Professional Documents

Culture Documents

Toro Irrigation Design Workbook

Uploaded by

Sushil KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toro Irrigation Design Workbook

Uploaded by

Sushil KumarCopyright:

Available Formats

Basic Irrigation Design

Instructors Guide

___________________________________________ Basic Irrigation Design

s

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . .iii System Diagram . . . . . . . . . . . . . . . . . . . . . . . . .1 Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Water Pressure . . . . . . . . . . . . . . . . . . . . . .2 Static Pressure . . . . . . . . . . . . . . . . . . . . . .3 Friction Loss . . . . . . . . . . . . . . . . . . . . . . . .3 Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Review . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 Available Water . . . . . . . . . . . . . . . . . . . . . . . . . .7 Bucket Test . . . . . . . . . . . . . . . . . . . . . . . . .9 Review . . . . . . . . . . . . . . . . . . . . . . . . . . .10 Sprinkler Layout . . . . . . . . . . . . . . . . . . . . . . . .11 Sprinkler Application . . . . . . . . . . . . . . . .11 Sprinkler Distribution Curve . . . . . . . . . .11 Square/Rectangular Layout . . . . . . . . . . .12 Triangular Layout . . . . . . . . . . . . . . . . . . .12 Steps for Laying Out Sprinklers . . . . . . . .13 Review . . . . . . . . . . . . . . . . . . . . . . . . . . .14 Zoning A System . . . . . . . . . . . . . . . . . . . . . . .16 Pipe Routing . . . . . . . . . . . . . . . . . . . . . . .17 Locating Valves . . . . . . . . . . . . . . . . . . . . .17 Review . . . . . . . . . . . . . . . . . . . . . . . . . . .18 Pipe Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 Review . . . . . . . . . . . . . . . . . . . . . . . . . . .21 System Operation Check . . . . . . . . . . . . . . . . .22 Review . . . . . . . . . . . . . . . . . . . . . . . . . . .25 Design Checklist . . . . . . . . . . . . . . . . . . . . . . . 27 Suggested Readings . . . . . . . . . . . . . . . . . . . . .28

Basic Irrigation Design ___________________________________________

s

Introduction

The Toro Company is proud to present Basic Irrigation Design. This workbook guides you, step-by-step, through the process of designing an effective and efficient irrigation system. In order to understand the process of irrigation design, there must first be a fundamental knowledge of the important irrigation components and their relationships to one another. Each element of an irrigation system has a direct effect on how the system operates as a whole. If some components are undersized or misused, the system may not operate properly. This may result in poor distribution of water and less-than-optimum growth for the plant material. When a project is designed and installed using the proper guidelines, the result is an efficient, long-lasting irrigation system a system of which you can be proud.

When asked to refer to the Toro Technical Data Book, use Form No. 490-1737. When asked to refer to the Toro Product Catalog, use Form No. 490-1809.

ii

NO TE

___________________________________________ Basic Irrigation Design

s

Terminology

Backflow Prevention Device the device, required by law, on an irrigation system that prevents water from re-entering the potable water lines once it flows into the irrigation pipes. Controller the device that sends timing commands to remote control valves for actuation. Coverage the pattern of water applied to an area by a sprinkler head. Design Operating Pressure the pressure a designer uses to determine spacing distances and flow for sprinkler heads. The design operating pressure is determined by subtracting estimated friction losses from the static water pressure. Dynamic Pressure the pressure reading in a pipeline system with water flowing. Flow the movement of water through the irrigation piping system; causes friction loss. FPS the abbreviation for "feet per second"; refers to the velocity of water in pipes. Friction Loss the loss of pressure (force) as water flows through the piping system. GPM the abbreviation for "gallons per minute" (unit of measure for water flow). Head-to-Head Spacing refers to the spacing distances of sprinklers when they do not exceed the radius of the sprinklers. Lateral the pipe in an irrigation system located downstream from the remote control valve. Lateral pipes carry water directly to sprinklers. Main Line the pipe in an irrigation system that delivers water from the backflow prevention device to the remote control valves. This is usually the largest pipe on the irrigation system, generally under constant pressure and located upstream from the remote control valves. Manifold a group of control valves located together in the same area. PSI the abbreviation for "pounds per square inch" (unit of measure for water pressure). PVC Pipe Poly Vinyl Chloride pipe; the most common pipe used in irrigation systems. P.O.C. abbreviation for "point of connection." This is the location on the irrigation system where a tap is made for connection of a backflow prevention device or water meter.

iii

Basic Irrigation Design ___________________________________________

s

Terminology

NOTES

Potable Water water used for drinking purposes. Precipitation Rate (PR) the rate at which sprinkler heads apply water to a specific area of coverage, over a given period of time, measured in inches per hour. Remote Control Valve the component in the irrigation system that regulates the on/off of water from the main line to the sprinkler heads; activated by the controller. Service Line the pipe supplying water from the city water main to the water meter. Spacing the distance between the sprinkler heads or the sprinkler head rows. Static Water Pressure the pressure that exists in a piping system when there is no flow; measured in pounds per square inch (PSI). Station a group of sprinkler heads that is controlled by the same remote control valve; same as a zone. Surge the build-up of water pressure in a piping system due to certain characteristics of the pipe, valves and flow. Velocity the speed at which water flows through the piping system; measured in feet per second (FPS). Water Main the city water pipe located in the street or right-of-way. Water Pressure the force of water that exists in a piping system; measured in pounds per square inch (PSI). Working Pressure the remaining pressure in the irrigation system when all of the friction losses are subtracted from the static pressure. Zone a group of sprinkler heads that are controlled by the same remote control valve; same as a station.

iv

Sprinkler Head Coverage Main Line Pipe Remote Control Valve

Lateral Line

Remote Control Valve

Head Spacing

Controller

Row Spacing

Sprinkler Head Main Line Pipe Lateral Line Pipes Pipe Sleeves Backflow Prevention Device P.O.C. Water Meter Sprinkler Head Service Line

s

Remote Control Valve

Lateral Line Pipes

Coverage

___________________________________________ Basic Irrigation Design

System Diagram

City Water Main

Controller

Valve in Box

V-1550-4

570Z

Backflow Prevention Device

Water Meter

Basic Irrigation Design ___________________________________________

s

Hydraulics

It is important to understand hydraulic principles before beginning an irrigation design. This section includes an explanation of water pressure, friction loss and water velocities. When you understand hydraulics, you then understand the physical properties of water and how they affect the operation of irrigation systems.

