Professional Documents

Culture Documents

Data Sheet & SLD

Uploaded by

vaithy2011Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet & SLD

Uploaded by

vaithy2011Copyright:

Available Formats

Mangala Field Development Project Enchance Oil Recovery Pilot (EORP)Project

DATA SHEET FOR POWER AND MOTOR CONTROL CENTRE

B A REV

12.02.2010 08.02.2010 DATE

NAK NAK BY

Issued for Review / Comments Issued for DIC/IDR DESCRIPTION

BPR BPR CHK'D

ADS ADS APPR

CLIENT

TOTAL OR PARTIAL REPRODUCTION AND / OR UTILISATION OF THIS DOCUMENTATION ARE FORBIDDEN WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

Document No:

EORP-EL-J-001

DATA SHEET FOR POWER AND MOTOR CONTROL CENTRE

DOC. NO: SERVICE: EORP-EL-J-001 Power & Motor Control Centre TAG NO : PAGE NO: 2 1 of 4

EORP-PMCC

NO OF UNITS:

1. GENERAL DATA Installation Ref. Specification No. Codes and Standard IS IEC Ambient temp. : Max/Min Design ambient temp. Relative Humidity

: : : : : :

Onshore EORP-EL-S-001

Altitude : Location

42/10.6 deg C 50 / -2 deg. C. 23 TO 74 %

Less than 1000 m Indoor Outdoor Outdoor Seismic Zone : Zone - III Desert area, Humid and Corrosive

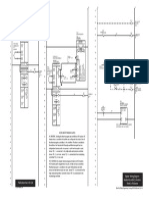

Atmosphere : 2. RATING Supply Voltage & Variation Frequency & Variation Number of Phases System Earthing Bus Bar Rating Supply system fault level (MVA/KA): Control Voltage Heater Circuit 3. TYPE Enclosure Metal Enclosed Metal Clad IP 42 6.OTHER Circuit Breaker Unit Mounting LV Switchboard (Incoming, Outgoing) Form of Construction Configuration / Feeder Arrangement MCCB (Outgoing) Air Circuit Breaker (Incomers) Single Front Double Front Draw Out Type (Incomers) Fixed Type (Outgoing) Form 4 Feeder List (EORP-EL-K-001) Key Single Line Diagram (EORP-EL-D-001) Protective Relay Incoming feeder connection point Electromechanical / Microprocessor based Top Bottom Cable Bus Duct Bottom Cable Top Bottom Painting Colour Painting Method : : : : : : : 415V (+/-) 10% 50HZ (+/-) 5% 3Ph + Netrual Reistance Earthed, 750mA Limit 1200A 50 kA for 1 sec 240V, AC 240V, AC 4.ACCESSORIES

Panel Space Heater Grounding Stud FloorFrame Internal Lighting Anchor Bolts Fuse Pullers 5.ADDITIONAL TEST According to Specification 1 2 3

Name Plate as per specification Lifting Lugs Internal Receptacle Breaker Trolley Colour mark for Buses Closing Rectifier

EORP-EL-001 Applied Standard

Degree of Protection

Manufacture's Standard As per Spec. (SUPP-ST-S-001) Manufacture's Standard As per Spec. (SUPP-ST-S-001)

7. NOTES 1. All status signals from PMCC to Instrument PLC will be through potential free contacts. 2. ON / OFF commands from instrument PLC to individual motor starters shall be through potential free contacts. 3. ESD Trip commands from Instrument PLC to air circuit breakers shall be through 24 VDC powered signal.

Outgoing feeder connection point Main Busbar Location

B A Rev

12.02.2010 08.02.2010 Date

NAK NAK Prepared

Issued for Review / Comments Issued for DIC/IDR Description

BPR BPR Checked

ADS ADS Approved

DATA SHEET FOR POWER AND MOTOR CONTROL CENTRE

DOC. NO: SERVICE: EORP-EL-J-001 Power & Motor Control Centre TAG NO : PAGE NO: 3 1 of 4

EORP-PMCC

NO OF UNITS:

DATA TO BE FILLED BY VENDOR 1 2 3 4 Equipment Tag No. Make Type / Designation Overall dimensions of PMCC - Width - Depth - Height Total Weight of PMCC Weight and Dimensions of largest shipping section - Weight - Width - Depth - Height Recommended clearances for PMCC - Front - Rear - Top - Sides Clearance in air Phase to Phase Phase to Earth Main Horizontal Busbars Main busbar current rating Main busbar size Main bas bar material Main bus bar location Vertical Busbars Busbar current rating Busbar size Busbar material Insulating material of busbars Earth Busbars Earth bus size Earth bus material 1 min. power frequency voltage 1.2/50 s Impulse withstand voltage 1 sec. short circuit withstand capacity 16 Peak dynamic withstand capacity 17 Safety shutter provided for test and drawout positions 18 MCCB 18.1 Rated current 18.2 Rated SC making capacity - Icm 18.3 Rated service SC breaking capacity - Ics 18.4 Thermal release setting range 18.5 Short circuit release setting range 18.6 Accessories - Auxiliary contacts - Shunt release - Undervoltage release - Trip alarm contacts - Rotary operating mechanism : : kA Yes / No : : : : : : : mm mm mm Kg 18.7 Mechanical life 19 CONTACTOR 19.1 Rated Current - AC-3 Duty - AC-4 Duty 19.2 Making Capacity 19.3 Breaking Capacity 19.4 Coil consumption - Pick up 19.5 Coil consumption - Hold on 19.6 No. of auxiliary contacts 20 THERMAL OVERLOAD RELAY 20.1 Setting range 20.2 Single phasing preventor 20.3 Temperature compensation feature 21 Heat Load of PMCC 22 AIR CIRCUIT BREAKERS 22.1 Rated current 22.2 Rated SC making capacity - Icm 22.3 Rated service SC breaking capacity - Ics 22.4 Type of built-in control unit 22.5 Auxiliary contacts 22.6 Closing & Trip Coil - Voltage - Power Consumption 23 Protective relays provided as per SLD 24 Indications / Alarms provided as per SLD 25 Interlocks and synchronizing facility privided as per SLD 26 Total Power Consumption for space heaters in PMCC 27 Mechanical life 28 Cable Glands with check nuts 28.1 Material / Type 28.2 Provided for all I/C & O/G power & control cables 29 Cable Lugs 29.1 Material / Type 29.2 Provided for all I/C & O/G power & control cables : : :

5 6

: : : : : : : : : : : : : : : : : : : : : : : : :

A A

VA at pf VA at pf NO + NC

: : : : : : : : : : : : : : : : : : : : : : :

Kg mm mm mm mm mm mm mm mm mm A sqmm Cu Top A sqmm Cu

Watts A kA kA

8 8.1 8.2 9 9.1 9.2 9.3 9.4 10 10.1 10.2 10.3 11 12 12.1 12.2 13 14 15

Yes / No Yes / No Yes / No

mm Cu kV kV kA

: : : : :

A kA kA

: : : : :

Note: Typical control schematic drawings for each type of feeder (motor feeder as well as power feeder) shall be prepared by vendor and submitted for Purchasers review and approval.

