Professional Documents

Culture Documents

A CFD Assessment To Subsonic Flow Around NACA4412

Uploaded by

Eslam NagyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A CFD Assessment To Subsonic Flow Around NACA4412

Uploaded by

Eslam NagyCopyright:

Available Formats

Journal Of Engineering And Development, Vol. 15, No.

4, Des 2011 ISSN 1813- 7822

173

A CFD assessment to Subsonic flow around NACA4412

Ali Abud AL-Nabi Abass

Affairs Contracts Department

The University of Mustansiriya

triplea71@yahoo.com

Abstract

The purpose of this study is determined values of Mach Number (Ma) for Subsonic

flow around NACA4412 which is begun shock wave and known the location it. A 2-

dimensional triangular C-type grid is used to match the reference measurements at an

airfoil cross-section was taken from NACA 4412 from leading edge to trailing edge. The

Mach numbers which used are (0.1 to 0.9) respectively and angles of attack (2.31 and

0.0)for three cases inviscid and viscous flow with choose two cases (K epsilon RNG and

Spalart-Allmaras turbulent models).

The numerical results show that the inviscid and two turbulence models well

predict the shock wave location and size as well as flow properties along the airfoil surface.

The Lift Force Coefficient (CL) decrease and the Drag Force Coefficient (CD) increase

with using viscous term as well as pressure coefficient (CP) give fit location for the shock

wave

Keyword:

Computational fluid dynamics(CFD), turbulence models, subsonic flow, Spalart-Allmaras

Model, k-epsilon rng model, grid technique,

CFD NACA 4412

NACA 4412 .

NACA 4412 . 1.0 - 1.0 )

1.20 1.1 ) (K-epsilon RNG

and Spalart-Allmaras turbulent models) .

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

174

.

Introduction

The design for model of airfoil such as NACA 4412 demanded knowledge

aerodynamic properties. It was built by using GAMBIT code, chosen and specified clustering

the mesh generation with boundary conditions. To study the flow properties such as Lift

Force Coefficient and Drag Force Coefficient, three cases were taken inviscid and viscose

flow (by using K epsilon (e) RNG and Spalart-Allmaras turbulent models). This study is

limited the effect of shock wave on flow properties for flow on airfoil surface by using the

curves of lift and drag force coefficients and curves of pressure coefficient on the wall while

is showed the size and location of shock waves through Mach number contours.

Various experimental and theoretical studies have been published about NACA

4412.Omar Badran et al(2003)[1]. studied mean flow and Reynolds stresses results, of a

NACA 4412 airfoil, cov-ering the boundary layers around the airfoil and the wake region at

angle of attack, = 15. Two-equation turbulence models are tested on NACA 4412 airfoil at

the position of maximum lift (angle of attack= 15). These models are the two-equation

Realizable and RNG k-e models and the Reynolds Stress Model (RSM). It was found that the

developed turbulence models had captured the physics of unsteady separated flow. The

resulting surface pressure coefficients, skin friction, velocity vectors, and Reynolds stresses

are compared with flying hot wire experimental data, and the models produce very similar

results. Also excellent agreements between computational and experimental surface pressures

and skin friction were observed. Also excellent agreement between computational and

experimental surface pressures and skin friction was observed. Serhat Duran(2005)[2].

Modified blade shape by using NACA 4412. The output of the blade design program

performed for the airfoil NACA 4412 When the designed blade shape is modified, it is seen

that the power extracted from the wind is reduced about 10% and the length of modified blade

is increased about 5% for the same required power. Modification of blade geometry promised

to be a good approximation would be explained it.B. Greschner et al (2005)[3] investigated

unsteady flows around a series of NACA airfoils included NACA 4412 carried out. They

designed case studies on the connections between an airfoil shape characteristics and its

aerodynamic and aeroacoustic performance, employed the unsteady CFD flow simulations in

the near field of an airfoil. The results include identifying the optimum symmetric and

asymmetric airfoils among the airfoils and suggesting the possible optimum airfoil

characteristics. The results can be used to guide the selections of the geometric parameters

and constraints in a fully automated aerodynamic and aeroacoustic optimization. Manish K et

al (2005)[4]. Studied CL,CD on NACA 4412 and NACA 0011at Mach number 0.2 and

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

175

different angles of attack (0.0

o

to 14

o

) and determined the effect of Gurney flap on NACA

4412 and NACA 0011 airfoils for Two dimensional steady state Navier-Stokes, used to

predict the flow field around the airfoils. Gurney flap sizes selected for the study range from

