Professional Documents

Culture Documents

Course 28

Uploaded by

myyouthCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course 28

Uploaded by

myyouthCopyright:

Available Formats

Course 28. Fluid Machinery (Web Course) Faculty Coordinator(s) : 1. Prof. Anoop. K.

Dass Department of Mechanical Engineering Indian Institute of Technology , Guwahati North Guwahati, Guwahati 781039 Email :

anoop@iitg.ernet.in

Off : 2582654 2584654 Res :

Telephone : (91- 361)

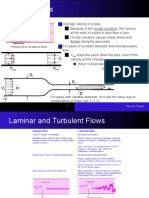

Detailed Syllabus : PART I: General Considerations Introduction Module-1: Nomenclature Concepts Theoretical aspects L1: Classification of Fluid Machinery, stage, stator, rotor L2: Cylindrical co-ordinate system, Moment of momentum, notations L3: Euler Equation for turbomachinery L4: Concept of relative velocity, Velocity-vector equation, Velocity triangle L5: Performance indices like power, efficiency Module-2: Dimensional Analysis & Similitude L6: Dimensional Analysis L7: Similitude PART II: Hydraulic Turbines Introduction Module-3: Impulse Turbines L8 & L9: Pelton wheel, its geometry and working; performance parameters; conditions for optimum operation L10: Brief description of a hydel plant; need for governing; governing technique Module-4: Reaction Turbines L11: Radial-flow reaction (Francis) turbine; geometry and working; flow at entry; velocity diagram. L12: Francis turbine contd.; net head across a reaction turbine; draft tube; justification of inward flow arrangement; flow rate; performance parameters; L13: Axial-flow reaction (propeller and Kaplan turbine); geometry and working; velocity diagram; performance parameters. L14: Draft tube and cavitation; net positive suction head (NPSH); Installation of reaction turbines. (Note: An additional lecture may be necessary) Module-5: Dimensional Analysis & Similitude L15: Dimensional Analysis; head, flow and power coefficient; nondimensional specific speed. L16: Similitude; geometric, kinematic and dynamic similarity.

PART III: Rotodynamic Pumps Introduction Module-6: Centrifugal pumps L17: Types; geometry and working; elementary pump theory; Euler equation; Bernoulli equation in rotating coordinates L18: Velocity diagrams at entry and exit of the impeller; output and performance parameters manometric head, manometric efficiency, overall efficiency; effect of blade angle on pump head. L19: Pump performance curves and similarity rules; NPSH and cavitation; specific speed for pumps; pumps andf fluid networks. Module-7: Axial-flow and Mixed-flow Pumps L 20 & L21: Specific speed and variation of shape; axial-flow pump theory; performance of axial- and mixed-flow pumps. Module-8: general Aspects L22 & L23: Matching of pumps to system characteristics; pumps combined in parallel; multistage pumps.

PART IV: Positive Displacement Pumps Introduction Module-9: Reciprocating pumps L24: Geometry and working; installation; pressure diagram; pump head and efficiency. L25: Discharge and its variation with crank angle; pump with air cylinders indicator diagram; theoretical and actual characteristic. Module-10: Rotary Pumps L26 & L27: Gear pump and performance curves; rotary vane pump and characteristics; screw pump.

PART V: Compressors Introduction Module-11: Centrifugal Compressors L28: Geometry, definitions, working; velocity diagrams across the impeller. L29: Theoretical analysis; enthalpy-entropy diagram of a stage; energy equation for the inlet casing, impeller and diffuser; conservation of rothalpy. L30: Inlet velocity limitations; optimum design of inlet; slip factor and correlations. L31: Head increase; performance efficiency; effect of vane angle; diffuser system; Module-12: 2D Compressor Cascade L32 & L33: Two-dimensional cascades; cascade nomenclature; Cascade forces lift and drag; cascade efficiency; losses; cascade correlations. Module-13: Axial-flow Compressors L34: Geometry and working; stage stator and rotor blading; velocity diagram across the rotor; L35: Thermodynamics of the compressor stage; enthalpy-entropy diagram for a stage; energy equation across the rotor and the diffuser; degree of reaction; stage loading; off-design performance.

L36: Stage pressure rise; pressure ratio of a multistage compressor; work done factor; efficiency; L37: Stall and surge phenomenon; control of flow instabilities; axial-flow ducted fans. Module-14: Reciprocating Compressors L38: Geometry and working; cycle analysis; actual indicator diagram, isothermal and volumetric efficiency. L39: Effect of multistage compression on volumetric efficiency; effect of intercooling; work of a multistage compressor.

PART VI: Miscelleneous Introduction Module-15: Hydraulic Transmissions L40: Fluid coupling L41: Torque converter Module-16: Wind Turbine L42 & L43: Horizontal axis turbine and associated fluid mechanics; geometry and working; general aspects. Module-17: Power from sea wave L44: The Wells turbine Module-18: Pure Reaction Turbine L45: Lawn sprinkler etc. (One or two additional lectures may be added later; minor shifting of topics from one lecture to another may be a necessity at the time of actual development of the course material)

Books: 1. 2. 3. S.L.Dixon, Fluid Mechanics and Thermodynamics of Turbomachinery, 4e, Butterworth and Heinemann, 1998 (Main text book). J.F.Douglas, J.M.Gasiorek and J.A.Swaffield, Fluid Mechanics, 3e (Ch 22, 23, 24 & 25), Addison-Wesley, 1995 (International Student Edition 1999) B.S.Massey, Mechanics of Fluids, 5e (Ch. 14 &9), Van Nostrand Reinhold (U.K.), 1983. H.I.H.Saravanamutto, G.F.C.Rogers and H.Cohen, Gas Turbine Theory, 5e (Ch. 4 & 5) Pearson Education (Singapore), 2001.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Specific Speed NotesDocument2 pagesSpecific Speed NotesUjwol PhaijuNo ratings yet