B A Rev

12.02.2010 08.02.2010 Date

NAK NAK Prepared

Issued for Review / Comments Issued for DIC/IDR Description

BPR BPR Checked

ADS ADS Approved

DATA SHEET FOR POWER AND MOTOR CONTROL CENTRE

DOC. NO: SERVICE: EORP-EL-J-001 Power & Motor Control Centre TAG NO : EORP-PMCC MAKE OF EQUIPMENT / COMPONENTS S.No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Item Electromechanical Relays Auxiliary relays Breaker control switch Power switches Control switches DC Switches CTs / PTs Meters PB & indicating lights Air circuit breakers Contactors Bimetallic relay Heavy duty switches / fuse switches / motor duty switches MCB Timer for re-acceleration Power fuse & base Control fuse & base MCCB Terminals Control transformer Battary (Ni-Cd) Battery charger Cable glands Cable lugs Vendor Alstom / ABB / Siemens / Easun Reyrolle Alstom / ABB / Siemens / Easun Reyrolle Alstom / RECOM Alstom / L&T / Siemens / Stromberg / Control & switchgear Alstom / L&T / Siemens / Kaycee Kaycee or equivalent AEP / Precise Electrical / Prayog / Silkans / Pragati AEP / Simco / IMP / MECO Siemens / L&T / Tecknic / BCH L&T / Siemens / Alstom / Control & switchgear L&T / Siemens / BCH / Telemechanique L&T / Siemens / BCH / Telemechanique Siemens / L&T / Alstom MDS / HAVELL / Indo-Asian BCH / Concord Siemens / L&T / Alstom Siemens / L&T / Alstom Siemens / L&T / Alstom ELMEX / TOSHA / Connectwell INDCOIL / AEP / Kappa / Precise Electrical AMCO / HBL-NIFE HBL-NIFE / Chhabi / Universal Industrial Products Comet / Baliga / Flexpro Dowell or equivalent PAGE NO: NO OF UNITS: 4 1 of 4

B A Rev

12.02.2010 08.02.2010 Date

NAK NAK Prepared

Issued for Review / Comments Issued for DIC/IDR Description

BPR BPR Checked

ADS ADS Approved

Mangala Field Development Project Enchance Oil Recovery Pilot (EORP)Project

DATA SHEET FOR DISTRIBUTION BOARDS

B A REV

12.02.2010 08.02.2010 DATE

NAK NAK BY

Issued for Review / Comments Issued For DIC/IDR DESCRIPTION

BPR BPR CHK'D

ADS ADS APPR

CLIENT

TOTAL OR PARTIAL REPRODUCTION AND / OR UTILISATION OF THIS DOCUMENTATION ARE FORBIDDEN WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

Document No:

EORP-EL-J-002

DATA SHEET FOR DISTRIBUTION BOARDS

DOC. NO: SERVICE: EORP-EL-J-002 Power DB Heat Tracing DB Lighting DB TAG NO : PAGE NO: 2 1 1 1 of 3

EORP-PDB EORP-HTDB EORP-LDB

NO OF UNITS:

1. GENERAL DATA Installation Ref. Specification No. Codes and Standard IS IEC Ambient temp. : Max/Min Design ambient temp. Relative Humidity

: : : : : :

Onshore EORP-EL-S-002

Altitude : Location

42/10.6 deg C 50 / -2 deg. C. 23 TO 74 %

Less than 1000 m Indoor Outdoor Outdoor Seismic Zone : Zone - III Desert area, Humid and Corrosive

Atmosphere : 2. RATING Supply Voltage & Variation Frequency & Variation Number of Phases System Earthing Bus Bar Rating Supply system fault level (MVA/KA): Control Voltage Space Heater Circuit 3. TYPE Enclosure Metal Enclosed Metal Clad IP 42 6.OTHER Circuit Breaker Unit Mounting LV Switchboard (I/C, O/G) Form of Construction Configuration / Feeder Arrangement ELCB / MCB (Outgoing) MCCB/ MCB (Incomers) Single Front Double Front Draw Out Type Fixed Type Form 2b Single Line Diagram (EORP-EL-D-002,003 & 004) Painting Colour Painting Method : : : : : : : 415V (+/-) 10% 50HZ (+/-) 5% 3Ph + Netrual Reistance Earthed, 750mA Limit As per SLD 10 kA for 1 sec 240V, AC 240V, AC 4.ACCESSORIES

Panel Space Heater Grounding Stud Wall mouting Internal Lighting Anchor Bolts Fuse Pullers 5. TESTS According to Specification 1 2 3

Name Plate as per specification Lifting Lugs Internal Receptacle Breaker Trolley Colour mark for Buses Closing Rectifier

EORP-EL-S-002 Applied Standard

Degree of Protection

Manufacture's Standard As per Spec. (SUPP-ST-S-001) Manufacture's Standard As per Spec. (SUPP-ST-S-001)

Protective Relay Incoming feeder connection point Top Bottom Cable Bus Duct Bottom Cable Top Bottom

Outgoing feeder connection point Main Busbar Location

B A Rev

12.02.2010 08.02.2010 Date

NAK NAK Prepared

Issued for Review / Comments Issued For DIC/IDR Description

BPR BPR Checked

ADS ADS Approved

DATA SHEET FOR DISTRIBUTION BOARDS

DOC. NO: SERVICE: EORP-EL-J-002 Power DB Heat Tracing DB Lighting DB TAG NO : PAGE NO: 3 1 1 1 of 3

EORP-PDB EORP-HTDB EORP-LDB

NO OF UNITS:

DATA TO BE FILLED BY VENDOR 1 2 3 3.1 3.2 3.3 4 4.1 4.2 4.3 5 5.1 5.2 6 6.1 6.2 6.3 6.4 7 8 8.1 8.2 9 10 11 12 12.1 12.2 13 13.1 13.2 Make Type / Designation Overall dimensions PDB HTDB LDB Total Weight PDB HTDB LDB Clearance in air Phase to Phase Phase to Earth Busbars Busbar current rating Busbar size Bus bar material Bus bar location Insulating material of busbars Earth Busbars Earth bus size Earth bus material 1 min. power frequency voltage 1 sec. short circuit withstand capacity Indications provided as per SLD Cable Glands with check nuts Material / Type Provided for all I/C & O/G cables Cable Lugs Material / Type Provided for all I/C & O/G cables : : : : : : : : : : : : : : : : : : : : : : : : mm mm mm Kg Kg Kg mm mm A sqmm Cu. Top 14.7 15 15.1 15.2 16 16.1 16.2 16.3 14 14.1 14.2 14.3 14.4 14.5 14.6 MCCB Rated current Rated SC making capacity - Icm Rated service SC breaking capacity - Ics Thermal release setting range Short circuit release setting range Accessories - Auxiliary contacts - Shunt release - Undervoltage release - Trip alarm contacts - Rotary operating mechanism Mechanical life MCB Rated current Rated service SC breaking capacity - Ics ELCB Rated current Rated service SC breaking capacity - Ics Earth Leakagetrip current : : : : : A kA kA

