Professional Documents

Culture Documents

Sodium Carboxymethyl Cellulose PDF

Uploaded by

Rezaul RazibOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sodium Carboxymethyl Cellulose PDF

Uploaded by

Rezaul RazibCopyright:

Available Formats

SODIUM CARBOXYMETHYL CELLULOSE

Chemistry, Functionality, and Applications

Andrew C. Hoefler Food Ingredients Group, Hercules Incorporated Wilmington, Delaware 19808

http://www.herc.com/foodgums/index.htm

Figure 1 is a diagrammatic representation of a cellulose molecule. Note that each glucose unit in the cellulose chain has three hydroxyl groups, each of which is capable of hydrogen bonding to an adjacent molecule. In the bottom of Figure 1, we indicate cellulose more pictorially as a series of circles connected together in a long, linear chain.

Figure 2 shows a group of cellulose molecules in water. Because of the abundance of hydroxyl groups, and their ability to hydrogen bond to a neighboring molecule, the chains are bound tightly together. Water molecules, at any temperature, cannot force their way in between the chains to hydrate them, thus cellulose is water insoluble ( which is just as well, since most of our houses are made of wood. I certainly would not want my house to dissolve the next time it rains! )

Figure 3 illustrates the reaction for the manufacture of CMC. It is essentially a two step process. In the first step, cellulose is suspended in alkali to open the bound cellulose chains, allowing water to enter. Once this happens, the cellulose is then reacted with sodium monochloroacetate to yield sodium carboxymethyl cellulose.

An idealized unit structure of CMC is depicted in figure 4. The CMC shown here has a D.S.( Degree of Substitution ) of 1.0. If the remaining two hydroxyl groups on this unit became substituted, the D.S. would be 3.0. A D.S. of 3.0 is the theoretical maximum one could attain.

Figure 5 is a pictorial representation of CMC molecules. Note that the carboxymethyl groups protrude from the cellulose backbone, such that the hydroxyl groups of the backbone cannot get close enough to hydrogen bond to each other. The result is that even in the dried state, water can slip in between the CMC molecules and hydrate them, causing them to "peel apart" from each other and go into solution.

Figure 6 depicts the nomenclature for Hercules cellulose gum. The specific product described is cellulose gum type 7H3SXF. The "7" stands for the degree of substitution. In the food industry,

there are "7" and "9" types of substitution. The pharmaceutical industry also has a "1.2" type to work with. The "H" signifies a high viscosity grade, and the "3" is a reference point which defines the maximum viscosity of the gum in a 1% solution at 25C (in this case, 3000 centipoise). There are "L", "M", and "H" types, representing low, medium, and high viscosity respectively. The "S" stands for special rheological properties (smooth flow). There are "S" types for smooth flow, and "O" types for tolerance in acidic systems. Both of these types show considerably less thixotropy than the randomly substituted regular types of cellulose gum (more will be said about this later). The "X" stands for fine grind material, while a "C" would indicate a coarse particle size, and no letter would indicate a "regular" particle size. The "F" represents food grade (FCC), while a "P" would be pharmaceutical grade (USP).

Some typical viscosity values are shown in Figure 7. Please note that "L" and "M" types are measured at a 2% concentration, while "H" types are measured at 1%. Figure 8 shows the concentration versus viscosity relationship in a more visual fashion.

The effect of the Degree of Substitution on the properties of CMC is shown in figure 9. Tolerance to salt increases and tendency towards thixotropic behavior decreases as the degree of substitution increases.

There is another factor which is as important as the Degree of Substitution, and that is the "Uniformity of Substitution", which is shown visually in Figure 10. The "smooth" or non-substituted regions of a non-uniformly substituted molecule behave just like cellulose because they are still cellulose! These regions can hydrogen bond to a similar region on an adjacent molecule, leading to the buildup of a loose gel network ( Figure 11 ).

