Professional Documents

Culture Documents

Molecular Engineering of Crystalline Polymer

Uploaded by

chiuchan888Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Molecular Engineering of Crystalline Polymer

Uploaded by

chiuchan888Copyright:

Available Formats

Chapter 3

Molecular Engineering of Liquid Crystalline Polymers

3.1.

INTRODUCTION

The molecular theories introduced in Chapter 2 are the principal guidelines for any successful molecular design of liquid crystalline polymers. According to the theories, rigid molecules with an anisotropic shape, rod-like in particular, are able to form nematic phases even if no soft interactions are included in the consideration. Thermal stability (characterizable by Ti , the clearing temperature) of the liquid crystal phase is a function of the axial ratio of the molecules. Those molecules with higher length-to-diameter ratios will result in nematic phases of a higher clearing temperature. When the ratio is large enough, the nematic phase is always more stable than the isotropic liquid phase and the clearing temperature will be innite. Dierent theoretical treatments have reached the same conclusion, although they have resulted in dierent critical axial ratios. In the literature of polymeric liquid crystals, the most cited value for the critical axial ratio of rigid rods is 6.4, given by Flory. Actual molecules always have certain exible elements and are not as rigid as a true rod. Taking the rod-like poly(1,4-phenylene) as one example,

3.1

n

rotation of phenylene rings about the interphenylene bonds, together with vibrations of the bonds, have brought about exibility of the molecule even

133

134

Liquid Crystalline Polymers

though a rod-like shape has persisted. The formability of a liquid crystal phase and the phase transition temperatures of the homologous compounds of poly(1,4-phenylene) are characterized and shown in Table 3.1. Two conclusions may be drawn from the data in Table 3.1. First, only the homologues with suciently large values of length-to-diameter ratio can form a liquid crystal phase. Secondly, both the melting point and the clearing temperature of the liquid crystal phase increase very fast with an increasing degree of polymerization (n + 2). The compound with only six 1,4-phenylene units and an axial ratio of 5.5 has a melting point of 438 C and a clearing temperature of 565 C, which is already too high a temperature for organic molecules to survive. It is therefore not practical to synthesize liquid crystal forming polymers by the simple linking-together of rigid structures into rod-like molecules, even if certain exible elements are present. By inserting in between every two phenylene rings a linking unit with a certain exibility, such as an ester group, the exibility of the molecules will be increased. For example, if an ester group is used as the linking unit, it will not only allow the crankshaft type movements in the molecule, but also serve as a separation between the phenylene rings and thus reduce the hindrance for a free rotation of the rings. As a result, poly(4-hydroxybenzoic acid), PHA, with the following formula does have much lower transition temperatures than poly-phenylenes as shown in Table 3.2. Specically, the compound with n = 3 has a melting point of 220 C and a clearing temperature of 464 C. The calculated axial ratio l/d is 6.4. In comparison, this compound has slightly higher axial ratio but much lower transition temperatures than the poly(1,4-phenylene) with n + 2 = 6 (l/d = 5.5, m.p.

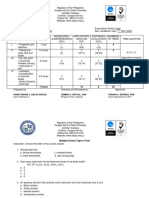

Table 3.1. The Axial ratio and Phase Transition Temperature of Poly(1,4-phenylene)s . n+2 1 2 3 4 5 6

Axial Ratio, l/d 1.0 2.0 3.0 3.9 4.8 5.5

Melt. Point, C 5.4 70.5 213 320 388 438

Clearing Point, C non-liquid-crystalline non-liquid-crystalline non-liquid-crystalline non-liquid-crystalline 418 565

Source: Irvine and Flory, 1984.

Molecular Engineering of Liquid Crystalline Polymers

135

Table 3.2. Axial ratio hydroxybenzoic acid) . n 1 2 3 13 100

and

Transition

Temperature

of

Poly(4-

Axial Ratio, l/d 3.8 5.1 6.4 19

Melt.Point, C 132 176 220 415 600

Clearing Point, C 100 monotropic 254 464

Source: Ballau and Flory, 1984; Economy, et al. 1988.