Water Pressure Water pressure is the force or exertion of water in a piping system. Pressure is created by increasing the height (downward force due to weight) of the water or by using a mechanical booster pump. Pressure is measured in pounds per square inch (PSI). One gallon of water weighs 8.3 pounds. There are approximately 7.5 gallons of water in a cubic foot. Therefore, a cubic foot of water has a total weight of 62.25 pounds. One cubic foot equals 1,728 cubic inches. When the weight of water in a cubic foot is converted to cubic inches, it weighs .036 pounds per cubic inch. 62.25 lbs./1728 cu. in. = .036 lbs./cu. in. By multiplying the weight of one cubic inch (.036 pounds) by 12 inches, it produces a force of .433 PSI for one foot of elevation. The pressure is measured at the base of the 12-inch column, which is the same as a square inch that is 1 foot high.

1" 1" .0366 x 12" = .433 PSI FIGURE 1.1 WATER TOWER

12"

Water Level

100'

When the column of water increases in height, the weight, force and pressure also increase. By multiplying the height of the water by .433 the pressure can be calculated. Therefore, a 100-foot column of water creates 43.3 PSI.

100' x .433 = 43.3 PSI FIGURE 1.2

2

___________________________________________ Basic Irrigation Design

s

Hydraulics

NOTES

Static Pressure Static pressure is the amount of water force that is measured in a closed or non-flowing water system. This pressure is measured by attaching a pressure gauge to a hose faucet. With no water flowing in the piping system, static pressure is determined. When there are no hose bibs from which to measure, a call to the local Public Works or Fire Department can usually provide the static readings. On a level site, the static pressure in the main will be approximately the same as the static pressure at the building. Knowing static pressure is essential before beginning any design.

NO TE

Water Main = 60 PSI Static Service Line Water Meter Static Pressure (No Water Flowing) Building Static Pressure 60 PSI

When water begins to flow in a piping system that was once static, the pressure reading on the gauge will drop. The pressure reading with water flowing is referred to as dynamic pressure.

FIGURE 1.3

Friction Loss Friction loss is the reduction in water pressure once water begins to flow through the piping system. Pressure loss occurs when flowing water comes in contact with the inside surface of the pipe and other devices. The rougher the inside surface, the more friction loss it will create. Friction loss may also occur due to increased flow in the pipes. Loss of water pressure occurs when water flows through the following components:

s s s s s s s s

service line water meter backflow prevention device main line pipe remote control valve lateral line pipe fittings other devices on the system

An estimate of the amount of friction loss on the site is required prior to designing the system.

3

Basic Irrigation Design ___________________________________________

s

Hydraulics

NOTES

Friction Loss (CONTINUED) On a residential or small commercial water system, there is typically 20 to 25 PSI loss due to friction from the water main to the last sprinkler.

NO TE

By taking the known static water pressure and subtracting the estimated friction loss, a maximum design operating pressure is determined for the sprinkler heads. For example, if static pressure equals 60 PSI and the estimated friction loss is 20 PSI, the maximum sprinkler design operating pressure should be between 35 and 40 PSI. Friction losses in pipe are calculated using the following information:

s s s s

type of pipe size of pipe length of pipe amount of water flowing through the pipe

Use the Toro Technical Data Book to determine exact friction losses for different types of pipe, water meters and gate valves. Friction losses for 100-foot lengths of pipe are listed. To convert friction losses to the exact length of pipe, the loss per 100-foot length is multiplied by a decimal factor of the actual length. Refer to Figure 1.4 below (page 8 of the Toro Technical Data Book ), 34" Class 200 PVC pipe flowing 10 GPM has a loss of 4.90 PSI per 100 feet. Therefore, 63 feet of 34" pipe has a loss of 3.09 PSI. 4.90 x .63 = 3.09 PSI loss

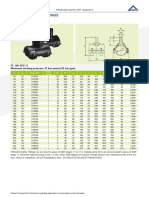

Pressure Loss From Friction per 100 of Pipe (lbs./sq. in.)

SDR 21 / Class 200 PVC 1120, PVC 1220, PVC 2120 Flow GPM 1 2 3 4 5 6 7 8 9 10

1 2

C = 140 112 2 212 3 4

3 4

114

.26 .89 1.86 3.12 4.76 6.62 8.82 11.26 14.10 17.11

.07 .26 .52 .90 1.37 1.90 2.52 3.21 4.05 4.90 .28 .42 .59 .80 1.02 1.24 1.52 .31 .40 .50 .26

FIGURE 1.4

___________________________________________ Basic Irrigation Design

s

Hydraulics

NOTES

Velocity Velocity is the speed at which water flows through components of a system. Velocity is measured in feet per second (FPS). When designing PVC irrigation systems, it is best to maintain velocities of 5 FPS or less. This reduces the chance of developing surge pressures in the piping system. Velocity information is found in the Toro Technical Data Book on the page adjacent to the friction losses for a particular type of pipe. Refer to Figure 1.5 below (page 9 of the Toro Technical Data Book) 34" Class 200 PVC pipe flowing 10 GPM has a velocity of 4.72 feet per second. This is a safe velocity of flow for 34" PVC pipe because it is under 5 FPS.

Velocity of Flow (Ft./Sec.)

SDR 21 / Class 200 Plastic Pipe Flow GPM 1 2 3 4 5 6 7 8 9 10 11

1 2

Q V = 144 A1

1 114 112 2 212 3 4

3 4

.80 1.59 2.39 3.19 3.98 4.78 5.58 6.38 7.17 7.97 8.77

.47 .94 1.42 1.89 2.36 2.83 3.30 3.78 4.25 4.72 5.19 1.16 1.45 1.73 2.02 2.31 2.60 2.89 3.18 1.46 1.64 1.82 2.00 1.38 1.52

FIGURE 1.5

Basic Irrigation Design ___________________________________________

s

Hydraulics

NOTES

Review___________________________________________________________ 1. How much pressure is created at the base of a 10-foot column of water?

4.33 PSI ________________

2. Approximately how much friction loss will occur when water flows from the water main to the last sprinkler on the system?

2025 PSI ________________

3. What is the maximum safe velocity of water through PVC pipe?

5 FPS ________________

4. Calculate static pressure at the base of the tower.

WATER TOWER

Water Level 165'

71.5 PSI _______

FIGURE 1.6

5. Determine the water pressure at each location on the piping system. The water is in a static (no flow) condition.

WATER TOWER Water Level 165'

A = 71.5 _____ PSI B = 80.1 _____ PSI A 20' B C D 7' 38' E C = 80.1 _____ PSI D = 77.1 _____ PSI E = 77.1 _____ PSI F = 93.5 _____ PSI F FIGURE 1.7

6

___________________________________________ Basic Irrigation Design

s

Available Water

The purpose of this section is to determine the safe amount of water that flows through the water meter and the service line for use by the irrigation system. This section includes a field checklist and calculations used to determine available water. By limiting the amount of water flowing through both the meter and the service line, the friction losses through these components are limited as well. Once the available water is determined, the number of sprinklers that operate from the same valve are then calculated. Correctly calculating available water prevents the system from excessive friction losses occurring in the water meter and service line. A field inventory of components is necessary before beginning. The following should be checked in the field: 1. The meter must be located and checked for size. The size is usually stamped on the side of the meter. 2. The service line from the city main to the meter should be examined for the type of material, diameter size and length of run. If the service line is made of copper, a string test will determine the exact diameter size. Place a string around the pipe and measure the length of string. Compare to the following: String Length 234" 314" 438" Pipe Size 3 4" 1" 114"

Once the components in the field are checked, refer to the Toro Technical Data Book to determine the safe flow. To determine available water:

Water Main

1. The pressure loss through the water meter should not exceed 10% of the static pressure. 2. The velocity of water should be maintained below 5 or 7 FPS in the service line, depending on the length of run from the city main to the meter. First, refer to Figure 2.2 on page 8 (page 38 of the Toro Technical Data Book) for the PRESSURE LOSSES THROUGH VALVES, METERS & FITTINGS.