: : : : : : : : A kA

mm Cu. kV kA Yes / No

: : :

A kA mA

Yes / No

Yes / No

MAKE OF EQUIPMENT / COMPONENTS 1 2 3 4 5 6 7 8 Meters Indicating lights MCB MCCB Terminals Cable glands Cable lugs ELCB AEP / Simco / IMP / MECO Siemens / L&T / Tecknic / BCH MDS / HAVELL / Indo-Asian Siemens / L&T / Alstom ELMEX / TOSHA / Connectwell Comet / Baliga / Flexpro Dowell or equivalent MDS / HAVELL / Indo-Asian

B A Rev

12.02.2010 08.02.2010 Date

NAK NAK Prepared

Issued for Review / Comments Issued For DIC/IDR Description

BPR BPR Checked

ADS ADS Approved

Mangala Field Development Project Enchance Oil Recovery Pilot (EORP)Project

DATA SHEET FOR LV MOTOR

B A REV

09.02.2010 05.02.2010 DATE

KA KA BY

Issued for Review / Comments Issued For DIC/IDR DESCRIPTION

BPR BPR CHK'D

ADS ADS APPR

CLIENT

TOTAL OR PARTIAL REPRODUCTION AND / OR UTILISATION OF THIS DOCUMENTATION ARE FORBIDDEN WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

Document No:

EORP-EL-J-003

DATA SHEET FOR LV MOTOR

DOC. NO: SERVICE: EORP-EL-J-003 TAG NO : PAGE NO: NO OF UNITS: 2 2 of 2

1. GENERAL DATA Installation Ref. Specification No. Codes and Standard IS IEC Ambient temp. : Max/Min Design ambient temp. Relative Humidity

: :

Onshore EORP-EL-S-003

Altitude Location

Less than 1000 m Indoor Outdoor Zone - III Desert area, Humid and Corrosive

: : :

42/10.6 deg C 50 / -2 deg. C. 23 TO 74 %

Seismic Zone : Atmosphere :

2. RATING KW rating : KW rating at design ambient : Number of Phases : Conform to International Std : Conform to project Standard : Supply Voltage & Variation : Frequency & Variation : Combined Voltage & frequency Variation: System Earthing : Supply system fault level (MVA/KA): Motor Ternimal box fault rating : Motor full load speed : Variable speed drive operation : Motor speed range for VSD : Method of motor starting : Duty : Direction of rotation (facing drive end (DE)) Mouting type per (IS -2253) Motor Frame Size Insulation Class Temperature rise Area Classification of installation Gas Group / Temperature Class EEx Protection type Atex certificate Enclosure IP Protection (IEC 60034-5): Position of Power terminal Box Vibration probes RTDs for Winding (6nos.) RTD cable size & type Space heater Rating Space heater cable size & type Name Plate Grounding stud Lifting Eyes Final Paint shade / thickness Tropical treatment required Power Cable size Routine Test as per IS : : : : : : : : : : : : : : : : : : : : : * kW @ * kW @ 3Ph * * 415V 50HZ C C

3.VENDOR DATA Name of motor Manufacturer Country of Manufacturer Service Centre (at delivery Location): Full load current (Amps) Starting time at full load (sec.) Starting current at 100% of voltage (%): Full load Torque ( kgm)

: :

: :

(+/-) 10% (+/-) 5% (+/-) 10% Resistance Earthed 50 kA for 1 sec * kA for * s * rpm yes No * * % to * * % N.A. DOL Continuous ** ** * Class F /B Limited to Class B Zone 2 Group IIA / T3 EEx'd ' or EEx' e' * IP55 * * Not Required Not Required * * Stainless Steel Required Required 631/632 as per IS:5/ * microns Yes Required

: Starting torque (as % of FLT) : Locked rotor current at Un(Amps) : Locked rotor withstand time in sec.-cold/ Hot: Powe factor at 100% /75% /50% load: Efficiency at 100% /75% /50% load: Motor Cooling method / Code : No.of consecutive starts in one hour: Reacceleration : Bearings: Bearing type Make Model no. Bearing life Insulated Lubricant type * * * * yes DE Bearing

* * * * * * * * * * * * * TEFC * *

/ IC

NDE Bearing * * * * Hours yes No

Hours No

4.DRIVEN EQUIPMENT DATA Driven Equipment description Type of driven equipment Coupling type Moment of intertia of the load Absorbed power Speed (Synchronous) 5. NOTES: 1. " * 2. " * * " To be furnished by Driven Equuipment Manufacturer 3. Motors rated above 30KW shall be provided with anti-condensation heaters. : : : : : : * * * * * * * * * * * * kg.m2 kW rpm

"

To be furnished by Motor Manufacturer

B A Rev

09.02.2010 05.02.2010 Date

KA KA Prepared

Issued for Review / Comments Issued For DIC/IDR Description

BPR BPR Checked

ADS ADS Approved

MANGALA FIELD DEVELOPMENT PROJECT

Enhance Oil Recovery Pilot (EORP) Project

ELECTRICAL CABLE SCHEDULE

B A REV

01.03.2010 12.02.2010 DATE

NAK NAK BY

Issued for Review / Comments Issued For DIC/IDR DESCRIPTION

BPR BPR CHK'D

ADS ADS APPR

CLIENT

TOTAL OR PARTIAL REPRODUCTION AND / OR UTILISATION OF THIS DOCUMENTATION ARE FORBIDDEN WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

Document No:

EORP-EL-K-002

Cairn Energy India Pty Ltd

Project Document Title Document No Revision No : MANGALA FIELD DEVELOPMENT PROJECT - ENHANCE OIL RECOVERY PILOT (EORP) PROJECT : ELECTRICAL CABLE SCHEDULE - INDEX, GLAND DESCRIPTION, CABLE DESCRIPTION, NOTES : EORP-EL-K-002 :B

VP Petro6 Engineers and Consultants Pvt Ltd

INDEX PAGE No. 1 2 3 4, 5 6,7,8 9 COVER SHEET INDEX , DESCRIPTION, NOTES CABLE NUMBERING CABLE SCHEDULE-POWER & MOTOR CONTROL CENTRE CABLE SCHEDULE-LIGHTING DISTRIBUTION BOARD TITLE

GLAND DESCRIPTION TYPES OF GLAND DESCRIPTION

Flameproof (EEX'd'), double compression cable glands suitable for use in Zone 2, gas group-II A, T3 area, G1 made of nickel plated brass, with soft sealing nylon washer, locknut, weatherproof, outdoor heat shrinkable hood, suitable for installation in sandy desert environment Double compression cable glands, made of nickel plated brass, with soft sealing nylon washer, locknut, G2 weatherproof IP55, outdoor heat shrinkable hood, suitable for installation in sandy desert environment Indoor type Double compression cable glands, made of nickel plated brass, with soft sealing nylon washer, locknut, G3 IP55.

