Professional Documents

Culture Documents

Phased Array Proposal For PETLIN

Uploaded by

Azrul HanifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phased Array Proposal For PETLIN

Uploaded by

Azrul HanifCopyright:

Available Formats

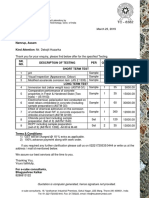

LOTT INSPECTION SDN. BHD.

(152445-X)

40, Jalan Anggerik Mokara 31/64 Seksyen 31, Kota Kemuning 40706 Shah Alam Selangor Darul Ehsan Tel: +603-5124 0736; Fax +063-5124 0734 Email: lottklg@tm.net.my

PROPOSAL

COMPUTERISED ULTRASONIC INSPECTION OF BUTT WELDS

Client: ETHYLENE MALAYSIA SDN BHD LOT 3834,KAWASAN BUKIT TENGAH KM105,JALAN KUANTAN-KUALA TERENGGANU 24300 KERTEH,KEMAMAN,TERENGGANU Attention: Zakaria Ali, Inspection Manager,Engineering Department

Project: Site: Kerteh, Kemaman Ali Rosli/Sangu Nelus Date : 28 February, 2008

Prepared By : 1.0

SCOPE OF WORKS To inspect and determine the quality of simple girth butt welds using computerized ultrasonic testing technique in-lieu of radiographic testing as per Client specifications Inspection will be carried out at the client .site

2.0 . 3.0

INSPECTION EQUIPMENTS AND SYSTEM TO BE USED Omniscan MX with manual handheld scanner for phased array technique on butt weld. ADVANTAGE OF PHASED ARRAY (a) Handheld scanner provides repeatable and faster scanning and eliminates the coupling/contact problems inherent to manual scanning. Computerized data acquisition provides all the advantages not available in manual system or manual probe scanning.

(b) The handheld scanner is on running on magnetic wheels. (c) Scanning can be carried out on piping that is in-service or off-service provided the service temperature is not exceeding 50C and not insulated. (d) This scanning speed is dependence on the scanning configuration used and overlapping of scanning path and coverage. Other factors that may affect the scanning speed are size & thickness of weld, location and height, scanning surface condition, condition at site, physical obstructions, presence of flaw of concern etc. (e) The Phased Array computerized system combined with ToFD minimized unnecessary repair or major flaw being missed. 4.0 CODES COMPLIANCE. 3.1 3.2 5.0 Procedures and Techniques - ASME Section V and Appendices. Compliance with ASME B31.3 Case 181

PROPOSED PHASED ARRAY AND TIME-OF-FLIGHT-DIFFRACTION (TOFD) 5.1 5.2 The whole volume of the weld shall be inspected using Phased Array technique Additional scanning using TOFD technique to be performs together with Phased Array scanning

6.0

DATA ACQUISITION AND REPORTING FOR UT PHASED ARRAY AND ToFD 6.1 Acquired data during scanning will be stored in the computer. In-situ and post-inspection data evaluation will be carried out. 6.2 For UT Phased Array, typical result presentation is in color print out.For ToFD, typical result presentation is in grey color. 6.3 Identification of the weld, a sketch of the weld and the datum for the flaw, if any, will be provided. 6.4 The flaw shall be marked on the pipe adjacent to the flaw to facilitate repair works.

7.0

ATTACHMENT Attachment 1: Typical scan plan for Phased Array and ToFD on butt welds. Attachment 2:, Use of Ultrasonic Examination in Lieu of Radiography.

ATTACHMENT 1 TYPICAL SCAN PLAN FOR PHASED ARRAY ON BUTT WELDS The whole volume of the weld shall be inspected Phased Array To ensure adequate coverage and optimum conditions for the Phased Array, the following set-up is recommended:

Legend Sectorial scanning Linear scanning TYPICAL SCAN PLAN FOR TIME OF FLIGHT DIFFRACTION (ToFD) ON BUTT WELDS

Legend

Beam Intersection Coverage

You might also like

- Wq-sj-Almco-qual-03129 - Pa and Tofd Procedure Rev ADocument41 pagesWq-sj-Almco-qual-03129 - Pa and Tofd Procedure Rev AJerry Man UtdNo ratings yet