This buildup is time dependent, and is called "thixotropy". The loose gel network can be disrupted by shearing the CMC solution, but upon standing under no shear conditions the network will reform over time. Visually, the difference between uniformly and non-uniformly substituted CMC solutions can be seen in Figure 12. Smooth flowing CMC types are desirable for food systems such as syrups or frostings where smooth consistency is a must. Thixotropic CMC would find use in structured, grainy foods such as sauces or purees.

Cellulose gum is probably the fastest gum to hydrate in cold water. Consequently, it is the gum most like to form lumps when dispersed into water, due to it's rapid swelling in water. To overcome the problem described above, four procedures are recommended in Figure 13: Method 1: direct addition: Here the gum is added directly to the vortex of a vigorously agitated body of water. The rate of addition should be slow enough to keep the particles separated, but fast enough so that all of the gum is added before the vortex disappears. The reason for this is that it is extremely difficult to thicken an already viscous solution of cellulose gum by adding more dry powder. The direct addition method is usually encountered in highly controlled processing situations. Method 2: dry blending: In this method, the CMC is dispersed with other dry ingredients, such as sugar, prior to their addition to aqueous systems. The other particles serve to keep the CMC particles away from each other. Commonly, one part of CMC is mixed with five to ten parts sugar to effectively prevent lumping. The dry mix beverage is a classic example of this dispersion technique. Method 3: dispersion in a water miscible non-solvent: Cellulose gum may be dispersed in glycerine, ethanol, or propylene glycol and the slurry is then added to water. An off-shoot of this method is to disperse the gum in corn syrup, and then add the mixture to water with the aid of agitation.

Method 4: mixing device: Another method for the addition of cellulose gum to food systems in plant operations is the use of a stainless steel mixing device (figure 14). The gum is fed through a smooth wall funnel into a water jet eductor, where it is dispersed by the turbulence of water flowing at high velocity. Each particle is individually wetted out to give a uniform solution. Under optimum conditions, cellulose gum leaving the eductor is about 80 - 90% hydrated.

ADD THE GUM FIRST! (Figure 15) This is a general rule to follow when adding cellulose gum to water in all food formulations.

As an example of the importance of order of addition, Figure 16 is a graph of CMC viscosity versus salt concentration. In one case, the CMC was dissolved in the water before the salt, and the salt had a minimal effect on the viscosity of the solution. In the other case, the CMC was dissolved AFTER the salt, and the resulting final viscosity was much lower, especially as the salt concentration increases.

Figure 17 gives an idea of how cellulose gum is effected by increasingly stronger salt solutions, and by the uniformity of substitution. Going from distilled water to 4% sodium chloride drops the viscosity by a factor of about 12 for 7HF, and by about 3 for the more evenly substituted 7H3SF. The proportions are similar when going to a saturated salt solution ( last column ).

Figure 18 shows the effect of some other ions on the viscosity of a CMC solution. The Aluminum salt actually increases the viscosity of CMC because it has the steric capability of gelling CMC. Unfortunately, for taste reasons, this has little application in the food industry.

Figure 19 shows the effect of water / non-solvent mixtures on the viscosity of CMC. In this case, the non-solvent is glycerin. The maximum viscosity is reached with a 30/70 mixture of water and glycerin. At higher than 70% concentrations of glycerin, the CMC is not fully in solution and thus does not give as much viscosity. At lower than 50% glycerin, there is less "crowding" and more availiable water for hydration, thus the CMC viscosity is lower.

Figure 20 shows that the viscosity of CMC, like most other water soluble polymers, decreases with increasing temperature. Under normal conditions, this effect is reversible (ie: raising or lowering the solution temperature has no permanent effect on the viscosity characteristics of the solution). However prolonged heating at extremely high temperatures will permanently degrade the cellulose gum (depolymerization) which results in a viscosity decrease. What this means to the food technologist is that CMC is not particularly retort stable.

Figure 21 indicates that CMC, like most food gums, is pseudoplastic. This means that the apparent viscosity will decrease at increasing shear rates, but the effect is totally reversible. As soon as the shear is stopped, the viscosity returns to it's original value.

