Professional Documents

Culture Documents

Asme Joint Review-Qrr-Uec 2012

Uploaded by

Keiti FilbrichOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Joint Review-Qrr-Uec 2012

Uploaded by

Keiti FilbrichCopyright:

Available Formats

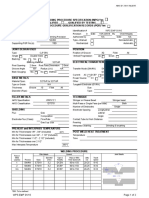

QUALIFICA1"ION REVIEW REPORT

,

[{] Renewal D New Authorization Application Number.

101902

j"''''11 'ttl "."".If,

D Rereview D Other Report Oate:

FebnltUY. 10, 2012

Part I General Infonnation

Applicant Details

Enter Company's

name and location

being reviewed.

Was Application or

Form 0 revised:

Requested

Authorization(s)

Indicate type of Certit

lcate(s) applied for:

Quality Program IS

applicable for'

(Company Name: ASME Idl!!ntlfklluon Number.

Unimit Engineering Public Company Limited 4J570

Division (If Applicable):

Shop Address:

1017-8 Mil. J Chonburi-Banbunl!-Pa-Yub Road, Nonllchak

City: county/District

Banbunll

State/Province:

Country: Postal Coae (ZIP):

Thailand 10170

Chonburi

[l] No DYes Revised & Enclosed: o"Application" D"Form 0" o"Application & Form 0"

___________________ ___________________ ___ _____

DA DE OM [l]S OPp

DH OHLW OHV DV DUV DUV3

DUM [{]U2 OU3 DRP DH(Cast)

Dr Ouo Orv Oro DPRO

[0 Shop Only o Field Only [l] Shop & Field Sites )

Certlflcate(l)

Prelently Held

Number(l) and

Expiration Date(s)

Dellgnator

S

U

U1

Certificate N

17636

17637

17638

Expiration Date

March 14,1012

March 14,2012

March 14. 2011

Dellgnator Certificate N Expiration Date

An extension to the Expiration Oate(s) was issued: o Yes [l]No Valid Until:

Remarks Indicate

New Additions,

Tenninations, or

Extensions

I

I

J l

I

ream Makeup

iTeam Leader: Jonathan T. J. Chen Organization: ASME

AIS: Cherdchai Sattayaphan Organization: ABS Boikr & Marine Il1Sllrtlllce Co.

Show Name and

AI: Chutchai Phromngam Organization: ABS Boikr & Marilre 111SIlrtIIIce Co.

Affiliation of each

J.A.:

Team Member

Observer:

Observer:

Order of Events

Activitv

Team Document and Manual Reliew

Entrance Meeting and Shop Tour

Manual Retiew Report

Implementation Demonstration

Implementation Demonstration

Team Closed Meeting

Exit Meeting

Organization:

Organization:

Organization:

Date

Feb. 09 11

Feb. 09,11

Feb. 09 11

Feb. 09,11

Feb. 10, 11

Feb. 10, 11

Feb. 10, 11

Duration (Hrs)

4 -Hrs.

1-Hrs.

0.5 -Hrs.

3.5 -Hrs.

7.5 -Hrs.

0.5 -Hrs.

1-Hrs.

Attendance List Ust of attendees is shown on the attached Attendance Sheet(s)

A115Form QRR01/0112011RO

Location

Hotel

On Site (Plmd & Ofjices)

On Site (Office)

On Site (OffICe)

On Site (Plant & Offices)

On Site (OfJke)

On Site (OffICe)

- - - -

------------- ----------------------------------------

-- - --- ---- --

---------------------------------------- -------------------

----------------------------------------- -------------------------------

---- -- - ----- - ------ - -- -- -

Part II - Administrative/QS QUALIFICA1"ION REVIEW REPORT

rCompany Name: ASME Identification Number:

Unimit Engineering Public Company Limited 43570

Previous Open

or Recurring

Deficiencies

Remarks Identify

previous deficiencies

that were either left

open in the previous

Joint Review or were

repeated during the

current Joint Review.

Explain corrective

action taken to close

deficiencies. Attach a

copy of previous and

current Forms ac

Inspection

Services

Remarks Enter any

information necessary

to explain Inspection

Services. An example

would be if coverage

by the AI or CI is not

considered adequate,

or if the Inspection

Service activities are

not performed.

Manual Review

Were any deficiencies identified during the previous Joint Review left open or were also found during this

Joint Review?

