Professional Documents

Culture Documents

3r

Uploaded by

Bilal AhmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3r

Uploaded by

Bilal AhmadCopyright:

Available Formats

IS 8783 ( Part 4/See 3 ) :1995

$mFiM WT%

~@fT

!JWlm )

Indian Standard

WINDING WIRES FOR SUBMERSIBLE MOTORS SPECIFICATION

PART Section 3 4 SPECIFICATION FOR INDIVIDUAL Insulated WIRES Winding Wires Polyester and Polypropylene

First Revision)

First Reprint NOVEMBER 1997

UDC

621.315.33696:621.3.045

:621.313.17.21332

@ BIS 1995

BUREAU

MANAK

OF

BHAVAN, 9

INDIAN

BAHADUR DELHI NEW

STANDARDS

SHAH 110002 ZAFAR MARG

,Yeptember1995

Price Group 2

Winding Wires Sectional Committee,

ETD 33

FOREWORD This Indian Standard ( Part 4/See 3 ) ( First Revision ) was adopted by the Bureau of Indian Standards, after the draft finalized by the Winding Wires Sectional Committee had been approved by the Electrotechnical Division Council. This standard was originally published in 1978 covering PVC insulated winding wires for Two other standards on winding wires for submersible submersible motors for 85C operation. motors, namely, IS 10051 : 1981 Specification for PVC insulated winding wires for submersible motors for 105C operation and IS 12788 : 1989 Specdication for PVC insulated winding wires overcoated with nylon for submersible motors have also been in vogue. In the recent past there has been demand from the industry to make comprehensive revision of the existing standards on winding wires for submersible motors and also to include other types of insulation which are being extensively used in manufacture of winding wires for submersible motors. In view of this the new series of winding wires standards for submersible motors is being brought out as follows: IS 8783 ( Part 1 ) :1995 ( Part 2 ) :1995 ( Part 3 ) :1995 ( Part 4/See 1 ) :1995 ( Part 4/See 2 ) :1995 ( Part 4/See 3 ) :1995 Winding wires for submersible motors Specification Conductor data Materials for dielectric and jacket Methods of tests Specification for individual wires, Section 1 HR PVC insulated winding wires Specification for individual wires,, Section 2 Crosslinked polyethylene insulated and polyamide jacketed wires Specification for individual wires, Section 3 Polyester and polypropylene insulated winding wires

With the publication of these standards the requirements of pVC insulated wires will be covered in part 4/See 1 of this series, and two new types of insulation, namely, XLPE insulated and polyester and polypropylene insulated wires have also been covered in this series. For the purpose of deciding whether a particular requirement of this standard is complied with, the final value, observed or calculated, expressing the result of a test, shall be rounded off in accordance with IS 2: 1960 Rules for rounding off numerical values ( revised ). The number of significant places retained in the rounded off value should be the same as that of the specified value in this standard.

U3 8783 ( Part 4/See 3 ) :1995

Indian Standard

WINDING WIRES FOR SUBMERSIBLE MOTORS SPECIFICATION

PART 4

SPECIFICATION

FOR INDIVIDUAL

WIRES Winding Wires

Section

Polyester

(

and Polypropylene

Insulated

First Revision)

4 REQUIREMENTS

4.1 Thickness of Insulation

1 SCOPE

standard ( Part 4/See 3 ) covers 1.1 This the requirements of high conductivity annealed solid and strande{i copper conductor with polyester and polypropylene insulated winding wires for submersible motors. 1.2 The wires covered in this standard are suitable for use where the combination of ambient temperature and temperature rise due to load results in conductor temperature not exceeding 105C.. 2 REFERENCES The following Indian Standards adjuncts to this standard:

IS No.

The minimum thickness of insulation shall not be less than the minimum value (ti) specified in Tables 1 and 2 as relevent. 4.2 Application

of Insulation

The insulation shall be so a!>plied that it fits close!y on the conducto; and it shall be possible to remove it without damage to the conductor. It shall be possible to separate polyester and polypropylene layers. 4.3 Colour The colour of insulation be natural. 4.4 Overall Diameter The overall diameter of winding wire shall not exceed the maximum value specified in Tables 1 and 2. 4.5 High Voltage Test ( Water Immersion Test ) The wires shall withstand the test at room temperature when an ac voltage of 3 kV at frequency of 50 Hz is applied for one minute after immersion of the wire for minimum 12 hours in water. 4.6 The overall surface of finished wires shall be reasonably smooth. 5 PACKING wire shall either be wound on spools/reels conforming to IS 482: 1981 or supplied in coils packed and labelled. 5.2 The packing length shall be agreed between the purchaser and the manufacturer. 1 to

