Professional Documents

Culture Documents

Sec-I 140

Uploaded by

Panchal ShaileshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec-I 140

Uploaded by

Panchal ShaileshCopyright:

Available Formats

2007 SECTION I

(c) The tubes shall not exceed 4 in. (100 mm) O.D., except for P-No. 1 material, which shall not exceed 6% in. (170 mrn) O.D. (d) The welding procedure used for the rework welding shall have been qualified to the requirements of Section IX for the thickness of rework welding to be performed and for the omission of postweld heat treatment.

PW-40.3 Defects in P-No. 1 Group Nos. 1, 2, and 3 materials, and in P-No. 3 Group Nos. 1 and 2 materials, and in the welds joining these materials, may be weld repaired after the final PWHT but prior to the final hydrostatic test. The welded repairs shall meet the requirements below. PW-40.3.1 Defect Removal for Base Materials. The defect shall be removed or reduced to an acceptable size. Before repair welding, the groove shall be examined to verify that the defect has been reduced to an acceptable size, using either the magnetic particle or the liquid penetrant examination methods. When the material is nonmagnetic, only the liquid penetrant method shall be used. Methods for magnetic particle examination and liquid penetrant examination shall be in accordance with A-260 and A-270, respectively; however, the acceptance standards for the examination shall be in accordance with the requirements of the original base material specification. PW-40.3.2 Defect Removal for Welds and Welded Repairs. The defect shall be removed, and the groove examined to verify defect removal, using either the magnetic particle or the liquid penetrant examination methods. When the material is nonmagnetic, only the liquid penetrant method shall be used. Methods and acceptance standards for magnetic particle examination and liquid penetrant examination shall be in accordance with A-260 or A-270, respectively. PW-40.3.3 The total repair depth shall not exceed 10% of the base material thickness. The total depth of a weld repair shall be taken as the sum of the depths for repairs made from both sides of a weld at a given location. The total area of such repairs shall not exceed 100 in. 2 (0.065 m2). PW-40.3.4 In addition to the requirements of Section IX for qualification of welding procedure specifications for groove welds, the following requirements shall apply: (a) The weld procedure qualification shall have been made using material of the same P-No. and Group No. as the material to be repaired. The specific welding technique or combination of welding techniques used shall have been developed and tested to assure adequate tempering of the underlying weld bead heat-affected zones. (b) The weld metal shall be deposited by the manual shielded metal-arc process. Only low hydrogen welding electrodes shall be used. The electrodes shall be properly

102

conditioned in accordance with Section II, Part C, SFA5.5, Appendix A6.11. (c) The maximum heat input for each weld layer shall not exceed that used in the procedure qualification test. (d) The maximum deposited weld bead width for any electrode shall be four times the electrode core diameter. (e) The repair area, including a band equal in width to 4 in. (100 mrn) or four times the thickness of the weld repair, whichever is greater, on either side of the groove, shall be preheated and maintained at a minimum temperature of 350F (175C) during welding. The maximum interpass temperature shall be 450F (230C). (f) The repair weld method shall be limited to the half bead weld repair technique as follows. The initial layer of weld metal shall be deposited over the entire area using Ys in. (3 mrn) maximum diameter electrodes. Approximately one half the thickness of this layer shall then be removed by grinding before depositing subsequent layers. The subsequent weld layers shall be deposited using ~2 in. (4 mm) maximum diameter electrodes, in such a manner as to assure tempering of the prior weld beads and their heat affected zones. A final temper bead weld shall be applied to a level above the surface being repaired without contacting the base material, but close enough to the edge of the underlying weld bead, to assure tempering of the base material heat affected zone. PW-40.3.5 For materials greater than 1 in. (25 mm) thick, after completing all welding, the repair area shall be heated to and maintained at a temperature of 450F to 550F (230C to 290C) for a minimum period of 4 hr. PW-40.3.6 Any final temper bead reinforcement shall then be removed substantially flush with the surface of the base material. PW-40.3.7 After the finished repair weld has reached ambient temperature, it shall be examined to the requirements of PW-40.3.2, using the same nondestructive examination technique that was used to examine the weld groove. PW-40.3.8 The vessel shall be hydrostatically tested in accordance with PW-54. PW-40.3.9 The Manufacturer shall obtain the approval of the Authorized Inspector, prior to making the repair.

PW-41

CIRCUMFERENTIAL JOINTS IN PIPES, TUBES, AND HEADERS

The rules in the following paragraphs apply specifically to the boiler proper and parts thereof. PW-41.1 Circumferential welded butt joints in pipe, tubes, and headers shall meet the radiographic and ultrasonic examination requirements of Table PW-11.

