Professional Documents

Culture Documents

26m Tug for Sale - $1.62m

Uploaded by

gamronOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26m Tug for Sale - $1.62m

Uploaded by

gamronCopyright:

Available Formats

Workboats International provides Boat and Ship Sales, Marine Insurance, Business Opportunities and Consutancy Services Professional

Services Division includes: Marine Valuations, Project Managment, Condition Reports, Consultancy and Deliveries HQ: +64 3 337 6253 | Fax: +64 3 337 6259 | ships@workboatsint.com | www.workboatsint.com

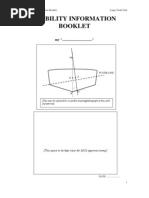

NEW BUILD - 26m Tug

Listing ID: 433875

DESCRIPTION: LENGTH: BEAM: DRAFT: LOCATION: BROKER: PRICE: PRICE NOTES: NEW BUILD - 26m Tug 26.0m 8.0m 3.65m ex Shipyard, HongKong Geoff Fraser USD 1.62m Available for Fast Delivery

General Description

26mNKTug

Principal Specification LOA: 26.0m LBP: 23.588m Breadth Mld: 8.0m Depth Mld: 3.65m Design Draft: 3.0m Classification: NK Complement: 10 person Registration: Singapore Fuel Tank Capacity: 134.0mt Water Tank Capacity: 53.0mt

Propulsion System Main Engine: 2 Units Yanmar 6AYM-ETE Marine Diesel; Engine at 610kW (829HP) at 1900RPM

Gear box: 2 Units Yanmar Gearbox Ratio 5.91:1 with class certificates

Generator: 2 Units Yanmar, 2x50kW

Propeller: FPP with Solid 4 Blades Manganese Bronze

Spark Arrestors: On all exhaust silencer

Kortz nozzle: 2 units

Steering Gear: 1 unit 2.5 tons electro hydraulic, single station

Deck Machinery and Equipment Anchor Windlass: 1 unit 380 model Dia. 17.5mm electrical hydraulic anchor windlass c/w double gypsy (based on class requirement)

Anchor: 2 units 420kg stockless bower anchor

Chain Cable: 10 shackles of dia 17.5mm Stud Link cable

Towing Hook: 1 unit c/w pin pulling quick release 25T-h capacity 25 Tons

Electrical

10 April 2013 - ID: 433875

Page 1 of 5

All Electrical cables and accessories (switch boxes, bulbs etc.) will be of marine type. Running of Electrical cables installed in proper marine trunking

Stern Tubes and Shafting Water Lubrication Stern Tubes with BTC Flange cutless bearing C/W 2 Length stainless steel (AISI316) Tail Shaft Dia. 6-1/2

Pumps All pumps and piped were arranged in accordance to be installed in Good Marine Practice and Classification Requirement

G.S. and Fire Pump: 1 unit KOSHIN brand with motor KOSHIN brand of capacity 450L/min at 40m total head

Bilge & Ballast Pump: 1 Unit KOSHIN brand with motor KOSHIN brand capacity 450L/min at 40m total head

Fuel Transfer Pump:1 Unit ASAHI brand with motor ASAHI brand of capacity 100L/min

Fresh Water Pressure: 1 Unit WARLUS brand of capacity 2cu.m/hr at 40PSI

EmergencyPortable:2PortableYANMARDieselWaterPump

Sea Water Pump: 1 Unit WARLUS Brand

Wheelhouse Equipment Steering and control console fitted with instrument panel, main engine control (Electronic Remote Control Type), switches for navigation lights, searchlights, flood lights, horn buttons, intercom and PA system, rudder indicator, and clear view screen wiper. Control: 1x Fwd Clear View Screen: 1 unit Clinometer: 1 unit Marine Clock: 1 unit Barometer: 1 unit Ship Set Shaft Tachometer: 1 unit Binoculars: 1 unit International code flags: 1 set Chart Table: 1 unit Marine Air Horn: 1 unit

