Professional Documents

Culture Documents

Solder Reliability

Uploaded by

bitconceptsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solder Reliability

Uploaded by

bitconceptsCopyright:

Available Formats

1

Contents:

Reliabilityof Solder interconnections- General aspects

Literature:

K. Puttlitz, Handbook of Lead-Free Solder Technology for

Microelectronic Assemblies

D. Frear, The Mechanics of Solder Alloy Interconnects

J. Lau, Thermal Stress and Strain in Microelectronic Packaging

K. Puttlitz, Area array interconnection handbook

Design for Reliability 20.11.2012

Solder J oint Reliability

As stated before, electronic assembly designs have incorporated

various types of technology configurations to form mechanical,

electrical and thermal interconnections.

These configurations have developed from through-hole

technologies (single-sides, double-sided and PTH architectures)

to SMT technology

SMT technology includes:

Standard, fine pitch and very fine pitch devices

Leaded and leadless components

Ball and column grid arrays

Max. input/output- to component size ratio without excessive use of board

acreage

Durable, long-lasting and inexpensive mass production methods

2

Solder Joint Reliability is the ability of solder joints to remain in

conformance to their visual/mechanical, thermal and electrical

specifications over a given period of time, under a specified set

of operating conditions.

Component-level solder joint reliability within the package

structure itself

Board-level solder joint reliability deals with the reliability of

the solder joints of a package after it has been mounted on a

board or substrate, encompassing both the solder-to-package

and solder-to-board interfaces.

board-level reliability testing is more difficult to implement.

Solder J oint Reliability

Board level vs. die level

Mechanisms that determine the reliability (fatigue, creep, corrosion etc.)

are same in board and die level, but the differences in material/process

characteristics have to be taken into consideration

Crack propagation distance is much larger in bigger board level solder

joints

Strain levels can be considerably higher in board level because of CTE

mismatch

The influence of design, process, materials (thermomechanical)

properties and environment has to be addressed on both levels in order

to fully understand the reliability especially under cyclic stresses

(fatigue)

Board-Level Area Array Interconnect Reliability

3

The solder properties are largely dependent on both the mechanical and

physical properties (which are also dependent on chemical

composition)

The bulk solder and substrate compositions together with the thermo-

mechanical history define the condition, state and properties of the joint

(microstructure)

These factors greatly contribute to joint properties

Creep and fatigue strengths

Ductility

Electrical and thermal conductivity

Diffusivity

CTE

Resistance to corrosion and other environmental effects

Solder J oint Reliability

CTE Mismatch and area array package solder joint fatigue

PCB expands about 6 times more than typical ceramic package

Board-Level Area Array Interconnect Reliability

Temperature excursions in electronic systems

It is to be noted that while a device may be turned

on and off thousands of times a second the solder

joints only experience the average device-power

dissipation

Since the IC is the heat source it has a higher

temperature than the chip carrier which in turn has

higher temperature than the solder joint

4

Product reliability is an important factor especially in portable

electronics, because these increasingly powerful and more

complexelectronic equipment experience different kinds of

electrical, thermal, mechanical, and thermo-mechanical

strains and stresses in their service environments.

The importance of solder interconnection reliability is increased

mainly due to two reasons:

Firstly, higher interconnection densities

Secondly, the employment of lead-free solders, component under bump

or lead metallizations, and PWB protective coatings add to the

complexity of the interconnection metallurgies

Solder J oint Reliability

Reliability testing

Lead-free technology more complex reactions

more complex microstructures

Testing even more important than before

Better understanding of failure mechanisms under

different loading conditions is needed

Different combinations of various tests:

Thermal cycling

Drop-testing

Power cycling

Vibrational testing

Corrosive environment

Thermal annealing

etc.

5

There are three major mechanisms of solder joint failure,

although these often interplay with each other simultaneously.

1) tensile rupture or fracture due to mechanical overloading

2) creep failure, or damage caused by a long-lasting permanent load or

stress

3) fatigue, or damage caused by cyclical loads or stresses.

One way to analyze solder joint reliability is to perform solder

joint modeling, or analysis of solder joint strengths and

weaknesses using computer models.