- Testing Session TOFD EECI - EurosonicDocument47 pagesTesting Session TOFD EECI - Eurosonicعزت عبد المنعم100% (1)

- High Temperature Ultrasonic TestingDocument3 pagesHigh Temperature Ultrasonic TestingCarlos Bustamante100% (1)

- Inspection, Expediting, Training, Aws Cwi, NDT, Isondt, API, Profile, DashinspectorateDocument22 pagesInspection, Expediting, Training, Aws Cwi, NDT, Isondt, API, Profile, DashinspectoratedashNo ratings yet

- Project 3 Technical NDT DocumentDocument18 pagesProject 3 Technical NDT Documentapi-242490471No ratings yet

- Past and Ongoing Projects Corrosion Resistant Alloys: (Vessel If Offshore)Document5 pagesPast and Ongoing Projects Corrosion Resistant Alloys: (Vessel If Offshore)haran2000No ratings yet

- PCN GenDocument27 pagesPCN GenMohammed ShamilNo ratings yet

- Mockup CBDocument18 pagesMockup CBabet_singkong8930100% (1)

- Introduction To UT Flaw DetectorDocument26 pagesIntroduction To UT Flaw DetectorNail Widya Satya100% (1)

- PAUT Demo Indication SummaryDocument1 pagePAUT Demo Indication SummaryRudolph RednoseNo ratings yet

- PAUT CatalogueDocument2 pagesPAUT CataloguebenmedNo ratings yet

- Mut Procedure For Coil-UtDocument5 pagesMut Procedure For Coil-Utmangalraj900100% (1)

- Cswip DocumentDocument23 pagesCswip DocumentAmit KumarNo ratings yet

- 081computed Radiographic Examination ReportDocument1 page081computed Radiographic Examination ReportMarcus AntoniusNo ratings yet

- Ultrasonic Testing of Tube To Tube SheetDocument6 pagesUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURANo ratings yet

- Confidence You Can See: Omniscan X3 Phased Array Flaw Detector With TFMDocument5 pagesConfidence You Can See: Omniscan X3 Phased Array Flaw Detector With TFMWayneNo ratings yet

- Asme Piping Block (Ut+Paut)Document1 pageAsme Piping Block (Ut+Paut)Muhammed Abo-FandoodNo ratings yet

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- Ewert WCNDT Standards 2012 04Document38 pagesEwert WCNDT Standards 2012 04bladdeeNo ratings yet

- VSSC Phased ArrayDocument140 pagesVSSC Phased Arraysentamil vigneshwaranNo ratings yet

- UT Thickness Digital 19-105 Rev.0 PDFDocument10 pagesUT Thickness Digital 19-105 Rev.0 PDFUmair JavedNo ratings yet

- PAUT of ''CRA WELDSDocument7 pagesPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- BPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Document32 pagesBPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Agung Prastyo WibowoNo ratings yet

- RT-Technique Sheet Items Level IIDocument3 pagesRT-Technique Sheet Items Level IISugianto TanNo ratings yet

- Purpose of Seminar: Phased Arrays: Codes and ApplicationsDocument6 pagesPurpose of Seminar: Phased Arrays: Codes and ApplicationsLương Hồ VũNo ratings yet

- UT L3 FormulaDocument11 pagesUT L3 FormulaJiten KarmakarNo ratings yet

- PA in Lieu of RT - CurtisDocument21 pagesPA in Lieu of RT - CurtisDennis ChaiNo ratings yet

- NDT Application FormDocument4 pagesNDT Application FormAhmed Shaban KotbNo ratings yet

- NDT Book Microsoft Word Version October 2009Document139 pagesNDT Book Microsoft Word Version October 2009keoke526100% (5)

- 3) Geometric Unsharpness (Radiographic)Document11 pages3) Geometric Unsharpness (Radiographic)Alirza AliyevNo ratings yet

- Course Notes - RT Level 1 Rev 29-3a 07-2006Document470 pagesCourse Notes - RT Level 1 Rev 29-3a 07-2006Juan LewisNo ratings yet