Radio and Navigation Equipment SSB radio: 1 set FURUNO IC-M710 c/w 1 Unit AC/DC power supply for SSB SART: 1 Set ACR Pathfinder 3 Echo Sounder: 1 Set FURUNO FVC-620 GPS Navigator: 1 Set FURUNO GP-32 EPIRB: 1 Set SEP-406 MHz SAMYUNG VHF Radio: 1 Set ICOM VHF Radio IC M304 c/w 1 Unit AC/DC Power Supply for VHF Radar AC/D: 1 Set Furuno 1715 MKII (24NM) c/w 1 unit AC/DC power supply for Radar

Ship Communication Electric Engine Telegraph: 1 set PA system: 1 set with Horn Speaker on deck Intercom: 3 Units Wall mounted Type

Navigation Lights, Fire Fighting Equipment and Life Saving Appliances AllinaccordancewithClassificationSocietysSpecificationandrequirementoftheGovernmentAuthorityfortheIntendedtradeofthe subject tug

Emergency Alarm System To be fitted with means of raising alarms in emergencies. The preferred system is bells operated by means of beak glass call poits or central control

Signals shall be as follows -IntermittentRingingGeneralEmergency -ContinuousRingingAbandonShip -ShortRingsAllclear

Engine Room Oily Water Separator: 1unit Dongfang brand with capacity of 0.25cu.m/hr , 15ppm (IMO comply) Fuel Filter: 1 unit TWIN Racor for Main engine and Genset Blower Fan: 2 units with 3800cfm Filter (Main engine And Generator): 1 unit Tool Bench: 1 unit

Washplace & Toilet One wc pedestal with seat One shower set One washbasin One mirror

10 April 2013 - ID: 433875

Page 2 of 5

Pumps, Plumbing and Piping All pumps and pipes were arranged in accordance to Good Marine Practice and Classification requirements

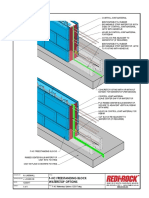

Main piping material used shall be as follow Bilge and Ballast Piping: Galvanized Steel SCH 80 Fuel Oil Piping: Seamless Black Mild Steel SCH 40 Lub Oil Piping: Seamless Black Mild Steel SCH 40 Raw Water Cooling Piping: Galvanized Steel SCH 80 Fresh Water piping: Galvanized Steel SCH 40 Salt water piping: Galvanized Steel SCH 80 Sea Chest: Galvanized Steel SCH 80

Pipe Work Colouring All exposed piping systems can be identified with colour bands in accordance with the international colour schemes Bilge and Ballast: Black Fire Main: Red Fresh water system cold: Blue Fresh water system hot: Blue with Red Bands Fuel Oil: Brown Lube Oil: Yellow Hydraulic: Purple Sea Suction: Green Sea Water Cooling: Light Green Compress Air: Pink

Accommodation and Galley Cabins: 1x2 on main deck; 2x4 below main deck W.C.: 1 VentilationFan:(2)8exhaustfan(2)18exhaustfan Side Scuttle: 7; each with dedlight cover Cement Flooring: reinforce with wire mesh finish with glaze tiles Freezer: 1 x 1.5 cbm Refrigerator: 1 x 1.0 cbm Electrical Stove: 1

Carpentry Work Fancy Plywood and Materials to be used for panelling accessories at wheelhouse, mess room, officers and crew cabin

Fenders Rubber Fenders and Tyres all around at appropriate places

Painting, Hull Finish and Cathodic Protection All external surfaces of bttom and side plating of the steel hull palte were wired brushed and sand-blasted before applying three (3) coat of marine paints of good ship building practice with Hempel Brand

Anodes Suitable numbers (about 28 pcs) are to be welded to the Hull

Painting, Engine Room Bilges Hempel brand used as suitable protection paint for the engine room bilges and areas below engine floor

Hull Coat Below the waterline Above the waterline Wheelhouse Engine Room F.O. tank engine room Water tank (engine room)

Under Coat 2 2 1 1 2

External 2 (anti-fouling) 2 2 2 -

Material and Scantling Keel Plate: 12mm Bottom Plate: 9mm Side Plate: 9mm Main Deck Plate: 9mm Bulkheads Plate: 8/90mm Bulwark Plate: 8mm Superstructure: 6mm