DNA (New Issue) DYes [Z] No (If "Yes" see Remarks)

The reviewteam has ,'erifiedthe effectiveness ofcorrective action taken for the deficiencies identified during the

DUV3

previous Joint Review. No recurrence ofsuch deficiencies was found during this Reliew.

AlA of Record: ABS Boiler and Marine Insurance Company

Type of 0 Full Tim=--0 Part Time [ ] No A. I. Required

Has an AlA other than the AlA of Record performed inspections?

___

If "Yes" Name of the other AlA:

If ''Yes'' does Manual address such use according to ASME Policy?

0yes DNo

(If "No" see Remarks)

If the applicant is operating under the Mass Production provisions of

the Code (such as UG-90(c)(2), and Appendix 35) have their

inspection and Quality Control procedures received acceptance by DYes

DNo [Z]NA

the AlA of Record, and the Legal Jurisdiction, or by an ASME

Designee?_________________

DH(Cast)

Duv

Applicant utilizes a Certified Individual

DUM DHV Dv DUD

(CI) for Certification of MDR under:

DPES DTD DTV

[Z] Not Applicable (No CI.)

Is coverage by AI or CI adequate? [Z] Yes D No (If "No" see Remarks)

Manual Presented to Tearn: Edition/Issue: 1 Revision: 24 Date: Dec. 29, 2011

.----------------------------- -- --- - -- -- ----

Was the Manual presented at the beginning of the Joint Review accepted by the Authorized Inspector?

DNA(NoAIA) [Z] Yes D No (If "No" see Remarks)

Was Manual Revised and Accepted by A. I. or ASME Designee? [Z]Yes DNo (If'No'seeRemarks)

Editionllssue: 2 Revision: 0 Date: Feb. 10,2012

ReView of the Manual IS against the applicable Construction Code requirements, WIth supplemental

information from the completed Guide for ASME Review Teams(A1.20). Indicate in Part IV of this report

the results of this review.

Remarks The second shop address has been listed in the Company Quality ManuaL

The Company Quality Manual includes controlsJeaturesfor Field Site

The Company Quality Manual includes controlsfeaturesforSection VIII-2 item construction activities.

I

l )

A1 15 Form ORR- 01/0112011-RO

--------- -- - -----

- ---- - -- ---- - -

Part III - Implementation QUALIFICATION REVIEW REPORT

[ Company Name: . ASME identifICation Number.

Unimit Engineering PubUc Company Limited 4J570

Description of

Implementation

Item (including

units of measure)

For Boiler and

Pressure Vessel

Programs

Remarks

Enter any other

information necessary

to explain the

demonstration item (i.e.

Code Cases, 831.1,

Earlier Code Ed. &

Addenda, How Code

knowledge established

to current Code or

when Applicant applies

for S, and U, or "T)

Description of

Implementation

Item for Pressure

Relief Device

Program

Remarks

Enter any other

information necessary

to explain the

demonstration item

Describe Vessel, Boiler or Part: TEST SEPARATOR, S-9930 (Named as per drawing)

____ A

_._---_...------_.._-_.__.......- .- --- . - - -.-- ..

-

Code Section, Edition, and if applicable, Addenda Section VIII Div. 1

Ed.

2010

Add.

11

-_._._.._-_.._........_.....__._.-

-----

._._-

-- ---

Design Pressure:

4585 kPa Design Temp.: 120 C MAWP:

4589 kPa

@

120 OC

--------_. ____ A

---- - --

MDMT:

10 C @

-----

--_.._..-._-_.._---_._--

4589

...

kPa

Extent of NDE:

lOO%,RT 1

----------------------------- ..__.__......_- ..

PWHT: Dyes [Z] No DNA

-_. ..._--------------_.__.-_. _

Overall Dimensions:Length

Component

SheU

2:1 elHpsoldal head

3500mm TLlTLx ID

--- -_.

..._..._--------.-._....

MAEWP: -

kPa

@ -

OC

-

-_.

-

..

...

-

Impact Testing: DYes [Z] No

_.

DNA

1400mm xOAL Iellgti 4727..

Class J(J() SA-105M DNSoo Maln Flange 16.5

SA-106M Gr.B 80 DN200 NouJes ScIuNWit

Class J(J(J SA-105M DNSO Long Neck Flanges 16.5

U drawing #: GA-0089-OS151789, Rev.02, Client Spec.PWGS-MEC-I0IIR0. Caklllatlon #:CA-tHJ89-0S1S17U.