Type K Copper Service LIne Water Meter

Building

FIGURE 2.1

Calculate 10% of the static water pressure on the site. If the static pressure is 50 PSI, then 10% equals 5 PSI. Find the appropriate WATER METER SIZE at

Basic Irrigation Design ___________________________________________

s

Available Water

NOTES

the top of the page. Read down this column to the pressure loss closest to, but not exceeding, 5 PSI. From this point, go to the far left column (FLOW GPM) and note this flow.

V. Pressure Losses Through Valves, Meters & Fittings

Pressure Losses Through Standard Water Meters Pounds per Square Inch Flow GPM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 25 30 35

5

3 4

114

112

212

.2 .3 .4 .6 .9 1.3 1.8 2.3 3.0 3.7 4.4 5.1 6.1 7.2 8.3 9.5 10.7 12.0 13.4 15.0

.1 .2 .3 .5 .6 .7 .8 1.0 1.3 1.6 1.9 2.2 2.6 3.1 3.6 4.1 4.6 5.2 5.8 6.5 10.3 15.0 .1 .2 .3 .4 .5 .6 .7 .8 .9 1.0 1.1 1.2 1.4 1.6 1.8 2.0 2.2 3.7 5.3 7.3 .1 .2 .2 .3 .3 .4 .4 .5 .6 .7 .8 1.3 1.8 2.6 .4 .5 .7 1.0

Not Standard Meter Size

FIGURE 2.2

Prior to determining safe flow through the service line, check the length of service line pipe from the city water main to the connection for the backflow prevention device. If the run is less than 35 feet, the maximum velocity may be 7 FPS. If the run of service line is more than 35 feet long, the velocity should be maintained at 5 FPS or less. This is done to prevent excessive friction loss in long runs of service lines. Next, refer to the page under VELOCITY OF FLOW for the type of pipe used. Refer to Figure 2.3 on page 9 (page 33, Type K Copper Tube of the Toro Technical Data Book). Locate the appropriate pipe size at the top of the page. Read down the column to the velocity of either 5 or 7 FPS, depending on the length of the service line. From this point, go to the far left column (FLOW GPM) and record the safe flow through the service line. Compare the safe flow (GPM) from the water meter and the safe flow (GPM) from the service line. Use the lower GPM as the amount of available water that should be used in the design of the system.

NO TE

Not Standard Meter Size

___________________________________________ Basic Irrigation Design

s

Available Water

Q V = 144 A1

NOTES

Velocity of Flow (Ft./Sec.)

TYPE K COPPER TUBE Flow GPM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 20

1

3 4

114

112

212

1.47 2.94 4.41 5.88 7.36 8.83 10.30 11.77

.74 1.47 2.21 2.94 3.68 4.42 5.15 5.89 6.62 7.36 8.10 8.83 9.57 10.30 11.04 14.72 1.65 2.06 2.48 2.89 3.30 3.71 4.13 4.54 4.95 5.36 5.78 6.19 8.25 2.11 2.37 2.64 2.90 3.16 3.43 3.69 3.95 5.27 2.23 2.42 2.61 2.79 3.72 2.13

FIGURE 2.3

For example, consider a site consisting of a 34" water meter, 25-foot-long, 34" Type K copper service line and static pressure of 50 PSI. Then, refer to Figure 2.2. Ten percent of 50 PSI is 5 PSI. Reading down the 34" METER SIZE column from the top of the page, the friction loss closest to 5 PSI is 4.6 PSI. The corresponding flow with 4.6 PSI loss in the meter is 17 GPM. This is read from the FLOW GPM column at the left side of the page. Since the service line is only 25 feet long, the maximum velocity may be 7 FPS. Refer to Figure 2.3 and locate the 34" column and read down to the point that does not exceed 7 FPS. At 6.62 FPS, the corresponding flow is 9 GPM. This is read from the FLOW GPM column. Since the safe flow through the water meter is 17 GPM and the safe flow through the service line is 9 GPM, the amount of available water is 9 GPM, the lower of the two numbers.

Bucket Test Another way to verify available water and working pressure is to conduct a bucket test. This requires the use of a five-gallon bucket and a pressure gauge. Attach the gauge to a hose faucet on the site. Another hose faucet is turned on downstream from the pressure gauge hose faucet. Collect water in the bucket for one minute. While the bucket is collecting water, a reading of working pressure is taken at the pressure gauge. This test tells you the amount of water available, measured in gallons per minute, as well as the dynamic pressure in the service line and meter.

9

Basic Irrigation Design ___________________________________________

s

Available Water

NOTES

Review___________________________________________________________ 1. What is the maximum acceptable friction loss through a water meter? 10% of static ______________________________________________________________ 2. What is the maximum velocity of water through a service line that is 5 greater than 35 feet in length? ________________ FPS 3. Which flow becomes the available water, the higher or lower amount? Lower ______________________________________________________________ 4. What is the maximum safe flow through a 112" water meter with static 50 pressure of 60 PSI? ________________ GPM 5. Determine the available water in the following examples: A. Static Pressure = 60 PSI

15 GPM (30)

1" Water Meter

Water Main

1" Type K Copper Service Line

Backflow 25'

(15)

FIGURE 2.4

B. Static Pressure = 50 PSI

80 GPM (80)

2" Water Meter

Water Main

212" Type K Copper Service Line

Backflow 30'

(100)

FIGURE 2.5

C. Static Pressure = 70 PSI

6 GPM (90)

2" Water Meter

Water Main

4" Type K Copper Service Line

Backflow 85'

(6)

FIGURE 2.6

10

___________________________________________ Basic Irrigation Design

s

Sprinkler Layout

Mastering sprinkler layout guarantees that your system will distribute water evenly over irrigated plant material. This section covers the basic rules and methods used for various layout styles. Irrigation systems with proper head layout produce an even growth rate of plant material. There are many ways to lay out sprinklers on a site. Each method will work as long as specific rules are applied to each layout. Many new designers believe there is only one way to place sprinklers on a site. This is not true! Sprinkler coverage must overlap to effectively and efficiently irrigate an area. All sprinklers have an ever-decreasing application of water as the distance increases from the head. Applied water decreases because the total square footage increases farther from the sprinkler.