438 C, T i = 565 C. Table 3.1). Thus, PHA can have a higher degree of polymerization than poly(1,4-phenylene) before the transition temperatures become innite. However, studies on PHA have shown that its melting point is already higher than its decomposition temperature if the degree of polymerization reaches only such a low value as 13 (Table 3.2).

CO O CO n O

3.2

In Table 3.2, the compound with n = 1 has a monotropic liquid crystalline phase. In the literature of liquid crystals a monotropic phase is a metastable phase which forms only in the process of cooling but not when the sample is heating. On the other hand, if a liquid crystalline phase forms not only in the process of cooling but also in the process of heating, the phase is termed enantiotropic. For example, a nematic phase is monotropic if the melting point, T m, of the sample is higher than the clearing temperature, T i, of the liquid crystal phase. It is enantiotropic if T i is higher than T m. It is worthwhile pointing out that the critical axial ratio 6.4 given by Florys theory is based on assumptions that include zero free volume and zero net interaction energy between the rods (Chapter 2). By increasing the free volume, for example, the ratio will be increased accordingly. It is thus also understandable that the critical axial ratio will become larger when the temperature is increased. On the other hand, no actual system will meet these assumptions to any perfection. In addition, the exibility of an actual molecule such as poly(1,4-phenylene) and PHA will increase with increasing temperature. In other words, the axial ratio of a molecule is not a constant,

136

Liquid Crystalline Polymers

but a function of temperature. The actual axial value of a compound will deviate from what was calculated for a standard condition, and will become lower and lower with the increase of experimental temperature. Therefore, no direct comparison may be made between the critical axial ratio given by the theory and the axial ratio of an actual compound for evaluation of the liquid crystalline properties of the compound. We have shown that polymers formed by the simple linking together of rigid rod-like mesogenic units, such as poly(1,4-phenylene) and poly(4hydroxybenzoic acid) formed by linking together the phenylene rings with single bonds or ester units, have melting temperatures so high that no liquid crystalline phase can actually exist above melting. To achieve liquid crystallinity, the melting point of the polymers has to be decreased. The most convenient way to achieve this is to mix the rod-like polymer with a solvent. Blades (1973, 1975) discovered that with sulfuric acid the high molecular weight poly(1,4-phenylene terephthamide) is able to form crystalline solvates with nite melting temperatures. The solvate formed with about one mole polymer and 10 moles of sulfuric acid melts and forms the lyotropic liquid crystalline phase at 70 C, a very convenient temperature for processing. Other rod-like polymers may form solvates also. Poly( -benzyL-glutamate), for example, forms crystal solvates with DMF. Watanabe et al. (1981) found the melting point of the solvates increases with the increasing of the polymer content. The lyotropic liquid crystal phase can form only when the polymer content is higher than 18 wt%. Papkov (1982) has given a phase diagram for the two-component system of a rigid rod polymer and a solvent. According to this researcher, with the addition of a solvent to the polymer, a two-phase system (crystal C + crystal-solvate CS) is rst formed. A single CS phase, then the second two-phase system of CS and the isotropic liquid phase will form with the further addition of the solvent. Thus in principle, liquid crystals of rigid rod-like polymers can be obtained by solvent incorporation and formation of crystal solvates with nite melting points. As a matter of fact, lyotropic liquid crystal phases are achieved not only with poly(1,4-phenylene terephthamide) (PPTA) and Poly( -benzy-L-glutamate), but also with such rigid rod-like polymers as poly(1,4-phenylene benzo-bis-thiazole) (PBT) and poly(1,4phenylene benzo-bis-oxazole) (PBO). PPTA, PBT and PBO are important lyotropic liquid crystal polymers that result in materials with very high tensile strength and modulus. Unfortunately, because of the very low mixing entropy, not many of the rigid rod-like high polymers have sucient solubility and form solvates. For example, among many others, poly(1,4-phenylene) and