For "U2" Demo., a Reactors Surge Drum, D-20oo, was designed in accordance willa Sec. VlIl-2,201MD.

Design PressureIMAWP: 6000Kpa, Design Temp.: 150OC, MDMT:15OC@60ooKpa, MAEWP:No. Joilfl CIIL A,

8.100% RT and 10%PT. CaL Do' 100%UTplus 10% PT. CaL C:100%RT. PTforedgepreparatioltfoulaell,

head and cut edgefor nozzle. PWHT; Yes, Impact Test, No. Lengtla:TL!TL8024x ID 2000mm, MtIiII. MateMl:

ShelVHead:SA-516M Gr. 485 x 42/37.4mm. Main Flange; SA-105M, Closs 600, BI6.5. UDSN 22SPD20fJ0-0l,

Rev.B and MDR # MD-U2-D2000, Rev.O. Both documents have been certified by RPEs respectively. C41a11t1do1t

report:CA-U2-001-D2000, Rev.O. througla the sojtware"COMPRESS BUILD 7200". Tlte COItIJHIIIy

demonstrated the capability ofproducing applicable calculations.

Device Manufacturer: N/A

Code Section, Edition, and if applicable, Addenda Ed. Add.

Device Type: Size:

Set Pressure: Test Medium:

[

]

Material Thickness - Class - Schedule

SA-Sl6M Gr.48S 28 ..

SA-Sl6M Gr. 485 Mill. 27 ..

General Team

Is there any addition information the Team feels is important for the ASME to consider?

Comments or

[ DYes [Z] No (If"Ves"seeRematts)

Concerns

Remarks r

Enter any information, I

general comments or I

concerns inclUding lack

of Team concurrence.

l

I

I

A115 Form ORR 01f0112011-RO

Part IV - Summary QUALIFICATION REVIEW REPORT

Company Name:

Unimit Engineering Public Company Limited

Shop Address:

1017-8 MIL 3 Chonburi-Banbun/:-Pa-Yub Road, Nongchak

ASME Identification Number.

43570

Elements marked "Yes" =Acceptable, "DFC" =Deficiency Found and Corrected, "No" =Deficiency Open, "NA" =Not Applicable.

Forms QS and QC detail elements marked "DFC" or "NO". Elements marked "NA" are explained in Comments below

MANUAL IMPLEMENTATION

N QUALITY SYSTEM ELEMENTS YES DFC NO NA QB N YES DFC NO NA QCN

1 General .{ 1 .{

2 Authority and Responsibility .{ .{

3

4

Organization

Drawings, Design Calculations and Specification Control

.{

.{ 2

.{

.{

,

5 Material Control .{ 3 .{ 2

6 Examination and Inspection Program .{ .{

7 Correction of Nonconformities .{ .{

8 Welding / Brazing .{ .{ 3

9 Nondestructive Examination .{ .{

10 Heat Treatment .{ .{

11 Calibration of Measurement and Test Equipment .{ .{

12 Record Retention .{ .{

13 Sample Forms .{ .{

14 Inspector or ASME Designated Organization .{ .{

15 Certified Individual .{ .{

16 Certifications (Methods other than written signature) .{ .{

N COMMENTS

I

Team Recommendation

[Z] Issue Certificate(s) with Scope(s) shown below,

D Issue Certificate(s) with Scope(s) shown below after acceptable Follow-Up Report (QCFR) is submitted within 30 days

by the; D AlA, D ADO or D ASME Designee

D Rereview or D Other:

List scope(s) to be used if Certificate(s) are issued: S-1, U-4, U1-3

Do differ from __.__._O Yes [Z] No ...__._..0.

Exit Meeting: The Applicant was advised of the deficiencies, if any, as noted on Form(s) QS and QC; the Team's

recommendation; the confidentiality of the Review; and their right to request reconsideration or an appeal. A copy of Part IV

__ .. __ __ to the Applicant. _ .__._.._._.

Team Consensus: We have reviewed this report along with any associated Forms QB or QC, and based upon this review,

D NA (No AlA Involved) [Z] A Team Consensus was reached and the AlA will not be issuing a Minority Report or,

t j) D A Team Consensus was not reached A will be issuing a Minority Report.