CABLE SCHEDULESCHEDULE POWER DISTRIBUTION BOARD

CABLE DESCRIPTION TYPE OF CABLE DESCRIPTION 600/1100 V Grade, Plain Annealed Copper - Stranded Conductor, XLPE Insulation, Extruded & Low Smoke Inner Sheath, A Galvanized Steel Wire Armored , LSLH PVC & Flame Retardant Outer Sheath , Outer Color - Black, halogen free, heat & oil resistant, UV resistant, power, control, and lighting FRLS cables conforming to IEC-60332-3 Cat A.

NOTES: 1. 2. 3. 4. This Cable Schedule lists all Electrical power, control, and lighting cables which are to be installed on the MPT off spec tank-tie in mangala train-1 . Cable lengths indicated are estimated route lengths only. Cables data selection is based on PRIMECAB KABELS catalogue Cable glands data selection is based on HAWKE cable gland catalogue.

Page 2 of 9

Cairn Energy India Pty Ltd

Project Document Title Document No Revision No : MANGALA FIELD DEVELOPMENT PROJECT - ENHANCE OIL RECOVERY PILOT (EORP) PROJECT : ELECTRICAL CABLE SCHEDULE - CABLE NUMBERING : EORP-EL-K-002 :B

VP Petro6 Engineers and Consultants Pvt Ltd

CABLE NUMBERING :

Generator & Synchronising Panel cable

Power & motor control cable

P - EORP- XX- 01

P - EORP- XX- YY-01

Cable Serial number reference Cable Serial number reference Distribution board/Equipemnt reference Enhance Oil Recovery Pilot (EORP) Project Cable type : P - 415VAC, Power cable C - 230VAC, Control cable H- Anti Condensation Heater Circuit reference Distribution board/Equipemnt reference Enhance Oil Recovery Pilot (EORP) Project Cable type : P - 415VAC, Power cable C - 230VAC, Control cable H- Anti Condensation Heater

Lighting & small power cable

L -EORP-XX- 01

Circuit reference Distribution board reference Enhance Oil Recovery Pilot (EORP) Project Cable type : L - Lighting cable P- Power cable

Page 3 of 9

Cairn Energy India Pty Ltd

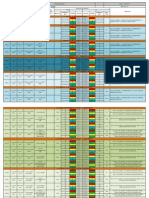

Project Document Title Document No Revision No : MANGALA FIELD DEVELOPMENT PROJECT - ENHANCE OIL RECOVERY PILOT (EORP) PROJECT : ELECTRICAL CABLE SCHEDULE- GENERATOR, POWER & MOTOR CONTROL CENTRE : EORP-EL-K-002 :B DESCRIPTION OF CABLE SL.NO. CABLE TAG NO. TOTAL EQUIPMENT TAG NO OF COND. SIZE TYPE OF APPROX. NO. LENGTH CORES (Sq.mm) CABLE OD (mm) (M) 3.5 3.5 3.5 1 1 3 7 2 3.5 3.5 3.5 1 1 3 7 2 3 3 7 3 3 7 3 3 185 185 185 300 6 2.5 2.5 2.5 185 185 185 300 6 2.5 2.5 2.5 6 2.5 2.5 6 2.5 2.5 4 2.5 A A A A A A A A A A A A A A A A A A A A A A A A 50 50 50 31 11 15 15 14 50 50 50 31 11 15 15 14 17 15 19 17 15 19 16 15 40 40 40 40 40 40 150 40 40 40 40 40 40 40 150 40 100 100 150 100 100 150 70 70 X-809A X-809A X-809A X-809A X-809A X-809A EORP-PMCC EORP-PMCC X-809B X-809B X-809B X-809B X-809B X-809B EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC FROM GLAND EQUIPMENT DESCRIPTION SIZE EQUIPMENT TAG NO. TYPE

VP Petro6 Engineers and Consultants Pvt Ltd

TO GLAND REMARKS EQUIPMENT DESCRIPTION SIZE TYPE

1 2 3 4 5 6 7 7 8 9 10 11 12 13 14 14 15 16 17 18 19 20 21 22

P-EORP-X-809A-01 P-EORP-X-809A-02 P-EORP-X-809A-03 P-EORP-X-809A-04 P-EORP-X-809A-05 C-EORP-X-809A-01 C-EORP-X-809A-02 H-EORP-X-809A-01 P-EORP-X-809B-01 P-EORP-X-809B-02 P-EORP-X-809B-03 P-EORP-X-809B-04 P-EORP-X-809B-05 C-EORP-X-809B-01 C-EORP-X-809B-02 H-EORP-X-809B-01 P-EORP-PMCC-01-01 C-EORP-PMCC-01-01 C-EORP-PMCC-01-02 P-EORP-PMCC-02-01 C-EORP-PMCC-02-01 C-EORP-PMCC-02-02 P-EORP-PMCC-03-01 C-EORP-PMCC-03-01

Diesel Generator Diesel Generator Diesel Generator Diesel Generator (Neutral) NGR Cubicle (Resistor) Diesel Generator (Neutral CT) Power & motor control centre (Incomer-1) Power & motor control centre Diesel Generator Diesel Generator Diesel Generator Diesel Generator (Neutral) NGR Cubicle (Resistor) Diesel Generator (Neutral CT) Power & motor control centre (Incomer-2) Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre

M63 M63 M63 M40 M20 M20 M20 M20 M63 M63 M63 M40 M20 M20 M20 M20 M25 M20 M20 M25 M20 M20 M25 M20

G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3

EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC X-809A EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC X-809B EORP-P-203A EORP-P-203B EORP-P-805A -

Power & motor control centre Power & motor control centre Power & motor control centre NGR Cubicle (Resistor) Earth Pit Power & motor control centre (for 64 Relay) IRP for Control Status Diesel Generator (Space heater) Power & motor control centre Power & motor control centre Power & motor control centre NGR Cubicle (Resistor) Earth Pit Power & motor control centre (for 64 Relay) IRP for Control Status Diesel Generator (Space heater) Fluid Transfer Pump A LCS for Fluid Transfer Pump A IRP for Control Status Fluid Transfer Pump B LCS for Fluid Transfer Pump B IRP for Control Status Chemical Injection Pump A LCS for Chemical Injection Pump A

M63 M63 M63 M40 M20 M20 M20 M63 M63 M63 M40 M20 M20 M20 M25 M20 M20 M25 M20 M20 M25 M20

G3 G3 G3 G3

G3 G3 G3 G3 G3 G3 G3 ON, OFF & Indication Status

G3 G3 G3 G1 G1 G3 G1 G1 G3 G1 G1 Start, Stop & Indication Status Start, Stop & Indication Status ON, OFF & Indication Status

