Professional Documents

Culture Documents

Half Pipe Calculation

Uploaded by

CaptainToniesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Half Pipe Calculation

Uploaded by

CaptainToniesCopyright:

Available Formats

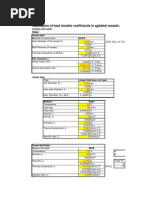

Input

Name 2 Jacket

Output

Unit

Comment Jacket type: 1. Annular jacket, spiral baffling 2. Half-pipe coil jacket 3. Dimple jacket Length of coil or jacket passage Baffled vessel? Input 1 for yes or 0 for no. Agitator type: see choices below 1. Flat blade turbine 2. Retreating blade turbine 3. Propeller 4. Paddle 5. Anchor 6. Helical Ribbon Number of agitator blades

L 0 Baffled 2 Type

178.2 ft

2 Blades 0.01 n/a ft

Agitator-ribbon pitch (input for Type 6 only)

Remarks Took average blade diameter Assume speed around 160rpm Mean Density Mean cp Mean k Mean viscosity Assume w= Turbulent

Confirmed input values Input 2.78871 9600 48.0695 0.599145 0.070779 34.09461

Name D N cp k w NRe NPr hi

Output

Unit ft rev/hr lbm/ft^3 Btu/lbm-F Btu/hr-ft^2-F/ft lbm/ft-hr 34.09461 lbm/ft-hr 105259.6251 288.6101858 121.8454108 Btu/hr-ft^2-F ft ft ft ft ft ft^2

Comment Blade diameter Blade Turning Speed Density, process fluid Specific heat, process fluid Thermal conductivity, process fluid Viscosity at the bulk fluid temperature Viscosity, wall surface temp Reynolds Number Prandtl Number Heat transfer coefficient Vessel Diameter Vessel Jacket OD Vessel jacket ID (Dji=DT) Equivalent diameter Center diameter of jacket Jacket cross-sectional area Density, heat transfer fluid Specific heat, heat transfer fluid Thermal conductivity, heat transfer fluid Viscosity at the bulk fluid temperature Viscosity, wall surface temp Volumetric flow rate Flow rate Mass flow rate Reynolds number Prandtl Number Heat Transfer Coefficient Heat conductance Process fluid entry temperature Process fluid exit temperature Heat transfer fluid entry temperature Heat transfer fluid exit temperature Log mean temperature change Temperature change Volume of process fluid in the tank Mass of fluid within the vessel Intermediate variable Wall area in contact with the process fluid Floor area in contact with the process fluid Total jacket area in contact with fluid Height of the process fluid in the vessel Time to change jacket temp from t1 to t2 V

670 640

5.93504 DT 6.13189 Djo Dji De Dc Ax 39.9539 0.721553 0.652902 1.47322 j C kj j wj

5.93504 0.400229008 6.033465 1.865615296

lbm/ft^3 Btu/lbm-F Btu/hr-ft^2-F/ft lbm/ft-hr 1.47322 lbm/ft-hr ft^3/hr 241.2072847 ft/hr 17979.255 lbm/hr 2618.126065 1.628125371 5.995315921 Btu/hr-ft^2-F 5.714155027 Btu/hr-ft^2-F 86 608 680 609 -92.84659539 -71 F F F F F F gal lbm ft^2 ft^2 ft^2 ft

450 Q V W NRej NPrj ho U t1 t2 T1 T2 Tlm T 217.942 vol m kk Aw Af Ak H

1400.490566 1.033339554 74.4572 0 74.4572 2.4148

4.230400109 hr

Assumptions Heat transfer due to the wall resistance can be neglected

Inside Film Coefficient Nnu1 FALSE Z 2.3 Nnu2 10217.09 Nnu3 Nnu4 Nnui 5 Nnu6 FALSE FALSE FALSE FALSE

Outside Film Coefficient NNu1 FALSE NNu2 3.675129 NNu3 FALSE x1 21.19749 x2 3.919847 x3 0.188578 x4 1.885776