Molecular Engineering of Liquid Crystalline Polymers

137

poly(4-hydroxybenzoic acid) hardly dissolve in any solvent. Therefore, these high-melting polymers are not able to form any liquid crystalline phase, neither thermotropic nor lyotropic, if no substantial chemical modications of the molecules are made. It has been indeed the focus of molecular engineering in this scientic area to design and synthesize polymers with desirable liquid crystallinity in desirable temperature regions. To achieve the goal, two principal ideas have been developed. The rst is to disrupt the chain sequence of mesogenic units by inserting into the chain, dierent structural moieties, so as to incorporate in the chain certain irregularity and exibility. The result of this practice are main-chain type liquid crystalline polymers. The second idea is to use the mesogenic units individually as side groups attached to the main chain of the polymer molecules, resulting in side-group type liquid crystalline polymers. Depending on the extent of disruption in the sequence of mesogenic units, main-chain type liquid crystalline polymers of very dierent properties can be synthesized. The polymers can still be rather rigid and have very high, but acceptable melting temperatures if only rigid moieties are used as the disruptions. Copolyesters of 4-hydroxybenzoic acid (HBA) with 6-hydroxy-2-naphthalic acid (HNA), and copolyesters of HBA with terephthalic acid (TA) and biphenol, are famous examples of these polymers. Properties of these copolyesters will be further discussed in Section 3.3 and Chapter 5. On the other hand, main-chain type liquid crystalline polymers can be very exible with very low melting points if exible spacers are frequently incorporated along the chain. By comparison, side-group type liquid crystalline polymers usually are exible polymers with low T g or low melting temperatures because the rigid mesogenic units with only limited length-to-diameter ratio are used only as individual side groups (Section 3.4). However, side-group type liquid crystalline polymers can have properties similar to that of rigid or semi-rigid main-chain type liquid crystalline polymers if unusual molecular designs are adopted (Section 3.5). Naturally, dierent molecular designs result in dierent polymer properties and dierent applications. Liquid crystalline polymers with higher chain rigidity and melting points may nd applications as high-strength, high-modulus, and heat-resistant materials (Chapter 5). Those with very low chain rigidity and transition temperatures may be used in display or information process devices (Chapter 6). Liquid crystalline polymers have been classied in a variety of ways according to the style of incorporation of mesogenic units in the molecules. The most basic types are shown in Figure 3.1, in which the squares are representative of mesogenic units. Mesogenic units are structural moieties with sucient rigidity and are mostly in the shape of straight rods. Other

138

Liquid Crystalline Polymers

Figure 3.1.

Basic types of liquid crystalline polymers.

anisotropic shapes such as discotic and bowl-like ones are rare but can also be found in certain liquid crystalline polymers. It is commonly believed that mesogenic units are essential to the formation of the liquid crystal phase. Liquid crystalline polymers without mesogenic units are rare and will be discussed in Section 3.6. 3.2. LOW MASS LIQUID CRYSTALLINE COMPOUNDS AND MESOGENIC UNITS

By and large, mesogenic units make up most of the principal components in a liquid crystalline polymer. The structure and property of mesogenic units are of primary importance in determining properties of a polymer. It is thus very instructive to have a brief study of the structure and its inuence on the property of mesogenic units with low mass liquid crystalline compounds as models and references.

You might also like

- Heat Exchanger Selection GuideDocument31 pagesHeat Exchanger Selection Guidemehul10941No ratings yet

- CHM3102 Polymer SolutionsDocument15 pagesCHM3102 Polymer SolutionsanisghaniNo ratings yet

- Trane - Coil Sizing Guide PDFDocument42 pagesTrane - Coil Sizing Guide PDFyousuffNo ratings yet

- Polymer SolutionDocument30 pagesPolymer Solutionscicws1133100% (1)

- Antique National School Long Test in Science 7: For Items 6-9Document3 pagesAntique National School Long Test in Science 7: For Items 6-9Christine Joy Millares GimenoNo ratings yet

- CAPE Chemistry Past Paper Answer - 2016 Unit 2 PaperDocument12 pagesCAPE Chemistry Past Paper Answer - 2016 Unit 2 PaperEllieNo ratings yet

- Liquids and Liquid Mixtures: Butterworths Monographs in ChemistryFrom EverandLiquids and Liquid Mixtures: Butterworths Monographs in ChemistryNo ratings yet

- 1e5 Glass Structures l5 Me Glued ConnectionDocument60 pages1e5 Glass Structures l5 Me Glued ConnectionPaulNo ratings yet

