Professional Documents

Culture Documents

ASTM A213 T2 ASME SA213 T2 Specification

Uploaded by

hamiraziCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM A213 T2 ASME SA213 T2 Specification

Uploaded by

hamiraziCopyright:

Available Formats

Sunny Steel Enterprise Ltd.

Collect Steel pipe and fitting Resources

ASTM A213 T2

ASTM A213 T5 is the part of ASTM A213 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Super heater, Heat-Exchanger Tubes.

ASTM A213 T2 Standard covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes.

Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H.

These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

Http://www.sunnysteel.com E-mail: sales@sunnysteel.com

Page:1 of ASTM A213 T2-ASME SA213 T2 specification.docx

Sunny Steel Enterprise Ltd.

Collect Steel pipe and fitting Resources

ASTM A209 through A213

Other standard specifications include the categories of A209 seamless carbon-molybdenum alloy-steel boiler and superheater tubes; A210 seamless medium-carbon steel boiler and superheater tubes and A213 seamless ferritic and austenitic steel boiler, superheater and heat-exchanger tubes. Piping wall thicknesses range from 1/2 inch to 5 inches. A213 grades also have the letter H or M assigned, which changes the composition and specifications for that series.

This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

View the data of the steel grade as below:

Mechanical properties

Tensile strength(min) Yield strength(min) Elongation Delivery condition 415Mpa 220Mpa 30% annealed

Referenced Documents (purchase separately)

Other ASTM Standards

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

E112 Test Methods for Determining Average Grain Size

Http://www.sunnysteel.com E-mail: sales@sunnysteel.com

Page:2 of ASTM A213 T2-ASME SA213 T2 specification.docx

Sunny Steel Enterprise Ltd.

Collect Steel pipe and fitting Resources

Chemical Composition(%) for ASTM A213 T2 Low Alloy Steel

UNS Designation Carbon Manganese Phosphorus Sulfur Silicon Nickel Chromium Molybdenum Vanadium Boron Niobium Nitrogen Aluminum Tungsten Other Elements K11547 0.100.20 0.300.61 0.025 0.025 0.100.30 ... 0.500.81 0.440.65 ... ... ... ... ... ... ...

Http://www.sunnysteel.com E-mail: sales@sunnysteel.com

Page:3 of ASTM A213 T2-ASME SA213 T2 specification.docx

Sunny Steel Enterprise Ltd.

Collect Steel pipe and fitting Resources

ASTM A213 Standard Scope

1.1 This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated Grades T5, TP304, etc. These steels are listed in Tables 1 and 2. 1.2 Grades containing the letter, H, in their designation, have requirements different from those of similar grades not containing the letter, H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. 1.3 The tubing sizes and thicknesses usually furnished to this specification are 1/8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification. 1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the M designation of this specification is specified in the order. TABLE 1 Chemical Composition Limits, %A, for Low Alloy SteelA Maximum, unless range or minimum is indicated. Where ellipses () appear in this table, there is no requirement, and analysis for the element need not be determined or reported.

B

It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3. Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV

in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering. Hardness testing shall be performed at mid-thickness of the product. Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report.

After testing, the test piece shall be free from cracks or breaks. However, slight incipient cracks at its edges shall not be regarded as justification for rejection.

Read more: http://www.sunnysteel.com/blog/index.php/astm-a213-t5/

Http://www.sunnysteel.com E-mail: sales@sunnysteel.com

Page:4 of ASTM A213 T2-ASME SA213 T2 specification.docx

Sunny Steel Enterprise Ltd.

Collect Steel pipe and fitting Resources

Read more information of seamless steel pipes

Why seamless steel pipe? Some benefits of Seamless Steel Pipe Seamless steel pipes for high temperature and pressure sevice

ASTM A213/ ASME SA213 Standard specification ASTM A213 T2/ ASME SA213 T2 specification ASTM A213 T2/ ASME SA213 T5 specification ASTM A213 T5b/ ASME SA213 T5b specification ASTM A213 T9/ ASME SA213 T9 specification ASTM A213 T11/ ASME SA213 T11 specification ASTM A213 T12/ ASME SA213 T12 specification ASTM A213 T17/ ASME SA213 T17 specification ASTM A213 T21/ ASME SA213 T21 specification ASTM A213 T22/ ASME SA213 T22 specification ASTM A213 T91/ ASME SA213 T91 specification

ASTM Standard for Boilers tube, Super heater tubes Seamless steel pipes for high temperature and pressure sevice Standards commonly used stainless steel tube Seamless tube, Seamless tubing What is boiler tube Heat exchanger tube

Http://www.sunnysteel.com E-mail: sales@sunnysteel.com

Page:5 of ASTM A213 T2-ASME SA213 T2 specification.docx

Sunny Steel Enterprise Ltd.