Input Output

825 L

You might also like

- Coil HeatDocument4 pagesCoil HeatTarmana Antt50% (2)

- Shell and Tube Heat ExchangerDocument19 pagesShell and Tube Heat Exchangerhuangjl33% (3)

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Calculation Overall Heat TransferDocument4 pagesCalculation Overall Heat TransferDavid LambertNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Coil DesignDocument7 pagesCoil DesignSajal Kulshrestha100% (3)

- Tank Coils - Design and UseDocument7 pagesTank Coils - Design and UseMartin DanzeNo ratings yet

- NT42 Calculation Heat Transfer of Storage Tank Rail TankDocument2 pagesNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHNo ratings yet

- Agitated VesselsDocument24 pagesAgitated VesselsAnuj Kumar100% (1)

- Method of Heat Exchanger Sizing (Kern Method)Document11 pagesMethod of Heat Exchanger Sizing (Kern Method)Hani Kirmani80% (5)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Jacket and Coils of Agitated Vessels PDFDocument2 pagesJacket and Coils of Agitated Vessels PDFlolofm25No ratings yet

- Tank Heat CalculationDocument7 pagesTank Heat CalculationElton Situmeang100% (3)

- Limpet Coil DesignDocument10 pagesLimpet Coil Designmaheshspawar0% (1)

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 pagesSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1No ratings yet

- Limpet Coil CalculationDocument1 pageLimpet Coil Calculationkirandas_mullassery100% (1)

- TEMA Shell & Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell & Bundle Entrance and Exit Areasnagtummala100% (3)

- Limpet Coil Reactor - 28-05Document3 pagesLimpet Coil Reactor - 28-05AJAY138150% (2)

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNo ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- TankjktDocument57 pagesTankjktAnonymous 20VAru100% (2)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelNo ratings yet

- Shell & Dish ThicknessDocument3 pagesShell & Dish Thicknesskirandas_mullasseryNo ratings yet

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- Steam Coil DesignDocument2 pagesSteam Coil DesignHendri SinagaNo ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Steam Coil SizingDocument21 pagesSteam Coil SizingMildogg100% (1)

- Agitated Vessel Heat Transfer (K.J. Carpenter)Document9 pagesAgitated Vessel Heat Transfer (K.J. Carpenter)Clarence AG Yue100% (2)

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3Document2 pagesSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Cone CalculationDocument4 pagesCone CalculationAkshat JainNo ratings yet

- Heat Exchanger Design CalculationsDocument6 pagesHeat Exchanger Design CalculationsryanarthurNo ratings yet

- Half Coil For VersselDocument1 pageHalf Coil For VersselhuangjlNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- AgitatorDocument6 pagesAgitatorSung Woong MoonNo ratings yet

- EjectorDocument6 pagesEjectorbadelitamarius100% (1)

- 2 Design CalculationDocument22 pages2 Design CalculationLynn HuiNo ratings yet

- Shell and Tube Heat ExchangDocument19 pagesShell and Tube Heat ExchangValium MorphineNo ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- InsulationDocument6 pagesInsulationBrinto VargheseNo ratings yet

- Heat Transfer Design Methods by John MC Ketta PDFDocument607 pagesHeat Transfer Design Methods by John MC Ketta PDFAlberto LazzarettiNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- HCL Scrubber DesignDocument5 pagesHCL Scrubber DesignManish0301198375% (4)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Handbook for Transversely Finned Tube Heat Exchanger DesignFrom EverandHandbook for Transversely Finned Tube Heat Exchanger DesignNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsFrom EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsRating: 2 out of 5 stars2/5 (1)

- A Practical Approach to Chemical Engineering for Non-Chemical EngineersFrom EverandA Practical Approach to Chemical Engineering for Non-Chemical EngineersNo ratings yet

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationdhavaleshNo ratings yet