- Crosslink Density of RubberDocument2 pagesCrosslink Density of Rubberchiuchan888No ratings yet

- Defraction of LightDocument21 pagesDefraction of LightPrakhar94% (18)

- Adrian Bejan - Evolution in Thermodynamics PDFDocument20 pagesAdrian Bejan - Evolution in Thermodynamics PDFSantiago Del Rio OliveiraNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Melting Point and Molecular SymmetryDocument8 pagesMelting Point and Molecular SymmetryMauricio AyalaNo ratings yet

- Corresponding State TheoryDocument15 pagesCorresponding State TheoryAravind KNo ratings yet

- Laboratory Report Experiment 5 - Group 7Document26 pagesLaboratory Report Experiment 5 - Group 7Jeremy Kyle Edson AustriaNo ratings yet

- Solution Theory: Hat Is A SolutionDocument20 pagesSolution Theory: Hat Is A SolutionIrvine MupambaNo ratings yet

- Condensed Mode Cooling in Ethylene Polymerisation Droplet EvaporationDocument6 pagesCondensed Mode Cooling in Ethylene Polymerisation Droplet EvaporationyamakunNo ratings yet

- Molecules: Rudolf Naef and William E. Acree JRDocument41 pagesMolecules: Rudolf Naef and William E. Acree JRanachiorNo ratings yet

- Intermolecular Forces & bp PredictionDocument4 pagesIntermolecular Forces & bp PredictionethanNo ratings yet

- Polymer CharacterizationDocument8 pagesPolymer CharacterizationGerald LimNo ratings yet

- Experiment 5 Written ReportDocument4 pagesExperiment 5 Written ReportGae CapistranoNo ratings yet

- The Effect of The Side Group Upon The Properties of The Poly (Epoxides)Document7 pagesThe Effect of The Side Group Upon The Properties of The Poly (Epoxides)Javier Vallejo MontesinosNo ratings yet

- Lab Report-1 PDFDocument4 pagesLab Report-1 PDFAyle NakamuraNo ratings yet

- Strut Chem CiteDocument24 pagesStrut Chem CitePunitha MohanNo ratings yet

- Theory of Dyeing-F. JonesDocument8 pagesTheory of Dyeing-F. JonesRezaul Karim TutulNo ratings yet

- 1982 - Mcelhaney - The Use of Differential Scanning Calorimetry and Differential Thermal Analysis in Studies of Model and Biological MembranesDocument31 pages1982 - Mcelhaney - The Use of Differential Scanning Calorimetry and Differential Thermal Analysis in Studies of Model and Biological MembranesymiyazyNo ratings yet

- Carbonilación de EtilenoDocument46 pagesCarbonilación de EtilenoNicpueurrNo ratings yet

- Can Ions Disolve FullerenesDocument22 pagesCan Ions Disolve FullerenesBryan396No ratings yet

- 1.1 Polymers: 1.1.1 Thermoplastics, Thermosets and ElastomersDocument16 pages1.1 Polymers: 1.1.1 Thermoplastics, Thermosets and ElastomerslatiefNo ratings yet

- Lecture 3Document12 pagesLecture 3Supriya KadamNo ratings yet

- Two Component System Reduced Phase Rule or Condensed Phase RuleDocument34 pagesTwo Component System Reduced Phase Rule or Condensed Phase RulecrizyNo ratings yet

- Polymer Solutions and GelsDocument45 pagesPolymer Solutions and Gelsحيدر الوائليNo ratings yet

- Experiment 5Document24 pagesExperiment 5monico3950% (2)

- Case Studies Analysis - PolymorphismDocument8 pagesCase Studies Analysis - Polymorphismtelmo rochaNo ratings yet

- 970 - State of Matter Part IIDocument7 pages970 - State of Matter Part IIElizabeth AtuchukwuNo ratings yet

- Unit 4Document11 pagesUnit 4Kalia ChoudhuryNo ratings yet

- APPROVAL SHEETDocument26 pagesAPPROVAL SHEETRafidah AmaliaNo ratings yet

- Glass Transition Temperature of PolymerDocument5 pagesGlass Transition Temperature of PolymerSWETHA GNo ratings yet

