Professional Documents

Culture Documents

Ref. - No.: 261 - Ruston Gas Turbine Power Generation Packages

Uploaded by

scribdkhatnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ref. - No.: 261 - Ruston Gas Turbine Power Generation Packages

Uploaded by

scribdkhatnCopyright:

Available Formats

Turbinen- und Anlagentechnik GmbH

Schulstrae 43 D-65795 Hattersheim / Germany Telefon : +49 6190 891678 Telefax : +49 6190 72546 E-Mail : tuba@tuba-turbine.de Internet : www.tuba-turbine.de

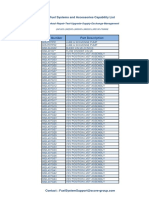

Ref. No.: 261 - Ruston Gas Turbine Power Generation Packages -

Description

Technical Data & Scope of Supply Unit 1 Alstom/Siemens TA1750 1980 1.1 MW 17.6% Dual Fuel Unit 2 Alstom/Siemens TA1750 1980 1.1 MW 17.6% Dual Fuel Unit 3 Alstom/Siemens TA1750 1980 1.1 MW 17.6% Dual Fuel

Turbine Manufacturer Turbine Type Date of Manufacture Power Rating ISO Efficiency Fuel Configuration Mounting Acoustics Start System Emissions Primary Steam/Water Injection Secondary Steam/Water Injection Operating Hours

261RustonTA

Skid

N/A Electrical N/A N/A N/A 49,810

Skid

N/A Electrical N/A N/A N/A 54,901

Skid

N/A Electrical N/A N/A N/A 51,339 1

(Package) Operating Hours (Gas Generator) Operating Hours (Power Turbine) Number Starts

49,810 49,810 654

54,901 54,901 461

51,339 51,339 550

Main Gearbox

Manufacturer Date of Manufacture Type RPM Running Hours

ALLEN-STOECK 1980 ALLEN-STOECK 1980 ALLEN-STOECK 1980

EPICICLYC EPICICLYC EPICICLYC 1,500 1,500 49,810

1,500 54,901

51,339

Alternator

Manufacturer Date of Manufacture Power Output kVA RPM Hertz Insulation Class Power Factor kW Amps Volts GEC GEC 1980 1,300 1,500 1,500 50 50 F 0.8LAG GEC 1980 1,300 1,500 50 F 0.8LAG

1980 1,300

F 0.8LAG

1,040 68

11,000 11,000

1,040 68

11,000

1,040 68

- Technical description TA1750 Refurbished Gas Turbine Packages We offer the well respected TA1750 gas turbines within a range of refurbished gas turbine packages to suit most customers' current needs. Building on our experience as RUSTON GAS TURBINES we now offer these units with the following enhancements and typical scopes of supply: TA1750 The refurbished TA1750 offers the established customer complete on-going fleet compatibility with their existing installations. Offered as driver only, generator, pump, or compressor packages, the TA1750 can generally be completely refurbished in less than 16 weeks from order placement for a standard style package. The TA1750 in it's refurbished form benefits strongly from re-engineering of the on-package systems. Compared to original-build TA machines a typical refurbished TA has the following enhancements: Gas Turbine

Fully refurbished rated core 2

261RustonTA

Refurbished or New hot path blading Cold path blading being sampled, and unacceptable blades replaced as necessary

New Bearings

Combustion chamber & hot elbow linings replaced Certified performance-tested gas generator Engine LP duct & exhaust elbow insulation replaced with new improved non-asbestos type

Gearbox

Refurbished gearcase All new internals, or fully refurbished

Gas Fuel System

Refurbished, tested & certified demister to existing design All new STAR fuel valves mounted within a new purpose-designed Fuel Valve Module, conveniently located on the turbine underbase Pressure monitoring by transmitters & differential transmitter direct to control suite New solenoid-operated safety shut-off valves fitted to system All new stainless steel 316L piping throughout, with double ferrule fittings where possible Fuel valve module incorporates fitted gauges of 100mm diameter, for fuel pressure; lube oil pressure & lube oil temperature

Lube Oil System

Refurbished, or new, engine-driven lube oil pump Refurbished auxiliary lube oil pump & DC flameproof motor Lube Oil system design to the proven TA standard with additionally... New Duplex filters & cartridges Stainless steel piping downstream of filters to bearings All new piping connections