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVANo ratings yet

- Boiler DataDocument28 pagesBoiler DataMonique ThomasNo ratings yet

- CPCDocument2 pagesCPCUok RitchieNo ratings yet

- Shell and Tube Heat Exchanger SpreadsheetDocument2 pagesShell and Tube Heat Exchanger SpreadsheetHernan Cardenas Franco100% (1)

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Process Calculations For DesignDocument26 pagesProcess Calculations For DesignOmprakaash MokideNo ratings yet

- Force CalculationDocument11 pagesForce CalculationCaptainToniesNo ratings yet

- CadDocument2 pagesCadCaptainToniesNo ratings yet

- Vertical Pressure VesselDocument5 pagesVertical Pressure VesselEnriqueGDNo ratings yet

- Flat Plate Deflection Chapter13 1Document29 pagesFlat Plate Deflection Chapter13 1Feeling_so_fly100% (2)

- 155Document4 pages155Dilip YadavNo ratings yet

- Blending Vessel v431Document13 pagesBlending Vessel v431CaptainToniesNo ratings yet

- 155Document4 pages155Dilip YadavNo ratings yet

- Wind ForcesDocument4 pagesWind ForcesCaptainToniesNo ratings yet

- 155Document4 pages155Dilip YadavNo ratings yet

- Design of Pressure VesselDocument137 pagesDesign of Pressure VesselCaptainToniesNo ratings yet

- Comparison of Analytical Methods For Calculation of Wind LoadsDocument66 pagesComparison of Analytical Methods For Calculation of Wind LoadsJImmy NasutionNo ratings yet

- Design Calc Saud It SampleDocument25 pagesDesign Calc Saud It SampleglazetmNo ratings yet

- Solidworks Tips & TricksDocument1 pageSolidworks Tips & TricksCaptainToniesNo ratings yet

- Simple Supported Beam Gravity OnlyDocument3 pagesSimple Supported Beam Gravity OnlyCaptainToniesNo ratings yet

- Rect. Tanks SampleDocument31 pagesRect. Tanks Samplenamasral100% (9)

- Report Vibration Analysis For - Support Agitator v-410Document54 pagesReport Vibration Analysis For - Support Agitator v-410CaptainToniesNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- B2 CreepDocument9 pagesB2 Creepnishith316No ratings yet

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDocument5 pagesAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesNo ratings yet

- 3772045Document13 pages3772045CaptainToniesNo ratings yet

- 21 Pressure Vessel HandbookDocument499 pages21 Pressure Vessel HandbookFelipe Arturo Biela Cornejo100% (22)

- Ar98 34Document29 pagesAr98 34CaptainToniesNo ratings yet

- Hai Su Trang Full Field and Hai Su Den Early Production System Development ProjectDocument2 pagesHai Su Trang Full Field and Hai Su Den Early Production System Development ProjectCaptainToniesNo ratings yet

- D N V C C: ET Orske Eritas Ertificate of OnformityDocument1 pageD N V C C: ET Orske Eritas Ertificate of OnformityCaptainToniesNo ratings yet

- Hai Su Trang Full Field and Hai Su Den Early Production System Development ProjectDocument2 pagesHai Su Trang Full Field and Hai Su Den Early Production System Development ProjectCaptainToniesNo ratings yet

- Engineering Design Guideline Storage Tank Rev 2Document8 pagesEngineering Design Guideline Storage Tank Rev 2CaptainToniesNo ratings yet

- D N V C C: ET Orske Eritas Ertificate of OnformityDocument1 pageD N V C C: ET Orske Eritas Ertificate of OnformityCaptainToniesNo ratings yet

- AL2041-D03-001-GA Drawing (01TK-6110) - EDocument4 pagesAL2041-D03-001-GA Drawing (01TK-6110) - ECaptainToniesNo ratings yet

- WP ValveDocument7 pagesWP ValveHamed ArianNo ratings yet

- PGBulletin 2019 2020 20200424Document40 pagesPGBulletin 2019 2020 20200424samNo ratings yet

