Professional Documents

Culture Documents

Elastomers SBR PDF

Uploaded by

Guoxiang ChungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elastomers SBR PDF

Uploaded by

Guoxiang ChungCopyright:

Available Formats

Carbon black reinforced styrene butadiene rubber (SBR)

Description

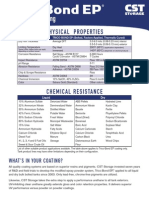

The material Styrene Butadiene Copolymer Rubber (SBR) is the synthetic rubber that is most widely used and has the highest production volume. It is nearly always compounded with reinforcing fillers such as carbon black. Strengths: When filled, its strength approaches natural rubber (NR) and polychloroprene. Similar chemical and physical properties to NR and somewhat better abrasion resistance. Limitations: Weaker and lower fatigue resistance than natural rubber (it does not undergo strain-induced crystallation) especially when unfilled. Like NR: prone to oxidation, degrades in ozone, swells readily in hydrocarbon fluids with loss of properties. Composition (summary) Copolymer of 23% styrene (CH2CH(C6H5))n and 77% butadiene (CH2CH=CHCH2)m reinforced with typically 30% Carbon Black Image

Page 1 of 4

Caption Styrene Butadiene Rubber is the most popular synthetic rubber in tyres.

General properties

Density Price Date first used ("-" means BC) 70.5 * 1.71 1932 71.8 1.88 lb/ft^3 USD/lb

Mechanical properties

Young's modulus Shear modulus Bulk modulus Poisson's ratio Yield strength (elastic limit) Tensile strength Compressive strength Elongation Fatigue strength at 10^7 cycles Fracture toughness Mechanical loss coefficient (tan delta) 5.51e-4 * 1.74e-4 * 0.218 0.48 2.32 2.32 * 2.78 320 * 0.928 * 0.892 * 0.08 8.7e-4 2.9e-4 0.29 0.496 3.77 3.77 4.53 550 1.51 0.978 0.14 10^6 psi 10^6 psi 10^6 psi ksi ksi ksi % strain ksi ksi.in^0.5

Thermal properties

Glass temperature Maximum service temperature Minimum service temperature Thermal conductor or insulator? Thermal conductivity Specific heat capacity -83.2 - -61.6 158 - 230 -58 - -40 Poor insulator 0.231 - 0.52 F F F BTU.ft/h.ft^2.F

Values marked * are estimates. Granta Design provides no warranty for the accuracy of this data

Carbon black reinforced styrene butadiene rubber (SBR)

Thermal expansion coefficient 0.346 88.9 0.382 100 BTU/lb. F strain/ F

Page 2 of 4

Electrical properties

Electrical conductor or insulator? Electrical resistivity Poor insulator 1e10 - 1e16 ohm.cm

Optical properties

Transparency Opaque

Processability

Moldability 3 4

Durability: water and aqueous solutions

Water (fresh) Water (salt) Soils, acidic (peat) Soils, alkaline (clay) Wine Excellent Excellent Excellent Excellent Excellent

Durability: acids

Acetic acid (10%) Acetic acid (glacial) Citric acid (10%) Hydrochloric acid (10%) Hydrochloric acid (36%) Hydrofluoric acid (40%) Nitric acid (10%) Nitric acid (70%) Phosphoric acid (10%) Phosphoric acid (85%) Sulfuric acid (10%) Sulfuric acid (70%) Excellent Limited use Excellent Excellent Limited use Acceptable Limited use Unacceptable Excellent Excellent Excellent Unacceptable

Durability: alkalis

Sodium hydroxide (10%) Sodium hydroxide (60%) Excellent Excellent

Durability: fuels, oils and solvents

Amyl acetate Benzene Carbon tetrachloride Chloroform Crude oil Diesel oil Lubricating oil Paraffin oil (kerosene) Petrol (gasoline) Silicone fluids Toluene Turpentine Vegetable oils (general) White spirit Unacceptable Unacceptable Unacceptable Unacceptable Unacceptable Unacceptable Unacceptable Unacceptable Unacceptable Excellent Unacceptable Unacceptable Unacceptable Excellent