Page 4 of 9

Cairn Energy India Pty Ltd

Project Document Title Document No Revision No : MANGALA FIELD DEVELOPMENT PROJECT - ENHANCE OIL RECOVERY PILOT (EORP) PROJECT : ELECTRICAL CABLE SCHEDULE- GENERATOR, POWER & MOTOR CONTROL CENTRE : EORP-EL-K-002 :B DESCRIPTION OF CABLE SL.NO. CABLE TAG NO. TOTAL EQUIPMENT TAG NO OF COND. SIZE TYPE OF APPROX. NO. LENGTH CORES (Sq.mm) CABLE OD (mm) (M) 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 10 7 4 4 4 4 2.5 4 2.5 4 2.5 4 2.5 4 2.5 4 2.5 4 2.5 95 2.5 2.5 2.5 16 16 150 A A A A A A A A A A A A A A A A A A A A A 16 15 16 15 16 15 16 15 16 15 16 15 16 15 33 15 20 14 22 22 45 70 70 65 65 65 65 60 60 60 60 55 55 55 55 225 225 15 150 25 25 25 EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC EORP-PMCC FROM GLAND EQUIPMENT DESCRIPTION SIZE EQUIPMENT TAG NO. TYPE

VP Petro6 Engineers and Consultants Pvt Ltd

TO GLAND REMARKS EQUIPMENT DESCRIPTION SIZE TYPE

23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43

P-EORP-PMCC-04-01 C-EORP-PMCC-04-01 P-EORP-PMCC-05-01 C-EORP-PMCC-05-01 P-EORP-PMCC-06-01 C-EORP-PMCC-06-01 P-EORP-PMCC-07-01 C-EORP-PMCC-07-01 P-EORP-PMCC-08-01 C-EORP-PMCC-08-01 P-EORP-PMCC-09-01 C-EORP-PMCC-09-01 P-EORP-PMCC-10-01 C-EORP-PMCC-10-01 P-EORP-PMCC-11-01 C-EORP-PMCC-11-01 C-EORP-PMCC-11-02 C-EORP-PMCC-11-03 P-EORP-PMCC-12-01 P-EORP-PMCC-13-01 P-EORP-PMCC-14-01

Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre Power & motor control centre ESP Motor VFD Panel Power & motor control centre Power & motor control centre Power & motor control centre

M25 M20 M25 M20 M25 M20 M25 M20 M25 M20 M25 M20 M25 M20 M40 M20 M20 M20 M25 M25 M40

G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3 G3

EORP-P-805B EORP-P-806A EORP-P-806B EORP-P-807A EORP-P-807B EORP-P-808A EORP-P-808B EORP-LDB-001

Chemical Injection Pump B LCS for Chemical Injection Pump B Chemical Injection Pump A LCS for Chemical Injection Pump A Chemical Injection Pump B LCS for Chemical Injection Pump B Chemical Injection Pump A LCS for Chemical Injection Pump A Chemical Injection Pump B LCS for Chemical Injection Pump B Chemical Injection Pump A LCS for Chemical Injection Pump A Chemical Injection Pump B LCS for Chemical Injection Pump B ESP Motor VFD Panel LCS for ESP Motor A ESP Motor VFD Panel IRP for Control Status Lighting distribution board

M25 M20 M25 M20 M25 M20 M25 M20 M25 M20 M25 M20 M25 M20 M40 M20 M20 M20 M25 M25 M40

G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G3 G1 G3 G3 G3 G3 G3 Start, Stop & Indication Status

EORP-PDB-001 Power distribution board EORP-HTDB-001 Heat Tracing Panel

Page 5 of 9

Cairn Energy India Pty Ltd

Project Document Title Document No Revision No : MANGALA FIELD DEVELOPMENT PROJECT - ENHANCE OIL RECOVERY PILOT (EORP) PROJECT : ELECTRICAL CABLE SCHEDULE- LIGHTING DISTRIBUTION BOARD : EORP-EL-K-002 :B DESCRIPTION OF CABLE SL.NO. CABLE TAG NO. NO OF COND. SIZE TYPE OF CORES (Sq.mm) CABLE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 L-EORP-LDB-01-01 L-EORP-LDB-01-02 L-EORP-LDB-01-03 L-EORP-LDB-01-04 L-EORP-LDB-01-05 L-EORP-LDB-01-06 L-EORP-LDB-01-07 L-EORP-LDB-01-08 L-EORP-LDB-01-09 L-EORP-LDB-01-10 L-EORP-LDB-01-11 L-EORP-LDB-01-12 L-EORP-LDB-01-13 L-EORP-LDB-01-14 L-EORP-LDB-02-01 L-EORP-LDB-02-02 L-EORP-LDB-02-03 L-EORP-LDB-02-04 L-EORP-LDB-02-05 L-EORP-LDB-02-06 L-EORP-LDB-02-07 L-EORP-LDB-02-08 L-EORP-LDB-02-09 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 4 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 4 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 A A A A A A A A A A A A A A A A A A A A A A A TOTAL EQUIPMENT TAG CABLE NO. LENGTH OD (mm) (M) 15 14 14 14 14 14 14 14 14 14 14 14 14 14 15 14 14 14 14 14 14 14 14 250 8 20 8 20 8 20 8 20 8 20 8 20 8 250 8 20 8 20 8 20 8 20 EORP-LDB-001 EORP-LDB-001 FROM GLAND EQUIPMENT DESCRIPTION SIZE EQUIPMENT TAG NO. TYPE

VP Petro6 Engineers and Consultants Pvt Ltd

TO GLAND REMARKS EQUIPMENT DESCRIPTION SIZE TYPE

Lighting distribution board at ckt - 1 Junction box-1 Junction box-1 Junction box -2 Junction box-2 Junction box-3 Junction box-3 Junction box-4 Junction box-4 Junction box-5 Junction box-5 Junction box-6 Junction box-6 Junction box-7 Lighting distribution board at ckt- 2 Junction box-8 Junction box-8 Junction box -9 Junction box-9 Junction box-10 Junction box-10 Junction box-11 Junction box-11

M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20

G3 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G3 G1 G1 G1 G1 G1 G1 G1 G1

Junction box-1 Light fitting-1 Junction box-2 Light fitting-2 Junction box-3 Light fitting-3 Junction box-4 Light fitting-4 Junction box-5 Light fitting-5 Junction box-6 Light fitting-6 Junction box-7 Light fitting-7 Junction box-8 Light fitting-8 Junction box-9 Light fitting-9 Junction box-10 Light fitting-10 Junction box-11 Light fitting-11 Junction box-12