5.1 The winding

are necessary

of winding wire shall

Title

Winding wires for submersible 8783 ( Part I ) :1995 motors Specification: Part 1 Conductor data ( jirst

revision )

8783 ( Part 2 ) :1995

Winding wires for submersible motors Specification: Part 2 Materials for dielectric and jacket ( jirst revision )

Windinz wires for submersible 8783 ( Part 3 ) : [995 motors Specification: Part 3 Methods of tests.( jirst revision ) 3 GENERAL 3.1 The tests on insulated winding wires shall be carried out in accordance with IS 8783 ( Part 3 ) :1995. 3.2 Conductors for this type of wires conform to IS 8783 ( Part 1 ) : 1995. shall

winding

3.3 Requirements of dielectric materials shall conform to Type 3 of IS 8783 ( Part 2 ) : 1995.

IS 8783( Part 4 /See 3 ) : 199S

Table 1 Insulation Thickness and Overall Diameter of Wires with Round Solid Conductor

( CIauses 4.1 and 4.4)

Sectionai Area

cross-

Nominai Conductor Diameter

Thickness of Insulation, ( ~ ) ~ ..A..__ .__

__

mm~

(1)

0.125 0.159 0196 0.238 0.283 0.332 0.385 0.442 0.502 0.638 0.769 0.785 0.850 1.13 1.33 1.54 1.77 2.01 2.27 2.54 2.84 3.14 3.46 3.80 4.15 4.52 4.91 5.31 5.73 6.16 6.61 7.67 7.55 8434 8.55 9.08 9.62 10.18 10.75 11.34 li.95 12.57

mm

(2)

0.4 0.45 0.5

Thickness of Polyester, Min mm (3)

0.05 005 0.05 0.05 0.05 0.05

Thickness of Polypropy]enc, Min mm (4)

0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 O*IO 0.10 0.10 0.10 0.15 015 0.15 0.15 015 0.15 015 0.15 0.15 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.17 0.20 0.20 0.20 0.20 0.20 0.20 0.20 020 0.20 0.20 0.20

Total Thickness of Insulation, Min mm (5)

0.20 0.20 020 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 020 0.20 0.25 025 0.25 0.25 0.25 0.25 0.25 025 0.25 0.30 0.30 0.30 0.30 0.30 0,30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 035 0.35 035

Overall Diameter,

Max

mm (6)

040 0.95 14)0 1.05 1.10 1.15 1.20 1.25 1.30 1.40 1.45 1.50 1.60 1.70 1.80 2@o 2.10 2.20 2.30 2-10 2.50

0.7 0.75 0.8 0.9 0.95 1.0 1.1 R

005 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0$05

1.7 1.8 1,9 2.0 2.1 2.2

0.05 005 0.05 0.05 0.05 0.05 007 007 0.07

2.80 3.10 3.20 3.30 340 350 3450 3.70 3.80 3.90 44)0 4.10 4.20

2.6 H 2.9 30 3.1 3s2 3.3 3.4 ::: 3.7 3.8 ::: 41 4.2 4.4 4.6 $:

0.07 0.07 0.07 O*C7 0.07 0.07 0.07 007 0.07 0.07 0.10 0.10 0.10 0.10 0.10 0.10 010 0.10 0.10 0.10 0.10

4.30 4.50 4%0 4.70 4.80 4.90 54)0 520 5.40 5.50 5.70 6.00

13.20 13.85 15.21 16.62 Wg

IS 8783 ( Part 4/See 3 ) :1995

Table 2 Insulation Thickness and Overall Diameter of Wires with Stranded Conductor

( Clauses 4.1 and 44 )

Conductor

Composition No. of Wires x Wire Oia

Crc ssSectional Area, Nominal

Nominal Conductor Diameter

Thictcness of Insulation (t, ) ______ ~ ...~

Polyester mm, Mitr

(4) 007 0.07 0.07 0.07 0.07 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

Polypropylene

mm, Min (5) 0.17 017 0.17 0.17 0.17 0.20 0.20 0.20 0.20 0.20 0.25 0.25 025 0.25 0.25