Mast Class and Port Register Requirement

Air Conditioning

10 April 2013 - ID: 433875

Page 3 of 5

Split unit air-conditioner in accommodation area and wheelhouse

Certificates Builder Certificate Certificate of Class Registration Certificate Safety Construction Certificate International Tonnage Certificate International Load Line Certificate Materials and Equipment Certificates

Drawings The relevant drawings as approved by Class are to be supplied and all installation drawings

Manuals of Machinery and equipment Manual of all machinery and equipment supplied will be provided in English version. These include all necessary drawings and schematics

10 April 2013 - ID: 433875

Page 4 of 5

IMPORTANT: The particulars and specifications are supplied by the vendor and not Workboats International. Such information has not been verified and may be incorrect. Please do not rely on particulars and specifications unless you have verified their accuracy.

NEW BUILD - 26m Tug Images

10 April 2013 - ID: 433875

Page 5 of 5

You might also like

- Marine Power CatalogueDocument98 pagesMarine Power Cataloguesafaa salamNo ratings yet

- Lifting MethodsDocument10 pagesLifting Methodsselva1965No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- PTT BVW#7 Compressor Station Electrical Design ManualDocument20 pagesPTT BVW#7 Compressor Station Electrical Design Manualgamron100% (2)

- Cargo Ship General ArrangementDocument1 pageCargo Ship General Arrangementgamron0% (1)

- SINGLE LINE DIAGRAM (H-8001) Rev 2Document13 pagesSINGLE LINE DIAGRAM (H-8001) Rev 2wahyuNo ratings yet

- Stability StandardDocument78 pagesStability StandardJORGE ARTURO TORIBIO HUERTANo ratings yet

- 26m Crew Boat SpecDocument18 pages26m Crew Boat SpecadhityamspNo ratings yet

- Sname New Steel EstimationDocument9 pagesSname New Steel EstimationAditya PriyawardhanaNo ratings yet

- 2350 TEU General ArrangementDocument1 page2350 TEU General Arrangementgamron100% (1)

- 50m AHTS GA PDFDocument1 page50m AHTS GA PDFgamron0% (1)

- Column Design of 300x400Document24 pagesColumn Design of 300x400karthik100% (1)

- Design Criteria (Based On BS)Document23 pagesDesign Criteria (Based On BS)Sebastian Eron DavidNo ratings yet

- SD 1.1.2 Ship DimensioningDocument52 pagesSD 1.1.2 Ship DimensioningTommyVercetti100% (1)

- SCANTLING (Alpha Tango)Document11 pagesSCANTLING (Alpha Tango)gelo_17No ratings yet

- Aluminum Structural Analysis of Porta Batumi FacadesDocument39 pagesAluminum Structural Analysis of Porta Batumi Facadesismail TORLAK100% (1)

- Propeller CatalogDocument156 pagesPropeller CatalogPoowadol NiyomkaNo ratings yet

- 1.H2219-20 MSBD (Rev.e - 11.04.11)Document138 pages1.H2219-20 MSBD (Rev.e - 11.04.11)Aleksandr AndreevNo ratings yet

- General Arrangement PDFDocument33 pagesGeneral Arrangement PDFJeesonAntonyNo ratings yet

- Effect of The Moonpool On The Total Resistance of A DrillshipDocument66 pagesEffect of The Moonpool On The Total Resistance of A DrillshipNitin ShindeNo ratings yet

- Piping Design and Operations Guideobook - Volume 1 PDFDocument86 pagesPiping Design and Operations Guideobook - Volume 1 PDFgamron89% (35)

- Inclining Experiment Report of Manzari - 1Document12 pagesInclining Experiment Report of Manzari - 1Hari RamNo ratings yet

- Adts 2732005Document2 pagesAdts 2732005Tejas PatilNo ratings yet

- Vanbenthuysen Adrian Nordhavn76Document53 pagesVanbenthuysen Adrian Nordhavn76api-299532402No ratings yet

- 5400 TEU General ArrangementDocument1 page5400 TEU General ArrangementgamronNo ratings yet

- 310-1512715 Bilge System H01Document11 pages310-1512715 Bilge System H01buturca sorinNo ratings yet