10

CMC is more tolerant to the presence of ethanol than most other food gums (Figure 22). This makes cellulose gum useful for cordials and other low alcohol content beverages which require optical transparency.

CMC will give a synergistic viscosity increase with other hydrocolloids such as guar or locust bean gum ( Figure 23 ). If one were to mix a 1% guar solution of 3800 centipoise with a 1% CMC solution of 4000 centipoise, the net result is not the 3900 centipoise average of the two; it will be closer to 6500 centipoise. There are more average "collisions per second" between unlike molecules, which results in this synergistic viscosity increase.

11

Food applications ( Figure 25): The availability of cellulose gum in different viscosity grades, particle sizes, special rheological grades, and combinations thereof permits tailor-made application of CMC to many different food systems. The following is a brief discussion of some of these applications:

Cake mixes CMC is used to improve the moisture retention in cake mixes, as a dried out cake is quite objectionable organoleptically. High D.S. types are preferred in cake mixes for maximum moisture binding. CMC also controls batter viscosity, imparts tolerance during mixing, protects against leavening loss, improves cake volume, and controls the uniformity of the cross sectional grain of the cake. For ease of mixing, fine grind types of CMC are preferred in cake mixes for rapid entry into solution. The homemaker does not want to spend all day mixing a cake. Frostings and Icings CMC may be used in frostings and icings to toughen the film prevent sticking to the package and reduce sugar crystal growth (graininess). In ready-to-spread frostings CMC helps stabilize the emulsion and adds creaminess. Most important, CMC prevents the icing or frosting from drying out. Uniformity substituted CMC (S types) are recommended to give a smooth icing or frosting. Pie fillings In starch based pie fillings, the addition of a small amount of CMC will prevent cracking control syneresis and firm the texture. The use of uniformity substituted 0 types of CMC are preferred for stability in acidic fillings such as in a lemon pie filling.

12

Dairy products CMC was originally pioneered in ice cream and today this application still remains as one of the largest single uses for the gum. In ice cream CMC prevents ice crystal growth, inhibits lactose crystal growth (sandiness); imparts mix viscosity and body to the finished product, gives correct meltdown, and provides freeze/thaw stability (heat shock control). The use of coarse particle size types of CMC are preferred for ice cream applications (dispersion) because of poor mixing conditions commonly encountered in dairies. CMC is utilized as a stabilizer in many other dairy products such as egg nog, soft serve ice cream, milk shakes, and ice cream ripples. Pancake syrup CMC enjoys widespread use in regular, reduced calorie and dietetic pancake syrups. Here the excellent clarity, viscosity ability compatibility with sugar and non caloric characteristics of the gum are put to good use.

Dry mix beverages The ability of CMC to hydrate rapidly and viscosity in aqueous systems for body and mouthfeel is used in instant breakfast drinks instant fruit drinks hot cocoa mixes and low calorie dry mix beverages. Uniformity substituted low or medium viscosity fine grind types of CMC are most frequently used in these products in order to minimize "fish eye" formation. High viscosity types of CMC are not recommended in these products regardless of particle size since higher molecular weight types take longer to dissolve and are more prone to form fisheyes if dispersion and energy input (stirring) are not optimum. Pet foods and animal feed In semi-moist pet foods, CMC facilitates extrusion, binds moisture, and improves the cosmetic appearance of the product. In dry gravy-forming pet foods CMC is "dusted" onto tallow coated "kibble" with other ingredients, so that upon reconstitution a rich viscous shiny gravy evolves. Another animal food application for CMC is its use as a physical binder in pelleted animal feeds. A small amount of low viscosity CMC in the product holds the pellet together and prevents accumulation of fines in the product package during shipment. Additionally, the gum assists the extrusion process during manufacture of the pellets and helps reduce energy consumption by the pellet mill.