M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20

G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1

Page 6 of 9

24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55

L-EORP-LDB-02-10 L-EORP-LDB-02-11 L-EORP-LDB-02-12 L-EORP-LDB-02-13 L-EORP-LDB-02-14 L-EORP-LDB-03-01 L-EORP-LDB-03-02 L-EORP-LDB-03-03 L-EORP-LDB-03-04 L-EORP-LDB-03-05 L-EORP-LDB-03-06 L-EORP-LDB-03-07 L-EORP-LDB-03-08 L-EORP-LDB-03-09 L-EORP-LDB-03-10 L-EORP-LDB-03-11 L-EORP-LDB-03-12 L-EORP-LDB-04-01 L-EORP-LDB-04-02 L-EORP-LDB-04-03 L-EORP-LDB-04-04 L-EORP-LDB-04-05 L-EORP-LDB-05-01 L-EORP-LDB-05-02 L-EORP-LDB-05-03 L-EORP-LDB-05-04 L-EORP-LDB-05-05 L-EORP-LDB-05-06 L-EORP-LDB-05-07 L-EORP-LDB-05-08 L-EORP-LDB-05-09 L-EORP-LDB-05-10

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A

14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

8 20 8 20 8 80 6 12 6 12 6 12 6 12 6 12 6 60 6 12 6 12 40 6 10 6 10 6 10 6 10 6

EORP-LDB-001 EORP-LDB-001 EORP-LDB-001 -

Junction box-12 Junction box-12 Junction box-13 Junction box-13 Junction box-14 Lighting distribution board at ckt- 3 Junction box-15 Junction box-15 Junction box -16 Junction box-16 Junction box-17 Junction box-17 Junction box-18 Junction box-18 Junction box-19 Junction box-19 Junction box-20 Lighting distribution board at ckt- 4 Junction box-21 Junction box-21 Junction box -22 Junction box-22 Lighting distribution board at ckt- 5 Junction box-23 Junction box-23 Junction box -24 Junction box-24 Junction box-25 Junction box-25 Junction box-26 Junction box-26 Junction box-27 Page 7 of 9

M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20

G1 G1 G1 G1 G1 G3 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G3 G1 G1 G1 G1 G3 G1 G1 G1 G1 G1 G1 G1 G1 G1

Light fitting-12 Junction box-13 Light fitting-13 Junction box-14 Light fitting-14 Junction box-15 Light fitting-15 Junction box-16 Light fitting-16 Junction box-17 Light fitting-17 Junction box-18 Light fitting-18 Junction box-19 Light fitting-19 Junction box-20 Light fitting-20 Junction box-21 Light fitting-21 Junction box-22 Light fitting-22 Junction box-17 Junction box-23 Light fitting-23 Junction box-24 Light fitting-24 Junction box-25 Light fitting-25 Junction box-26 Light fitting-26 Junction box-27 Light fitting-27

M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20 M20

G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1 G1

56 57 58 59 60 61 62

L-EORP-LDB-05-11 L-EORP-LDB-05-12 L-EORP-LDB-05-13 L-EORP-LDB-05-14 L-EORP-LDB-05-15 L-EORP-LDB-05-16 L-EORP-LDB-06-01

2 2 2 2 2 2 2

2.5 2.5 2.5 2.5 2.5 2.5 2.5

A A A A A A A

14 14 14 14 14 14 14

10 6 10 6 10 6 15

Junction box-27 Junction box-28 Junction box-28 Junction box-29 Junction box-29 Junction box-30 Lighting distribution board at ckt- 6

M20 M20 M20 M20 M20 M20 M20

G1 G1 G1 G1 G1 G1 G3

Junction box-28 Light fitting-28 Junction box-29 Light fitting-29 Junction box-30 Light fitting-30 Operator cabin lighting

M20 M20 M20 M20 M20 M20 M20

G1 G1 G1 G1 G1 G1 G3

Page 8 of 9

Cairn Energy India Pty Ltd

Project Document Title Document No Revision No : MANGALA FIELD DEVELOPMENT PROJECT - ENHANCE OIL RECOVERY PILOT (EORP) PROJECT : ELECTRICAL CABLE SCHEDULE-POWER DISTRIBUTION BOARD : EORP-EL-K-002 :B DESCRIPTION OF CABLE SL.NO. CABLE TAG NO. NO OF COND. SIZE TYPE OF CORES (Sq.mm) CABLE 1 2 3 4 5 6 7 8 P-EORP-PDB-01 P-EORP-PDB-02 P-EORP-PDB-03 P-EORP-PDB-04 P-EORP-PDB-05 P-EORP-PDB-06 P-EORP-PDB-07 P-EORP-PDB-08 2 2 2 2 2 2 2 2 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 A A A A A A A A TOTAL CABLE LENGTH OD (mm) (M) 14 14 14 14 14 14 14 14 20 40 30 20 20 20 20 20 EQUIPMENT TAG NO. FROM GLAND EQUIPMENT DESCRIPTION SIZE TYPE EQUIPMENT TAG NO.

VP Petro6 Engineers and Consultants Pvt Ltd

TO GLAND REMARKS EQUIPMENT DESCRIPTION SIZE TYPE

EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board EORP-PDB-001 Power distribution board

M20 M20 M20 M20 M20 M20 M20 M20

G3 G3 G3 G3 G3 G3 G3 G3

24V DC Charger for Instrumention X-809A EDG Auxiliaries X-809B EDG Auxiliaries Operator Cabin A/C Unit -1 Operator Cabin A/C Unit -2 Operator Cabin A/C Unit -3 Operator Cabin A/C Unit -4 24V Charger for operation of CB & Synchronizing

M20 M20 M20 M20 M20 M20 M20 M20

G3 G3 G3 G3 G3 G3 G3 G3

Page 9 of 9

You might also like

- Electrical Operating Philosophy JI 191 EL 08 0000 10006 Rev 0.Document64 pagesElectrical Operating Philosophy JI 191 EL 08 0000 10006 Rev 0.jool8078% (9)

- Single Line DiagramDocument1 pageSingle Line DiagramGhanshyam Singh100% (2)

- Nissan Pathfinder EcDocument674 pagesNissan Pathfinder EcLiane Spanemberg82% (11)

- MD-402-7400-EG-EL-SCH-51301 - 0 Electrical Cable Schedule For Substation 7400-SU1260 Precipitation SubstationDocument22 pagesMD-402-7400-EG-EL-SCH-51301 - 0 Electrical Cable Schedule For Substation 7400-SU1260 Precipitation SubstationyogeshNo ratings yet

- Arar-4.16kV Cable Sizing Calc 1.11.2004Document20 pagesArar-4.16kV Cable Sizing Calc 1.11.2004srigirisetty208100% (1)

- Main Substation Earthing Layout R0-Layout1Document1 pageMain Substation Earthing Layout R0-Layout1zabiruddin786No ratings yet

- LT Cable ScheduleDocument3 pagesLT Cable ScheduleSaquib Khan100% (2)