Servo system removed ( no longer required )

Not required with a STAR fuel system from new Engine management now via PLC Controls More accurate fuel & speed monitoring Mechanical governor redundant, gearbox top now has better access Load & start limiters redundant Servo operated fuel shut-off valves replaced by new solenoid-operated type Instrument cabinet removed & replaced by new fuel valve module assembly Servo piping removed, reducing risk of oil leakage & improving engine access cleanliness

Gas Start System

Refurbished motor All new supply & vent piping

261RustonTA

Compressor cleaning system

Optional conventional TA dry wash system, or simple manual fluid wash system with combustion chamber auto drain valve

Junction Boxes

New Klippon TB range To current safety standards, BASEEFA certified, Eexe High ingress protection, IP66 All junction boxes located in one area for ease of access & cabling

Cables

Modern EPR/CSP rubber shipwiring cables Steel wire braided for mechanical strength & flexibility Heat & oil resistant, flame retardant

Thermocouples

Current standard, more robust than original type Wired via safety barriers to be intrinsically safe

Earthing

All electrical devices & junction boxes are now individually earthed for added safety

Control System

New PLC or RUSTRONIC MKII control system Compact single bay cabinet Fully integrated controls for all gas turbine functions & driven unit Control System New PLC or RUSTRONIC MKII control system Compact single bay cabinet Fully integrated controls for all gas turbine functions & driven unit batteries NiCd type, able to operate over a wide range of ambient temperatures Long life, typically 25 years Good performance at low temperatures, with resistance to high temperature ageing Resistance to electrical abuse Resistance to mechanical shock & vibration Simple maintenance Low installation cost & life cycle cost Strong, welded polypropylene cases

Battery Charger

New compact, efficient, & reliable unit Provides AC power to TCM & includes controller for lube oil pump motor Separate DC contactor box no longert required

Combustion Air inlet system

New Combustion Air Filter incorporating modern filter technology and design, specifically matched to suit the installation conditions 4

261RustonTA

All new ducting throughout, based on the existing design New silencer with improved attenuation All new fasteners & joints

Combustion Exhaust system

All new ducting based on the existing layout New silencer with improved attenuation ( if required ) Non-asbestos insulation applied to diffuser section All new fasteners & joint

Air Blast Lube Oil Cooler

New cooler manufactured by Specialist Heat Exchangers to well-proven long life design All new high specification copper/copper matrix. High ambient 240,000 Btu/hr heat dissipation Supplied with sun canopy (if required)

Lube Oil Tank Breather system

All new latest standard 4 stainless steel piping Stainless steel enhanced design Flame Trap

General

The turbine undergoes a full & thorough clean & repaint to as-new condition A refurbished TA1750 packaged set will typically comprise the following:

Core Engine

The model RUSTON TA1750 twin shaft heavy duty industrial gas turbine, refurbished, tested and warranted complete with: Air inlet casing phased vertically upwards Air inlet flexible joint Gas generator assembly, including water wash compressor cleaning Combustor assembly incorporating one single combustion chamber Power turbine assembly Exhaust outlet casings phased vertically upwards

Lube Oil System

Refurbished Lube oil system serving the gas turbine, gearbox and driven unit Lube oil tank in carbon steel New Main pump, gearbox driven Auxiliary pump, DC electric motor driven, for pre- and post-lubrication Lube oil supply piping in stainless steel downstream of the filters Duplex filters with indicator; dp transmitter and manual changeover valve New Lube oil pressure gauge and transmitter New Oil tank temperature transmitter Oil tank level gauge

261RustonTA

Gas Fuel System

New Gas fuel piping in 316L stainless steel New Gas fuel pressure gauge New STAR Gas fuel valve, actuator-operated New Gas fuel pressure transmitters New Gas fuel differential pressure transmitter New Gas shutoff valves, automatic solenoid-operated New Fuel Valve module for mounting the above Refurbished Gas fuel demister New Gas fuel Pressure Regulator/Relief Valve ( if required ) New Block and Vent Valves supplied loose for off-package mounting

Liquid Fuel System (if required)