Durability: alcohols, aldehydes, ketones

Acetaldehyde Acetone Unacceptable Limited use

Values marked * are estimates. Granta Design provides no warranty for the accuracy of this data

Carbon black reinforced styrene butadiene rubber (SBR)

Ethyl alcohol (ethanol) Ethylene glycol Formaldehyde (40%) Glycerol Methyl alcohol (methanol) Excellent Excellent Limited use Excellent Excellent

Page 3 of 4

Durability: halogens and gases

Chlorine gas (dry) Fluorine (gas) O2 (oxygen gas) Sulfur dioxide (gas) Unacceptable Unacceptable Unacceptable Unacceptable

Durability: built environments

Industrial atmosphere Rural atmosphere Marine atmosphere UV radiation (sunlight) Excellent Excellent Excellent Fair

Durability: flammability

Flammability Highly flammable

Durability: thermal environments

Tolerance to cryogenic temperatures Tolerance up to 150 C (302 F) Tolerance up to 250 C (482 F) Tolerance up to 450 C (842 F) Tolerance up to 850 C (1562 F) Tolerance above 850 C (1562 F) Unacceptable Acceptable Unacceptable Unacceptable Unacceptable Unacceptable

Geo-economic data for principal component

Annual world production Reserves 1.01e7 * 2.85e8 1.04e7 2.9e8 ton/yr l. ton

Primary material production: energy, CO2 and water

Embodied energy, primary production CO2 footprint, primary production Water usage Eco-indicator 99 * 1.21e4 * 6.29 * 7.63 342 1.34e4 6.95 22.9 kcal/lb lb/lb gal(US)/lb millipoints/kg

Material processing: energy

Polymer molding energy Grinding energy (per unit wt removed) * 1.67e3 * 182 1.84e3 200 kcal/lb kcal/lb

Material processing: CO2 footprint

Polymer molding CO2 Grinding CO2 (per unit wt removed) * 1.23 * 0.126 1.36 0.139 lb/lb lb/lb

Material recycling: energy, CO2 and recycle fraction

Recycle Recycle fraction in current supply Downcycle Combust for energy recovery Heat of combustion (net) Combustion CO2 Landfill Biodegrade Toxicity rating 0.1 %

* 4.68e3 * 3.11

4.91e3 3.27

kcal/lb lb/lb

Non-toxic

Values marked * are estimates. Granta Design provides no warranty for the accuracy of this data

Carbon black reinforced styrene butadiene rubber (SBR)

A renewable resource? Environmental notes Styrene Butadiene elastomers are thermosets, and thus cannot be recycled. Their disposal creates an environmental problem.

Page 4 of 4

Supporting information

Design guidelines SBR is much weaker than NR if unfilled, but gains similar strength by compounding with 30-50 wt% carbon black. Typical uses Car and truck tires, belt, hose, footwear

Links

Reference ProcessUniverse Producers

Values marked * are estimates. Granta Design provides no warranty for the accuracy of this data

You might also like

- 1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualDocument3 pages1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualBobbi Jo Bach-Oachs50% (2)

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- SingaporeLabCap 2009Document36 pagesSingaporeLabCap 2009Mubeen RehmanNo ratings yet

- IBM-Tandy Guide for Secret Weapons of the LuftwaffeDocument41 pagesIBM-Tandy Guide for Secret Weapons of the Luftwaffetestinghb100% (1)

- Film Properties GuideDocument22 pagesFilm Properties GuidecattausNo ratings yet

- 2.synthetic Rubber TRG DR - JACOB K VARKEYDocument40 pages2.synthetic Rubber TRG DR - JACOB K VARKEYbodekizNo ratings yet

- Technical Guidance Notes: Level 2, No. 13Document4 pagesTechnical Guidance Notes: Level 2, No. 13Τε ΧνηNo ratings yet