0.5% to 4% of the airfoil chord. They Computed results have been compared with available

experimental and computational data. There was good correlation observed between

computed and experimental data. Addition of Gurney flap increased the lift coefficient

significantly with very little drag penalty if proper Gurney flap height was selected.

Inviscid flow

For studying inviscid flow Euler equation by Ali Al-Hussaini [5]:

Continuity equation:

( ) ( )

0 =

c

c

+

c

c

+

c

c

y

v

x

u

t

......................................................................... (1)

The conservation of momentum equation is:

( )

( ) ( ) 0

2

=

c

c

+ +

c

c

+

c

c

uv

y

p u

x t

u

................................................................... (2)

( )

( ) ( ) 0

2

= +

c

c

+

c

c

+

c

c

p v

y

uv

x t

v

.................................................................... (3)

The conservation of energy equation is

( )

( ) | | ( ) | | 0 = +

c

c

+ +

c

c

+

c

c

v p E

y

u p E

x t

E

t t

t

........................................................... (4)

Where : density (Kg/m

3

( , u: Velocity component in x direction (m/s), v: Velocity

component in y direction (m/s), p: pressure (Pa), E

t

: Total internal energy per unit volume

(J/m

3

)

The RNG K- Model

Yakhot, et al. [6] have proposed a variant of the k--Model to improve performance

characteristics compared to the standard model. The new model is based on the

Renormalization-Group-Theory [7], and is referred to as RNG-k--Model. The transport

equations of the RNG are very similar to the standard (k-) model, but employ an additional

source/sink term in the () equation and the values of the coefficients differ from those in the

standard (k-) model. The turbulent kinetic energy, k, and its rate of dissipation, epsilon, are

obtained from the following transport equations::

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

176

YM B G

x

k

k

x Dt

Dk

eff

+ +

|

.

|

\

|

c

c

c

c

= c o .(5)

And

2

*

2 3

) ( 1

k

C B C G

k

C

x x Dt

D

eff

c

c c

oc

c

+ +

|

.

|

\

|

c

c

c

c

= ..(6)

Where C1, C2and C3 are empirical coefficients and

k

and are the turbulent Prandtl number

respectively Schmidt number. The effective viscosity

eff

(Equation (5, 6) in Modeling the

Effective Viscosity) to account for low-Reynolds-number effects.

3679 . 0 6321 . 0

3929 . 2 3929 . 1 + = o o

eff

o o where o=1in the high Reynolds No.

|

|

|

|

.

|

\

|

+

|

.

|

\

|

+ =

3

0

3

2

*

2

1

1

|q

q

q

q

C

C C

(7)

The term B is the buoyancy-term (depending on whether stratification is stable or unstable)

( g B

p

t

~ ). Where B: depends on the fluctuating density field, where is the turbulent

Prandtl / Schmidt number for density.

The dilation dissipation term in the k-equation

2

2

a

K

YM c = is modelled according to

Sarker, a: sound speed [8].

S is the tensor of the mean rate-of-strain, defined as:

With

c

q

k

S = and

ij

S s 2s

ij

= =

t

G

with

|

|

.

|

\

|

c

c

+

c

c

=

xi

uj

xj

ui

s

ij

2

1

.It can be shown that is a

function of generation and dissipation of k and can be Written as

c

q

G

C

1

= which

indicates that characterises the equilibrium characteristic of the turbulence field.

C

= 0.09, (G=

t

S

2

),

t

= C

c

2

K

the two new coefficients,

0

and , can be obtained directly

from the primary model coefficients and the Von Karman constant,

0

= 4.38 and = 0.012.