New Liquid fuel piping in 316L stainless steel New/Refurbished AC Motor-driven Liquid Fuel Pump New/Refurbished Duplex Liquid Fuel Filters New Liquid fuel pressure gauge New STAR Liquid fuel valve, actuator operated New Liquid fuel pressure transmitters New Liquid fuel differential pressure transmitter New Liquid shutoff valve, automatic solenoid operated New Fuel Valve module for mounting the above

New Block and Thermal Relief Valves supplied loose for off-package mounting

New Air Purge System

Starting System

New/refurbished Gas Starter Motor New/refurbished Gas Start Piping system New Block and Vent Valves supplied loose for off-package mounting

Gearbox

Refurbishment of the turbine output gearcase Refurbished/new reduction gear assembly

Coupling

New Flexible element type output shaft coupling New Coupling Guard ( Industrial grade brass )

Underbase

Refurbishment of the TA standard design underbase of fabricated carbon steel construction with integral lube oil tank and designed for mounting of the gas turbine

Instrumentation

New Air Inlet Temperature Thermocouples; Crossover Duct Thermocouples and Interduct Thermocouples Refurbished Compressor Turbine speed pick-up New Power Turbine speed pick-up New Accelerometer mounted on gas generator 6

261RustonTA

New Accelerometer mounted on gearbox

New Control System

New PLC or MKII based Control System including: Starting and stopping sequencing Fault monitoring Status annunciation Speed governing module Temperature monitoring for turbine All necessary controls for normal operation and emergency protection Vibration monitoring for turbine & gearbox using Entek - IRD 3100 series English language annunciation on the control system VDU

Electrical Accessories

New on-package AC & DC cabling New Integral earth protection bonding New Battery charger/inverter New Battery Cabinet New 24V Ni-Cd batteries New Junction Boxes located at non-drive end of turbine New Emergency Stop button on each side of package All on package electrical equipment to Zone 2 area classification

Turbine/Generator Skid

New fabricated carbon steel skid for the Gas Turbine/AC Generator Package forming a single lift for transport and installation.

Driven Unit

New or Refurbished driven unit to suit client's requirements

Acoustic Enclosure

New Acoustic Enclosure to reduce overall package noise to a level of 85dB(A) New Ventilation Air Inlet Screen New Ventilation Air Fan New Ventilation Air Inlet and Outlet Dampers New Ventilation Air Inlet and Outlet Silencers for an overall 85dB(A) rating New Ventilation Air Inlet/Outlet Ducting New Fire Protection and Gas Detection System New twin shot CO2 fire suppression system

Alternative Turbine/Driven Unit Canopy

New open-sided canopy over turbine &/or driven unit, designed to support ancillary equipment

Lub Oil Cooler

New Air Blast Radiator type Lubricating Oil Cooler with AC electric motor-driven cooling fan, suitable for maximum site ambient temperature, remote-mounted 7

261RustonTA

Lube Oil Tank Breather System

New off-package Breather System including Sand Trap, Flame Trap and stainless steel piping

Combustion Air Inlet System

New 3-stage Combustion Air Inlet Filter with housing New Industrial grade Combustion Air Inlet Silencer for an overall 85dBA rating New Air Inlet Ducting / Transition duct

Exhaust Outlet System (Twin Stack)

New/Refurbished Twin Exhaust Diffuser New Exhaust Ducting Stack (to elevation of approx. 6m above grade) New Exhaust Silencer(s) for an overall 85dB(A) rating New Exhaust Drain Piping

Miscellaneous

Our standard industrial quality paint finish Our standard Quality Assurance Programme Standard Works Performance Test of Gas Generator

Tools and Installation Materials

One Set of commissioning tools and equipment (per site) One Set of consumable commissioning spare parts (per site)

Drawings and Documentation

3 copies - Standard set of Drawings and Documentation 3 copies - Operating and Maintenance Instruction Manuals 3 copies - Spare Parts Lists

261RustonTA

You might also like

- CapabilityList Score Part NumbersDocument150 pagesCapabilityList Score Part NumbersEDBNo ratings yet

- Overview of SCF6 ExchangeDocument2 pagesOverview of SCF6 Exchangechdi100% (1)