Solder J oint Reliability

Ref:C Bailey, University

of Greenwich

6

Ref:C Bailey, University

of Greenwich

Numerous studies have been made of the effect of geometry on the

reliability

The most accurate models are finite element representations which consider

plastic flow properties

In the most sophisticated cases also the time- dependent processes

Creep deformation

Fatigue crack initiation and propagation

These suffer from the lack of parametric generality

Other models, which are analytic and parametric in nature, are weakened by

gross approximations in the solder behaviour and failure criteria

SMT-J oint Geometry and Design

} }

= A

A

= A dV dt W

V

V W

W

e

e

e

e

c o ,

7

Stress distribution (von Mises) FC-joint

Elastic analysis(also solder):

Heating: 0 100 C

Max stress =170 MPa

Time dependent deformation:

Heating: 0 100 C

Max stress =11 MPa

40 - 50 MPa

Life-time according tom Darveaux

Crack nucleation [cycles]

Crack propagation [m/cycle]

Cysles to fracture

( )

2

1 0

C

f

W C N A =

( )

4

3

C

W C

dN

da

A =

dN

da

a

N N

f f

+ =

0

a

8

The joint design, including lead shape and height, and volume (shape

and size) of the solder, has great effect on the long-term performance

of a joint.

An extremely simplified equation for estimating the shear stress () in the joint

is:

Ao=CTE difference,

AT=temperature change,

D

np

=distance from the neutral point (component centre) and

t=joint height

The flexible component leads decrease the stress affecting the solder joint in

leaded SMT-components

SMT-J oint Geometry and Design

t

D T

np

o A A

=

t

D T

np

o A A

=

9

t

D T

np

o A A

=

t

D T

np

o A A

=

10

Coefficient of Thermal Expansion

(CTE)

Global, local and internal effects result

from the CTE difference between

Component and PWB

Solder and metallizations

Different phases in solder etc.

Heating and cooling operations during

soldering processes can result in

extremely large ATs and temperature

gradients

Also power dissipation during use can

cause problems

Complicated states of stress and strain

may result

SMT-J oint Geometry and Design

t

D T

np

o A A

=

Aside from modeling, solder joint reliability is also assessed

through reliability testing.

Reliability testing consists of subjecting representative samples

bearing the solder joint of interest to industry-standard

reliability tests so that:

1) factors that cause or accelerate the various solder joint failure

mechanisms will be uncovered and understood

2) actual reliability data may be generated for further analysis.

Solder J oint Reliability

11

Solder volume associated with a joint affects the stress distribution and

can also affect crack propagation rates once crack has been initiated

Poorly formed joints can have built-in stress concentration sites that provide

premature crack initiation

Large solder volumes in leadless chip carriers have demonstrated better fatigue

resistance than smaller- volume joints

Larger volumes distribute the applied stress over larger cross-sectional area

Also large solder volume provides additional area for the crack to propagate

through

The main factors determining reliable solder joint are:

Uniform properties

Chemical composition

Microstructure

Joint shape

SMT-J oint Geometry and Design

Through-hole joint configurations refer to package types in

which the component leads are inserted and soldered into

predrilled holes in PWB

Solder J oint Reliability- Through Hole Components

12

As PTH-joints are generally very reliable especially from mechanical

point of view, most problems arise from the quality of coatings and

manufacturing process.

Some rules of thumb:

A gap of 150-200m between lead and hole wall is normally specified

The protrusion of lead should be kept small (0.8-2.0 mm) to minimize drainage

of the solder fillet

The through-hole pad should be round and approx. three times the lead

diameter

To maintain appropriate fillet formation, the minimum height of the lead

should equal the pad width

Solder J oint Reliability- Through Hole Components

Process problems

Cold joints

Temperature of the surfaces are not high enough

Dissolution is slowed down/ prevented

Wetting problems

Macroscopic movement during cooling

Voids/cavities

Crack nucleation sites

Solder bridging

Bath contamination (Zn, Cd)

icicling

Bridging (also wave pressure affects)

Solder J oint Reliability- Through Hole Components

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Experiments Manual To Accompany - Tokheim, RogerDocument418 pagesExperiments Manual To Accompany - Tokheim, RogerKarl Ng89% (9)

- Bolt Pressure DistributionDocument24 pagesBolt Pressure DistributionbitconceptsNo ratings yet

- Role of Additives in XLPE PDFDocument5 pagesRole of Additives in XLPE PDFbitconceptsNo ratings yet

- Long-Life Xlpe Insulated Power Cable PDFDocument6 pagesLong-Life Xlpe Insulated Power Cable PDFbitconceptsNo ratings yet

- 25 Permanent Magnet Motor Design PDFDocument39 pages25 Permanent Magnet Motor Design PDFbitconcepts60% (5)

- XMR AzDocument9 pagesXMR AzbitconceptsNo ratings yet

- Thermoelectric Cooling WhitepaperDocument9 pagesThermoelectric Cooling WhitepaperbitconceptsNo ratings yet

- 1 Numerical Analysis of Shock ResponseDocument115 pages1 Numerical Analysis of Shock ResponseLeonichevNo ratings yet