- Midterm CaeDocument17 pagesMidterm CaeDianne AlarconNo ratings yet

- 2007 0164 Stauch Maas The Auto-Ignition of Single J HeatMassTransV50 p3047 3053Document7 pages2007 0164 Stauch Maas The Auto-Ignition of Single J HeatMassTransV50 p3047 3053Shirish MaheshwariNo ratings yet

- Freezing PT DepDocument15 pagesFreezing PT Dep문성욱0% (1)

- Interphase Mass Transfer: Demonstrating The Effect of in A Transparent Fluidized Bed Reactor Science - Gov (United States)Document6 pagesInterphase Mass Transfer: Demonstrating The Effect of in A Transparent Fluidized Bed Reactor Science - Gov (United States)Sandeepkumar SharmaNo ratings yet

- Synthesis and Properties of Novel Aggregation-Induced Emission Compounds With Combined Tetraphenylethylene and Dicarbazolyl Triphenylethylene MoietiesDocument9 pagesSynthesis and Properties of Novel Aggregation-Induced Emission Compounds With Combined Tetraphenylethylene and Dicarbazolyl Triphenylethylene MoietiesAsfa ChinuNo ratings yet

- States of MatterDocument9 pagesStates of MatterfaedNo ratings yet

- Chem 2Document34 pagesChem 2Hannah DaddNo ratings yet

- Synthesis of A New Side-Chain Type Liquid Crystal Polymer Poly (Dicyclohexyl Vinylterephthalate)Document3 pagesSynthesis of A New Side-Chain Type Liquid Crystal Polymer Poly (Dicyclohexyl Vinylterephthalate)FiyanNo ratings yet

- MW Vs Melting TempDocument12 pagesMW Vs Melting Temptripti060586No ratings yet

- Determination of the differential heat of solution of benzoic acidDocument3 pagesDetermination of the differential heat of solution of benzoic acidLoveFreequencyNo ratings yet

- Chen 1992Document9 pagesChen 1992Estefany PajaroNo ratings yet

- Melting and Boiling Point DeterminationDocument5 pagesMelting and Boiling Point DeterminationVanessa ValdezNo ratings yet

- Binary SystemDocument40 pagesBinary SystemNoraNo ratings yet

- ChemistryDocument47 pagesChemistryAbhishek Singh (ABHISHEK SINGH)No ratings yet

- Polymers: Conducting PolymersDocument40 pagesPolymers: Conducting PolymersyashNo ratings yet

- Lipid Structure and Membranes, Summary IDocument3 pagesLipid Structure and Membranes, Summary INorman Albon100% (2)

- Cellulose PyrolysisDocument5 pagesCellulose PyrolysisVIxi OkNo ratings yet

- Livro Cap 08Document16 pagesLivro Cap 08Natalia BiziakNo ratings yet

- Full Download Solution Manual For Chemistry The Science in Context 5th Edition Thomas R Gilbert Rein V Kirss Natalie Foster Stacey Lowery Bretz Geoffrey Davies PDF Full ChapterDocument36 pagesFull Download Solution Manual For Chemistry The Science in Context 5th Edition Thomas R Gilbert Rein V Kirss Natalie Foster Stacey Lowery Bretz Geoffrey Davies PDF Full Chaptermeow.switchel.2kjze7100% (19)

- Cambridge Practice Tests For IELTS 1Document127 pagesCambridge Practice Tests For IELTS 1HamitŞekNo ratings yet

- Applied Chemistry - Lecture 3Document70 pagesApplied Chemistry - Lecture 3Muhammad RafayNo ratings yet

- RIGBYDocument3 pagesRIGBYapi-3733260No ratings yet

- 2423L3Document8 pages2423L3Ruben SyNo ratings yet

- Partially Miscible LiquidsDocument8 pagesPartially Miscible LiquidsRenz Roger Esteves Buendicho100% (1)

- Draft 75 Applications of Inverse Gas Chromatography in The Study of Liquid Crystalline Stationary PhasesDocument36 pagesDraft 75 Applications of Inverse Gas Chromatography in The Study of Liquid Crystalline Stationary PhasesberkahNo ratings yet