NO TE

Sprinkler Distribution Curve

Inches/Hour 100 80 60 40 20 0 5' 10' 20'

Sprinkler Application

40' 30' 20' 10' Sprinkler Head A B 30' Distance C 40' D FIGURE 3.2

FIGURE 3.1

A = 314 sq. ft. (6%) B = 942 sq. ft. (19%) C = 1571 sq. ft. (31%) D = 2199 sq. ft. (44%)

Recommendations for spacing considerations are based on wind conditions. The range of spacing can be from 45% to 60% of the diameter, depending on the wind. The stronger the prevailing wind, the closer the sprinklers should be spaced. In most situations, it is best to maintain a spacing of close to 50% of the diameter of the sprinkler throw, or 100% of the radius. This is often referred to as "head-to-head" spacing. The rules that must be followed when laying out sprinklers apply to the different layout styles that are used. The two basic styles of sprinkler layout are square/rectangular and triangular. There are uses and rules for both.

11

Basic Irrigation Design ___________________________________________

s

Sprinkler Layout

NOTES

Square/Rectangular Layout This layout is well-suited to very defined, geometric spaces, such as small, rectangle-shaped yards, or sites divided by sidewalks and other paved areas. Square/rectangular spacing of heads also protects all borders from overthrow of water by placing sprinklers in the corners and along the perimeters. The remaining sprinklers are then used to fill between the corners evenly.

NO TE

q = V-1550 3.0 GPM @ 45 PSI = 38'

38' (Row Spacing)

38' (Sprinkler Spacing) FIGURE 3.3

The primary rule for square/rectangular layout design is that the recommended distance from one sprinkler to the next should not exceed the radius of the sprinkler.

In order to best fit the site, it may be necessary to adjust the spacing. It is, therefore, acceptable to increase or decrease spacing of spray heads 1 foot. Rotary sprinklers may be adjusted 3 feet. If the sprinkler spacing is increased, do not increase the row spacing. Conversely if row spacing is increased, do not increase sprinkler spacing. For example, the Toro Product Catalog indicates that a V-1550 sprinkler discharges 3 GPM at 45 PSI with a radius of 38 feet. Therefore, the recommended spacing from one sprinkler to another is 38 feet (see Figure 3.3). The recommended row spacing is also 38 feet. After finding the spacing distance, it is acceptable, depending on the plant type and wind, to adjust spacing between sprinklers and rows to fit the site. This produces the rectangular shape in the layout.

Triangular Layout Triangular layout is a good choice for sites with irregular borders or open areas where overthrow of water is not a problem. The actual coverage from triangular spacing of sprinklers tends to provide better overall coverage versus square spacing. The main disadvantage is the edge of coverage where an oddly spaced sprinkler will throw water beyond the edge of the site.

12

q = V-1550 3.0 GPM @ 45 PSI = 38'

36.5' (Row Spacing)

42' (Sprinkler Spacing) FIGURE 3.4

___________________________________________ Basic Irrigation Design

s

Sprinkler Layout

NOTES

Most designers space sprinklers at 50% to 55% of the sprinkler diameter using triangular spacing. The row distance is then calculated by multiplying the actual distance between sprinklers by .866. This provides the recommended distance to the next row. As with square spacing, these distances are recommended, and similar adjustments can be made to suit the size and shape of the site. When using a Toro V-1550 sprinkler set to 3 GPM operating at 45 PSI, the radius is 38 feet. Diameter equals two times the radius. Therefore, the diameter is 76 feet. By taking 55% of the diameter (.55 x 76'), the calculated distance between sprinklers is 42 feet. The row distance is calculated by multiplying 42 feet by .866. This distance is calculated to be 36.5 feet. Adjustments can be made to compensate for specific site requirements.

Steps for Laying Out Sprinklers 1. Determine the static pressure of the site. Estimate the friction losses through the system and the design operating pressure of the sprinklers. 2. Measure the site. Break the entire site into smaller geometric shapes for different layouts and sprinklers. Consider plant material and varying watering needs. Determine which layouts are best for the site: square, rectangular or triangular. 3. Determine which sprinklers will be used, the operating pressure and the maximum spacing. 4. Identify the critical line of the site. This is the line of sprinklers that must protect a border such as a street or building. 5. Identify the critical corner of the first line of sprinklers (the combination of the critical line and an adjacent border). This could be the corner of two streets, or the corner of a street and driveway, sidewalk or neighboring property. 6. Place the first sprinkler in the critical corner, then divide the distance of the critical line to evenly space the remaining sprinklers. If square spacing is used, there should be a sprinkler in each corner with evenly spaced sprinklers in between. If the layout is triangular, the spacing may cause an oddly placed sprinkler at the end. 7. Lay out the next row of sprinklers along a second critical line, such as the edge of a building. Fill in the interior area with evenly spaced rows of sprinklers. Adjust the spacing of the sprinklers and rows to fit the site.

13

Basic Irrigation Design ___________________________________________

s

Sprinkler Layout

NOTES

Review___________________________________________________________ 1. Which sprinkler layout style is best suited to protecting borders?

Square/Rectangular ______________________________________________________________

2. What is the multiplier used to determine the row distance for triangular .866 spacing? _______________________________________________________ 3. Is knowing static pressure of the site necessary before laying out Yes sprinklers? _____________________________________________________ 4. Is the critical line of sprinklers usually along an edge or in the middle of a Edge site? ___________________________________________________________ 5. Use Toro sprinklers to lay out the site in Figure 3.5 on the next page.

14

___________________________________________ Basic Irrigation Design

s

Sprinkler Layout

V-1550 or 300 Series

Static Pressure = 65 PSI

Building

570 Series

FIGURE 3.5

15

Main Street Parking Lot Sidewalk

Scale 1" = 10'

Basic Irrigation Design ___________________________________________

s

Zoning A System

The main purpose of grouping sprinklers together is to regulate the demand from the water source. This section covers the reasons for zoning an irrigation system and proper procedures. By zoning an irrigation system properly, different requirements within the site are irrigated independently. When zoning an irrigation system, the designer groups sprinklers together to run at the same time. In the Available Water section in this workbook, we covered how to calculate the most efficient amount of water through a water meter and service line. Once this amount is determined, there should never be a demand from any zone on the system greater than the supply capacity. If the demand in a zone is greater than the calculated available water, friction losses will increase throughout the system. The result is sprinklers that perform at less-than-optimum pressure, reduced radius and possible dry areas.