You might also like

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 pageTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNo ratings yet

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshNo ratings yet

- Sec-I 139Document1 pageSec-I 139Panchal ShaileshNo ratings yet

- Sec-I 138Document1 pageSec-I 138Panchal ShaileshNo ratings yet

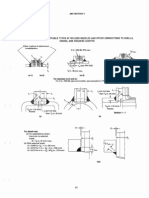

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Sec-I 130Document1 pageSec-I 130Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNo ratings yet

- Sec-I 136Document1 pageSec-I 136Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNo ratings yet

- Sec-I 129Document1 pageSec-I 129Panchal ShaileshNo ratings yet

- Sec-I 132Document1 pageSec-I 132Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNo ratings yet

- Sec-I 133Document1 pageSec-I 133Panchal ShaileshNo ratings yet

- Sec-I 131Document1 pageSec-I 131Panchal ShaileshNo ratings yet

- Sec-I 128Document1 pageSec-I 128Panchal ShaileshNo ratings yet

- Sec-I 127Document1 pageSec-I 127Panchal ShaileshNo ratings yet

- Sec-I 119Document1 pageSec-I 119Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNo ratings yet

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 pageFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNo ratings yet

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 pageFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNo ratings yet

- Sec-I 121Document1 pageSec-I 121Panchal ShaileshNo ratings yet

- Sec-I 117Document1 pageSec-I 117Panchal ShaileshNo ratings yet

- Sec-I 116Document1 pageSec-I 116Panchal ShaileshNo ratings yet

- Boiler welding design rules for joints of unequal thicknessDocument1 pageBoiler welding design rules for joints of unequal thicknessPanchal ShaileshNo ratings yet

- Sec-I 114Document1 pageSec-I 114Panchal ShaileshNo ratings yet

- Sec-I 113Document1 pageSec-I 113Panchal ShaileshNo ratings yet

- Horizontal-return tubular boiler locationsDocument1 pageHorizontal-return tubular boiler locationsPanchal ShaileshNo ratings yet

- Sec-I 112Document1 pageSec-I 112Panchal ShaileshNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Industrial Training PresentationDocument9 pagesIndustrial Training PresentationSyazaNo ratings yet

- Upmilling Vs DownmillingDocument4 pagesUpmilling Vs DownmillingSaurabh BiswasNo ratings yet

- Assignment 1 For AMTDocument5 pagesAssignment 1 For AMTPrasanna TikarNo ratings yet

- Cold Chain Logistics in ChinaDocument8 pagesCold Chain Logistics in ChinaSunny ZhengNo ratings yet

- Supply Chain Management-BinusDocument8 pagesSupply Chain Management-BinusdsuharnoNo ratings yet

- Front Office OperationDocument29 pagesFront Office OperationKrista ZeyNo ratings yet

- InterExchange JobListingsDocument742 pagesInterExchange JobListingsAdmir BerbiuNo ratings yet

- Indian Institute of Technology Kanpur Institute Works Department Division - IDocument12 pagesIndian Institute of Technology Kanpur Institute Works Department Division - ISantosh ThakurNo ratings yet

- Effect of Depth of Cut On MRR in Surface GrindingDocument7 pagesEffect of Depth of Cut On MRR in Surface GrindingshubhamNo ratings yet

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDocument6 pagesAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- PSB Administrative Order No. 06, SDocument15 pagesPSB Administrative Order No. 06, SMeg Sembrano50% (2)

- The Future of The Logistics IndustryDocument20 pagesThe Future of The Logistics IndustryTubagus Donny SyafardanNo ratings yet

- Shur JointDocument132 pagesShur JointCleiton Rodrigues100% (1)

- Save PetrolDocument9 pagesSave PetrolMaliniUpadhyaNo ratings yet

- Transport DiaryDocument2 pagesTransport Diaryapi-532456098No ratings yet

- Aircraft Fuselage Construction TypesDocument7 pagesAircraft Fuselage Construction TypesRajesh KumarNo ratings yet

- 2 1 4 P Framedesign Engine 1Document3 pages2 1 4 P Framedesign Engine 1api-345465088No ratings yet

- Industrial Maintenance Loctite® Wastewater Treatment GuideDocument6 pagesIndustrial Maintenance Loctite® Wastewater Treatment GuideDragoslav DzolicNo ratings yet

- FuturePipe SRC FlyerDocument4 pagesFuturePipe SRC FlyerA_ValsamisNo ratings yet

- Method For Concrete Repair - 11.12.13Document3 pagesMethod For Concrete Repair - 11.12.13imran11novNo ratings yet

- ENGINEERING DESIGN GUIDELINES FOR PAVEMENT DESIGNDocument13 pagesENGINEERING DESIGN GUIDELINES FOR PAVEMENT DESIGNShida ShidotNo ratings yet

- Company MergersDocument9 pagesCompany MergersShriram JaiswalNo ratings yet

- To TIG or MIG: Choosing the Right WelderDocument2 pagesTo TIG or MIG: Choosing the Right WeldersuparnaNo ratings yet

- Role of Transport in Logistics ChainsDocument14 pagesRole of Transport in Logistics ChainsArun RaiNo ratings yet

- PGDM OM 3.1 Logistics ManagementDocument1 pagePGDM OM 3.1 Logistics ManagementAlok SinghNo ratings yet

- Galvashield LJDocument4 pagesGalvashield LJkalidindivenkatarajuNo ratings yet

- List of Agricultural Training Institutes 2018-2019Document2 pagesList of Agricultural Training Institutes 2018-2019MATHIAS KAVISHE LEKUNDAYO75% (4)

- System Description Englisch 01Document10 pagesSystem Description Englisch 01dannyzuanNo ratings yet

- A New Era For AirshipsDocument5 pagesA New Era For AirshipsHajdu CsabaNo ratings yet

- Impact of Just-In-Time Inventory Systems On OEM Suppliers: Imds 106,2Document18 pagesImpact of Just-In-Time Inventory Systems On OEM Suppliers: Imds 106,2newview111No ratings yet