- Polymer Structure and Synthesis-4Document8 pagesPolymer Structure and Synthesis-4NinhHoàngHảiNo ratings yet

- Solid-State Chemistry Synthesis and CharacterizationDocument3 pagesSolid-State Chemistry Synthesis and CharacterizationOm Prakash SinghNo ratings yet

- GlycerolDocument10 pagesGlycerolAshwani KumarNo ratings yet

- Organic Chemistry Lab Determines Melting and Boiling PointsDocument4 pagesOrganic Chemistry Lab Determines Melting and Boiling PointsAlyssa Ortega100% (1)

- Baffle and Wash Trough Assembly For Granular Media FiltersDocument10 pagesBaffle and Wash Trough Assembly For Granular Media Filterschiuchan888No ratings yet

- Water Purification Using A Granular Filter Medium With Sliding ContactsDocument8 pagesWater Purification Using A Granular Filter Medium With Sliding Contactschiuchan888No ratings yet

- Human Gait Recognition - Motion AnalysisDocument5 pagesHuman Gait Recognition - Motion Analysischiuchan888No ratings yet

- Physically Crosslinked ElastomerDocument5 pagesPhysically Crosslinked Elastomerchiuchan888No ratings yet

- Chemical PET RecyclingDocument20 pagesChemical PET Recyclingchiuchan888No ratings yet

- Polymer CrystallinityDocument7 pagesPolymer Crystallinitychiuchan888No ratings yet

- Chemical PET RecyclingDocument20 pagesChemical PET Recyclingchiuchan888No ratings yet

- Auto-Flushing Drainage Filter SystemDocument4 pagesAuto-Flushing Drainage Filter Systemchiuchan888No ratings yet

- Cardio Pulmonary LecturesDocument18 pagesCardio Pulmonary Lectureschiuchan888No ratings yet

- Human Gait Recognition - Motion AnalysisDocument5 pagesHuman Gait Recognition - Motion Analysischiuchan888No ratings yet

- Automatic Gait Recognition by Symmetry AnalysisDocument9 pagesAutomatic Gait Recognition by Symmetry Analysischiuchan888No ratings yet

- Human Gait Recognition - Motion AnalysisDocument5 pagesHuman Gait Recognition - Motion Analysischiuchan888No ratings yet

- Polymer and Polymerization TechniquesDocument27 pagesPolymer and Polymerization Techniqueschiuchan888No ratings yet

- Viscoelastic Behavior of Polymers PDFDocument9 pagesViscoelastic Behavior of Polymers PDFchiuchan888No ratings yet

- Fiber Spinning and Other ProcessesDocument5 pagesFiber Spinning and Other Processeschiuchan888No ratings yet

- Polymer TG Dependence On Time and FrequencyDocument5 pagesPolymer TG Dependence On Time and Frequencychiuchan888No ratings yet

- Modulus and Poisson's Ratio of PolymerDocument6 pagesModulus and Poisson's Ratio of Polymerchiuchan888No ratings yet

- Rubber Elasticity - Continuum TheoriesDocument7 pagesRubber Elasticity - Continuum Theorieschiuchan888No ratings yet

- Light Scattering of Solutions of PolymersDocument5 pagesLight Scattering of Solutions of Polymerschiuchan888No ratings yet

- Functional PolymersDocument9 pagesFunctional Polymerschiuchan888No ratings yet

- Zimms PlotDocument5 pagesZimms Plotchiuchan888No ratings yet

- Functional PolymersDocument9 pagesFunctional Polymerschiuchan888No ratings yet

- Fox Equation For Polymer Blend TGDocument6 pagesFox Equation For Polymer Blend TGchiuchan888No ratings yet

- Polymer Crosslink NetworksDocument6 pagesPolymer Crosslink Networkschiuchan888No ratings yet

- Automatic Gait Recognition by Symmetry AnalysisDocument9 pagesAutomatic Gait Recognition by Symmetry Analysischiuchan888No ratings yet

- Polymer Crosslink NetworksDocument6 pagesPolymer Crosslink Networkschiuchan888No ratings yet

- Polymer Presentation in ChinaDocument29 pagesPolymer Presentation in Chinachiuchan888No ratings yet