Total = mm, Min

(6) 030 ().?0 030 030 030 0.35 0.35 035 0.35 0.35 0.40 040 040 040 0.40

Overall Diameter mm, Max (7) 3.1 3.3 34 ~.6 3.8 4.0 4.2 4.5 4.7 4.9 5.6 58 5.9 6.1 6.3

mm (1)

19X049 19x052 19X055

mm~

(2) 358 404 451

mm

(3) 245 2.60 2.75

19x058

19x061 19xo@l 19x0.68 19X(),73 19x078

5.02

5.55 6.11 640 795 9.08 10.03 1209 13.18 144)0 1492 16.14

240

3.05 3s20 340 3.65 390 4.10 4.50 4.70 485 500 5.20

19x082

19X090 19X094 19X097 19x100 19XI.04

19X11O 19x1.16

27x1OO

18.06 20.08

21.21

5.50 580

6.15

0.15 0.15

015

0.25

0.25 0.25

0.45

0.4s 045

6.6

6.9 73

27x I.1O 6 MARKING 6.1 The

25.67

680

0.15

0.30 f) Country

050

and

8.2

of manufacturer;

winding wire shall carry following information marked on the label on spool/reel:

g) Year of manufacture.

6.2

BIS Certification

Marking

a) Reference to this Indian Standard, for example, Ref IS 8783 ( Part 4/See 3 );

b) Manufacturers

The product may also be marked with Standard Mark. 6.2.1 The use of the Standard

Mark is governed by the provisions of the Bureau of Indian Standard Act, 1986 and the Rules and Regulations made thereunder. The details of conditions

name,

brand

name

or

trade-mark;

c) Size

of diameter;

conductor/Maximum on spool/reel;

overall

d) Length of conductor e) Number

of lengths more than one );

on spool/reels

( if

under which the licence for the use of Standard Mark may be granted to manufacturers or producers may be obtained from the Bureau of Indian Standards.

l]m-eau of Indian Standards

BISisastatuto~ institution estal>lished under the Bureau o~lndian Standards Act, 1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications maybe reproduced in any form without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed periodically a standard along with amendments is reaffirmed when such review indicates that no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of BIS Handbook and Standards: Monthly Additions.

This Indian Standard has been developed fromDoc : No. ET 33 I 3532 j

Amendments

Issued Since PuMication

Amend No.

Date of Issue

Text Affected

BUREAU OF INDIAN STANDARDS Headquarters: Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telephones: 3230131,3233375,3239402 Regional Offices: Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg NEW DELHI 110002 : 1/14 C. I.T. Scheme VII M, V. I. P. Road, Maniktola CALCUTTA 700054 SCO 335-336, Sector 34-A CHANDIGARH 160022 Telegrams: Manaksanstha (Common to all offices) Telephone 3237617 3233841 { 3378499,3378561 { 3378626,3379120 603843 { 602025 2350216,2350442 { 2351519,2352315 8329295,8327858 { 8327891,8327892

Eastern

Northern:

Southern:

C. I. T. Campus, IV Cross Road, CHENNAI 600113

Western

: Manakalaya, E9 MIDC, Marol, Andheri (East) MUMBAI 400093

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD. GHAZJABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. , LUCKNOW. NAGPUR. PATNA PUNE. THIRUVANANTHAPURAM. ... .

Printc~ atPrirrtogmph.Ne\~ L)eltIi,I% : 5 / 2.6847

IS

NO. 1 FEBRUARY 2000 TO 8783 ( PART 4/SEC 3 ) :1995 WINDING WIRES FOI< SUBMERSIBLE MOTORS SPECIFICATION

PART 4 SPECIFICATION FOR individual WiRES

AMENDMENT

Section

Polyester and Polypropylene ( First Revision)

Insulated Winding Wires

( Page 1, CIUI(SC 4.2, la.vl sen[ence ) Delete. ( Page 1, clfrl~se 5.2 ) Dclclc. ( Page 3, clause 6.1) Substitute [ Page 3, dame 6.l(d)] spooi/reei/coii for spooi/reci. for spool/reel. for spool/reel.