&4",

Feb. 10, 1011 Chutchai Phromngam 11813 A Feb. 10, 1012. Jonathan T. J. Chen

Date A.I..J9nature Nat'!. Bel # Endorsement Date Team Leader Signature Certificate' Expiration

7 . ASMEStaff

Feb. 10, 1011 Cherdchai Sattayaphan 11435 A & B Review: ----j

Date A.I.S. Signature Nal'l. Bel # Endorsement ASME Staff Signature Date

A1.15 Form QRR-0110112011-RO

FORMQB SUMMARY OF MANUAL DEFICIENCIES AND CORRECTIVE ACTION Page 1 of 1

Company Name: ASME Identification Number.

Unimit Engineering Public Company Limited 43570

J

Code Reference

N:

1

DESCRIPTION OF DEFICIENCY

Paragraph

Section I Editorial change.5 necessaryfor continuity, clarification ofmeaning, consistency ofassignment and

A-301 responsibilities.

Section VIII-I,

Appendix 10-1, (

Section VIII-2

Annex2.E.l

General

Code Reference

N: 2 DESCRIPTION OF DEFICIENCY

Paragraph

Section VIII-2

Annex 2.E.5,

Para. The Manual does not address that

2.2.2.3, 2.3.3.2 -any change made to information provided in User's Design Specification andlor Manufacturer's Design RefHJrt

shall be reconciled with RPE or QE who certified the original documents.

Para. 2.4.3.2 -User's Design Specification and Manufacturer's Design RefHJrt shaY be presented to AIfor review to verify the

certification.

Code Reference

N: 3 DESCRIPTION OF DEFICIENCY

Paragraph

Section VIII-2 The Manual does not address that

Annex 2.E. 6, any material substitutions by the Company are subject to approval ofthe user.

Para.2.3.2.2,

Code Reference

N: DESCRIPTION OF DEFICIENCY

Paragraph

CORRECTIVE ACTION

Prior to exit meeting the Review Team was presented with a revised QC Manual incorfHJrating the corrections for the above

deficiencies along with the discussed editorial modifications and clarifications. The Manual was reliewed by the Team and accepted

by the Authorized Inspector as: Edition 2, Rt!lision 0 dated February 10,2012.

f -Ikn -r. ~ . ~ l

~ n T. J. Chen ~ p o r t Date: February. 10, 2012

Team Leader Print Name & Signature

A 1 35 Form-QB-01101/2011 RO

FORMQC

IMPLEMENTATION DEFICIENCY AND CORRECTIVE ACTION

Company Name: ASME Identification Number:

Unimit Engineering Public Company Limited 43570

CODE REFERENCE

N:

QCM PARAGRAPH

1 DESCRIPTION OF DEFICIENCY

Manual, Section 3,

Para. 3.4.2

Section VIll-2,

Para. 6.3.1.1(b) &

(c)

STATUS

[Z]Closed

DOpen

per Company Manual requirements, the NDE requirements for the vessel are one part ofinformation described

in the manufacturing drawings.

The NDE requirements for aU categoryjoint welds of "Reactors Surge Drum" designed according to the Section

VIll-2 have been specified in the drawings respectively. However,

the NDE requirements for joints preparation of cut edges in base materials to be used in constructing such

drum are not available in the drawings.

CORRECTIVE ACTION TAKEN

1. A Nonconformity Report #NCR-U2-00l-fHJ2 was issued to affected personnel in accordance with the QC

System.

2. Revised the drawings to include NDE requirements for joints preparation of cut edges in base materials to be I

used in constructing "Reactors Surge Drum".

3. The revised drawings have been reviewed and approved by authorizedpersonneL

4. Re-training ofthe required NDE's and extent described in drawing to COl'f!r Code requirements to affected

personnel by QC Manager.

5. NCR was closed out and accepted by AI.

TEAM LEADER REMARKS

a. Re-training of Code and Manual requirements to affectedpersonnel was conducted by QC Manager under AI's guidance.

b. No impact on acceptance ofSection VIII-2 l'essel design demonstration regarding Code compliance.

c. The actions taken are considered satisfactory and sufficient to permil closure ofthe deficiency.

d. No additional actions are considered necessary.

I

I

I

I

I

P ,114:" r;

T. J. Chen Report Date: February. 10,2012

Team Leader Print Name & Signature

A1.36 Form-QC- 01/01120 11-RO

FORMQC

IMPLEMENTATION DEFICIENCY AND CORRECTIVE ACTION Page 2 of

Company Name: ASME Identification Number.