13

CMC greatly modifies the behavior of water in sugar solutions (figure 26). Combinations of sugar and CMC display a significant "boost" in viscosity which is believed to be the consequence of a crowding mechanism. Cellulose gum decreases the tendency towards syneresis in high sugar food systems by serving as a water binder. Most importantly, CMC also reduces the rate of sugar crystal growth and crystal size in concentrated sugar systems. This functionality becomes important in confectionery applications such as fondants ( Figure 27 below).

Just as CMC controls sugar crystal growth in confectionery applications, it controls ice crystal growth in ice cream the same way ( Figure 28 ). Texturally, it is desirable to have a large number of small ice crystals (smooth) rather than a small number of large ones (sandy).

14

A few cautions about using cellulose gum in food products: Exposure to UV light and entrained air in a food system should be minimized to prevent degradation of the gum. Molecular oxygen will cause the gum to breakdown by a free radical mechanism similar to that which occurs during the autoxidation of lipids. The presence of cations (calcium, iron, aluminum) will accelerate the process. Therefore it is recommended that a sequestrant such as sodium hexametaphosphate be used in systems where CMC is exposed to air and cations.

To summarize, cellulose gum is a very useful hydrocolloid for the food industry. It's water binding ability is second to none, and it is completely transparent in solution. CMC can add viscosity or mouthfeel, control syneresis, and control the rate / size of crystal growth.

15

You might also like

- Carboxymethyl Cellulose - Wikipedia, The Free EncyclopediaDocument3 pagesCarboxymethyl Cellulose - Wikipedia, The Free EncyclopediaBenni WewokNo ratings yet

- Chemical Modification, Properties, and Usage of LigninDocument291 pagesChemical Modification, Properties, and Usage of LigninMustafa ÇiçeklerNo ratings yet

- Preservative Efficacy Test For Cosmetic Product: 1 Scope and Field of ApplicationDocument5 pagesPreservative Efficacy Test For Cosmetic Product: 1 Scope and Field of ApplicationNukiAdelaNo ratings yet

- Spray-Drying: Basic Theory and ApplicationsDocument15 pagesSpray-Drying: Basic Theory and ApplicationsDarkwraith007No ratings yet

- Diammonium PhosphateDocument3 pagesDiammonium PhosphateJohannah Jane AbuelNo ratings yet

- Guar GumDocument64 pagesGuar GumAnshul JhaNo ratings yet

- Raffinage Des Huiles Et Des Corps Gras Et Élimination Des ContaminantsDocument14 pagesRaffinage Des Huiles Et Des Corps Gras Et Élimination Des ContaminantsBoussebha NoureddineNo ratings yet

- Polyol Y-1537 Technical Data Sheet: Specifications Guide FormulationDocument1 pagePolyol Y-1537 Technical Data Sheet: Specifications Guide FormulationVaittianathan MahavapillaiNo ratings yet

- Recovery of Glycerine From Spent Palm Kernel Soap and Palm Oil Soap LyeDocument8 pagesRecovery of Glycerine From Spent Palm Kernel Soap and Palm Oil Soap LyeNadya Larasati KrdNo ratings yet

- Adsorption PDFDocument49 pagesAdsorption PDFMarisol BravoNo ratings yet

- AditivesDocument25 pagesAditivesabhi858No ratings yet

- Production of Maleic Anhydride From Oxidation of BenzeneDocument1 pageProduction of Maleic Anhydride From Oxidation of BenzeneChetal Bhole100% (2)

- D323-15a - Vapor Pressure (Reid Method)Document11 pagesD323-15a - Vapor Pressure (Reid Method)Johu VeNo ratings yet

- 6 - Forms of ChlorinationDocument14 pages6 - Forms of ChlorinationSheeraz Ahmed100% (1)

- Distillation TypesDocument34 pagesDistillation TypesJoshua Johnson100% (1)

- Cellulose - Fascinating Biopolymer and Sustainable Raw MaterialDocument36 pagesCellulose - Fascinating Biopolymer and Sustainable Raw MaterialJun Rey LincunaNo ratings yet

- Ion-Exchange and Adsorbent Resins For Food IndustryDocument28 pagesIon-Exchange and Adsorbent Resins For Food IndustryMario Darío Gatto0% (1)