- Update Material For MI CTG 103 EditDocument48 pagesUpdate Material For MI CTG 103 Editabdi negaraNo ratings yet

- GT Major Overhaul ReportDocument30 pagesGT Major Overhaul ReportFarrukh AhmedNo ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladNo ratings yet

- Equipment Definition: Component LiteratureDocument11 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- STK BSC AvailabilityDocument4 pagesSTK BSC AvailabilityNanthini PalanisamyNo ratings yet

- LM Gas Turbine Spare Parts ListDocument3 pagesLM Gas Turbine Spare Parts ListMohamed Bin IerousNo ratings yet

- Mnit001 Meter Manual PDFDocument9 pagesMnit001 Meter Manual PDFSergio Andres Rivera JaramilloNo ratings yet

- LM6000-InD-239 - Improved LPT Coupling NutDocument9 pagesLM6000-InD-239 - Improved LPT Coupling NutIqbal UsmaniNo ratings yet

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pages(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- Solar 5.2MVADocument15 pagesSolar 5.2MVAsohaila7No ratings yet

- Datasheet Industrial 501 Kb7sDocument2 pagesDatasheet Industrial 501 Kb7sNebojsa100% (1)

- 2.3.8 Liquid FuelDocument16 pages2.3.8 Liquid FuelSarah CohenNo ratings yet

- Technical Paper - SGT400 ASME 2002Document9 pagesTechnical Paper - SGT400 ASME 2002usaid saifullahNo ratings yet

- Spare Part WS2&R2Document24 pagesSpare Part WS2&R2Anonymous Mm6ffYNo ratings yet

- Kawasaki GPB30 Gas Turbine Generator Operation and Troubleshooting GuideDocument65 pagesKawasaki GPB30 Gas Turbine Generator Operation and Troubleshooting GuideAceel FitchNo ratings yet

- SGT-200 (Tornado) : Capability Overview 2015Document17 pagesSGT-200 (Tornado) : Capability Overview 2015OmeedHassanNo ratings yet

- Ge LM6000 Training 1Document74 pagesGe LM6000 Training 1sasa hh100% (1)

- Sistema de Lubricacion de Turbina SGT 800Document10 pagesSistema de Lubricacion de Turbina SGT 800ginoNo ratings yet

- GE Energy Data Sheets Technical SpecificationsDocument7 pagesGE Energy Data Sheets Technical SpecificationsAbisholita MecaTronics100% (1)

- Factsheet Industrial Trent 60 Us LowresDocument2 pagesFactsheet Industrial Trent 60 Us LowresAsri GaniNo ratings yet

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDocument3 pagesDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezNo ratings yet

- Siemens Typhoon V1 CH01 PDFDocument48 pagesSiemens Typhoon V1 CH01 PDFbvq1987100% (3)

- NUOVO PIGNONE Compressor Spares (2010-37)Document4 pagesNUOVO PIGNONE Compressor Spares (2010-37)sianas1706No ratings yet

- Technical Specifications, Fuel Nozzle GR 127 PDFDocument8 pagesTechnical Specifications, Fuel Nozzle GR 127 PDFMadhan KumarNo ratings yet

- MFS Gas Turbine MaintenanceDocument34 pagesMFS Gas Turbine MaintenanceThanapaet Rittirut0% (1)

- Scope of Supply Titan130Document32 pagesScope of Supply Titan130danferreiro8318No ratings yet

- Seal Oil System Modifications Instability in The Seal Oil SystemDocument67 pagesSeal Oil System Modifications Instability in The Seal Oil SystemJONATHAN100% (1)

- Parts ListDocument31 pagesParts ListMohammed ElarbedNo ratings yet

- Vol IV Illustrated Part ListDocument460 pagesVol IV Illustrated Part ListmargaretramosNo ratings yet

- Improve force feed lubrication upgradesDocument8 pagesImprove force feed lubrication upgradesdiego yecid millan mendozaNo ratings yet

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocument13 pagesI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifNo ratings yet

- 4-Hour Lockout Avoidance For LM2500 and LM6000 Gas Turbines: Conversion, Modification and Upgrade OfferingDocument1 page4-Hour Lockout Avoidance For LM2500 and LM6000 Gas Turbines: Conversion, Modification and Upgrade OfferingabedurahmanNo ratings yet