Unimit Engineering Public Company Limited 43570

I

I

CODE REFERENCE

QCM PARAGRAPH

N: 2 DESCRIPTION OF DEFICIENCY

Section VIII-I, per Company Manual requirements, "the material mill certificate shaU be checked by authorizedpersonnelfor

Appendix 10-5, compliance with the applicable Code Section, Material Specifu:ation and Purcha'ie Order requirements ".

Manual, Section 4,

Para. 4.5.1.3. The supplemental requirements ofmaximum value ofcarbon content and carbon equivalent (CE) have been

specified in Material Purchasing Specification " PS-PL-0089-1'' for steel plates and "PS-FG-0089-1"for forged I

Material

Purchasing

parts.

Evidences show that the material certifu:ates ofpurchased steel plates andforged flanges hal'e been reviewed by I

Specification

"PS-PL-0089-1 ",

authomed personneL Howel'er,

the maximum value ofcarbon content and carbon equivalent (CE) was noll'erifled per requirements ofMaterial I

"PS-FG-00891 " Purchasing Specification" PS-PL-0089-1"for plate and "PS-FG-0089-1"for forged parts.

STATUS CORRECTIVE ACTION TAKEN

[Z]Closed

DOpen

1. A Nonconformity Report #NCR-54-0089-003 was ifsued to affected personnel in accordance with the QC

System.

1. Calculated the CE and Re-verifled the value ofcarbon content and carbon eqllivalent (CE) per informotion

shown on miU certificates according to requirements ofMaterial Purchasing Specifu:ation respectively by

authomedpersonneL

3. The value ofcarbon content and carbon equivalent (CE) ofpurchased steel plates andforged flanges are

found acceptable per results ofre-verification.

4. Re-training ofthe receiving inspection requirements to be covered by Code section, material specification and

material purchasing specification to affected personnel by QC Manager.

5. NCR was closed out and accepted by AI.

TEAM LEADER REMARKS

a. Re-training of Code and Manual requirelllents to affected personnel was conducted by QC Manager under AI's guidance.

b. No impact on acceptance ofdemonstration items regarding Code compliance.

c. The actions taken are considered satisfactory and sufficient to permit closure ofthe deficiency.

d. No additional actions are considered neceS.'iary.

~ / A w n T ; ~ . ~

Jonathan T. J. Chen Report Date: February. 10,1011

Team Leader Print Name & Signature

A1 36 Form-QC- 01/0112011-RO

FORMQC

IMPLEMENTATION DEFICIENCY AND CORRECTIVE ACTION Page __of_

Company Name: ASME Identification Number. )

Unimit Engineering Public Company Limited 43570

I

I

I

CODE REFERENCE N":

QCM PARAGRAPH

3 DESCRIPTION OF DEFICIENCY

Section IX

QW-200.2(b),

QW-200.I(b)

STATUS

[ZjClosed

DOpen

WPSlPQR:

I. The FCAWweldingprocedure qualification record, #PR07-470, does not include the information of essential

variables per QW-404.24.

2. The SA W welding procedure qualification record, #PRIO-558, does not include the information of essential

variables per QW-404.24 and QW-404.36.

3. The GTA W weldingprocedure specijication,# WPll-1l307, Rev.l, does not li..t the information of

nonessential variables per QW-404.22(Consum. insert) and QW-409.3 (e.g. Pulsing CUn'ent).

CORRECTIVE ACTION TAKEN

1. A Nonconfonnity Report #NCR-54-0089-004 was issued to affected personnel in accordance with the QC

System.

2. The company expresses and declares that they never used the supplemental filler metal orfluxfrom recrushed

slag to any welding process. (Review Team has verified that to be truth at company production site)

3. Updated the Welding Procedure QualifICation Records, #PR07-470 & #PRI0-558, to indicate no use of

supplementalfiller metal orfluxfrom recrushed slag. The updated PQR's haw! been re-certifred by authorized

personneL

4. Revised the GTA W weldingprocedure specijication,# WPll-1l307, Rt!1'.I, to list the information of

nonessential variables per QW-404.22(Consum. insert) and QW-409.3 (e.g. Pulsing Current).

5. Re-training ofthe required information per QW-200.2(b), QW-200.1(b) to affected personnel by Welding

Diviliion Manager.