- Atlas Copco: Stationary Air CompressorsDocument66 pagesAtlas Copco: Stationary Air CompressorsChriss Vzz100% (4)

- Technical Report on Basic Naval Architecture CourseDocument415 pagesTechnical Report on Basic Naval Architecture Coursenauval.arch100% (1)

- Learning Maxsurf: ManualDocument169 pagesLearning Maxsurf: ManualRAJESH GANESANNo ratings yet

- BOLLARD PULL TRIAL CODE FOR TUGS WITH STEERPROP PROPULSORSDocument12 pagesBOLLARD PULL TRIAL CODE FOR TUGS WITH STEERPROP PROPULSORSKimcuong LeNo ratings yet

- Optimize Cargo Ship Design for 5500 DWT PayloadDocument70 pagesOptimize Cargo Ship Design for 5500 DWT PayloadTuswanNo ratings yet

- Fundamentals of Metal FormingDocument9 pagesFundamentals of Metal FormingGeorge CamachoNo ratings yet

- The Use of Geosynthetics in Road ConstructionDocument47 pagesThe Use of Geosynthetics in Road ConstructionPaulo Nascimento100% (2)

- Offshore Hydro MechanicsDocument570 pagesOffshore Hydro MechanicsAsier DCNo ratings yet

- ASD Tug Specification PTB PDFDocument29 pagesASD Tug Specification PTB PDFAndi irfanNo ratings yet

- Bow Thruster Tb35tDocument5 pagesBow Thruster Tb35tGiyan Arpero ManiaNo ratings yet

- SeaBoats ID1127Document14 pagesSeaBoats ID1127nipper7No ratings yet

- Tug - ESKORTDocument6 pagesTug - ESKORTudelmark100% (1)

- ABS Rules HSC Part 3e PDFDocument236 pagesABS Rules HSC Part 3e PDFamin100% (2)

- Doka Bean h20 P ManualDocument20 pagesDoka Bean h20 P Manualnikosbbw100% (2)

- Container Ship PlanDocument1 pageContainer Ship PlangamronNo ratings yet

- Container Ship PlanDocument1 pageContainer Ship PlangamronNo ratings yet

- Container Ship PlanDocument1 pageContainer Ship PlangamronNo ratings yet

- SD 1.5.1 Hull FormDocument48 pagesSD 1.5.1 Hull Formadi_wirawan3837100% (1)

- Estimativas CatamaranDocument145 pagesEstimativas CatamaranAndersonNo ratings yet

- Section Modulus CalculationDocument3 pagesSection Modulus Calculationtejaswi_rao_1No ratings yet

- Electrical Load Requirements for 36M Catamaran FerryDocument11 pagesElectrical Load Requirements for 36M Catamaran FerryVECTOR MARINE & OFFSHORE TECHNOLOGYNo ratings yet

- Building Project ReportDocument32 pagesBuilding Project ReportAssif Yousuf100% (2)

- Dimensional Constraints in Ship DesignDocument6 pagesDimensional Constraints in Ship DesignTat-Hien LeNo ratings yet

- Havyard 934 Technical Specification Rev-0 (27 02 2018), Søker PDFDocument151 pagesHavyard 934 Technical Specification Rev-0 (27 02 2018), Søker PDFNovan AndriantoNo ratings yet

- Ship Hull DesignDocument66 pagesShip Hull DesignRiyan EsapermanaNo ratings yet

- Ballast CalculationDocument18 pagesBallast Calculationmyusuf_engineerNo ratings yet

- Tug - BUYUKDEREDocument6 pagesTug - BUYUKDEREudelmarkNo ratings yet

- Damen Year Book No1Document132 pagesDamen Year Book No1minhloc4100% (1)

- CR Mo Issues of Concern 6Document33 pagesCR Mo Issues of Concern 6Asad Bin Ala Qatari100% (1)

- MO Aluminium Catamarans Rule Developments Supporting Document V1.0Document37 pagesMO Aluminium Catamarans Rule Developments Supporting Document V1.0tyu100% (2)

- Qingdao Luhang Marine Airbag SpecsDocument1 pageQingdao Luhang Marine Airbag SpecsantonNo ratings yet