NO TE

All of the sprinklers in a zone are connected with lateral line pipe. The remote control valve is installed upstream from the sprinklers and connects to the main line pipe. Although flow is very important in determining the number of zones in a system, it is not the only reason to group sprinklers together. Some of the other considerations for zoning include: 1. Grouping similar sprinklers with the same precipitation rate. 2. Separating varying plant material into different zones. 3. Irrigating sloped areas separately from level areas.

Lateral Line Pipes

Water Meter Backflow Prevention Device

Main Line Pipe

Lateral Line Pipes Remote Control Valve Main Line Pipe

Remote Control Valve

4. Zoning shaded areas separately from sunny areas. 5. Creating different zones for varying soil conditions.

16

FIGURE 4.1

___________________________________________ Basic Irrigation Design

s

Zoning A System

NOTES

Pipe Routing Once it has been decided which groups of sprinklers will run together, the next step is to route the pipe. Routing connects the heads within a zone on the lateral line pipe and the valves to the water source on the main line pipe. The lateral lines should be placed between the sprinklers and the valve location. It is usually best to run the lateral lines along the rows of sprinklers. This is especially true if the spacing is triangular in layout. The best pattern of piping looks like an H when designed properly. On slopes, the lateral pipe should run horizontally along the contours of the slope, not up and down. This minimizes pressure variations due to elevation changes within the zone.

Locating Valves The remote control valves can be placed independently within the site (remote location) or grouped together with other valves (manifolding). Remote location of REMOTE VALVE LOCATION valves produces minimal runs of lateral line pipes. This reduces friction loss Remote and also allows the Control Valve placement of valves in Main Line Pipe the optimum hydraulic Remote Lateral locations within the Line Control system. The Pipes Valve disadvantages of remote location To Other Sprinklers include difficulty in FIGURE 4.2 locating valves on the site after construction as well as an increased chance of damage to a valve or valve box from maintenance equipment. Manifolding valves requires less wire from the valves to the controller location, and the valves are easily located for troubleshooting. Usually, the manifolded valves are located outside the landscaped or maintained area. Therefore, there is a reduced chance that damage may be caused by maintenance equipment. The main disadvantage of manifolding is that more pipe is needed to run from the valves to the sprinkler locations. Additionally, servicing the manifolded valves becomes difficult if valves are installed too close together.

17

Basic Irrigation Design ___________________________________________

s

Zoning A System

NOTES

After the system is zoned, piped and begins to operate, the valves will typically operate in a sequential manner. Therefore, when one valve is open and operating, the remaining valves are closed.

MANIFOLD VALVE LOCATION

Remote Control Valves Lateral Line Pipes Main Line Pipe

To Other Sprinklers

FIGURE 4.3

Review __________________________________________________________ 1. If 25 sprinklers discharge 4 GPM each and the available water is 20 GPM, 5 how many remote control valves should there be?____________________ 2. If a water supply is calculated to provide 20 GPM, should there be one zone designed to 25 GPM and another designed to 15 GPM within this No system?________________________________________________________ 3. If there is similar plant material in an area with both heavy shade and sun, No should all of the plants be on the same zone? ________________________ 4. On a slope, should the lateral line pipes run vertically or horizontally to Horizontally the slope?______________________________________________________ 5. Using Figure 4.4 on the next page, zone the system according to available water.

18

___________________________________________ Basic Irrigation Design

s

Zoning A System

NOTES

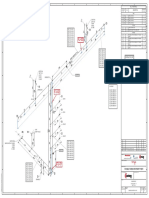

Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6

14.05 GPM 13.64 GPM 13.72 GPM 13.65 GPM 11.60 GPM 11.60 GPM

2 6

1

Water Meter

.6 GPM x 4 = 2.4 1.3 GPM x 16 = 20.8 Total 23.2

570Z-12-Q

V-1550-1.5 V-1550-3.0

1.49 GPM x 6 = 8.9 3.06 GPM x 10 = 30.6 4.54 GPM x 2 = 9.1 6.44 GPM x 1 = 6.4 Total 55.0

570Z-12-H V-1550-4.5

V-1550-6.0

Static Pressure = 65 PSI

GPM Available Water = 15 __________ 40 PSI Design Pressure = _________

FIGURE 4.4

19

Basic Irrigation Design ___________________________________________

s

Pipe Sizing

The purpose of sizing pipe correctly is to ensure that the pipe delivering water to the sprinkler carries the required flow without excessive friction loss. In this section, the steps for properly sizing irrigation lateral and main line pipes are outlined. When pipe is sized properly, the irrigation system flows water at safe velocities with minimal friction losses. There are several methods to determine the proper pipe size. One of the most common is the velocity method. Using the velocity method, the designer limits the speed in each segment of pipe supplying water to the sprinklers. The most agreed upon speed limit of water flow in pipe is 5 FPS. By limiting the speed to under 5 FPS, friction losses are also kept to a minimum. The process of sizing pipe using the velocity method is as follows: 1. Begin at the sprinkler farthest from the remote control valve. Check the gallonage of the sprinkler at the estimated design operating pressure. This information comes from the Toro Product Catalog nozzle data. 2. Choose the type of pipe needed for the system, for example, SDR 21 CLASS 200 PVC. Refer to the Velocity of Flow Chart on page 9 in the Toro Technical Data Book. 3. Read down the far left column under FLOW GPM. Follow until the GPM of the sprinkler used in the design of the system, at its operating pressure, is located. To the right of this GPM, locate the smallest pipe size which flows the water under 5 feet per second.

1" Water Meter

112" Main Line

252-06-04 (Angle)

112"

5 GPM Sprinkler Heads

1"

3

4"

2"

Note: All pipe CL 200 PVC

FIGURE 5.1

4. Continue adding the GPM from upstream sprinklers to each segment of pipe. Follow Step 3 for all segments. The pipes will increase in size closer to the remote control valves. 5. Valves are sized using the total GPM flow demand from all downstream sprinklers. Refer to the Toro Product Catalog for valve sizing. Once the valve type is selected, it is sized by referring to the pressure loss charts in the Toro Product Catalog. As velocity of water is limited in the pipes, there is a limit of allowable friction loss in the valve.

20

___________________________________________ Basic Irrigation Design

s

Pipe Sizing

6. To size the main line, follow the same procedures used on the lateral pipe using the maximum total flow from the largest remote control valve.

Review___________________________________________________________ 1. What is the allowable feet per second (FPS) velocity used to size pipe? 5 FPS ______________________________________________________________ 2. What determines the amount of flow demand in the irrigation system Sprinkler Head Demand pipes? ________________________________________________________ 3. What is the maximum allowable friction loss in any remote control valve 5 PSI; Manufacturers Catalog and where is that information found?_______________________________ 4. Size the lateral line pipes, main line pipe and remote control valves in Figure 5.2 below.