Collect Steel pipe and fitting Resources

Boiler Tube in the following Spec/Grades:

ASTM A178 Grade A, C, D ASTM A192 SA210 / A210 Grade A1, C SA213 / A213 Grades (limited sizes) T-5, T-9, T-11, T-22, T-91 BS3059-I 320 CFS BS3059-II 360, 440, 243, 620-460, 622-490, S1, S2, TC1, TC2 EN10216-1 P195TR1/TR2, P235TR1/TR2, P265TR1/TR2 EN10216-2 P195GH, P235GH, P265GH, TC1, TC2 DIN17175 ST35.8, ST45.8 DIN1629, DIN1629 ST37.0, DIN1629 ST44.0, DIN1629 ST52.0 JIS G3454 STPG370, STPG410 JIS G3461 STB340, STB410, STB440 GB5310 20G, 15MoG, 12CrMoG, 12Cr2MoG, 15CrMoG, 12Cr1MoVG, 12Cr2MoWVTiB GB9948 10, 20, 12CrMo, 15CMo

Inspection and Test: Chemical Composition Inspection, Mechanical Properties Test Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test Surface and Dimension Test, No-destructive Test, Hydrostatic Test.

Get in Touch If you are interested in our products or cooperating with us, even having a comment or a suggestion please contact us now, for more detailed information. Tel.: +8621 3378 0199 | E-mail:sales@sunnysteel.com

-------------- www.sunnysteel.com --------------

Http://www.sunnysteel.com E-mail: sales@sunnysteel.com

Page:6 of ASTM A213 T2-ASME SA213 T2 specification.docx

You might also like

- Astm A312-A312m-05Document11 pagesAstm A312-A312m-05NadhiraNo ratings yet

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 pagesASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroNo ratings yet

- Astm A312Document3 pagesAstm A312Zeeshan HasanNo ratings yet

- ASTM A312 Stainless Steel PipesDocument11 pagesASTM A312 Stainless Steel Pipeschua8No ratings yet

- A 814 - A 814m - 01 Qtgxnc9bode0ts1sruqDocument7 pagesA 814 - A 814m - 01 Qtgxnc9bode0ts1sruqsachinguptachdNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- ASTM A335 P92 SpecificationDocument4 pagesASTM A335 P92 SpecificationTarun ChandraNo ratings yet

- ASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 pagesASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel Pipesessai expertiseNo ratings yet

- ASTM A210 Seamless Medium Carbon Steel Tube1 PDFDocument5 pagesASTM A210 Seamless Medium Carbon Steel Tube1 PDFaditya ekaNo ratings yet

- ASTM Bolt and Nut Material SpecificationsDocument2 pagesASTM Bolt and Nut Material SpecificationsAkshay PoddarNo ratings yet

- A 814 - A 814M - 03 Qtgxnc9bode0tqDocument6 pagesA 814 - A 814M - 03 Qtgxnc9bode0tqsachinguptachdNo ratings yet

- Astm A312Document2 pagesAstm A312faisi778No ratings yet

- Astm A312 PDFDocument12 pagesAstm A312 PDFStephen TilleyNo ratings yet

- A 312 PDFDocument10 pagesA 312 PDFmilecsaNo ratings yet

- A105-2010 Flange ACDocument5 pagesA105-2010 Flange ACbmalbertNo ratings yet

- Stainless steel pipe specs for corrosion resistanceDocument3 pagesStainless steel pipe specs for corrosion resistance1trungson1No ratings yet

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 pagesSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipeschandrasekarNo ratings yet