- Parts 328 - WWW - Powerplant.partsDocument31 pagesParts 328 - WWW - Powerplant.partsQuinhan LtdNo ratings yet

- Oman Energy Conference - World Record Gas Turbine Service ExperiencesDocument16 pagesOman Energy Conference - World Record Gas Turbine Service ExperiencesabelsgNo ratings yet

- BHGE Antisurge Valves BrochureDocument2 pagesBHGE Antisurge Valves BrochureAnderson SiqueiraNo ratings yet

- 03 Product OverviewDocument44 pages03 Product OverviewMamdouh ElhanafyNo ratings yet

- LM6000 PC O&M - GEK 105059 CHG 06Document1,988 pagesLM6000 PC O&M - GEK 105059 CHG 06Alejandro J. Vigo50% (2)

- Datasheet lm500 PDFDocument2 pagesDatasheet lm500 PDFvcharlesNo ratings yet

- Parts ListDocument31 pagesParts ListMohammed ElarbedNo ratings yet

- GE Energy - MS7001EA Gas TurbineDocument2 pagesGE Energy - MS7001EA Gas TurbineJiho AhnNo ratings yet

- GTG 1699iec Solart60 60hzDocument10 pagesGTG 1699iec Solart60 60hzKhaldoon Alnashi100% (1)

- 04 - LM2500 OverviewDocument27 pages04 - LM2500 OverviewLudovic LeroyNo ratings yet

- A-VIP Compressor BrochureDocument6 pagesA-VIP Compressor BrochureAvrinFakherniaNo ratings yet

- Siemens Technical Paper Gas Turbine ModernizationDocument14 pagesSiemens Technical Paper Gas Turbine ModernizationAldiarso UtomoNo ratings yet

- Fr5002D Turbine CasingDocument13 pagesFr5002D Turbine CasingJJ100% (1)

- 01 Tab01 130916060639 Phpapp02 PDFDocument36 pages01 Tab01 130916060639 Phpapp02 PDFajo zinzoNo ratings yet

- Ficha Técnica Engine Gas L7042GSI PDFDocument2 pagesFicha Técnica Engine Gas L7042GSI PDFCamilo Sanchez VanegasNo ratings yet

- Gek105054 File0007Document18 pagesGek105054 File0007outilprok22kNo ratings yet

- Electrical Equipment and Instrumentation CatalogDocument247 pagesElectrical Equipment and Instrumentation CatalogMahdi HassanNo ratings yet

- TIL 476C - Exhaust Temperature Spread GuidelinesDocument2 pagesTIL 476C - Exhaust Temperature Spread GuidelinesHernan Giraut100% (1)

- DDocument18 pagesDMahmoud El-abdNo ratings yet

- 3 U 141 IplDocument346 pages3 U 141 IplGAS PLANTNo ratings yet

- Paxman SpecsDocument9 pagesPaxman Specsbastech100% (2)

- Steam TurbineDocument27 pagesSteam Turbinecram1960100% (1)

- Hurto A PDVSA: Sobreprecio de $18,2MM Rolls Royce Trent60Document23 pagesHurto A PDVSA: Sobreprecio de $18,2MM Rolls Royce Trent60Tomás LanderNo ratings yet

- .: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWDocument10 pages.: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWAkram GeadNo ratings yet

- 60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BDocument5 pages60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BvcharlesNo ratings yet

- Industrial Diaphragm Valves: SaundersDocument14 pagesIndustrial Diaphragm Valves: SaundersscribdkhatnNo ratings yet

- Manual de Utilizare PT DELCOS Pro PDFDocument28 pagesManual de Utilizare PT DELCOS Pro PDFLucyan Ionescu100% (2)

- Connection of Redundant I/O Devices To S7-1500: Lredio LibraryDocument31 pagesConnection of Redundant I/O Devices To S7-1500: Lredio LibraryscribdkhatnNo ratings yet

- 2078 V1.0 ESD 5100 - Series PTI1000XC Datasheet 08 09 23 MH enDocument4 pages2078 V1.0 ESD 5100 - Series PTI1000XC Datasheet 08 09 23 MH ennhocti007No ratings yet