- Tank Sounding Manual (MANUAL-T - 4681251 - 1 - A) - 1Document143 pagesTank Sounding Manual (MANUAL-T - 4681251 - 1 - A) - 1Hung LeNo ratings yet

- Ship Hull Calculation - Calculations - Paint Inspector Com PDFDocument3 pagesShip Hull Calculation - Calculations - Paint Inspector Com PDFНиколай СтешенкоNo ratings yet

- Putri Iona - Survey StatusDocument28 pagesPutri Iona - Survey StatusDiana Triswasti KumariNo ratings yet

- Design of Ship RuddersDocument82 pagesDesign of Ship RuddersGerard Sarg100% (1)

- Evaluation of Resistance Prediction For High-Speed Round Bilge Hull Forms - 2011Document10 pagesEvaluation of Resistance Prediction For High-Speed Round Bilge Hull Forms - 2011Maurizio BernasconiNo ratings yet

- Crew Boat 20 MDocument1 pageCrew Boat 20 MokaNo ratings yet

- Legally Binding US Document Standard for Sliding Watertight DoorsDocument7 pagesLegally Binding US Document Standard for Sliding Watertight DoorsRajkumarNo ratings yet

- Tug DesignDocument8 pagesTug DesignCharles DublinNo ratings yet

- Advanced OutfittingDocument43 pagesAdvanced OutfittingjishnusajiNo ratings yet

- Marine Engineering & Naval Architecture DictionaryDocument848 pagesMarine Engineering & Naval Architecture Dictionaryandevari100% (1)

- Koelbel Steps PDFDocument54 pagesKoelbel Steps PDFOnggo Firstha Nichita100% (1)

- RB - Aluminium A60 Hinged DoorDocument2 pagesRB - Aluminium A60 Hinged DoorHayden Kyle KeigleyNo ratings yet

- Design and Simulation of Marine Propeller With Different Blade GeometryDocument9 pagesDesign and Simulation of Marine Propeller With Different Blade GeometryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Shipbuilding Drawing-II SBT-8054 T P C 0 9 3Document2 pagesShipbuilding Drawing-II SBT-8054 T P C 0 9 3reaz uddin100% (1)

- Deltamarin Eedi Study For Emsa Final ReportDocument159 pagesDeltamarin Eedi Study For Emsa Final ReportPipolo PippoNo ratings yet

- Recent Advances in Damage Stability AssessmentDocument18 pagesRecent Advances in Damage Stability AssessmentgksahaNo ratings yet

- MV AzzirDocument106 pagesMV AzzirDominic VillamanteNo ratings yet

- Giulio Verne Cable Laying ShipDocument9 pagesGiulio Verne Cable Laying ShipGaetan Dufour100% (1)

- Dry Docking: The Major EventDocument25 pagesDry Docking: The Major EventSukesh DattaNo ratings yet

- Operation & Maintenance ManualDocument21 pagesOperation & Maintenance ManualMohammed BasionyNo ratings yet

- Form CoefficientsDocument5 pagesForm CoefficientsjishnusajiNo ratings yet

- MV IreliaDocument74 pagesMV IreliaDominic VillamanteNo ratings yet

- Stability CriteriaDocument7 pagesStability CriteriaSuperducksNo ratings yet

- Windship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985From EverandWindship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985C SatchwellNo ratings yet

- The Theory and Practice of Ship BuildingDocument121 pagesThe Theory and Practice of Ship BuildinggamronNo ratings yet

- Advances in Marine StructuresDocument2 pagesAdvances in Marine StructuresgamronNo ratings yet

- 20M Workboat - Pelagic Design - Marine Engineers - CornwallDocument1 page20M Workboat - Pelagic Design - Marine Engineers - CornwallgamronNo ratings yet

- 2 Op Amp ConceptsDocument50 pages2 Op Amp ConceptssurajkaulNo ratings yet

- Double Hulls PDFDocument54 pagesDouble Hulls PDFgamronNo ratings yet

- Sib Motor - 06 April 2011 PDFDocument15 pagesSib Motor - 06 April 2011 PDFgamronNo ratings yet

