNo ratings yet

- Rajat Baran Chakravarty: ST THDocument4 pagesRajat Baran Chakravarty: ST THSAMSON GLOBALNo ratings yet

- Sasikumar MuniappanDocument2 pagesSasikumar MuniappansasikumartvsNo ratings yet

- Vinod Kumar - K J S Cement PDFDocument4 pagesVinod Kumar - K J S Cement PDFvinod_eicsNo ratings yet

- Resume: Sunil Kumar Morwal Oct. Mechanical Engineer Project & CommissioningDocument4 pagesResume: Sunil Kumar Morwal Oct. Mechanical Engineer Project & CommissioningSunil kumar MorwalNo ratings yet

- Project Report: Recruitment & Selection ProcessDocument43 pagesProject Report: Recruitment & Selection ProcessnutanNo ratings yet

- Curiculum Vitae: Liju ThomasDocument2 pagesCuriculum Vitae: Liju ThomasNikhil SinghNo ratings yet

- Milan DelavadiyaDocument1 pageMilan Delavadiyamilldell67No ratings yet

- Seeking SAP PP Consultant RoleDocument3 pagesSeeking SAP PP Consultant RoleUma MaheshwarNo ratings yet

- Updated ALOK RESUME PDFDocument4 pagesUpdated ALOK RESUME PDFALOK KUMARNo ratings yet

- Senior Mechanical Engineer Seeking Challenging Energy Audit AssignmentsDocument2 pagesSenior Mechanical Engineer Seeking Challenging Energy Audit AssignmentsShankker KumarNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)