- Ect EngineDocument63 pagesEct EngineAnonymous gFcnQ4goNo ratings yet

- Ust ProcedureDocument18 pagesUst ProcedureVikiseptNo ratings yet

- Changes in ASTM E 1444Document5 pagesChanges in ASTM E 1444Vicky SinghNo ratings yet

- API UT21 ThicknessProcedure 20190304Document7 pagesAPI UT21 ThicknessProcedure 20190304michaelNo ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- Pipe Clamps For Welding Alignment (DWT Babcock) 3Document2 pagesPipe Clamps For Welding Alignment (DWT Babcock) 3Daniel AriefinNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- ATTAR Hands On Intro To NDTDocument3 pagesATTAR Hands On Intro To NDTRony Prayitno Simeon0% (1)

- Product TechnologyDocument138 pagesProduct TechnologyRaja SekarNo ratings yet

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Document10 pagesNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNo ratings yet

- NDTDocument64 pagesNDTmohamedyoussef1No ratings yet

- Armco UTTG ProcedureDocument10 pagesArmco UTTG ProcedureSurajit Singha100% (2)

- 6.4 - NDT-Magnetic Particle ExaminationDocument38 pages6.4 - NDT-Magnetic Particle ExaminationKatsaras SotirisNo ratings yet

- Computed Radiographic Testing (CRT) Qualification Report: Rev. ADocument12 pagesComputed Radiographic Testing (CRT) Qualification Report: Rev. ATrung Tinh HoNo ratings yet

- Hasan NDT ServicesDocument4 pagesHasan NDT ServicesShahbaz KhanNo ratings yet

- Radiation Safety ProcedureDocument57 pagesRadiation Safety ProcedureibrahimNo ratings yet

- Referance Block PDFDocument45 pagesReferance Block PDFDağhan GrdNo ratings yet

- Thickness GaugingDocument3 pagesThickness GaugingAmit HasanNo ratings yet

- Dacon PAUT PresentationDocument20 pagesDacon PAUT Presentationbacabacabaca100% (1)

- RT Standards NotesDocument4 pagesRT Standards NotesprabhuNo ratings yet

- JIMAH East PAUT Procedure - Rev.0 - 14062017 PDFDocument62 pagesJIMAH East PAUT Procedure - Rev.0 - 14062017 PDFRoslan Ali100% (2)

- JIMAH East PAUT Procedure Rev 0 14062017 PDFDocument62 pagesJIMAH East PAUT Procedure Rev 0 14062017 PDFRiccoNo ratings yet

- Aut ProceedureDocument42 pagesAut Proceedureநந்த குமார் சம்பத் நாகராஜன்100% (3)

- Achieve High Test Coverage For SoCDocument26 pagesAchieve High Test Coverage For SoCUmesh Parashar100% (3)

- HT - Paut-Asme-01: Hi-Tech NDT Inspections Services (S) Pte. LTDDocument25 pagesHT - Paut-Asme-01: Hi-Tech NDT Inspections Services (S) Pte. LTDphanthanhhungNo ratings yet

- General Procedure For AUTDocument19 pagesGeneral Procedure For AUTalinor_tn100% (2)

- Paut Procedure - Asme 31.3 Process PipingDocument26 pagesPaut Procedure - Asme 31.3 Process PipingKarthikeyan Ganesan100% (3)

- 2 - 10-Design of Voice Control Robot and Breakdown AnalysisDocument53 pages2 - 10-Design of Voice Control Robot and Breakdown AnalysisChirag ThakurNo ratings yet

- DIN en 1321 (October 1996)Document15 pagesDIN en 1321 (October 1996)Azrul HanifNo ratings yet

- Method StatementDocument19 pagesMethod Statementjohney292% (12)

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Basic Ultrasonic TrainingDocument42 pagesBasic Ultrasonic TrainingAzrul HanifNo ratings yet

- WPS - P-15-15 - 47 - Rev 0 & PQR - P5B - G06-SR Rev 0Document17 pagesWPS - P-15-15 - 47 - Rev 0 & PQR - P5B - G06-SR Rev 0Azrul HanifNo ratings yet

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Automated Ultrasonic Report Sample PHASE ARRAYDocument2 pagesAutomated Ultrasonic Report Sample PHASE ARRAYAzrul Hanif100% (2)