- 10 Vedlegg DDocument14 pages10 Vedlegg DscribdkhatnNo ratings yet

- Connection of Redundant I/O Devices To S7-1500: Lredio LibraryDocument31 pagesConnection of Redundant I/O Devices To S7-1500: Lredio LibraryscribdkhatnNo ratings yet

- 3500 Monitoring SystemsDocument12 pages3500 Monitoring SystemsscribdkhatnNo ratings yet

- Interfax Equipos Deiff y GobernadoresDocument40 pagesInterfax Equipos Deiff y Gobernadoreshumcata100% (2)

- 6.6 Wiring Diagram 6.6.1 Version GCP-20 & AMG 3/NEBDocument1 page6.6 Wiring Diagram 6.6.1 Version GCP-20 & AMG 3/NEBscribdkhatnNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Interfax Equipos Deiff y GobernadoresDocument40 pagesInterfax Equipos Deiff y Gobernadoreshumcata100% (2)

- 6.6 Wiring Diagram 6.6.1 Version GCP-20 & AMG 3/NEBDocument1 page6.6 Wiring Diagram 6.6.1 Version GCP-20 & AMG 3/NEBscribdkhatnNo ratings yet

- Boiler Controls and Systems: An OverviewDocument8 pagesBoiler Controls and Systems: An OverviewscribdkhatnNo ratings yet

- Eaton's MTL product range and the ATEX directive explainedDocument1 pageEaton's MTL product range and the ATEX directive explainedscribdkhatnNo ratings yet

- Diesel ECU and Fuel Injector DriversDocument32 pagesDiesel ECU and Fuel Injector DriversscribdkhatnNo ratings yet

- Steam Regenerators: Application Technical DataDocument1 pageSteam Regenerators: Application Technical DatascribdkhatnNo ratings yet

- Neural Network Monitoring System Used For The Frequency Vibration Prediction in Gas TurbineDocument5 pagesNeural Network Monitoring System Used For The Frequency Vibration Prediction in Gas TurbinescribdkhatnNo ratings yet

- REM610 Ref Manual IECDocument160 pagesREM610 Ref Manual IECfiatraj1No ratings yet

- Study of Selected Petroleum Refining Residuals Industry StudyDocument60 pagesStudy of Selected Petroleum Refining Residuals Industry StudyOsama AdilNo ratings yet

- Extinguishing Control Unit A6V10061857 HQ en PDFDocument4 pagesExtinguishing Control Unit A6V10061857 HQ en PDFscribdkhatnNo ratings yet

- Fan FactsDocument28 pagesFan FactsmadbakingNo ratings yet

- Extinguishing Control Unit A6V10061857 HQ enDocument38 pagesExtinguishing Control Unit A6V10061857 HQ enscribdkhatn0% (1)

- Overview of The Oil and Gas ExplorationDocument7 pagesOverview of The Oil and Gas ExplorationArcenio Jimenez MorganNo ratings yet

- Bently Nevada 22MDocument9 pagesBently Nevada 22MscribdkhatnNo ratings yet

- flwch2pg PDFDocument2 pagesflwch2pg PDFscribdkhatnNo ratings yet

- Lal 125Document20 pagesLal 125Zvonko TrajkovNo ratings yet

- Study of Selected Petroleum Refining Residuals Industry StudyDocument60 pagesStudy of Selected Petroleum Refining Residuals Industry StudyOsama AdilNo ratings yet

- Steam Regenerators: Application Technical DataDocument1 pageSteam Regenerators: Application Technical DatascribdkhatnNo ratings yet

- Gas Turbine ModellingDocument12 pagesGas Turbine ModellingscribdkhatnNo ratings yet

- ISO 18436 Category IV-4page-V04Document4 pagesISO 18436 Category IV-4page-V04scribdkhatnNo ratings yet

- Al Khanif 2Document31 pagesAl Khanif 2Muhammad DahlanNo ratings yet

- Air Regulations CPL Level QuestionsDocument56 pagesAir Regulations CPL Level QuestionsRahul100% (3)

- Ethylene Glycol PDFDocument2 pagesEthylene Glycol PDFAngela0% (1)

- Communicating Across AgesDocument35 pagesCommunicating Across AgesConrad TarihoranNo ratings yet