6. NCR was closed out and accepted by AI.

TEAM LEADER REMARKS

a.. Re-training of Code requirement'> and the knowledge pertaining to the required infonnation for WPSIPQR to affectedpersonnel

was conducted by Welding Manager under AI's guidance.

b. No impact on acceptance ofdemonstration items regarding Code compliance.

c. The actions taken are considered satisfactory and sufficient to pennit closure ofthe deficiency.

tL No additional actions are considered nece...sary.

J?o.Mc.q -r,;;J. ~

~ ~ n T. J. Chen Report Date: February. 10,2012

Team Leader Print Name & Signature

A1 36 Form-QC- 01101/2011-RO

7

ATrENDANCE SHEET

Page: 1 of

SUI/Itt 'It' SIJHIIH'Hl

ACTIVITY

Entrance Meeting

D Survey D Pre-Assessment

DAudit D Assessment

Review conducted on: Feb. 09, 12 to Feb. 10, 12

[{jReview

D Other _

Company Name: ASME Identification Number:

Unimit Engineering Public Company Limited 43570

Division (If Applicable):

Shop Address:

10/7-8 Mu. 3 Chonburi-Banbung-Pa-Yub Road, Nongchak

City: County/District:

Banbung

State/Province: Country: Postal Code (ZIP):

Chonburi

Thailand 20170

NAME

SIGNATURE

TITlE ORGANIZATION AFFIUATION

(PRINT)

-

(PRINT) (PRINT)

Jonathan T. J. Chen

)' -#-v, 7: /1

rJmLeader ASME

PttA-N. A.I.S. ABS Boiler and Marine Insurance Co.

tttt70MNGf(

M. fd. A.I. ABS Boiler and Marine Insurance CO.

Unimit Engineering Public Company

-' Limited

fi ... "V'-e ,J(.",,"- L

\J ..

Unimit Engineering Public Company

Limited

(2

..

V,/)

0\.. .... t.-}... \1e.-q.... .I' -Ditto

..,

----.., .

"

--

W.P/h;) P/V))I/l--

Mr

j

-

'r-\,r _ V0""'''' V

eM ""-I) u-v

5e.,.d"", }/A----

'" (J

(I,'i

'" --::::>

Mr,

P,-('f2.

./

"':fl

-

-

)

-

v v

M'1". WeTl1,. NlNff\k

Dc.513'n G.1'f\";Ii 'l'\ur{

----

nr JV'OJ

\...-

--

M( , l'\f1 Je1Jlkm

u , ...-/

v

-raJ

"", .."....

Jt:--)\ ()

t$fJu.,

t1y.

!(I/VI \')aJfYr /tW-

...

"'--,

V \.(, .

Letrd JIt

t.--A UonYf)

\.AI" '}'\<;fa' b

;:/

v

<...-/

Form-ASME-8/16/2009

You might also like

- I10 Workshop Manual - ADocument292 pagesI10 Workshop Manual - ANorthstartechnology Company82% (11)

- Asme BPVC SSC, Iii, Ii, V, Ix-2023Document52 pagesAsme BPVC SSC, Iii, Ii, V, Ix-2023maritza.estefes04100% (1)

- MoeDocument214 pagesMoemahmud517No ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Evaluation of The Ductile-To-Brittle Transition Temperature in Steel Low CarbonDocument12 pagesEvaluation of The Ductile-To-Brittle Transition Temperature in Steel Low CarbonBurag HamparyanNo ratings yet

- Introduction To UT Flaw DetectorDocument26 pagesIntroduction To UT Flaw DetectorNail Widya Satya100% (1)

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- RT-Technique Sheet Items Level IIDocument3 pagesRT-Technique Sheet Items Level IISugianto TanNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- Case Study Oil and Gas - PowerpointDocument8 pagesCase Study Oil and Gas - PowerpointYaxssNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- AWS D1.1 Welder Quallification RequirementsDocument3 pagesAWS D1.1 Welder Quallification RequirementsKrishna VachaNo ratings yet

- WPS PQR-08Document8 pagesWPS PQR-08Ranjan KumarNo ratings yet

- WPS For P1 MaterialDocument1 pageWPS For P1 Materialasirul_meNo ratings yet

- 4#600 Body RSSDocument1 page4#600 Body RSSRavi patelNo ratings yet

- S/A 106 Spec Sheet A106 Pipe Specifications: ScopeDocument7 pagesS/A 106 Spec Sheet A106 Pipe Specifications: ScopeyanurarzaqaNo ratings yet