- Fire Load CalculationDocument6 pagesFire Load CalculationGunvant Patel91% (11)

- Pre - Project Report: September: 2011Document11 pagesPre - Project Report: September: 2011mahaveersuwalka100% (1)

- 5.c.raw Material TestingDocument30 pages5.c.raw Material Testingbodekiz50% (2)

- Jotun Tankguard HBDocument5 pagesJotun Tankguard HBrheriNo ratings yet

- Project Plan Tyre RecyclingDocument4 pagesProject Plan Tyre RecyclingAjit Chauhan100% (3)

- Production of Acetic Acid via Methanol CarbonylationDocument68 pagesProduction of Acetic Acid via Methanol CarbonylationNoman Aslam100% (5)

- Eco Audit Report Energy and CO2 SummaryDocument5 pagesEco Audit Report Energy and CO2 Summaryaddai262No ratings yet

- Production of Ferro Metals (In Millipoints Per KG)Document7 pagesProduction of Ferro Metals (In Millipoints Per KG)Corina Cristina ConstantinescuNo ratings yet

- Datasheet Jotun-Tankguard StorageDocument5 pagesDatasheet Jotun-Tankguard Storagebudi handoyoNo ratings yet

- Ceramic PanDocument8 pagesCeramic PanAzinuddin AsriNo ratings yet

- Technical Data Sheet TexanolDocument4 pagesTechnical Data Sheet TexanolRICHARD ODINDONo ratings yet

- Eco-GPE™: General Purpose EpoxyDocument5 pagesEco-GPE™: General Purpose EpoxyServandoNo ratings yet

- Plastics & The EnvironmentDocument45 pagesPlastics & The EnvironmentChathura Priyankara WijayarathnaNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Plant Design (SBR)Document8 pagesPlant Design (SBR)Aljay Neeson ImperialNo ratings yet

- Tankguard Special Ultra Jotun PaintDocument5 pagesTankguard Special Ultra Jotun PaintGurdeep Sungh AroraNo ratings yet

- Carbon Fiber Quasi-Isotropic LaminateDocument3 pagesCarbon Fiber Quasi-Isotropic LaminateGonçalo FonsecaNo ratings yet

- TDS 525 Jotamastic 87 GF Euk GBDocument5 pagesTDS 525 Jotamastic 87 GF Euk GBhidayatNo ratings yet

- Pluronic PeDocument16 pagesPluronic PeTrev GlasbeyNo ratings yet

- (Company Logo Here) : Model NameDocument6 pages(Company Logo Here) : Model NameLê Sỹ LinhNo ratings yet

- Hebel Cored Block DownloadDocument2 pagesHebel Cored Block DownloadCarlos BastiasNo ratings yet

- Steel Master 1200 WF PDSDocument5 pagesSteel Master 1200 WF PDSshameelNo ratings yet

- Technical Data Sheet for Tankguard Plus Epoxy CoatingDocument5 pagesTechnical Data Sheet for Tankguard Plus Epoxy CoatingGurdeep Sungh AroraNo ratings yet

- Acrylonitrile Butadiene Styren1Document6 pagesAcrylonitrile Butadiene Styren1NaeemNo ratings yet

- TDS - Tankguard SF - Issued 04.08.2014Document5 pagesTDS - Tankguard SF - Issued 04.08.2014Arya Kemal Pratama PutraNo ratings yet

- Jotamastic 87 PDFDocument6 pagesJotamastic 87 PDFGurdeep Sungh AroraNo ratings yet

- A Framework for Sustainable Concrete ConstructionDocument32 pagesA Framework for Sustainable Concrete ConstructionAshok Kumar TiwariNo ratings yet

- TDS - Tankguard Storage - Issued 04.08.2014Document5 pagesTDS - Tankguard Storage - Issued 04.08.2014Arya Kemal Pratama PutraNo ratings yet

- TDS SteelMaster 1200WF GB English ProtectiveDocument5 pagesTDS SteelMaster 1200WF GB English Protective폴로 쥰 차No ratings yet