These values are referred to as the original set of coefficients. The quantities

k

and

are

the inverse effective Prandtl numbers for k and .

Yakhot, et al. [6] recommended the following set of model coefficients:

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

177

Spalart-Allmaras Model

The Spalart & Allmaras model belongs to the one equation family of eddy viscosity models.

This family is based on the assumption that Reynolds stress-tensor

, ,

v u is related to the

mean strain rate through an apparent turbulent viscosity called eddy viscosity t, which can be

computed from the Reynolds Stresses:

|

|

.

|

\

|

c

c

+

c

c

=

x

v

y

u

v v u

t

.

, ,

Actually the computation uses an intermediate transport variable with the damping function

f

v1

() relating to turbulent viscosity by t = f

v1

() to solve the following transport equation

...(8)

The intermediate variable is in general identical to the turbulent kinematic viscosity t

except in the near-wall region [9].

G and Y are the production and destruction terms of turbulent viscosity. Both are strong in

the near-wall region due to wall blocking and viscous damping. Besides denotes the

turbulent Prandtl number, Cb2 a calibration constant and is the molecular kinematic

viscosity.

Boundary conditions specify the flow and properties variables on the boundaries of the

physical model. The boundary conditions in GAMBIT are classified, flow inlet and exit

boundaries: pressure far field, pressure outlet, Wall, the internal face boundary conditions are

defined on cell faces, which means that they do not have a finite thickness and they provide a

means of introducing a step change in flow properties[10].

In solid wall, there are two types of flow on the wall, depending on viscous or inviscid

flow, wherein viscous wall boundary condition, no-slip condition, enforced at walls,

tangential fluid velocity equal to wall velocity. Normal velocity component = 0, shear stress

can also be specified [10].

In inviscid wall boundary condition imposes flow tangency at the zone boundary (wall

surface) while maintaining the same total velocity as the point adjacent to the boundary [10].

The far field boundary conditions are more difficult to specify in a way that facilitates

computation. It is necessary to differentiate between inflow and outflow boundary conditions,

which can determine pressure far field, pressure outlet boundary condition.

Pressure outlet boundary conditions are used to define the static pressure at flow outlet. The

use of a pressure outlet boundary condition instead of an outflow condition often results in a

better rate of convergence when backflow occurs during iteration .

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

178

Pressure far field boundary conditions are used to model a free stream compressible or

incompressible flow at infinity, with free stream Mach number and static conditions specified.

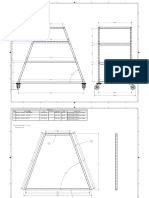

For grid generation FLUENT used grids comprising of triangular. the major motivation for

using unstructured grids employing triangular cells, the range of length scales of the flow is

large, a triangular mesh can often be created with far fewer cells than the equivalent mesh

consisting of quadrilateral cells. This is because a triangular mesh allows cells to be clustered

in selected regions of the flow domain, whereas structured quadrilateral meshes will generally

force cells to be placed in regions where they are not needed, the reason behind case in the

current study unstructured triangular meshes as shown fig (1) [4].

At convergence, all discrete conservation equations (momentum, energy, etc.) obey in all cells

to a specify tolerance. Solution no longer changes with more iteration, solution to equation on

overall mass, momentum, energy, and scalar balances are obtained. Monitoring convergence

with residuals, generally shows, a decrease in residuals by 3 orders of magnitude indicating at

least qualitative convergence, major flow features established, scaled species residual may

need to decrease to 10-4 to achieve species balance, monitoring quantitative convergence and

monitoring other variables for changes, ensure that conservation satisfies the convergence [4].

Results and Discussion

The flow computations required about 800 iterations to converge. At the end of every

computational run, flow residuals are reduced by more than three orders of magnitude. An

example of residual history is shown in Fig 2.

At angle of attack =2.31

0

. The shock wave started creation and separation flow on the surface

of trail of airfoil at Mach-number 0.7 and angle of attack =2.31

0

as shown in Figures (3, 3a,

4, 4a and 5a) while the flow is subsonic as shown in fig. 5.