- Máquina Moer Alumina PDFDocument36 pagesMáquina Moer Alumina PDFDulce GabrielNo ratings yet

- Efficient LiquifactionDocument10 pagesEfficient LiquifactionMuhammadTalalNooriNo ratings yet

- Prepared By: Jalpa KhutwadDocument23 pagesPrepared By: Jalpa KhutwadHarshita KaleNo ratings yet

- Corn Steep Liquor in Microbiology PDFDocument15 pagesCorn Steep Liquor in Microbiology PDFNasser KemmouNo ratings yet

- Reactions in Kraft PulpingDocument6 pagesReactions in Kraft Pulpingdppriya1984No ratings yet

- The Effects of Catalysts in Biodiesel ProductionDocument41 pagesThe Effects of Catalysts in Biodiesel ProductionAnonymous VpLeMjINo ratings yet

- Internship Report HPFL 2012Document52 pagesInternship Report HPFL 2012butterfily50% (4)

- Wet MillingDocument9 pagesWet MillingMinh VõNo ratings yet

- PBE 1 Flyer Lug09 PDFDocument8 pagesPBE 1 Flyer Lug09 PDFchantran90No ratings yet

- Polyethylene Terephthalate (Pet) : HistoryDocument3 pagesPolyethylene Terephthalate (Pet) : HistoryMaleha SalimNo ratings yet

- Luff Schoorl MethodDocument4 pagesLuff Schoorl MethodrheamaeNo ratings yet

- SAND Study For Orifice PDFDocument48 pagesSAND Study For Orifice PDFAnoop GeorgeNo ratings yet

- Priya Seminar ReportDocument19 pagesPriya Seminar ReportVinay Bagade50% (4)

- Lecture 34 PDFDocument5 pagesLecture 34 PDFSonuNo ratings yet

- Proposal of Methylamine 99Document20 pagesProposal of Methylamine 99Hafiz Abdul Hanan waliNo ratings yet

- Luwax Eva3Document4 pagesLuwax Eva3abcde909No ratings yet

- Actas3 19Document7 pagesActas3 19Muhammad HumaidiNo ratings yet

- History of Nano FiltrationDocument42 pagesHistory of Nano FiltrationKieran Sexton100% (2)

- (Type Text) (Type Text) (Type Text)Document4 pages(Type Text) (Type Text) (Type Text)Manoj Kumar GautamNo ratings yet

- Ethyl Cellulose PDFDocument2 pagesEthyl Cellulose PDFEricNo ratings yet

- Theory and Conclusion of Membrane Separation UnitDocument6 pagesTheory and Conclusion of Membrane Separation UnitDhiyyah Mardhiyyah50% (2)

- Avicel PH 101 & PH 102 - Microcrystalline Cellulosa PH 101 & PH 102 (p.129-133) 158-162Document5 pagesAvicel PH 101 & PH 102 - Microcrystalline Cellulosa PH 101 & PH 102 (p.129-133) 158-162Marsha Fendria PrastikaNo ratings yet

- StarchDocument4 pagesStarchFahmi Januar AnugrahNo ratings yet

- Quality Requirements of Uht MilkDocument7 pagesQuality Requirements of Uht Milkaparna muthuthaiNo ratings yet

- Ion Exchange ResinDocument7 pagesIon Exchange ResinAnup Bajracharya75% (4)

- Hydro de AlkylationDocument15 pagesHydro de Alkylationanon_429955241No ratings yet

- Kinetics of Hexamine Crystallization in Industrial ScaleDocument8 pagesKinetics of Hexamine Crystallization in Industrial ScaleRafaelNo ratings yet

- Article Tabletting Resolving Tablet DefectsDocument5 pagesArticle Tabletting Resolving Tablet DefectsTueNo ratings yet

- Measurement of The Starch Content of Commercial Starches PDFDocument3 pagesMeasurement of The Starch Content of Commercial Starches PDFwahyuthp43No ratings yet