- A Presentation BY Mbah Chinedu Drilling Engineer Segofs Energy Services LimitedDocument16 pagesA Presentation BY Mbah Chinedu Drilling Engineer Segofs Energy Services LimitedAwani KesterNo ratings yet

- Tetrahydrofuran (THF) Storage and Handling: Basf IntermediatesDocument20 pagesTetrahydrofuran (THF) Storage and Handling: Basf IntermediatesRidho AmaliaNo ratings yet

- Jotatemp 1000 CeramicDocument5 pagesJotatemp 1000 CeramicNabeel K SNo ratings yet

- TricoBondSpecSheet 2Document2 pagesTricoBondSpecSheet 2David HoffmanNo ratings yet

- Tank Guard Plus For 160 Deg CDocument5 pagesTank Guard Plus For 160 Deg CTahir aminNo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- Technical Data Sheet for Baltoflake CoatingDocument6 pagesTechnical Data Sheet for Baltoflake CoatingSaul AntayhuaNo ratings yet

- Common Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Document4 pagesCommon Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Yashi SrivastavaNo ratings yet

- Jotamastic 80 Technical Data SheetDocument6 pagesJotamastic 80 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotatemp 1000 CeramicDocument5 pagesJotatemp 1000 CeramicBiju_PottayilNo ratings yet

- Gas Encyclopaedia: Aller Au Menu Aller Au ContenuDocument9 pagesGas Encyclopaedia: Aller Au Menu Aller Au ContenuMalvatkar SunilNo ratings yet

- Jotun - Technical Data Sheet - Tankguard Storage - 09.2019Document5 pagesJotun - Technical Data Sheet - Tankguard Storage - 09.2019Victor PomboNo ratings yet

- Contract project-2004 With Ministry of Environment, Japan: Air Pollution Control Technology in Thermal Power PlantsDocument29 pagesContract project-2004 With Ministry of Environment, Japan: Air Pollution Control Technology in Thermal Power PlantsPallavi BhattNo ratings yet

- EP PPT 1Document88 pagesEP PPT 1satyam parasharNo ratings yet

- MATS324A8 EnvImplDocument21 pagesMATS324A8 EnvImplAlessandro CastagnaNo ratings yet

- Tert Butyl Acrylate (BASF)Document2 pagesTert Butyl Acrylate (BASF)Mario RollanoNo ratings yet

- Jotamastic 80 Aluminium - TDSDocument6 pagesJotamastic 80 Aluminium - TDSTeknik produksi wikonNo ratings yet

- Proprietatile Polietilenei de Inalta DensitateDocument11 pagesProprietatile Polietilenei de Inalta DensitateCatalin FrincuNo ratings yet

- SAN & ABS Polymers GuideDocument9 pagesSAN & ABS Polymers GuideSdkmega HhNo ratings yet

- Tankguard Plus: Technical Data SheetDocument5 pagesTankguard Plus: Technical Data SheetKris WilliamsNo ratings yet

- Tankguard HB Classic Jotun PaintDocument5 pagesTankguard HB Classic Jotun PaintGurdeep Sungh AroraNo ratings yet

- NHP210series 202104Document2 pagesNHP210series 202104Inovar Engineering and Consultants LLPNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Harvard Quick Guide Tcm44-47797Document4 pagesHarvard Quick Guide Tcm44-47797Guoxiang ChungNo ratings yet

- MS3002 CaDocument14 pagesMS3002 CaGuoxiang ChungNo ratings yet

- Natural & Synthetic RubberDocument8 pagesNatural & Synthetic RubberH.J.PrabhuNo ratings yet

- Materials Commonly Associated With OutsolesDocument5 pagesMaterials Commonly Associated With OutsolesGuoxiang ChungNo ratings yet

- MS3001 Ceramics 02 CrystalDocument71 pagesMS3001 Ceramics 02 CrystalGuoxiang ChungNo ratings yet