- Business Plan: in Partial Fulfillment For The Requirements in Entrepreneurship 2 Semester, S.Y. 2019-2020Document48 pagesBusiness Plan: in Partial Fulfillment For The Requirements in Entrepreneurship 2 Semester, S.Y. 2019-2020John Guden100% (1)

- Chapter Test A: Teacher Notes and Answers 17Document5 pagesChapter Test A: Teacher Notes and Answers 17Mmf 123 JanNo ratings yet

- Everything You Need to Know About Gas Metal Arc Welding (GMAWDocument31 pagesEverything You Need to Know About Gas Metal Arc Welding (GMAWAhmetDuranCeyhanNo ratings yet

- DC72D MK2 Genset Controller User Manual V1.5Document61 pagesDC72D MK2 Genset Controller User Manual V1.5Cristobal AvecillaNo ratings yet

- EPG Health Report The Future of HCP Engagement Impact 2023Document73 pagesEPG Health Report The Future of HCP Engagement Impact 2023paulilongereNo ratings yet

- Mindray UMEC 12 Specifications FDADocument11 pagesMindray UMEC 12 Specifications FDAAlejandra Baas GuzmánNo ratings yet

- 1 s2.0 S0149763418301957 MainDocument24 pages1 s2.0 S0149763418301957 MainjackNo ratings yet

- Duty Resume ReportDocument1 pageDuty Resume ReportaleemuddinNo ratings yet

- Distance Protection SchemesDocument10 pagesDistance Protection SchemesdebasishNo ratings yet

- Simonson 20033wDocument15 pagesSimonson 20033wbahrul.hidayah@yahoo.comNo ratings yet

- MSDS Summary: Naphtha VM&PDocument6 pagesMSDS Summary: Naphtha VM&PRizki Adwitiyo 'Dito'No ratings yet

- Transactional Analysis (TA)Document21 pagesTransactional Analysis (TA)Rohan TandonNo ratings yet

- ABS and Air Conditioner Wiring DiagramDocument207 pagesABS and Air Conditioner Wiring Diagramservice_00783% (30)

- Brake System Troubleshooting GuideDocument98 pagesBrake System Troubleshooting Guideruben7mojicaNo ratings yet

- Masagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningDocument6 pagesMasagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningjhonaNo ratings yet

- QCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)Document41 pagesQCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)lwin_oo2435No ratings yet

- Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetDocument4 pagesCompact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetLê ĐạtNo ratings yet

- Pastillas DelightDocument12 pagesPastillas DelightBryan DutchaNo ratings yet

- Thermax ION Exchange Resins SDS BrochureDocument8 pagesThermax ION Exchange Resins SDS Brochureparthibanemails5779No ratings yet

- Police Log January 23, 2016Document9 pagesPolice Log January 23, 2016MansfieldMAPoliceNo ratings yet

- Prof. J.L. HumarOffice: HP 3051Phone: 613-520-2600 ext. 3051Email: jhumar@cmail.carleton.caOffice Hours: Tuesdays and Thursdays, 2:00-3:00 pmDocument2 pagesProf. J.L. HumarOffice: HP 3051Phone: 613-520-2600 ext. 3051Email: jhumar@cmail.carleton.caOffice Hours: Tuesdays and Thursdays, 2:00-3:00 pmBhind NijjarNo ratings yet

- JSS20-48 Single Time Control Digital Display Time Relay: Page 1 / 2Document2 pagesJSS20-48 Single Time Control Digital Display Time Relay: Page 1 / 2FranciscoNo ratings yet

- تحليل البول بالصور والشرحDocument72 pagesتحليل البول بالصور والشرحDaouai TaaouanouNo ratings yet

- Round Warre HivesDocument16 pagesRound Warre HivesBender Rodríguez100% (1)

- Crypto Hash Algorithm-Based Blockchain Technology For Managing Decentralized Ledger Database in Oil and Gas IndustryDocument26 pagesCrypto Hash Algorithm-Based Blockchain Technology For Managing Decentralized Ledger Database in Oil and Gas IndustrySIMON HINCAPIE ORTIZNo ratings yet

- Establishment of Retirement PlanDocument3 pagesEstablishment of Retirement PlanVioleta StancuNo ratings yet