The general effect of Mach number 0.729 and separation flow on the trail of airfoil shown in

Figures (6, 6a, 7, 7a, 8, and 8a). Especially the size and location of the shock wave region (Ma

> 1,0) can be seen at(X/C > 15).

The shock wave grew moving towards tail as well as the interaction with the boundary layer

after flow separation as shown in figures (9, 9a, 10, 10a, 11 and 11a). At last the location of

shock in (X/C > 70).

At angle of attack =0.0

o

, Mach numbers (0.7 and 0.729), the figures (12, 12a, 13, 13a, 14, 14a,

15, 15a, 16, 16a, 17, 17a) in Mach number contours shown location and size shock wave at

(x/c>50) while velocity magnitude contours appeared the boundary layer on the surface of

trail of airfoil.

Figures (18, 18a, 19, 19a, 20, 20a) shown Mach number and velocity magnitude contours the

behavior of flow properties are similar to previous cases at Mach number 0.8 .

In Figures (12, 13 and 14) the pressure distribution along airfoil surface is presented by

pressure coefficient. The comparison of the chosen turbulence models with inviscid flow

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

179

which is one of the main subjects of the investigation. The curves of all three models fit and

give a good indication to the location of the shock wave. The high gradient in pressure

coefficient (X/C 15, 17.5 and 50) indicates the back boundary of the shock region. The

effect of the viscosity was gradually increased which cause the deference between the CD and

CL. when increase the value of Mach number above 0.7 the values of CL and CD are jump

because of the shock wave was created on the middle surface of airfoil as shown in the figures

(15, 16).

Conclusion

As the aim of study the effect of shock wave on airfoil surface is to know the value of Mach

number, which start to create shock wave and effect boundary layer on the shock. The

calculations show good agreement in values of Mach number 0.729 in three cases on RAE

2822,at angle of attack 2.31

o

with Al-Dulaimy [11], but it deferent in the location of shock

wave because the shape of airfoil for this reason different the results from angle of attack 0.0

o

.

The curves of pressure coefficient give exact location for shock wave. The curves of CL, CD

and CP give effect of shock wave on CL, CD and CP on surface of airfoil. The effect of

viscosity is clearance on CL, CD and values of Mach numbers contours but is disappear in

pressure coefficient .

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

180

60 70 80 90 100 110

X/C

Velocity Magnitude

311.598

290.825

270.051

249.278

228.505

207.732

186.959

166.186

145.412

124.639

103.866

83.0928

62.3196

41.5464

20.7732

60 70 80 90 100 110

X/C

Velocity Magnitude

311.598

290.825

270.051

249.278

228.505

207.732

186.959

166.186

145.412

124.639

103.866

83.0928

62.3196

41.5464

20.7732

Fig.2 Residual history of

Solution Convergence

Fig.1Grid Generation

(Triangular Mesh, C-Type)

Fig. 3 Mach number contours

(free stream Mach number0.7 for

inviscid flow and =2.31

degree)

Fig.3a velocity magnitude contours

At Mach Number 0.7 for inviscid

flow and =2.31

degree

Fig. 4 Mach number contours

(free streamMach number0.7

for k-epsilon RNG flow

and =2.31

degree)

Fig.4a velocity magnitude

contours at Mach number 0.7

for k-epsilon RNG flow and

=2.31

degree

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

181

60 70 80 90 100 110

X/C

Velocity Magnitude

311.598

290.825

270.051

249.278

228.505

207.732

186.959

166.186

145.412

124.639

103.866

83.0928

62.3196

41.5464

20.7732

70 80 90 100 110 120 130

X/C

Velocity Magnitude

363.187

342.579

321.972

301.364

280.756

260.148

239.541

218.933

198.325

177.717

157.109

136.502

115.894

95.2862

74.6784

60 70 80 90 100 110 120

X/C

Velocity Magnitude

349.876

326.551

303.226

279.901

256.576

233.251

209.926

186.6

163.275

139.95

116.625

93.3002

69.9752

46.6501

23.3251

Fig.5a velocity magnitude contours

at Machnumber 0.7 for Spalart-

Allmaras flow and =2.31 degree

Fig. 5 Mach number contours (free

stream Mach number0.7 for Spalart-

Allmaras flow and =2.31

degree

Fig.6a velocity magnitude contours

at Machnumber 0.729 for inviscid

flow and =2.31 degree

Fig. 6 Mach number contours (free

streamMach number 0.729 for

inviscid flow and =2.31 degree)