- Data Sheet For Power TransformerDocument3 pagesData Sheet For Power TransformerNakkolopNo ratings yet

- Fault Level Calcn in 11KV & 415VDocument4 pagesFault Level Calcn in 11KV & 415Vvaithy201180% (5)

- Power Transformers DatasheetDocument3 pagesPower Transformers DatasheetMuhammad Ibad AlamNo ratings yet

- Single Line DiagramDocument15 pagesSingle Line DiagramKhang TrangNo ratings yet

- Bsi STD DWG El 001 Electrical Standard Installation 2of6Document1 pageBsi STD DWG El 001 Electrical Standard Installation 2of6dharuNo ratings yet

- Key - SLD - R2Document1 pageKey - SLD - R2Satya Narayana BandaruNo ratings yet

- Power Cable Schedule FormatDocument60 pagesPower Cable Schedule Formatapi-3844354100% (3)

- 3 DG Auto Load Sharing SchemeDocument9 pages3 DG Auto Load Sharing Schemeuump100% (1)

- HT Cable Schedule, R1Document16 pagesHT Cable Schedule, R1kxalxoNo ratings yet

- 6.6kV CABLE SIZINGDocument2 pages6.6kV CABLE SIZINGmahesh_sali2003No ratings yet

- NGR Panel - Rev 01 PDFDocument20 pagesNGR Panel - Rev 01 PDFnaveen prasadNo ratings yet

- EARTHING CABLE SCHEDULE-Rev.0B - FloresDocument4 pagesEARTHING CABLE SCHEDULE-Rev.0B - Floresbram87No ratings yet

- Ocl Ele Main SLD 1-11-2017 Main SLDDocument1 pageOcl Ele Main SLD 1-11-2017 Main SLDSanjay SahulNo ratings yet

- ID091005-00-140-01 - SWGR-361 Single Line Diagram Rev 06Document25 pagesID091005-00-140-01 - SWGR-361 Single Line Diagram Rev 06Matthew Kuttikad100% (3)

- SLDDocument1 pageSLDjigyesh100% (1)

- 1MWp SLD Rev 1 Model (Annexure I)Document1 page1MWp SLD Rev 1 Model (Annexure I)Unique FriendNo ratings yet

- VP-THI-QG59-130 Data Sheet For Main Motor (QG3&4) Rev.C2Document12 pagesVP-THI-QG59-130 Data Sheet For Main Motor (QG3&4) Rev.C2umeshNo ratings yet

- 240V Ac Ups Sizing Calculation: Document TitleDocument6 pages240V Ac Ups Sizing Calculation: Document Titlephanendra2No ratings yet

- LTJ-ELC-002 - MCC - Switchgear & MCC Specification - Rev2 PDFDocument14 pagesLTJ-ELC-002 - MCC - Switchgear & MCC Specification - Rev2 PDFsswahyudiNo ratings yet

- Cable ScheduleDocument12 pagesCable ScheduleamilasriNo ratings yet

- Electrical Design CriteriaDocument45 pagesElectrical Design Criteriamohan babuNo ratings yet

- Electrical Load ScheduleDocument14 pagesElectrical Load ScheduleAtty AttyNo ratings yet

- 1004 E GD 0010 X Electrical Load ListDocument7 pages1004 E GD 0010 X Electrical Load Listcherif yahyaoui100% (1)

- SLD of 6.6kV Unit Board 7UADocument10 pagesSLD of 6.6kV Unit Board 7UAVenkatesh RaoNo ratings yet

- 900 Spe 5001 Met&systDocument30 pages900 Spe 5001 Met&systyoi_123No ratings yet

- Voltage Dip Calculation For DG SizingDocument1 pageVoltage Dip Calculation For DG SizingshivaramNo ratings yet

- List Drawing - Uip ViiDocument47 pagesList Drawing - Uip Viizainalabidin3388No ratings yet

- 5 EarthingDocument4 pages5 EarthingPrabhash Verma0% (1)

- Data Sheet For Cable Glands and LugsDocument8 pagesData Sheet For Cable Glands and LugsBasabRajNo ratings yet

- Power Consumption & Heat Dissipation-COB#1-Rev1Document10 pagesPower Consumption & Heat Dissipation-COB#1-Rev1mnm_somuNo ratings yet

- Gen Auxiliary Trafo Sizing CalDocument4 pagesGen Auxiliary Trafo Sizing CalSridhar Reddy GandraNo ratings yet

- Transformer KVA Sizing Calculation - Easy Version PDFDocument2 pagesTransformer KVA Sizing Calculation - Easy Version PDFmathan_ae100% (1)

- NPT10111-PE-V-EC-621101-01 UPS Sizing Calculation - Rev-01 PDFDocument5 pagesNPT10111-PE-V-EC-621101-01 UPS Sizing Calculation - Rev-01 PDFkkumar_717405No ratings yet

- Control Philosophy Rafha-18.11.2004Document14 pagesControl Philosophy Rafha-18.11.2004srigirisetty208No ratings yet

- 4a1fn3 6se7134+l08Document31 pages4a1fn3 6se7134+l082003vinay100% (1)

- SLD of Main PanelDocument1 pageSLD of Main PanelHytech Pvt. Ltd.100% (1)

- SBIT Electrical Load ListDocument35 pagesSBIT Electrical Load ListKiran AllaNo ratings yet

- Design Criteria Document of Electrical Systems For 2 X 660 MW Thermal Power Plant DCD NPT10111-PE-E-ED-500100-001 - R2Document141 pagesDesign Criteria Document of Electrical Systems For 2 X 660 MW Thermal Power Plant DCD NPT10111-PE-E-ED-500100-001 - R2Suresh ChintaNo ratings yet

- Electrical Design Basis - Rev 0Document17 pagesElectrical Design Basis - Rev 0DeepmalaJayeshNo ratings yet

- Stage-1 Power Transformer SizingDocument1 pageStage-1 Power Transformer Sizingshantaram_patil5495No ratings yet

- Single Line Diagram-2Document1 pageSingle Line Diagram-2asmt25hainamNo ratings yet

- Bibiyana 300-450 MW CCPP Volume-II Part ADocument304 pagesBibiyana 300-450 MW CCPP Volume-II Part AboiporaNo ratings yet

- S0442 GPS E H01 CA 0003 0 UPS Sizing CalculationDocument6 pagesS0442 GPS E H01 CA 0003 0 UPS Sizing Calculationoctieu247No ratings yet

- Fault Level CalculationDocument2 pagesFault Level CalculationAkhil GuptaNo ratings yet

- Voltage Drop and Cable SizingDocument12 pagesVoltage Drop and Cable SizingFek Lakhdar100% (1)

- Transformer Sizing CalculationDocument8 pagesTransformer Sizing CalculationArunava BasakNo ratings yet

- Report On Study of Electrical Equipments in Power SystemDocument92 pagesReport On Study of Electrical Equipments in Power Systemvanya gupta100% (2)