Substitute spool/reel/coii spooi/reel/coil

[ Page 3, clalise 6.1(c)] Subslitule

(ETD

33 /

737

Reprography Unil. 1+1S, Ncw Delhi. 1I)ii

You might also like

- Islamic Studies Book 1 PDFDocument251 pagesIslamic Studies Book 1 PDFBilal AhmadNo ratings yet

- Who Moved The StoneDocument6 pagesWho Moved The Stoneazee0% (1)

- Indian Standard: Methods of Test For CablesDocument3 pagesIndian Standard: Methods of Test For CablesBilal AhmadNo ratings yet

- BioDataDocument2 pagesBioDataBilal AhmadNo ratings yet

- JKPDD: Procedure For Determination of Connected LoadDocument1 pageJKPDD: Procedure For Determination of Connected LoadBilal AhmadNo ratings yet

- The Etiquettes of Marriage and WeddingDocument12 pagesThe Etiquettes of Marriage and WeddingBilal AhmadNo ratings yet

- Messengers and BooksDocument33 pagesMessengers and Booksumer shafiqueNo ratings yet

- Al - Muhaddithat PDFDocument337 pagesAl - Muhaddithat PDFEl ZéphyrNo ratings yet

- The Ideal Muslim by Muhammad Ali Al-HashimiDocument109 pagesThe Ideal Muslim by Muhammad Ali Al-HashimiAwais ChaudryNo ratings yet

- The Muslim at Prayer: A Comparative StudyDocument11 pagesThe Muslim at Prayer: A Comparative StudyBilal AhmadNo ratings yet

- Anatomski Atlas PDFDocument68 pagesAnatomski Atlas PDFIVANANo ratings yet

- JKPDD: (Tick Whichever Applicable)Document2 pagesJKPDD: (Tick Whichever Applicable)Bilal AhmadNo ratings yet

- The Signs Before The Day of JudgementDocument43 pagesThe Signs Before The Day of JudgementmoremoneyformeNo ratings yet

- The Afghanistan Pakistan Theater PDFDocument161 pagesThe Afghanistan Pakistan Theater PDFBilal AhmadNo ratings yet

- D SusaDocument28 pagesD SusaBilal AhmadNo ratings yet

- Form No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBDocument1 pageForm No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBIam KarthikeyanNo ratings yet

- SERC 1-9 FormatDocument18 pagesSERC 1-9 FormatBilal AhmadNo ratings yet

- Form No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBDocument1 pageForm No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBIam KarthikeyanNo ratings yet

- SERC RainawariDocument48 pagesSERC RainawariBilal AhmadNo ratings yet

- SERC 1-9 FormatDocument18 pagesSERC 1-9 FormatBilal AhmadNo ratings yet

- List of State Department of Electric Maintains Sub Division HawalDocument3 pagesList of State Department of Electric Maintains Sub Division HawalBilal AhmadNo ratings yet

- Change Name Consumer FormDocument1 pageChange Name Consumer FormBilal Ahmad100% (1)

- State Departments. S.No Name and Location Id - No: Column1 Column2 Column3Document3 pagesState Departments. S.No Name and Location Id - No: Column1 Column2 Column3Bilal AhmadNo ratings yet

- SERC APDRP Upto January 2013Document76 pagesSERC APDRP Upto January 2013Bilal AhmadNo ratings yet

- SERC APDRP 2012 Final Rainawari Form 10Document76 pagesSERC APDRP 2012 Final Rainawari Form 10Bilal AhmadNo ratings yet

- 25kVA Endingfor The Year 2011-12IDocument94 pages25kVA Endingfor The Year 2011-12IBilal AhmadNo ratings yet

- Public Notice: WWW - Jkpdd.govDocument3 pagesPublic Notice: WWW - Jkpdd.govBilal AhmadNo ratings yet

- Public NoticeDocument3 pagesPublic NoticeBilal AhmadNo ratings yet

- VLDSclearifiDocument1 pageVLDSclearifiBilal AhmadNo ratings yet

- Public Notice: WWW - Jkpdd.govDocument3 pagesPublic Notice: WWW - Jkpdd.govBilal AhmadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Automatic lighting control with light dependent resistorsDocument10 pagesAutomatic lighting control with light dependent resistorsAyush PattnaikNo ratings yet

- Aluminium Foil AB - 711 S/S: Cool - Comfort - Energy SavingDocument2 pagesAluminium Foil AB - 711 S/S: Cool - Comfort - Energy SavingcandraNo ratings yet

- Research Article: Synthesis and Properties of Adhesive Polymer-Methylmethacrylate MaterialsDocument10 pagesResearch Article: Synthesis and Properties of Adhesive Polymer-Methylmethacrylate MaterialsMuradNo ratings yet