- FluidSystem09 ReactionTurbine FrancisandKaplanDocument18 pagesFluidSystem09 ReactionTurbine FrancisandKaplanmyyouthNo ratings yet

- FluidSystem09 ReactionTurbine FrancisandKaplanDocument18 pagesFluidSystem09 ReactionTurbine FrancisandKaplanmyyouthNo ratings yet

- Fluid Mechanics (Video)Document1 pageFluid Mechanics (Video)myyouthNo ratings yet

- Field Testing and Optimising Efficiency of Hydro TurbinesDocument12 pagesField Testing and Optimising Efficiency of Hydro TurbinesmyyouthNo ratings yet

- Theoretical Background of PELTON TurbineDocument7 pagesTheoretical Background of PELTON TurbinemyyouthNo ratings yet

- Theoretical Background of PELTON TurbineDocument7 pagesTheoretical Background of PELTON TurbinemyyouthNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Flow in PipesDocument29 pagesFlow in PipesRafa MartínezNo ratings yet

- 325 Hydraulic SystemDocument7 pages325 Hydraulic SystemUMA AKANDU UCHENo ratings yet

- Pn2thd Flow Chart GPM 2018v3Document2 pagesPn2thd Flow Chart GPM 2018v3VICTOR RALPH FLORES GUILLENNo ratings yet

- Flow Control ManifoldsDocument4 pagesFlow Control ManifoldsBrayan AguileraNo ratings yet

- PRFD - Design ManualDocument2 pagesPRFD - Design ManualSreepathy RangarajanNo ratings yet

- Plumbing SystemDocument16 pagesPlumbing SystemVholts Villa VitugNo ratings yet

- PC2000 - Parts Book-Pages-694-695,706-707,712-715,719,721,724Document11 pagesPC2000 - Parts Book-Pages-694-695,706-707,712-715,719,721,724clyde justine cayabanNo ratings yet

- Centrifugal End Suction Firepump NFPA 20Document5 pagesCentrifugal End Suction Firepump NFPA 20huseeeNo ratings yet

- BOQ DrainageDocument8 pagesBOQ DrainageNeal JohnsonNo ratings yet

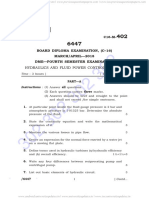

- 2347 Hydraulics and Fluid Power Control SystemsDocument3 pages2347 Hydraulics and Fluid Power Control SystemsKollikonda RameshNo ratings yet

- FPC Unit 1Document28 pagesFPC Unit 1Ravi MishraNo ratings yet

- Relief Valve (Main) - Test and Adjust - Heavy Lift: 320D Excavator Hydraulic SystemDocument6 pagesRelief Valve (Main) - Test and Adjust - Heavy Lift: 320D Excavator Hydraulic SystemKJDNKJZEFNo ratings yet

- Unit 2: Load Sensing, Pressure Compensated Hydraulic SystemsDocument19 pagesUnit 2: Load Sensing, Pressure Compensated Hydraulic SystemsMohammed KhalidNo ratings yet

- 10 Artificial Lift SystemsDocument109 pages10 Artificial Lift SystemsTania Arteta100% (1)

- AFSA Inspection Form - Water Based PDFDocument4 pagesAFSA Inspection Form - Water Based PDFMYSTerB100% (2)

- Problem Set 2 - Fluid MachineryDocument1 pageProblem Set 2 - Fluid MachineryRonard Pa–aNo ratings yet

- BoQ MEP Club House KosongDocument53 pagesBoQ MEP Club House KosongkelikNo ratings yet

- MC105 Full CatalogDocument204 pagesMC105 Full Catalogதமிழன் இராமசாமிNo ratings yet

- 2 Pumps Part IDocument5 pages2 Pumps Part IJoel CariazNo ratings yet

- Uf Module Rack-Rev01Document4 pagesUf Module Rack-Rev01Smit BhivgadeNo ratings yet

- A10 A Pid Va 718768 206Document1 pageA10 A Pid Va 718768 206zhangNo ratings yet

- Water Mist Test Report PDFDocument5 pagesWater Mist Test Report PDFMomed MdNo ratings yet

- Olefin ASME Valve BasketDocument77 pagesOlefin ASME Valve Basketshiv kamathNo ratings yet

- 2.1 Facilities of Existing Water Supply SchemeDocument3 pages2.1 Facilities of Existing Water Supply SchemeLakmal SooriyabandaraNo ratings yet

- HIDRAULICO Cat 772Document2 pagesHIDRAULICO Cat 772Tom SouzaNo ratings yet

- EH-SolutionsLibrary 999902104 1Document16 pagesEH-SolutionsLibrary 999902104 1Alfonso Lopez toroNo ratings yet

- Juni Now2022Document479 pagesJuni Now2022Hello yusiNo ratings yet

- Listado de Instrumentos - DescripciónDocument33 pagesListado de Instrumentos - DescripciónDaniel Camargo Perez100% (1)

- AL78 Brocure Sangdo Breaker-1Document2 pagesAL78 Brocure Sangdo Breaker-1kemrosokkNo ratings yet

- Mark Qty Size Description Length: Petrobras P-52 Total Piping BOM 2/1/05Document6 pagesMark Qty Size Description Length: Petrobras P-52 Total Piping BOM 2/1/05Marcos AndréNo ratings yet