NO TE

NOTES

The total flow of the downstream sprinklers should not create more than 5 PSI loss through the valve selected. If it is more than 5 PSI, a larger valve is required.

1" Water Meter

112" 1" 252-06-04 (Angle)

1 1 3

114"

CL 200 PVC Main Line

1" 3 4"

1

2" 4"

2"

2"

1 2" 1" 252-06-04 (Angle) or 112" 252-26-06

1

112"

3

4"

1 1

2"

1 4"

2" 1"

3

4"

2"

5 GPM Sprinkler Heads ______

FIGURE 5.2

21

Basic Irrigation Design ___________________________________________

s

System Operation Check

The purpose of performing a system operation check is to guarantee that the system operates at the proper design operating pressure selected previously. In order for the system to operate correctly the most critical sprinkler should have adequate design operating pressure. A system operation check will alert the designer to any potential problems in the system, allowing for corrections to the design. This section includes the steps required to calculate friction losses in all components flowing water within the system.

Lateral Line Pipes

The most critical sprinkler head on the system is usually located at the point farthest from the water source. It may also be the farthest sprinkler on the largest flow demand zone.

NO TE

112" 1"

112"

Main Line Pipe 1" Valve

4"

2" Critical Sprinkler

FIGURE 6.1

Friction losses occur through the following components of the irrigation system:

s s s s s s s

Service Line Water Meter

service line water meter backflow prevention device main line pipe remote control valve lateral line pipes fittings

Backflow Main Line Pipe Lateral Line Pipes

Remote Control Valve

FIGURE 6.2

As outlined in the Hydraulics Section, an estimated amount of total friction loss should be used to decide sprinkler design operating pressure. For example, if 25 PSI is deducted from a static pressure of 65 PSI, then 40 PSI remains for design operating pressure. Friction losses in the system should not be so great that they cause the design operating pressure to fall below 40 PSI.

22

___________________________________________ Basic Irrigation Design

s

System Operation Check

NOTES

After all friction losses are calculated, the total amount is subtracted from the static water pressure. If the remaining pressure is less than the design operating pressure, the system design must be altered. If the remaining pressure is greater than the design operating pressure by approximately 10%, the hydraulic design is adequate. Begin calculating the friction losses at the critical head and work back to the water source. Follow the direct path from the critical head to the water source. Friction loss must be calculated on all components that carry water directly to the critical sprinkler. Flows increase through each piece of lateral line pipe as the losses are calculated toward the water source.

NO TE

To calculate the friction loss in the lateral lines, refer to Figure 6.3. Section A is the closest pipe to the critical head, delivering 5 GPM through 50 feet of 1 2" PVC.

D 114" = 50' 25 GPM

E 112" = 25' 35 GPM

Main Line

1" = 25' 15 GPM

112" Valve

3 4" = 50' 10 GPM

2" = 50' 5 GPM

Critical Sprinkler Note: All lateral line pipes are CL200 PVC

FIGURE 6.3

23

Basic Irrigation Design ___________________________________________

s

System Operation Check

NOTES

Friction losses for CLASS 200 PVC are found on page 8 of the Toro Technical Data Book. The FLOW GPM column is located at the left side of the page and the PIPE SIZE is across the top. Find 5 GPM in the FLOW GPM column. Directly to the right, the friction loss is indicated for the 12" pipe. It shows a loss of 4.76 PSI per 100 feet, which is converted to the actual length of 50 feet by multiplying 4.76 by .50. The loss per 50 feet = 2.38 PSI.

Pressure Loss From Friction per 100 of Pipe (lbs./sq. in.)

SDR 21 / Class 200 PVC 1120, PVC 1220, PVC 2120 Flow GPM 1 2 3 4 5 6 7 8 9 10

1 2

C = 140 1

1 2

3 4

1 4

212

.26 .89 1.86 3.12 4.76 6.62 8.82 11.26 14.10 17.11

.07 .26 .52 .90 1.37 1.90 2.52 3.21 4.05 4.90 .28 .42 .59 .80 1.02 1.24 1.52 .31 .40 .50 .26

FIGURE 6.4

Section B is calculated the same way as Section A, but the flow increases in the pipe to 10 GPM because the pipe is delivering water to two sprinklers, each demanding 5 GPM. As the calculations are done for each pipe, the flow continues to increase due to sprinkler demand downstream. The process of calculating the friction loss is the same. Examine the following calculations for the example: Section A: 4.76 PSI (.50) = 2.38 Section B: 4.90 PSI (.50) = 2.45 Section C: 3.26 PSI (.25) = .82

Section D: 2.67 PSI (.50) = 1.34 Section E: 2.56 PSI (.25) = .64

Total Lateral Line PSI Loss = 7.63

24

___________________________________________ Basic Irrigation Design

s

System Operation Check

NOTES

Review___________________________________________________________ 1. Is a system friction loss check necessary to determine if the irrigation Yes system will operate properly? _____________________________________ 2. Which sprinkler on the irrigation system should be checked for correct Critical Head operating pressure?______________________________________________ 3. Where is the zone containing the critical head typically located in the Furthest from source; Highest GPM zone irrigation system? _______________________________________________ 4. Is it necessary to check the friction loss through the backflow prevention Yes device when doing a system friction loss check? _____________________ 5. Determine the critical head in Figure 6.5 on the next page. Then, calculate the working pressure at the critical head.

25

Basic Irrigation Design ___________________________________________

s

System Operation Check

NOTES

(5.3)

1" Water Meter

(1.4)

25' 1 2" Type K Copper Service Line

1

Toro 220-14 PVB Backflow Prevention Device

(3.8)

200' 112" CL200 PVC MainLine

(3.9)

(5.0)

Toro 1" 252-06-04 (Angle)

112" = 50'

(.97)

114" = 50'

Critical Head (2.45)

3

(.88) (.82)

1" = 25'

(.69)

3

4" = 50'

4" = 50'

5 GPM Sprinkler Heads _______

Note: All lateral lines are CL200 PVC

FIGURE 6.5 FRICTION LOSS CALCULATION

5.8 Lateral Line ________________ PSI 5.0 Zone Valve ________________ PSI 3.9 Main Line ________________ PSI 3.8 Backflow ________________ PSI 5.3 Water Meter ________________ PSI 1.4 Service Line ________________ PSI 25.2 Total PSI Loss ________________ PSI

26

60 Static Pressure ________________ PSI 25.2 Total PSI Loss ________________ PSI 34.8 Working Pressure _______________ PSI