- Joint Efficiency TutorialDocument47 pagesJoint Efficiency TutorialJignesh ShahNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipeashokkahirwar100% (1)

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- PA Probe Catalog en 201308Document24 pagesPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaNo ratings yet

- Ultrasonic Testing Austenitic Stainless SteelDocument31 pagesUltrasonic Testing Austenitic Stainless SteelElias Kapa100% (1)

- Acceptance Standards RTDocument1 pageAcceptance Standards RTRaju Tiwary100% (1)

- 3.3.3-Fillet Weld Design 9th Mar 21Document40 pages3.3.3-Fillet Weld Design 9th Mar 21Vivek kmNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- MDR Form A-1Document2 pagesMDR Form A-1Yuvraj ThoratNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Pws Convention PresentationDocument93 pagesPws Convention Presentationbenj100% (1)

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Twi Hardness TestingDocument8 pagesTwi Hardness TestingchungndtNo ratings yet

- Sample PWHT ProcedureDocument9 pagesSample PWHT ProcedurefizanlaminNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- Comparison of Flange Face Finish As Per B16-5Document1 pageComparison of Flange Face Finish As Per B16-5Vivi OktaviantiNo ratings yet

- (First Revision) : Indian StandardDocument8 pages(First Revision) : Indian StandardBhanu Pratap ChoudhuryNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDocument1 pageWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- 38 MM DAC Block - Master SUDHANDocument5 pages38 MM DAC Block - Master SUDHANmaxpan maxNo ratings yet

- MHN-PPLQ-WPS-STR-50B R0 PDFDocument2 pagesMHN-PPLQ-WPS-STR-50B R0 PDFsurya1960No ratings yet

- ST 60-2Document1 pageST 60-2AmiNo ratings yet

- DIN EN 12517-1: Deutsche NormDocument17 pagesDIN EN 12517-1: Deutsche Normmarcos crisostoNo ratings yet

- Eqt Test RecordsDocument12 pagesEqt Test RecordsBabu Pro50% (2)

- D:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)Document1 pageD:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)deepakNo ratings yet

- Liquid Penetrant (Lev1el-I-level - II''Document100 pagesLiquid Penetrant (Lev1el-I-level - II''Chandresh100% (1)

- DAC Block Details PDFDocument2 pagesDAC Block Details PDFShrikant UtekarNo ratings yet

- Hidden Defects in FittingsDocument3 pagesHidden Defects in FittingsFerlie IndrapatiNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Twi Impact TestingDocument17 pagesTwi Impact TestingchungndtNo ratings yet

- WPS FormatDocument7 pagesWPS FormatPradip SalunkheNo ratings yet

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

- Asme Form U-1. v-11201 ADocument3 pagesAsme Form U-1. v-11201 ASalman KhanNo ratings yet

- Sample Specifications GuidelinesDocument10 pagesSample Specifications GuidelinesArunprasad MurugesanNo ratings yet

- Mill Inspection Certificate 質 量 証 明 書: Changshu Walsin Specialty Steel Co.,Ltd. 常熟華新特殊鋼有限公司Document4 pagesMill Inspection Certificate 質 量 証 明 書: Changshu Walsin Specialty Steel Co.,Ltd. 常熟華新特殊鋼有限公司Weipeng LvNo ratings yet

- Tigweldarc Alloys: Certification of TestsDocument1 pageTigweldarc Alloys: Certification of TestsArunNo ratings yet

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamNo ratings yet

- E390-11 Standard Reference Radiographs For Steel Fusion WeldsDocument4 pagesE390-11 Standard Reference Radiographs For Steel Fusion WeldsAhmed Shaban KotbNo ratings yet

- Hot Tap Welding ParametersDocument7 pagesHot Tap Welding ParametersSiva RamNo ratings yet

- QW-451 Welding THK - June5Document17 pagesQW-451 Welding THK - June5Raj SNo ratings yet

- QMS FormDocument4 pagesQMS FormsarvaNo ratings yet

- Lesson Plan 1 - Agriculture in Your LifeDocument6 pagesLesson Plan 1 - Agriculture in Your Lifeapi-235918896No ratings yet