- Fox Equation For Polymer Blend TGDocument6 pagesFox Equation For Polymer Blend TGchiuchan888No ratings yet

- Chemical PET RecyclingDocument20 pagesChemical PET Recyclingchiuchan888No ratings yet

- SLES Concentration Effect On The Rheolog TraducidoDocument22 pagesSLES Concentration Effect On The Rheolog TraducidoJose GamezNo ratings yet

- Synthesis of Mesoporous Carbon MaterialsDocument7 pagesSynthesis of Mesoporous Carbon MaterialsMaria IgnatNo ratings yet

- P8-4 (Page 572 Fogler 4th Ed.) : K M V VDocument15 pagesP8-4 (Page 572 Fogler 4th Ed.) : K M V VSILPA ASTI NURANo ratings yet

- Genchem Act#2 ManiulitDocument3 pagesGenchem Act#2 ManiulitMelissa Kayla ManiulitNo ratings yet

- Computer Simulation of Vapor-Liquid Equilibrium in Mixed Solvent Electrolyte SolutionsDocument10 pagesComputer Simulation of Vapor-Liquid Equilibrium in Mixed Solvent Electrolyte SolutionsJoseCastilhoNo ratings yet

- Ionic Bonding Lecture NotesDocument65 pagesIonic Bonding Lecture Noteskaushik247100% (1)

- Physics Grade 7Document6 pagesPhysics Grade 7hiscoreNo ratings yet

- Data Sheet - ATP 20Document1 pageData Sheet - ATP 20HhelenaaNo ratings yet

- Experiment 14 - Radiation Heat TransferDocument13 pagesExperiment 14 - Radiation Heat TransferMohamad Amin75% (4)

- CPS Lab ReportDocument7 pagesCPS Lab Reportbenmon3000No ratings yet

- Begg Cousland Envirotec - Oil & Gas - 2017Document8 pagesBegg Cousland Envirotec - Oil & Gas - 2017Wili Nur RahmanNo ratings yet

- L3 Equilibrium ConversionDocument17 pagesL3 Equilibrium ConversionChristopher RamosNo ratings yet

- AnachemDocument115 pagesAnachemRochie DiezNo ratings yet

- Xi Xiii: Electrocrystallization in Nanotechnology. Edited by Georgi Staikov ISBN: 978-3-527-31515-4Document6 pagesXi Xiii: Electrocrystallization in Nanotechnology. Edited by Georgi Staikov ISBN: 978-3-527-31515-4fardin65No ratings yet

- Electrometallurgy Exam QuestionsDocument2 pagesElectrometallurgy Exam QuestionsRohan SinghNo ratings yet

- Unit 2 Gas Laws and Power CyclesDocument103 pagesUnit 2 Gas Laws and Power CyclesNishad BhavsarNo ratings yet

- EXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSUREDocument44 pagesEXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSURESite EngineeringtiaNo ratings yet

- Fiber Joints & Joint LossesDocument29 pagesFiber Joints & Joint Lossesrashiborgohain100% (1)

- Very Short Answer QuestionDocument35 pagesVery Short Answer QuestionAyush SigdelNo ratings yet

- Assignment 2 Pool PDFDocument2 pagesAssignment 2 Pool PDFSambhav JainNo ratings yet

- Properties and 4 - Strong and 5: Haney Marie U. Delos Arcos Gemma A. Gruyal, PHD Odinah C. Enteria, PHDDocument8 pagesProperties and 4 - Strong and 5: Haney Marie U. Delos Arcos Gemma A. Gruyal, PHD Odinah C. Enteria, PHDChrist YoungNo ratings yet

- Solution Manual For Human Biology 16th Edition Sylvia Mader Michael WindelspechtDocument36 pagesSolution Manual For Human Biology 16th Edition Sylvia Mader Michael Windelspechtoverspinmeetklac40100% (46)

- Reciprocating Compressor Tutorial SolutionsDocument12 pagesReciprocating Compressor Tutorial SolutionsArif SabainNo ratings yet

- Preparative Thin-Layer (Planar) ChromatographyDocument12 pagesPreparative Thin-Layer (Planar) ChromatographybarinputriNo ratings yet