Design Operating 40 Pressure ______________ PSI

___________________________________________ Basic Irrigation Design

s

Design Checklist

s s s

Measure the site and record specific irrigation requirements. Determine the size and location of the water meter. Determine the type of material, size and length of the service line from the city water main to the proposed location of the backflow prevention device. Measure and record the static water pressure. Estimate the amount of friction loss in the entire system. Determine the design operating pressure from the estimated friction losses. Calculate the available water on the site. Divide the site into separate, smaller geometric shapes. Choose the type of spacing needed, square/rectangular or triangular. Find the critical line and critical corner on the site and lay out the first row of sprinklers. Continue placing sprinklers until the site is covered adequately. Determine the number of zones from the available water and total number of sprinklers. Route the lateral line pipe and the control valves. Route the main line pipe. Size the lateral lines, remote control valves, main lines and backflow prevention device. Check for total friction losses from the P.O.C. to the most critical head on the system. Make any necessary adjustments to component sizes and design.

s s s

s s s s

s s

s s s

27

Basic Irrigation Design ___________________________________________

s

Suggested Reading

1. Melby, Pete 1995 Simplified Irrigation Design, Second Edition Van Nostrand Reinhold New York, NY. 2. Rochester, Eugene 1995 Landscape Irrigation Design American Society of Agricultural Engineers St. Joseph, MI. 3. Sarsfield, A. C. 1966 The ABCs of Lawn Sprinkler Systems Irrigation Technical Services Lafayette, CA. 4. Smith, Stephen W. 1996 Landscape Irrigation: Design and Management John Wiley & Sons New York, NY. 5. Weinberg, Scott S. 1988 Handbook of Landscape Architectural Construction - Irrigation Landscape Architecture Foundation Washington, DC.

28

The Toro Company Irrigation Division An ISO 9001-Certified Facility

PO Box 489 Riverside, CA 92502 Phone (800) 654-1882 www.toro.com

Form No. 490-2945

1997 The Toro Company All Rights Reserved March 1997

PC5M397

You might also like

- Irrigation ManualDocument168 pagesIrrigation Manualmote34100% (1)

- Irrigation HandbookDocument196 pagesIrrigation Handbookegroner100% (1)

- Pressurizes Irrigation JoinedDocument296 pagesPressurizes Irrigation Joinedmosne1100% (1)

- Basic Irrigation BookDocument300 pagesBasic Irrigation Bookhaithamelramlawi7503100% (3)

- Irrigation Cost AnalysisDocument24 pagesIrrigation Cost AnalysisAnuj_Kanwal_1156No ratings yet

- Sprinkler Irrigation 2011 CompleteDocument294 pagesSprinkler Irrigation 2011 Completemosne1100% (8)

- Irrigation Design ManualDocument140 pagesIrrigation Design Manualabinet100% (8)

- Simplified Irrigation Design, 2nd Edition (Landscape Architecture) PDFDocument463 pagesSimplified Irrigation Design, 2nd Edition (Landscape Architecture) PDFᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- Irrigation Pipe DesignDocument53 pagesIrrigation Pipe DesignVinod100% (11)

- Irrigation Handbook 220165Document68 pagesIrrigation Handbook 220165Tommy StrømhaugNo ratings yet

- IrrigationDocument747 pagesIrrigationGustavo1722100% (8)

- Irrigation Project ManualDocument66 pagesIrrigation Project ManualHorace Prophetic DavisNo ratings yet

- 05 Drip IrrigationDocument21 pages05 Drip IrrigationDileesha WeliwaththaNo ratings yet

- Irrigation HandbookDocument68 pagesIrrigation HandbookGrundfosEgypt83% (6)

- Irrigation Manual FAO Module 7Document169 pagesIrrigation Manual FAO Module 7Zac Mweb86% (7)

- USDA Sprinkle Irrigation Handbook Chapter 11Document125 pagesUSDA Sprinkle Irrigation Handbook Chapter 11James K. KirahukaNo ratings yet

- IRRIGATION Pump HandbookDocument96 pagesIRRIGATION Pump HandbookGrundfosEgypt100% (4)

- Drip Irrigation 2013Document88 pagesDrip Irrigation 2013mosne1No ratings yet

- Pumping and Automation in Irrigation 2014Document81 pagesPumping and Automation in Irrigation 2014mosne1No ratings yet

- Handbook On Pressurized Irrigation TechniquesDocument287 pagesHandbook On Pressurized Irrigation TechniquesDimitar KondinskiNo ratings yet

- Drip Irrigation PDFDocument109 pagesDrip Irrigation PDFshahid aliNo ratings yet

- Report-Irrigation System Design 14Document55 pagesReport-Irrigation System Design 14HAFIZ ARSALAN ALINo ratings yet

- Sprinkler Irrigation Nov 2014Document295 pagesSprinkler Irrigation Nov 2014mosne1100% (1)

- Micro Irrigation Systems Design BookDocument247 pagesMicro Irrigation Systems Design BookNguyen Van Kien100% (1)

- Irrigation System DesignDocument90 pagesIrrigation System Designmirza_adil99100% (2)

- 1.1 History of IrrigationDocument8 pages1.1 History of IrrigationRubelyn AlabadoNo ratings yet

- Irrigation HandbookDocument68 pagesIrrigation Handbookingrbarros100% (1)

- Irrigation Pipe CalculationDocument8 pagesIrrigation Pipe CalculationNguyen Van KienNo ratings yet

- Drip Irrigation Manual 2005 - IsraelDocument134 pagesDrip Irrigation Manual 2005 - IsraelFriends of Catalyst Magazine100% (2)

- Sprinkler Systems ExplainedDocument132 pagesSprinkler Systems ExplainedpraveenakkNo ratings yet

- Micro Irrigation - Technology and ApplicationsDocument146 pagesMicro Irrigation - Technology and Applicationsmosne175% (8)

- National Irrigation GuideDocument754 pagesNational Irrigation GuideAbdou75% (4)

- Drip Irrigation 2014Document117 pagesDrip Irrigation 2014mosne1100% (1)

- Sprinkler and drip irrigation componentsDocument22 pagesSprinkler and drip irrigation componentsSANDIE YEYANo ratings yet

- Drip Irrigation DesignDocument43 pagesDrip Irrigation DesignAshraf Bestawy100% (1)

- Sewer DesignDocument234 pagesSewer Designvgbarros85780% (1)

- Methods and Techniques of IrrigationDocument9 pagesMethods and Techniques of IrrigationEmmanuel Sto TomasNo ratings yet

- Methods of IrrigationDocument77 pagesMethods of IrrigationYrol-Angel Peralta100% (1)

- IRRIGATION Pump Handbook PDFDocument96 pagesIRRIGATION Pump Handbook PDFSigit PrasetyoNo ratings yet

- Diseño de Riego Por Goteo ToroDocument28 pagesDiseño de Riego Por Goteo ToroNicolás HovagimianNo ratings yet

- PVsyst Tutorials V7 PumpingDocument22 pagesPVsyst Tutorials V7 PumpingΤσιμπινός ΣπύροςNo ratings yet