- A511 96 PDFDocument7 pagesA511 96 PDFJohano AraújoNo ratings yet

- Astm A312Document2 pagesAstm A312aezeadNo ratings yet

- A 632 - 01 Qtyzmi0wmqDocument4 pagesA 632 - 01 Qtyzmi0wmqLUISALBERTO06011985No ratings yet

- ASME SA213M / SA213 T9 Seamless Alloy Steel TubesDocument7 pagesASME SA213M / SA213 T9 Seamless Alloy Steel TubesJayminNo ratings yet

- Astm A312Document12 pagesAstm A312Ruth Sarai YañezNo ratings yet

- Stainless Steel Pipe SpecificationsDocument11 pagesStainless Steel Pipe SpecificationsGonzalo MazaNo ratings yet

- Astm A999 A999m 13Document11 pagesAstm A999 A999m 13islamakthamNo ratings yet

- A 632 - 02 Qtyzmi0wmkeDocument4 pagesA 632 - 02 Qtyzmi0wmkeLUISALBERTO06011985No ratings yet

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423Venkat Dora100% (1)

- STAINLESS STEEL PIPE SPECIFICATIONSDocument3 pagesSTAINLESS STEEL PIPE SPECIFICATIONSWahyuTantraFauziNo ratings yet

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument4 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- A813A813M-14 Standard Specification For Single - or Double-Welded Austenitic Stainless Steel PipeDocument7 pagesA813A813M-14 Standard Specification For Single - or Double-Welded Austenitic Stainless Steel PipeChuthaNo ratings yet

- 9-Csc Asme SpecificationsDocument5 pages9-Csc Asme SpecificationsDany FerdianNo ratings yet

- ASTM A333 Grade 6 SpecificationDocument9 pagesASTM A333 Grade 6 SpecificationmaldonadohansNo ratings yet

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Document4 pagesHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- Astm A192 Asme Sa192Document4 pagesAstm A192 Asme Sa192Mingo EvaNo ratings yet

- Sa 312 PDFDocument14 pagesSa 312 PDFAnilNo ratings yet

- Stainless steel pipe specifications guideDocument3 pagesStainless steel pipe specifications guideBhairu BaniNo ratings yet

- Astm A999Document12 pagesAstm A999Gustavo FreitasNo ratings yet

- F568MDocument9 pagesF568Maldert_pathNo ratings yet

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForJoshua SteigerwaldNo ratings yet

- Valve DetailDocument5 pagesValve DetailRakesh RanjanNo ratings yet

- A 953Document3 pagesA 953José Ramón GutierrezNo ratings yet

- A 108 - 99 - Qtewoc05oqDocument4 pagesA 108 - 99 - Qtewoc05oqvhenriquezmNo ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- Astm A356Document6 pagesAstm A356Srinivasan KrishnamoorthyNo ratings yet

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- A 1011 - A 1011M - 03 Qtewmtetmdm - PDFDocument7 pagesA 1011 - A 1011M - 03 Qtewmtetmdm - PDFTiến Lượng NguyễnNo ratings yet

- Steel Pipe Manufacturing ProcessDocument22 pagesSteel Pipe Manufacturing ProcessNatthasartNo ratings yet

- ASTM Specifications GuideDocument7 pagesASTM Specifications GuideSherif AdelNo ratings yet

- A 269 - 02 Qti2os0wmke - PDFDocument6 pagesA 269 - 02 Qti2os0wmke - PDFMan98No ratings yet

- Astm A312 PDFDocument12 pagesAstm A312 PDFGustavo Freitas100% (1)

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 pagesSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesAdrian RenteriaNo ratings yet

- 010 Sa29 Sa29mDocument26 pages010 Sa29 Sa29mWeniton OliveiraNo ratings yet

- Astm A530Document2 pagesAstm A530Thiruvengadam75% (4)

- Astm B221 5052 6063 6061Document3 pagesAstm B221 5052 6063 6061Son-Tuan PhamNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Introduction to Engineering ProfessionDocument29 pagesIntroduction to Engineering ProfessionhamiraziNo ratings yet

- ASTM A210, ASME SA210 American StandardDocument1 pageASTM A210, ASME SA210 American StandardhamiraziNo ratings yet

