Professional Documents

Culture Documents

Pneu Diagnoseee

Uploaded by

Amal Smiley SmallOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pneu Diagnoseee

Uploaded by

Amal Smiley SmallCopyright:

Available Formats

: Diagnose and repair faults in pneumatic equipment Questions 1.

Explain the causes of overheating and how to solve the problem *For proper service, the filter element must be cleaned or replaced periodicall y. Frequency depends on ambient conditions. A dirty filter element can restrict air flow through the compressor, causing overloading and consequent overheating . *The motor is running hot this is when parts of the motor are rubbing into each other which causes the increase in heat. In order to solve this problem you lubr icate the motor or replace it. 2. Why is it necessary to drain the compressor tank? Moisture should be drained from the receiver regularly, especially in cold weat her to avoid problematic accumulation. 3. Before servicing the Compressor machine name four safeties precautions that must be observed Ensure that only those with the necessary knowledge, training and equipment does the operation Be alert for sounds of arcing (sizzling, sputtering or popping) inside the compr essor. Immediately get away if you hear these sounds. Disconnect all electrical power before removing the protective terminal cover Never energize the system unless- the protective terminal cover is securely fast ened, and the compressor is properly connected to the ground. 4. What materials should never be used on or around a Compressor Unit? 5. Explain one technique of how lubricating devices should be checked to ensure operation. 6. Explain what are: A. air Dryers - air dryer is a device for removing water vapor from compressed

B. moisture separators - MOISTURE SEPARATORS. The moisture separator in a pne umatic system is always located downstream of the compressor. Its purpose is to remove any moisture caused by the compressor. A complete moisture separator cons ists of a reservoir, a pressure switch, a dump valve, and a check valve, and it may also include a regulator and a relief valve. The dump valve is energized and de-energized by the pressure switch. When de-energized, it completely purges th e separator reservoir and lines up to the compressor. The check valve protects t he system against pressure loss during the dumping cycle and prevents reverse fl ow through the separator C. moisture traps - A part of an air receiver that traps and drains away th e condensation formed due to reducing the air temperature in the receiver. D. Intercoolers - A component that cools air inside a compressor. An intercooler is a type of heat exchanger that also removes moisture. 7. List at least six (6) Check/inspect should be done with compressors. Explain

8. What are the pertinent questions you would ask when checking components if you unfamiliar with these components? 9. What safety precaution should be applied during the inspection? 10. Explain the types of instruments to diagnose the pneumatic system

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chemical Engineering Projects List For Final YearDocument2 pagesChemical Engineering Projects List For Final YearRajnikant Tiwari67% (6)

- Pneu DiagnoseDocument3 pagesPneu DiagnoseAmal Smiley SmallNo ratings yet

- Compressor DocsDocument6 pagesCompressor DocsAmal Smiley SmallNo ratings yet

- Types of CompressorDocument2 pagesTypes of CompressorAmal Smiley SmallNo ratings yet

- HydraulicDocument1 pageHydraulicAmal Smiley SmallNo ratings yet

- Lathe PDFDocument5 pagesLathe PDFAugusto MonjardimNo ratings yet

- Machinist Course - Lathe Operation ManualDocument140 pagesMachinist Course - Lathe Operation Manualmerlinson1100% (16)

- Factsheet Lockout TagoutDocument2 pagesFactsheet Lockout TagoutYousuf IbrahimNo ratings yet

- Care of Clients With Problems in OxygenationDocument5 pagesCare of Clients With Problems in OxygenationSkyla FiestaNo ratings yet

- Solar Refrigeration: Prepared by M.DevakumarDocument21 pagesSolar Refrigeration: Prepared by M.DevakumarEasy StudyNo ratings yet

- Soal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaDocument5 pagesSoal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaAstrid AlifkalailaNo ratings yet

- GrowNote Faba South 3 Pre PlantingDocument22 pagesGrowNote Faba South 3 Pre PlantingDawitNo ratings yet

- How To Import Medical Devices Into The USDocument16 pagesHow To Import Medical Devices Into The USliviustitusNo ratings yet

- Long Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesDocument4 pagesLong Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesAngélica Valenzuela AndrighiNo ratings yet

- Rules For State Competitions and Iabf Approved TournamentsDocument56 pagesRules For State Competitions and Iabf Approved TournamentsQuality management systems documentsNo ratings yet

- BV Lesson Plan 4Document3 pagesBV Lesson Plan 4api-252119803No ratings yet

- ALL102-Walker Shirley-Unemployed at Last-The Monkeys Mask and The Poetics of Excision-Pp72-85Document15 pagesALL102-Walker Shirley-Unemployed at Last-The Monkeys Mask and The Poetics of Excision-Pp72-85PNo ratings yet

- DPA Fact Sheet Women Prison and Drug War Jan2015 PDFDocument2 pagesDPA Fact Sheet Women Prison and Drug War Jan2015 PDFwebmaster@drugpolicy.orgNo ratings yet

- Senior Project RiceberryDocument76 pagesSenior Project RiceberryIttisak PrommaNo ratings yet

- Intro To Psychological AssessmentDocument7 pagesIntro To Psychological AssessmentKian La100% (1)

- Itrogen: by Deborah A. KramerDocument18 pagesItrogen: by Deborah A. KramernycNo ratings yet

- MajorProjects 202112 e 1Document64 pagesMajorProjects 202112 e 1xtrooz abiNo ratings yet

- User ManualDocument21 pagesUser ManualKali PrasadNo ratings yet

- API 510 Practise Question Nov 07 Rev1Document200 pagesAPI 510 Practise Question Nov 07 Rev1TRAN THONG SINH100% (3)

- Xi 3 1Document1 pageXi 3 1Krishnan KozhumamNo ratings yet

- Cover Letter UchDocument1 pageCover Letter UchNakia nakia100% (1)

- Money Tree International Finance Corp. Checklist of Standard Loan RequirementsDocument2 pagesMoney Tree International Finance Corp. Checklist of Standard Loan RequirementsAgape LabuntogNo ratings yet

- HUM110 Gilgamesh EssayDocument4 pagesHUM110 Gilgamesh EssaynsmeganNo ratings yet

- Maxillofacial Notes DR - Mahmoud RamadanDocument83 pagesMaxillofacial Notes DR - Mahmoud Ramadanaziz200775% (4)

- Dr. Nastiti K - Manajemen Asma Pada Anak 2018 PDFDocument72 pagesDr. Nastiti K - Manajemen Asma Pada Anak 2018 PDFagnesspratiwiNo ratings yet

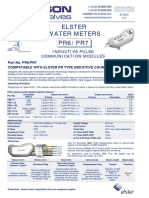

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- REV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Document2 pagesREV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Bacano CapoeiraNo ratings yet

- Revision Ror The First TermDocument29 pagesRevision Ror The First TermNguyễn MinhNo ratings yet

- Biopolymers: Overview of Several Properties and Consequences On Their ApplicationsDocument10 pagesBiopolymers: Overview of Several Properties and Consequences On Their ApplicationsrafacpereiraNo ratings yet

- SGT PDFDocument383 pagesSGT PDFDushyanthkumar DasariNo ratings yet

- General Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsDocument12 pagesGeneral Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsHazel EncarnacionNo ratings yet

- Big 9 Master SoalDocument6 pagesBig 9 Master Soallilik masrukhahNo ratings yet