- PVsyst Tutorials V7 PumpingDocument22 pagesPVsyst Tutorials V7 PumpingcosphiNo ratings yet

- Surge Control in Pumping Systems: White PaperDocument15 pagesSurge Control in Pumping Systems: White PapermaiNo ratings yet

- Water LinesDocument34 pagesWater LinesJudy Dela PenaNo ratings yet

- Carrier - Water Piping Systems and PumpsDocument33 pagesCarrier - Water Piping Systems and PumpsRebecca TerryNo ratings yet

- Condenser Water Pump Guide SummaryDocument31 pagesCondenser Water Pump Guide SummaryMelaku TamiratNo ratings yet

- Pressure Boosting PumpsDocument4 pagesPressure Boosting PumpsmabuhayehNo ratings yet

- Subsurface Irrigation ManualDocument41 pagesSubsurface Irrigation ManualLeoPérezNo ratings yet

- PumpControlBulletin Sept04Document32 pagesPumpControlBulletin Sept04francisco_chamorr_12No ratings yet

- ProFlowEliminatorCertifiedManual PDFDocument24 pagesProFlowEliminatorCertifiedManual PDFintermountainwaterNo ratings yet

- KSB Surge PublicationDocument34 pagesKSB Surge PublicationDiego AguirreNo ratings yet

- Pressure Booster SizingDocument4 pagesPressure Booster SizingSam Choi100% (1)

- 2017 CIV 81 Report of Water SupplyDocument40 pages2017 CIV 81 Report of Water SupplyTaha UsamaNo ratings yet

- Org - pdi.PDI WH 201 011810 PDFDocument37 pagesOrg - pdi.PDI WH 201 011810 PDFEslam ElsayedNo ratings yet

- PipesysDocument188 pagesPipesysKrisTian EdogawaNo ratings yet

- Viking Foam Manual 001Document24 pagesViking Foam Manual 001Trần VânNo ratings yet

- Irrigation Evaluation 2Document29 pagesIrrigation Evaluation 2Emanuel FuenzalidaNo ratings yet

- Sump DesignDocument47 pagesSump DesignJessica HuberNo ratings yet

- Potable Water PumpingDocument38 pagesPotable Water PumpingThiruvasagam SubramanianNo ratings yet

- Directional Control Valve WM WN WP WHD Mechanical Manual. Pneumatic Hydraulic Actuated Re22331 PDFDocument12 pagesDirectional Control Valve WM WN WP WHD Mechanical Manual. Pneumatic Hydraulic Actuated Re22331 PDFRS Rajib sarkerNo ratings yet

- Manual de Reparacion TXV75Document16 pagesManual de Reparacion TXV75Ovh MaquinariasNo ratings yet

- Centrifugal Pump CharacteristicsDocument27 pagesCentrifugal Pump Characteristicskarioke mohaNo ratings yet

- 8009 PDFDocument42 pages8009 PDFlungu mihaiNo ratings yet

- Centrifugal Pump Head and EfficienciesDocument27 pagesCentrifugal Pump Head and EfficienciesEpicNewtonNo ratings yet

- Petrochemical TranslationDocument28 pagesPetrochemical TranslationStory FunnyNo ratings yet

- Module 5: Activity No. 2: P D D Q 150 GPM P PDocument4 pagesModule 5: Activity No. 2: P D D Q 150 GPM P PLeyzer MalumayNo ratings yet

- Fluid Power Symbols GuideDocument40 pagesFluid Power Symbols GuideShalom LivingstonNo ratings yet

- Product Catalogue & Technical Reference Guide Highlights Key ComponentsDocument54 pagesProduct Catalogue & Technical Reference Guide Highlights Key Componentsr rNo ratings yet

- HP Hydraulic Manual Override: Hpa / HPB / HPC / Hp1Document8 pagesHP Hydraulic Manual Override: Hpa / HPB / HPC / Hp1mar mayoNo ratings yet

- Boiler Feed Pump New 1Document39 pagesBoiler Feed Pump New 1789krishnaNo ratings yet

- Hydraulic Tech InfoDocument195 pagesHydraulic Tech InfojosueNo ratings yet

- Spigot Saddles: Frialen Safety FittingsDocument2 pagesSpigot Saddles: Frialen Safety FittingsAlbertoNo ratings yet

- Pirobloc Electric Steam BoilersDocument3 pagesPirobloc Electric Steam Boilerslhphong021191No ratings yet

- Series-90 Pump Service 520L0818 2008-02 PDFDocument72 pagesSeries-90 Pump Service 520L0818 2008-02 PDFsfe100% (1)

- Boiler Calucation SheetDocument84 pagesBoiler Calucation Sheet9913489806No ratings yet

- Y32.2.3 (Symbols For Piping) PDFDocument12 pagesY32.2.3 (Symbols For Piping) PDFGabriel Rojas MendozaNo ratings yet

- John Deere 644G Loader Brake Valve Hydraulics Parts CatalogDocument3 pagesJohn Deere 644G Loader Brake Valve Hydraulics Parts CatalogComando Guerra0% (1)

- Dosing Pump Accessories - CMSDocument64 pagesDosing Pump Accessories - CMSzivkovic brankoNo ratings yet

- Hydraulic drive system basicsDocument6 pagesHydraulic drive system basicsyamnul khairNo ratings yet

- 999 enDocument52 pages999 enMohamed Rashed100% (3)

- LR3 (A)Document6 pagesLR3 (A)Jerome SamuelNo ratings yet

- RENR5268-01: D5N and D6N Track-Type Tractor Hydraulic SystemDocument2 pagesRENR5268-01: D5N and D6N Track-Type Tractor Hydraulic SystemivanNo ratings yet

- Bomba Proteccion Contra IncendioDocument9 pagesBomba Proteccion Contra IncendioYairton Vargas MuñozNo ratings yet

- Sizing For Liquid Relief: Pressure Relief Valves Not Requiring Capacity CertificationDocument6 pagesSizing For Liquid Relief: Pressure Relief Valves Not Requiring Capacity CertificationKais MessaoudiNo ratings yet

- Pipe Fabrication and Welding Project Cost BreakdownDocument2 pagesPipe Fabrication and Welding Project Cost BreakdownRuelNo ratings yet

- 270 S.J. S.J.: ID QTY DN Description Sch/Cla SSDocument2 pages270 S.J. S.J.: ID QTY DN Description Sch/Cla SSABAID ULLAHNo ratings yet

- Water Supply System - Module 1Document49 pagesWater Supply System - Module 1Harshita MittalNo ratings yet

- AWH-Brochure LeakageBVDocument2 pagesAWH-Brochure LeakageBVElleuch HaithemNo ratings yet

- Swash-Plate Pump (Portfolio)Document2 pagesSwash-Plate Pump (Portfolio)Jannen V. ColisNo ratings yet