- Luo 2019Document13 pagesLuo 2019Amrit DasNo ratings yet

- Smith Et al-1958-AIChE Journal PDFDocument3 pagesSmith Et al-1958-AIChE Journal PDFAlastairNo ratings yet

- 6th ICGH TurnerDocument12 pages6th ICGH Turnerscata1117No ratings yet

- An Experimental Investigation of A Single Stage Wet Gas Centrifugal CompressorDocument11 pagesAn Experimental Investigation of A Single Stage Wet Gas Centrifugal CompressorAnibal AriasNo ratings yet

- MASS TRANSFER Diffusion LectureDocument11 pagesMASS TRANSFER Diffusion LectureRashmi Walvekar SiddiquiNo ratings yet

- Hydrocyclone ISWTDocument69 pagesHydrocyclone ISWTSwarnaRakshit100% (1)

- Basic Design of Flying Wing ModelsDocument31 pagesBasic Design of Flying Wing ModelsGiang Bui100% (3)

- A. True: B.FalseDocument4 pagesA. True: B.FalseSnigdha YadavNo ratings yet

- Reservoir Simulation - Note01Document11 pagesReservoir Simulation - Note01naefmubarakNo ratings yet

- (DRAFT) TheApplication of 3D CFD Simulation For Risk and Safety Assessment in Oil and Gas Industry Facilities Rev00dDocument17 pages(DRAFT) TheApplication of 3D CFD Simulation For Risk and Safety Assessment in Oil and Gas Industry Facilities Rev00dandi suntoroNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDocument2 pagesWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhNo ratings yet

- Valve and Pipeline Design Notes - Part 1Document29 pagesValve and Pipeline Design Notes - Part 1Anilduth Baldan100% (2)

- Stokes' Law and The Coffee Filters: A ProblemDocument3 pagesStokes' Law and The Coffee Filters: A Problemabdul_azemiNo ratings yet

- Appropriate Separator Sizing - A Modified Stewart and Arnold Method F. Boukadi, V. Singh, R. Trabelsi, F. Sebring, D. Allen, and V. PaiDocument9 pagesAppropriate Separator Sizing - A Modified Stewart and Arnold Method F. Boukadi, V. Singh, R. Trabelsi, F. Sebring, D. Allen, and V. PaigermangsilvaNo ratings yet

- Book 1Document16 pagesBook 1chanjunkaiNo ratings yet

- Fluid Properties LabDocument18 pagesFluid Properties LabsilasNo ratings yet

- Pressure Build-Up in Wells: HornerDocument19 pagesPressure Build-Up in Wells: HornerandriNo ratings yet

- PHY 101 2019-2020 Fluid MechanicsDocument26 pagesPHY 101 2019-2020 Fluid MechanicsDave LarryNo ratings yet

- 8 Most Common Problems in Hydraulic Operated Remote Valve System On ShipsDocument23 pages8 Most Common Problems in Hydraulic Operated Remote Valve System On ShipsVasileios PantouvakisNo ratings yet

- Flow Over Weirs ReportDocument6 pagesFlow Over Weirs ReportميسرةNo ratings yet

- Yanbu: Export Refinery ProjectDocument7 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Open Bow Shock 2 DDocument11 pagesOpen Bow Shock 2 Dmathis.dumenilNo ratings yet

- Computation Water Hammer With Finite ElementDocument6 pagesComputation Water Hammer With Finite ElementyousefNo ratings yet

- Eregiron Control SystemDocument32 pagesEregiron Control SystemJose Hurtado OjedaNo ratings yet

- Basics of Mechanical Engineering:: Integrating Science, Technology and Common SenseDocument142 pagesBasics of Mechanical Engineering:: Integrating Science, Technology and Common SenseNeville TamNo ratings yet

- Modeling and Simulation of Hemihydrate Phosphoric Acid PlantDocument10 pagesModeling and Simulation of Hemihydrate Phosphoric Acid PlantIngrid ContrerasNo ratings yet

- Venturimeter, Orifice, PitotDocument2 pagesVenturimeter, Orifice, PitotVoora GowthamNo ratings yet