- Corn Wet Milling Brochure 12209Document8 pagesCorn Wet Milling Brochure 12209amanawatNo ratings yet

- Recent Developments On The Synthesis and Cleavage of Tert-Butyl Ethers and Estersfor Synthetic Purposes and Fuel Additive PDFDocument12 pagesRecent Developments On The Synthesis and Cleavage of Tert-Butyl Ethers and Estersfor Synthetic Purposes and Fuel Additive PDFcarbonloveNo ratings yet

- A Simple Approach For The Isolation of Cellulose Nanofibers From BananaDocument22 pagesA Simple Approach For The Isolation of Cellulose Nanofibers From BananaVŨ NGUYỄN TRẦNNo ratings yet

- Newtons Law of Viscosity Chapter 1 BSLDocument29 pagesNewtons Law of Viscosity Chapter 1 BSLJaymee DelfinadoNo ratings yet

- Certificate of Analysis: Benzoic AcidDocument4 pagesCertificate of Analysis: Benzoic AcidTANIA MARGARITA ANGEL GALINDONo ratings yet

- Polyvinyl Chloride (PVC) : A Petrochemical ProductDocument21 pagesPolyvinyl Chloride (PVC) : A Petrochemical ProductifyNo ratings yet

- The Cellulose Derivatives: Cellulose Gum, Methylcellulose, Methylhydroxypropylcellulose, and HydroxypropylcelluloseDocument24 pagesThe Cellulose Derivatives: Cellulose Gum, Methylcellulose, Methylhydroxypropylcellulose, and HydroxypropylcelluloseAnandNo ratings yet

- Synthesis and Applied Properties of Carboxymethyl CornstarchDocument5 pagesSynthesis and Applied Properties of Carboxymethyl CornstarchAkshay DakheNo ratings yet

- 5.1 Basics of MicroemulsionsDocument27 pages5.1 Basics of Microemulsionsحيدر الوائليNo ratings yet

- 6.1 Formation of EmulsionsDocument39 pages6.1 Formation of Emulsionsحيدر الوائليNo ratings yet

- 205report 2Document11 pages205report 2RPh Krishna Chandra JagritNo ratings yet

- Polymer-Solute Complexation, Ov. 8 - AShDocument7 pagesPolymer-Solute Complexation, Ov. 8 - AShSara AlrubaiiNo ratings yet

- PatenteDocument4 pagesPatenteAnonymous Bpy4biucdQNo ratings yet

- Dissolution of Cellulose With Ionic LiquidsDocument2 pagesDissolution of Cellulose With Ionic LiquidsAditya ShrivastavaNo ratings yet

- Functions of Growth HormoneDocument19 pagesFunctions of Growth HormoneRezaul RazibNo ratings yet

- MV Ú WZK I PJGVB Nubvcöevn (Evsjv 'K)Document16 pagesMV Ú WZK I PJGVB Nubvcöevn (Evsjv 'K)shakhawat remonNo ratings yet

- ( ) .PDF Version 1Document21 pages( ) .PDF Version 1Jamshedul Islam100% (1)

- Endocrinology: Differences Between Nervous and Endocrine SystemDocument34 pagesEndocrinology: Differences Between Nervous and Endocrine SystemRezaul RazibNo ratings yet

- 200 Special Topics For 42 BCSDocument187 pages200 Special Topics For 42 BCSRezaul RazibNo ratings yet

- Exclusive Mock Test Answer SheetDocument39 pagesExclusive Mock Test Answer SheetRezaul RazibNo ratings yet

- Exclusive 42 BCS Solve SheetDocument272 pagesExclusive 42 BCS Solve SheetRezaul RazibNo ratings yet

- Azithromycin USPDocument5 pagesAzithromycin USPRezaul RazibNo ratings yet

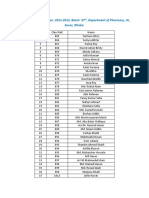

- Class: M.Pharm, Session: 2011-2012, Batch: 37, Department of Pharmacy, JU, Savar, DhakaDocument2 pagesClass: M.Pharm, Session: 2011-2012, Batch: 37, Department of Pharmacy, JU, Savar, DhakaRezaul RazibNo ratings yet