- MHS E000 El CC 107 05Document24 pagesMHS E000 El CC 107 05sivasan10006098No ratings yet

- Chapter 26 - Battery Sizing and Discharge Analysis PDFDocument45 pagesChapter 26 - Battery Sizing and Discharge Analysis PDFAmirNo ratings yet

- Electrical Data SheetDocument5 pagesElectrical Data Sheetrajpre1213100% (1)

- J0263-Ff-El-Dsh-211 Data Sheet For LV Motors (Part Iia)Document7 pagesJ0263-Ff-El-Dsh-211 Data Sheet For LV Motors (Part Iia)jaikolangaraparambilNo ratings yet

- Orissa Power Gen. Co. Ltd. 2 X 660 MW (Unit #3 & 4) Ib Thermal Power Station, BanharpaliDocument6 pagesOrissa Power Gen. Co. Ltd. 2 X 660 MW (Unit #3 & 4) Ib Thermal Power Station, BanharpaliSantoshkumar GuptaNo ratings yet

- LVC Pricelist Wef 1st July 2014Document104 pagesLVC Pricelist Wef 1st July 2014manoj031No ratings yet

- Sov - 1Document1 pageSov - 1biswasdipankar05No ratings yet

- Technical Schedule: Section - Vi-EDocument7 pagesTechnical Schedule: Section - Vi-EAnonymous 7ZYHilDNo ratings yet

- SARAS-EL-D-1000, Key Single Line Diagram, Rev.BDocument2 pagesSARAS-EL-D-1000, Key Single Line Diagram, Rev.Bvaithy2011No ratings yet

- Check Sheet For DesignDocument3 pagesCheck Sheet For Designvaithy2011No ratings yet

- DG CalculationDocument3 pagesDG Calculationvaithy2011No ratings yet

- 315 Kva STD QapDocument1 page315 Kva STD Qapvaithy2011No ratings yet

- Electrical For ALLDocument51 pagesElectrical For ALLvaithy2011No ratings yet

- Protection Relays Guide 2012-Schneider ElectricDocument56 pagesProtection Relays Guide 2012-Schneider ElectricPradeep_Vashist100% (1)

- Busbar Trunking SystemDocument16 pagesBusbar Trunking Systemdidarul_01013431100% (1)

- Wr2 ChecklistDocument14 pagesWr2 Checklistvaithy2011No ratings yet

- Wr2 ChecklistDocument14 pagesWr2 Checklistvaithy2011No ratings yet

- LCIPL CatalogueDocument6 pagesLCIPL Cataloguevaithy2011No ratings yet

- IOCL Price List 29.10.10Document3 pagesIOCL Price List 29.10.10vaithy2011No ratings yet

- Installation and Commissioning Manual Line Differential Protection Terminal Rel551 2.5Document184 pagesInstallation and Commissioning Manual Line Differential Protection Terminal Rel551 2.5vaithy2011No ratings yet

- EL2 P SRelaysDocument75 pagesEL2 P SRelaysAnonymous vMzbUJNo ratings yet

- On-Line Power Repair Procedure: 1.0 Fru ListDocument18 pagesOn-Line Power Repair Procedure: 1.0 Fru ListSacha HinduNo ratings yet

- Lintels AutoCad Files ListDocument6 pagesLintels AutoCad Files ListAngel MurrayNo ratings yet

- Motor CaculationDocument28 pagesMotor CaculationThiet PhamNo ratings yet

- 6-09-224 Wiring Diagram SHT 2 4001098Document1 page6-09-224 Wiring Diagram SHT 2 4001098Jozsef MagyariNo ratings yet

- Caminhão Volvo FM - Relés e FusíveisDocument5 pagesCaminhão Volvo FM - Relés e FusíveisWiterMarcosNo ratings yet

- On A/C All: Reference Qty DesignationDocument7 pagesOn A/C All: Reference Qty DesignationRicardoBillEdwinNo ratings yet

- 02contactors 03 22Document78 pages02contactors 03 22carlos yepezNo ratings yet

- PBC 6200 PDFDocument28 pagesPBC 6200 PDFSahand Aras100% (2)

- Transformer Data SheetDocument5 pagesTransformer Data Sheetact_rahul53No ratings yet

- 4.chint Contactor (NXC)Document5 pages4.chint Contactor (NXC)Yamendra GurungNo ratings yet

- Design For CHBDocument20 pagesDesign For CHBmeoNo ratings yet

- Sounders For CO / NO2 System: Carbon Monoxide Detection SystemDocument2 pagesSounders For CO / NO2 System: Carbon Monoxide Detection SystemfesterrNo ratings yet

- Plan 3D View Wall A & BDocument20 pagesPlan 3D View Wall A & BEarnest FNo ratings yet

- Instructions Manual: PrefaceDocument60 pagesInstructions Manual: PrefaceGonzalo DoniniNo ratings yet

- Lada t132 Service ManualDocument17 pagesLada t132 Service ManualЕленаNo ratings yet

- Caterpillar 14G SENR3652Document2 pagesCaterpillar 14G SENR3652Jaime Villalba Flor100% (1)

- R448 Leroy Somer Manual enDocument4 pagesR448 Leroy Somer Manual enJohn GarnetNo ratings yet

- Equipment / System Report: Project: MMTHQ Equipment Type: MDB - Main Distribution Board Panel Tag: Fed FromDocument3 pagesEquipment / System Report: Project: MMTHQ Equipment Type: MDB - Main Distribution Board Panel Tag: Fed FromifranNo ratings yet

- Biological Microscope: Theia Fi Is Also Known As MLX Plus in Certain RegionsDocument36 pagesBiological Microscope: Theia Fi Is Also Known As MLX Plus in Certain Regionsmclock 1616No ratings yet

- BWSSB SRDocument33 pagesBWSSB SRLokesh BhNo ratings yet

- Shinkawa cv86 SeDocument1 pageShinkawa cv86 SeKaaberNo ratings yet

- EPSS 627: DescriptionDocument2 pagesEPSS 627: DescriptionudayakumartNo ratings yet

- PB 76012 153Document3 pagesPB 76012 153Rafael Dutil LucianaNo ratings yet

- 60 PowerlineDocument4 pages60 PowerlineSame FirdausNo ratings yet

- Códigos de Falha.Document41 pagesCódigos de Falha.Anonymous ljkiyqJt8MNo ratings yet

- Specifications: I. General ProvisionsDocument4 pagesSpecifications: I. General Provisionsemem CatzNo ratings yet

- NEMA & General Purpose Controls IC14 - Sect09Document186 pagesNEMA & General Purpose Controls IC14 - Sect094685752No ratings yet

- Product HSN GST Rate MRP: Selec Controls PVT LTD.Document6 pagesProduct HSN GST Rate MRP: Selec Controls PVT LTD.Sourabh ChoudharyNo ratings yet