- UT Basic 0 Degree Setting Ut Set (USM 35)Document2 pagesUT Basic 0 Degree Setting Ut Set (USM 35)Azrul HanifNo ratings yet

- HempelbookMPC Jun 2010Document445 pagesHempelbookMPC Jun 2010Azrul HanifNo ratings yet

- HempelbookMPC Jun 2010Document445 pagesHempelbookMPC Jun 2010Azrul HanifNo ratings yet

- HempelbookMPC Jun 2010Document445 pagesHempelbookMPC Jun 2010Azrul HanifNo ratings yet

- CBEU Service ConditionsDocument623 pagesCBEU Service ConditionsAtul ModiNo ratings yet

- Jun Judging ClinicDocument1 pageJun Judging Cliniccsponseller27No ratings yet

- Art of Facing InterviewsDocument15 pagesArt of Facing Interviewskrish_cvr2937100% (2)

- Republic Act No. 10389Document5 pagesRepublic Act No. 10389Marge RoseteNo ratings yet

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70No ratings yet

- DEIR Appendix LDocument224 pagesDEIR Appendix LL. A. PatersonNo ratings yet

- A Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaDocument32 pagesA Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaSonu PradhanNo ratings yet

- Paper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Document11 pagesPaper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Mayank ShelarNo ratings yet

- Inlet Manifold Pressure - Test: Testing and AdjustingDocument2 pagesInlet Manifold Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHENo ratings yet

- Sustainable Development at British Petroleum: Presented by Amardeep Kulshrestha 09BS0000172 Section-EDocument20 pagesSustainable Development at British Petroleum: Presented by Amardeep Kulshrestha 09BS0000172 Section-EAmar KulshresthaNo ratings yet

- AFMAN91-201 NewDocument458 pagesAFMAN91-201 NewbombtechNo ratings yet

- Thesis ProposalDocument19 pagesThesis Proposaldharmi subedi75% (4)

- Bhert - EoDocument2 pagesBhert - EoRose Mae LambanecioNo ratings yet

- BQ - Electrical Calibration Relay Bld803, NPBDocument2 pagesBQ - Electrical Calibration Relay Bld803, NPBKazuya KasumiNo ratings yet

- UK Tax SystemDocument13 pagesUK Tax SystemMuhammad Sajid Saeed100% (1)

- QA-QC TPL of Ecube LabDocument1 pageQA-QC TPL of Ecube LabManash Protim GogoiNo ratings yet

- Maxillofacial Notes DR - Mahmoud RamadanDocument83 pagesMaxillofacial Notes DR - Mahmoud Ramadanaziz200775% (4)

- A Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceDocument16 pagesA Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceiporrasNo ratings yet

- Task 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 pagesTask 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoNo ratings yet

- 1A Wound Care AdviceDocument2 pages1A Wound Care AdviceGrace ValenciaNo ratings yet

- Arsenal Strength Catalog 6.2-1Document41 pagesArsenal Strength Catalog 6.2-1Mohammed NavedNo ratings yet

- 3 Activities For Adults To Practice Modeling SELDocument10 pages3 Activities For Adults To Practice Modeling SELDavid Garcia PerezNo ratings yet

- Ds0h Ufaa68 ProposalDocument11 pagesDs0h Ufaa68 Proposaledward baskaraNo ratings yet

- Home Composting SystemsDocument8 pagesHome Composting Systemssumanenthiran123No ratings yet

- Food and Beverage Control Systems Can Help You Introduce The Same Financial Rigour To Your Dining Establishment or Catering Company That YouDocument11 pagesFood and Beverage Control Systems Can Help You Introduce The Same Financial Rigour To Your Dining Establishment or Catering Company That Younarinder singh saini100% (4)

- HVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionsDocument1 pageHVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionssoftallNo ratings yet

- Heat Transfer ExampleDocument4 pagesHeat Transfer Examplekero_the_heroNo ratings yet

- Science 9 Q4 SML17 V2Document15 pagesScience 9 Q4 SML17 V2HotdogNo ratings yet

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIDocument48 pagesDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadNo ratings yet

- Royal British College IncDocument5 pagesRoyal British College IncLester MojadoNo ratings yet