- EDO ScriptDocument59 pagesEDO ScriptThais Andrés JiménezNo ratings yet

- LightsDocument33 pagesLightsEduardo Almeida SilvaNo ratings yet

- 12V-100Ah FTA DatasheetDocument1 page12V-100Ah FTA Datasheetchandrashekar_ganesanNo ratings yet

- Multical® 402: Data SheetDocument20 pagesMultical® 402: Data SheetSundar RamasamyNo ratings yet

- Paracetamol BPDocument4 pagesParacetamol BPjaimurugeshNo ratings yet

- DalmatiaDocument265 pagesDalmatiaomissam2No ratings yet

- Geo-Technical Investigation On Black Cotton Soils: GeotechnicalinvestigationonblackcottonsoilsDocument5 pagesGeo-Technical Investigation On Black Cotton Soils: GeotechnicalinvestigationonblackcottonsoilsDevendrasinh PadhiyarNo ratings yet

- 2015 Nissan 370Z 3.7L Eng VIN A BaseDocument69 pages2015 Nissan 370Z 3.7L Eng VIN A BaseData TécnicaNo ratings yet

- Power System Analysis and Design EE-461: Tassawar Kazmi Lecturer, EE Department, Seecs, NustDocument10 pagesPower System Analysis and Design EE-461: Tassawar Kazmi Lecturer, EE Department, Seecs, NustShahab SaqibNo ratings yet

- XL4016 Step Down Buck DC DC ConverterDocument7 pagesXL4016 Step Down Buck DC DC ConverterCésar Fernando Rueda PortillaNo ratings yet

- Brochure - Citadines Flatiron Phnom Penh - EnglishDocument4 pagesBrochure - Citadines Flatiron Phnom Penh - EnglishTix VirakNo ratings yet

- Proyector SNF 111Document3 pagesProyector SNF 111Liliana Patricia PederneraNo ratings yet

- Air Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaDocument8 pagesAir Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaPriyanka SinhaNo ratings yet

- The CyclotronDocument10 pagesThe CyclotronSupriya DuttaNo ratings yet

- PGC Inquiries Chapter 7 Grid ProtectionDocument7 pagesPGC Inquiries Chapter 7 Grid ProtectionhansamvNo ratings yet

- Divine Child International School, Adalaj Revision Worksheet Grade 6, Maths Choose The Correct OptionDocument2 pagesDivine Child International School, Adalaj Revision Worksheet Grade 6, Maths Choose The Correct OptionNatasha VidhaniNo ratings yet

- Relay Identification: Example CDG31FF002SACHDocument5 pagesRelay Identification: Example CDG31FF002SACHRohit RanaNo ratings yet

- r315 Quick Start PDFDocument80 pagesr315 Quick Start PDFfdsfasdsfadsNo ratings yet

- CR300 Wireless Communication ProtocolDocument130 pagesCR300 Wireless Communication ProtocolHenry Martinez BedoyaNo ratings yet

- Board of Technical Education Uttar Pradesh Lucknow: CODE 2298Document2 pagesBoard of Technical Education Uttar Pradesh Lucknow: CODE 2298Md Shaaz100% (1)

- Morality Speaks of A System of Behavior in Regards To Standards of Right or Wrong Behavior. The WordDocument3 pagesMorality Speaks of A System of Behavior in Regards To Standards of Right or Wrong Behavior. The WordTHEO DOMINIC REQUERME SILVOSANo ratings yet

- Be Project Presentation SuspensionDocument17 pagesBe Project Presentation SuspensionGabrielNo ratings yet

- Anritsu Metal Detection GuideDocument32 pagesAnritsu Metal Detection GuideJesus Roberto De La Vega GermanNo ratings yet

- Unipoxy LiningDocument3 pagesUnipoxy LiningDien Thoai Nguyen HuuNo ratings yet

- A Lightweight True Random Number Generator For Root of Trust ApplicationsDocument11 pagesA Lightweight True Random Number Generator For Root of Trust ApplicationsMADDULURI JAYASRINo ratings yet

- BOQ For Softscape and Hardscape Bendungan Karian-3Document23 pagesBOQ For Softscape and Hardscape Bendungan Karian-3greenorchidresidenceNo ratings yet

- Amendment No. 2 To AS 2047-2014 Windows and External Glazed Doors in BuildingsDocument2 pagesAmendment No. 2 To AS 2047-2014 Windows and External Glazed Doors in BuildingsTommy AndersNo ratings yet