- Apex Discount MailDocument1 pageApex Discount MailRezaul RazibNo ratings yet

- It 11 GaDocument8 pagesIt 11 GaSadav ImtiazNo ratings yet

- Methylphenidate HydrochlorideDocument3 pagesMethylphenidate HydrochlorideRezaul RazibNo ratings yet

- Tax CalculationDocument3 pagesTax CalculationRezaul RazibNo ratings yet

- Ropinirole Extended-Release TabletsDocument4 pagesRopinirole Extended-Release TabletsRezaul RazibNo ratings yet

- Ropinirole HydrochlorideDocument4 pagesRopinirole HydrochlorideRezaul RazibNo ratings yet

- Joining Letter TemplateDocument1 pageJoining Letter TemplateRezaul RazibNo ratings yet

- CONCERTA Extended-Release Tablets PILDocument37 pagesCONCERTA Extended-Release Tablets PILRezaul RazibNo ratings yet

- Passport MRPOnline Instruction 2013 - Techtunes - COm.BDDocument14 pagesPassport MRPOnline Instruction 2013 - Techtunes - COm.BDTechtunesNo ratings yet

- USP Dissolution Apparatus 5, 6, 7Document8 pagesUSP Dissolution Apparatus 5, 6, 7Rezaul Razib0% (1)

- Racecadotril Tablet FormulationDocument14 pagesRacecadotril Tablet FormulationRezaul RazibNo ratings yet

- Requip XL PilDocument39 pagesRequip XL PilRezaul RazibNo ratings yet

- MRP Information Alteration Correction PDFDocument2 pagesMRP Information Alteration Correction PDFRezaul RazibNo ratings yet

- Comprehensive List of GuidancesDocument54 pagesComprehensive List of GuidancesRezaul RazibNo ratings yet

- PAT - A Framework For Innovative Pharmaceutical Development, Manufacturing, and Quality AssuranceDocument19 pagesPAT - A Framework For Innovative Pharmaceutical Development, Manufacturing, and Quality AssuranceHeba El-TayebNo ratings yet

- Naming of Drug Products Containing Salt Drug SubstancesDocument12 pagesNaming of Drug Products Containing Salt Drug SubstancesRezaul RazibNo ratings yet

- Labeling For Biosimilar ProductsDocument15 pagesLabeling For Biosimilar ProductsRezaul RazibNo ratings yet

- Content Uniformity (CU) Testing For The 21st Century CDER PerspectiveDocument36 pagesContent Uniformity (CU) Testing For The 21st Century CDER PerspectiveRezaul Razib100% (1)

- Tablet Scoring - Nomenclature, Labeling, and Data For EvaluationDocument8 pagesTablet Scoring - Nomenclature, Labeling, and Data For EvaluationRezaul RazibNo ratings yet

- GL New FDA Stability CDER2013213 Guidance May - StabilityDocument17 pagesGL New FDA Stability CDER2013213 Guidance May - StabilitydpakindianNo ratings yet

- Guidelines Packaging Pharmaceutical Products TRS902 Annex 9Document38 pagesGuidelines Packaging Pharmaceutical Products TRS902 Annex 9Shuhash100% (1)

- My-Visual 59702531Document26 pagesMy-Visual 59702531Dalton Pharma ServicesNo ratings yet

- Polypropylene - Chemistry and Production ProcessesDocument45 pagesPolypropylene - Chemistry and Production Processeschiuchan888No ratings yet

- Respiration in Plants - Shobhit NirwanDocument14 pagesRespiration in Plants - Shobhit Nirwananitalimbachiya86No ratings yet

- BRJ - Volume 6 - Issue 2 - Pages 962-979Document18 pagesBRJ - Volume 6 - Issue 2 - Pages 962-979SAKDA MAPRADITKULNo ratings yet