- 30m Tug GADocument1 page30m Tug GAgamronNo ratings yet

- PT1801 Ga PDFDocument1 pagePT1801 Ga PDFgamronNo ratings yet

- 37m Landing CraftDocument3 pages37m Landing CraftgamronNo ratings yet

- PipingDocument1 pagePipinggamronNo ratings yet

- l297 - Stepper Motor Driver Circuit PDFDocument1 pagel297 - Stepper Motor Driver Circuit PDFgamronNo ratings yet

- Asus Laptop Schematic DiagramDocument56 pagesAsus Laptop Schematic Diagramlisycat100% (1)

- LC - 40L Schematic Diagram PDFDocument13 pagesLC - 40L Schematic Diagram PDFgamronNo ratings yet

- Build the K-28 Pocket CruiserDocument15 pagesBuild the K-28 Pocket Cruisergamron100% (1)

- Tanker Pilot Detail PlanDocument1 pageTanker Pilot Detail PlangamronNo ratings yet

- PTT HVAC Bidding Documents for BVW #7 Compressor Station ProjectDocument19 pagesPTT HVAC Bidding Documents for BVW #7 Compressor Station ProjectyugerajdNo ratings yet

- K60 Boat Mechanical DrawingDocument1 pageK60 Boat Mechanical DrawinggamronNo ratings yet

- Marine Steel Plates: Supply SpecificationDocument1 pageMarine Steel Plates: Supply SpecificationgamronNo ratings yet

- Name of Project: Structure Parcel OfficeDocument31 pagesName of Project: Structure Parcel Officemohan sundarNo ratings yet

- Shear Behavior of RC Beams With Full or Partial SFRC Shear SpanDocument16 pagesShear Behavior of RC Beams With Full or Partial SFRC Shear SpansanjusamsonNo ratings yet

- GREE CATALOGO Cac 2011Document162 pagesGREE CATALOGO Cac 2011lasNo ratings yet

- Shear Strengthening of RC Beams With Web-Bonded Continuous Steel PlatesDocument12 pagesShear Strengthening of RC Beams With Web-Bonded Continuous Steel PlatesRachida KrachaiNo ratings yet

- Sleepers (RBT)Document85 pagesSleepers (RBT)Shonak G PurohitNo ratings yet

- Warkworth BridgesDocument2 pagesWarkworth BridgesandreeaNo ratings yet

- News 01 08 01 2019 PDFDocument109 pagesNews 01 08 01 2019 PDFShaileshRastogiNo ratings yet

- Raffles CityDocument2 pagesRaffles CityCherylyn ConcepcionNo ratings yet

- Biax For Ms Windows: Strength Analysis of Reinforced Concrete SectionsDocument51 pagesBiax For Ms Windows: Strength Analysis of Reinforced Concrete SectionsEdisson Alberto Moscoso AlcantaraNo ratings yet

- Kobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesDocument6 pagesKobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesPhilNo ratings yet

- Romanesque ArchitectureDocument15 pagesRomanesque ArchitectureRida Irfan100% (1)

- Ministry Hospital Project Coordination IssuesDocument1 pageMinistry Hospital Project Coordination IssuescdnaveenNo ratings yet

- Live Loads On Bridge Superstructures: BelowDocument8 pagesLive Loads On Bridge Superstructures: BelowMark Angelo FloresNo ratings yet

- ACE GuidanceDocument53 pagesACE Guidancemohamed_gameel_3No ratings yet

- Brazing and Braze WeldsDocument13 pagesBrazing and Braze WeldsdocsdownforfreeNo ratings yet

- Macaulay's MethodDocument20 pagesMacaulay's MethodMalingha SamuelNo ratings yet

- Control Joint Waterstop Installation GuideDocument1 pageControl Joint Waterstop Installation GuideED WARMONDNo ratings yet

- Tech Tips 16 - What Causes Gray Coloured Hot Dip Galvanized Coatings On SteelDocument2 pagesTech Tips 16 - What Causes Gray Coloured Hot Dip Galvanized Coatings On SteelLong TomahawkNo ratings yet

- WWT6 - Colection and Conveyance of SewageDocument37 pagesWWT6 - Colection and Conveyance of SewageHelder MbidiNo ratings yet