- CFX TutDocument149 pagesCFX Tutthiagopalmieri3253No ratings yet

- Condenser Design in Aspen PlusDocument9 pagesCondenser Design in Aspen Plusvsraochemical1979100% (7)

- Synchro and Resolver Hand BookDocument35 pagesSynchro and Resolver Hand BookAbdul KurniadiNo ratings yet

- Three-Dimensional Integrated Circuits (3D IC) Floorplan and Power/Ground Network Co-SynthesisDocument6 pagesThree-Dimensional Integrated Circuits (3D IC) Floorplan and Power/Ground Network Co-SynthesisVikas ZurmureNo ratings yet

- CS302 Short NotesDocument13 pagesCS302 Short NotesAbdul WahabNo ratings yet

- Lecture Notes - Voltage ControlDocument12 pagesLecture Notes - Voltage ControlNik Mohd Bazli100% (1)

- SiC MOS UIS Failure Mechanism of SiC Power MOSFETsDocument5 pagesSiC MOS UIS Failure Mechanism of SiC Power MOSFETsterry chenNo ratings yet

- "Simple Touch Alarm System" Subject: Report On Course Project OnDocument14 pages"Simple Touch Alarm System" Subject: Report On Course Project OnRichaNo ratings yet

- Project On Substation 220kv 132kvDocument40 pagesProject On Substation 220kv 132kvindianapsterNo ratings yet

- Luminescence, Plasmonic, and Magnetic Properties of Doped Semiconductor NanocrystalsDocument17 pagesLuminescence, Plasmonic, and Magnetic Properties of Doped Semiconductor NanocrystalsTrần ChứcNo ratings yet

- Measuring CMOS Dynamic Input CapacitanceDocument118 pagesMeasuring CMOS Dynamic Input CapacitanceDalton BentleyNo ratings yet

- Estamat PFC Mounting Instructions Mv1161: Issue February 2002 Document Number: 13124Document38 pagesEstamat PFC Mounting Instructions Mv1161: Issue February 2002 Document Number: 13124aroybNo ratings yet

- Unit-III Bipolar Junction Transistor PDFDocument16 pagesUnit-III Bipolar Junction Transistor PDFAnonymous 4F6VkOkWNo ratings yet

- Nema MG2 PDFDocument40 pagesNema MG2 PDFRyukiNo ratings yet

- LICA NotesDocument20 pagesLICA NotesSatya Narayana100% (1)

- Arkan Kovan ABudllahDocument13 pagesArkan Kovan ABudllahYasir Yasir KovanNo ratings yet

- HCPL 314JDocument14 pagesHCPL 314JonafetsNo ratings yet

- MPXV7007Document11 pagesMPXV7007Phi MacNo ratings yet

- C DilmDocument61 pagesC DilmotavioalcaldeNo ratings yet

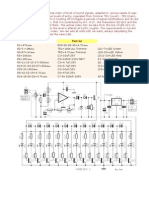

- Circuit of Optical Index of Level of Sound SignalsDocument1 pageCircuit of Optical Index of Level of Sound Signalsionioni2000No ratings yet

- Ntroduction To Pintronics: Josh Schaefferkoetter February 27, 2007Document21 pagesNtroduction To Pintronics: Josh Schaefferkoetter February 27, 2007irmaNo ratings yet

- PLA M Series RelaysDocument2 pagesPLA M Series RelaysYogesh DetheNo ratings yet

- Thermal Cooling Fan ControllerDocument2 pagesThermal Cooling Fan ControllerPabloReyesNo ratings yet

- The Breaker Failure Protection BFP Schemes in UtilitiesDocument9 pagesThe Breaker Failure Protection BFP Schemes in UtilitiesTrigras Bangun PerkasaNo ratings yet

- PM4Q (Admzp0da)Document29 pagesPM4Q (Admzp0da)Ricardo Gamez OrtegaNo ratings yet

- Translate SchaumDocument1,035 pagesTranslate SchaumImam RinjaniNo ratings yet

- Supresores TipoCDocument16 pagesSupresores TipoCCristian Garcia MartinezNo ratings yet

- 12.1 The Bipolar-Junction Transistor: Basic PrinciplesDocument25 pages12.1 The Bipolar-Junction Transistor: Basic PrinciplessamuraiNo ratings yet

- 2 SK 1056Document9 pages2 SK 1056Bryan WahyuNo ratings yet

- Biasing For Zero Distortion: Using The EKV/BSIM6 ExpressionsDocument6 pagesBiasing For Zero Distortion: Using The EKV/BSIM6 ExpressionsLaurMateiNo ratings yet

- Charger M HDocument4 pagesCharger M HgeorgeNo ratings yet