- Industrial Training Report 18se02ch014Document9 pagesIndustrial Training Report 18se02ch014Alis Navadiya0% (1)

- TOUCHLESS VEHICLE WASH W NATSURF 265 HCAC20v1Document1 pageTOUCHLESS VEHICLE WASH W NATSURF 265 HCAC20v1rezaNo ratings yet

- Alitame: SynonymsDocument4 pagesAlitame: Synonymsyuni fadilahNo ratings yet

- ViDHAI Profile TDocument10 pagesViDHAI Profile TdaresavioNo ratings yet

- 2020-Srikaya Seed Granule Different TemperatureDocument7 pages2020-Srikaya Seed Granule Different TemperatureDwiNo ratings yet

- RCER 2010, Volume I-Regulations and Standards-Final Copy - January 15,2011Document121 pagesRCER 2010, Volume I-Regulations and Standards-Final Copy - January 15,2011syfu_deen100% (3)

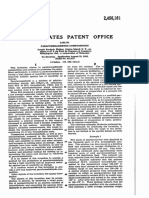

- Us2456161 PDFDocument3 pagesUs2456161 PDFهیمن مNo ratings yet

- Substitution Versus Elimination Reactions: Presented By: Hina Javed Punjab Group of Colleges Rwp/IsbDocument15 pagesSubstitution Versus Elimination Reactions: Presented By: Hina Javed Punjab Group of Colleges Rwp/IsbRaja Haris JavedNo ratings yet

- Synthetic Approaches To The 2002-2007 New DrugsDocument120 pagesSynthetic Approaches To The 2002-2007 New DrugsBen ZoeNo ratings yet

- ICSE Class 10 Chemistry Previous Year Question Paper 2019Document9 pagesICSE Class 10 Chemistry Previous Year Question Paper 2019Hotam singh100% (1)

- Jurnal Vit KDocument6 pagesJurnal Vit KTisenda TimiselaNo ratings yet

- Startingppt 160206152054Document57 pagesStartingppt 160206152054salmanNo ratings yet

- Chapter 1 and 2 Pre OralDocument36 pagesChapter 1 and 2 Pre OralSherwin CruzNo ratings yet

- Korir Et Al. (2014) The Fortification of Tea With Sweeteners and Milk and Its Effect On in Vitro PDFDocument9 pagesKorir Et Al. (2014) The Fortification of Tea With Sweeteners and Milk and Its Effect On in Vitro PDFYvonne TongNo ratings yet

- A Review Biogas Production From Tofu Liquid WasteDocument14 pagesA Review Biogas Production From Tofu Liquid WasteadNo ratings yet

- PROJECT 2ndDocument27 pagesPROJECT 2ndJagrat SevakNo ratings yet

- Engineering With R 030189 MBPDocument512 pagesEngineering With R 030189 MBPangelo2529No ratings yet

- En MiscellaneousDocument7 pagesEn Miscellaneousdoc_abdullahNo ratings yet

- Polyethylene Glycol (PEG) : A Versatile Polymer For Pharmaceutical ApplicationsDocument20 pagesPolyethylene Glycol (PEG) : A Versatile Polymer For Pharmaceutical ApplicationsFranciscoNo ratings yet

- AshlandDocument80 pagesAshlandb4rf100% (3)

- Corrsheild Md4100Document11 pagesCorrsheild Md4100mevansmetreelNo ratings yet

- Aits 1718 FT V Jeea Paper 2 Sol PDFDocument17 pagesAits 1718 FT V Jeea Paper 2 Sol PDFPhysics loveNo ratings yet

- Alcohols-Phenols and EthersDocument16 pagesAlcohols-Phenols and EthersTr Mazhar PunjabiNo ratings yet

- Functional Groups KeyDocument2 pagesFunctional Groups KeyalfredNo ratings yet

- Processes For Modifying RosinDocument5 pagesProcesses For Modifying RosinBatuhan ElçinNo ratings yet

- Humanure HandbookDocument259 pagesHumanure Handbookanon-326067100% (12)