- Eschede NASA Case StudyDocument4 pagesEschede NASA Case StudyGuoxiang ChungNo ratings yet

- BCE-Practical SyllabusDocument2 pagesBCE-Practical SyllabusGovind TivadiNo ratings yet

- Traffic Engineering Bachelor of Science in Civil EngineeringDocument22 pagesTraffic Engineering Bachelor of Science in Civil EngineeringDaisy AstijadaNo ratings yet

- DISCOVERY SP-ENG V. 0.6 - Leonali 1463Document30 pagesDISCOVERY SP-ENG V. 0.6 - Leonali 1463Hanz RodriguezNo ratings yet

- (Reprint From Handbuch Der Physik - Encyclopedia of Physics) R. N. Bracewell (Auth.) - Radio Astronomy Techniques-Springer-Verlag Berlin Heidelberg (1962)Document91 pages(Reprint From Handbuch Der Physik - Encyclopedia of Physics) R. N. Bracewell (Auth.) - Radio Astronomy Techniques-Springer-Verlag Berlin Heidelberg (1962)garfacio30No ratings yet

- Geotech Civ150 CompressDocument4 pagesGeotech Civ150 CompressismaeelNo ratings yet

- Math TaskDocument2 pagesMath TaskAsher MananganNo ratings yet

- Solar Mosquito DestroyerDocument2 pagesSolar Mosquito DestroyerNIKITA KANGRALKARNo ratings yet

- Radiography 2 ProcedureDocument9 pagesRadiography 2 ProceduresheikmoinNo ratings yet

- RtosDocument78 pagesRtossekinNo ratings yet

- 10.4 Modes of TransportDocument12 pages10.4 Modes of TransportAya Magdy AhmedNo ratings yet

- CAD (ME2155) Lab ManualDocument18 pagesCAD (ME2155) Lab Manualharishj93No ratings yet

- Pilot Operated Safety Relief ValvesDocument6 pagesPilot Operated Safety Relief ValvesfabioNo ratings yet

- Sewing 04-Needle Class 118 of Groz-Beckert For Union Special FlatseamersDocument6 pagesSewing 04-Needle Class 118 of Groz-Beckert For Union Special Flatseamersfriendztoall4351No ratings yet

- ITU Rec. BT.709-5 Defines Parameters for HDTV StandardsDocument31 pagesITU Rec. BT.709-5 Defines Parameters for HDTV StandardsHarold Coila VillenaNo ratings yet

- Compressed Air Fittings & Equipment Catalogue: Importers and Direct Sellers of Quality Hand ToolsDocument18 pagesCompressed Air Fittings & Equipment Catalogue: Importers and Direct Sellers of Quality Hand ToolsVin KenNo ratings yet

- Naval Arch - Incline TestDocument11 pagesNaval Arch - Incline TestDheerajKaushalNo ratings yet

- Galaxy Electrical: Zener DiodesDocument3 pagesGalaxy Electrical: Zener Diodesdragon-red0816No ratings yet

- SyllabusDocument2 pagesSyllabusjackychen101No ratings yet

- EC 351 AC Analog Communication Lab ManualDocument117 pagesEC 351 AC Analog Communication Lab Manualhodibaaba1No ratings yet

- Portfolio Isaura SagredoDocument22 pagesPortfolio Isaura SagredoIsauraNo ratings yet

- NCP1117, NCV1117Document17 pagesNCP1117, NCV1117kalimbaloNo ratings yet

- Dell Operation ManagementDocument13 pagesDell Operation ManagementIsha GosainNo ratings yet

- Basic Electronics PowerpointDocument16 pagesBasic Electronics PowerpointEarle Sean MendozaNo ratings yet

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- HE Hydra Jar Manual 6-80Document31 pagesHE Hydra Jar Manual 6-80Yuri KostNo ratings yet

- FD-SOI and FinFET Technologies ComparedDocument25 pagesFD-SOI and FinFET Technologies ComparedDhanishtha SinghNo ratings yet