- Superheater Problems, Their Causes and SolutionsDocument12 pagesSuperheater Problems, Their Causes and Solutionshamirazi67% (3)

- Hanger DesignDocument5 pagesHanger DesignhamiraziNo ratings yet

- Aramco US Vendors For P F FDocument1 pageAramco US Vendors For P F Fhemantmech099200No ratings yet

- Items To Review at Hostel CHC ZAMKODocument1 pageItems To Review at Hostel CHC ZAMKOHumphrey OnyejegbuNo ratings yet

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridNo ratings yet

- 19th Southeast Asian Geotechnical Conference ProceedingsDocument6 pages19th Southeast Asian Geotechnical Conference ProceedingsSen HuNo ratings yet

- Gas Safety Regulations PDFDocument55 pagesGas Safety Regulations PDFPhil MoffatNo ratings yet

- Coal combustion calculationsDocument3 pagesCoal combustion calculationsShane PatulotNo ratings yet

- U-5 - 2022 - Tecnologías de Tratamientos - BDocument39 pagesU-5 - 2022 - Tecnologías de Tratamientos - BSimón OsésNo ratings yet

- Arandelas Hill Side A325Document1 pageArandelas Hill Side A325Oscar SanabriaNo ratings yet

- Literature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Document115 pagesLiterature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Patricia BrandNo ratings yet

- Carbofill Dec08Document4 pagesCarbofill Dec08Cristian Andres Araya CisternasNo ratings yet

- Healthcare WasteDocument32 pagesHealthcare WasteEddiemtongaNo ratings yet

- Manual For ConcretingDocument43 pagesManual For Concretinglwin_oo2435No ratings yet

- Liquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationDocument11 pagesLiquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationRajendrasinh PuvarNo ratings yet

- Metallurgical Characterization of Electrical Discharge Textured Roll SurfaceDocument8 pagesMetallurgical Characterization of Electrical Discharge Textured Roll Surfacevishalbhojak vishalbhojakNo ratings yet

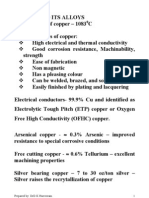

- Copper and It's AlloysDocument5 pagesCopper and It's AlloysReza MortazaviNo ratings yet

- Testing For Biological MoleculesDocument3 pagesTesting For Biological MoleculessariniNo ratings yet

- FP TackifierDocument8 pagesFP TackifierNguyễn Viết LươngNo ratings yet

- PQT First Aplication Banyu Urip Painting PrimerDocument19 pagesPQT First Aplication Banyu Urip Painting PrimerHeri FebriyantoNo ratings yet

- Angora Wool: Ultra-Soft Fiber From RabbitsDocument2 pagesAngora Wool: Ultra-Soft Fiber From RabbitsYogen Garbiyal100% (1)

- SOP On LMO Tank 20210401 - USAID RISEDocument25 pagesSOP On LMO Tank 20210401 - USAID RISEBoke BelayNo ratings yet

- Defects / Imperfections in Crystalline MaterialsDocument41 pagesDefects / Imperfections in Crystalline Materialsjayant thakareNo ratings yet

- Heraklith CatalogueDocument54 pagesHeraklith CatalogueN P SrinivasaraoNo ratings yet

- Vertical Drains May Not Work Alone Due To Thick Uniform Soft ClayDocument77 pagesVertical Drains May Not Work Alone Due To Thick Uniform Soft ClayChitharanjan VishnukripalNo ratings yet

- Lec 6 Module 1Document18 pagesLec 6 Module 1vedant chavanNo ratings yet

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- High Temperature Plastic Deformation of CuZn30 BraDocument6 pagesHigh Temperature Plastic Deformation of CuZn30 Bramahan nikNo ratings yet

- Safety Data Sheet for Penguard HB - Comp. ADocument5 pagesSafety Data Sheet for Penguard HB - Comp. ABalasubramanian AnanthNo ratings yet

- Ionic Bond of LoveDocument1 pageIonic Bond of LoveMohd FarisNo ratings yet

- Mechanical Design of Overhead LinesDocument26 pagesMechanical Design of Overhead LinesAsheque Iqbal100% (1)