- FT Bitumseal enDocument1 pageFT Bitumseal enGerman GonzalezNo ratings yet

- Hempaline External FlyerDocument2 pagesHempaline External FlyerMohamed NouzerNo ratings yet

- Cowdung and Wood Ash Study for Flyash Brick PropertiesDocument5 pagesCowdung and Wood Ash Study for Flyash Brick PropertiesAnas AkbarNo ratings yet

- Recarburization of Ductile IronDocument2 pagesRecarburization of Ductile IronWalton BangladeshNo ratings yet

- 01 Ch5 Static FailureDocument28 pages01 Ch5 Static FailureAbdulNo ratings yet

- Analysis of The Flax Fibres Tensile Behaviour and Analysis of The Tensile Stiffness IncreaseDocument10 pagesAnalysis of The Flax Fibres Tensile Behaviour and Analysis of The Tensile Stiffness Increasejomingues98No ratings yet

- DSM-0319.1 AM MaragingSteel C300Document3 pagesDSM-0319.1 AM MaragingSteel C300ApichitNo ratings yet

- PBT 17 Smart MaterialsDocument12 pagesPBT 17 Smart MaterialsRama WijayaNo ratings yet

- CE 337/CE 568: Prestressed Concrete Design: Prof. Sasankasekhar MandalDocument11 pagesCE 337/CE 568: Prestressed Concrete Design: Prof. Sasankasekhar MandalNavvay DhingraNo ratings yet

- Cable Lugs Bonding WireDocument3 pagesCable Lugs Bonding WireJwalaNo ratings yet

- Maintenance Products 1. Wear Abrasion Resistant Products: Salient FeaturesDocument12 pagesMaintenance Products 1. Wear Abrasion Resistant Products: Salient FeaturesjohnNo ratings yet

- Sustainability of Biodegradable Plastics A Review On Social Economic and Environmental FactorsDocument22 pagesSustainability of Biodegradable Plastics A Review On Social Economic and Environmental FactorsMonalisa MasomeraNo ratings yet

- Celo Remform Technical DataDocument4 pagesCelo Remform Technical DataEnric DelgadoNo ratings yet

- Duconmix G 501Document2 pagesDuconmix G 501FounTech612No ratings yet

- Listado Articulos PVPDocument116 pagesListado Articulos PVPfausto.ca68No ratings yet

- TRH14 (1985) Guidelines For Road Construction MaterialsDocument69 pagesTRH14 (1985) Guidelines For Road Construction MaterialsTensarAfrica60% (5)

- Creep Testing MachineDocument30 pagesCreep Testing MachineUsman NadeemNo ratings yet

- BusbarDocument119 pagesBusbarGabriel IrimiaNo ratings yet

- JebChem Productlist AntifoamDocument4 pagesJebChem Productlist AntifoamCao LongNo ratings yet

- Butorlap Katalogus Falco Elegant 2012 SMDocument13 pagesButorlap Katalogus Falco Elegant 2012 SMJozsef GaborNo ratings yet

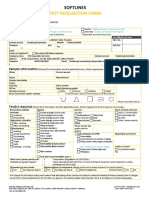

- Test Requisition Form: SoftlinesDocument4 pagesTest Requisition Form: SoftlinesArslan HaiderNo ratings yet

- Potential Applications of Nanotechnology in Pavement EngineeringDocument9 pagesPotential Applications of Nanotechnology in Pavement EngineeringIvan WibowoNo ratings yet

- Durability of Steel Fiber ReinforcedDocument22 pagesDurability of Steel Fiber Reinforcedmudasar205No ratings yet

- Reinforced Concrete Design PrinciplesDocument28 pagesReinforced Concrete Design PrinciplesLenard GarciaNo ratings yet

- ShaliFloor SL TC 4EDocument3 pagesShaliFloor SL TC 4EPrashant BaruaNo ratings yet

- Anchorage Devices Used To Improve The Performance of Reinforced Concrete Beams Retrofitted With FRP Composites: State-of-the-Art ReviewDocument20 pagesAnchorage Devices Used To Improve The Performance of Reinforced Concrete Beams Retrofitted With FRP Composites: State-of-the-Art ReviewMohammed Al-momaniNo ratings yet

- Materials and Design: Sumrerng Rukzon, Prinya ChindaprasirtDocument6 pagesMaterials and Design: Sumrerng Rukzon, Prinya ChindaprasirthenryNo ratings yet