Fig.7a velocity magnitude contours at

Machnumber 0.729 for k epsilon

RNG flow and=2.31 degree

Fig. 7 Mach number contours (free

stream Mach number 0.729 for

k-epsilon RNG flow and =2.31degree )

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

182

-

60 70 80 90 100 110

X/C

Velocity Magnitude

349.918

326.59

303.262

279.935

256.607

233.279

209.951

186.623

163.295

139.967

116.639

93.3115

69.9836

46.6558

23.3279

70 80 90 100 110

X/C

Velocity Magnitude

422.328

399.322

376.316

353.31

330.304

307.298

284.292

261.286

238.28

215.274

192.268

169.262

146.256

123.25

100.244

70 80 90 100 110 120 130

X/C

Velocity Magnitude

374.137

349.195

324.252

299.31

274.367

249.425

224.482

199.54

174.597

149.655

124.712

99.77

74.8275

49.885

24.9425

Fig8a velocity magnitude contours at

Mach number 0.729 for Spalart Allmaras

flow and =2.31 degree

Fig. 8 Mach number contours (free stream

Mach number 0.729 for Spalart- Allmaras

flow and =2.31degree)

Fig.9a velocity magnitude contours

at Mach number 0.8 for

inviscid flow and =2.31 degree

Fig. 9 Mach number contours (free

streamMach number 0.8

for inviscid flow and =2.31 degree)

Fig.10a velocity magnitude contours at

Mach number 0.8 for k-epsilon RNG

flow and =2.31 degree

Fig. 10 Mach number contours (free

stream Mach number 0.8 for

k-epsilon RNG flowand =2.31 degree

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

183

Fig. 11a velocity magnitude contours at

Mach number 0.8 for Spalart- Allmaras

flow and =2.31 degree

Fig. 11 Mach number contours free

stream Much number 0.8 for Spalart-

Allmaras flow and =2.31 degree)

Fig 12 Mach number contours (free

stream Mach number 0.7 for inviscid

flow and =0.0 degree

Fig.13a velocity magnitude contours at

Mach number 0.7for k- epsilon RNG flow

and =0.0 degree

Fig 13 Mach number contours (free stream

at Mach number 0.7 for k- epsilon RNG

flow and =0.0 degree

60 70 80 90 100 110 120 130

X/C

Velocity Magnitude

373.398

348.505

323.611

298.718

273.825

248.932

224.039

199.145

174.252

149.359

124.466

99.5727

74.6796

49.7864

24.8932

0 50 100

X/C

Mach Number

1.00326

0.944855

0.886447

0.82804

0.769632

0.711225

0.652817

0.59441

0.536002

0.477595

0.419187

0.36078

0.302372

0.243965

0.185557

0 50 100

X/C

Mach Number

0.951811

0.894293

0.836774

0.779255

0.721736

0.664218

0.606699

0.54918

0.491661

0.434143

0.376624

0.319105

0.261586

0.204068

0.146549

60 70 80 90 100

X/C

Velocity Magnitude

311.598

290.825

270.051

249.278

228.505

207.732

186.959

166.186

145.412

124.639

103.866

83.0928

62.3196

41.5464

20.7732

60 70 80 90 100 110 120

X/C

Velocity Magnitude

326.184

307.515

288.846

270.177

251.507

232.838

214.169

195.5

176.831

158.162

139.493

120.824

102.154

83.4853

64.8162

Fig.12a velocity magnitude contours at Mach

number 0.7for inviscid flow and )

=0.0 degree

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

184

0 50 100

X/C

Mach Number

0.95669

0.894231

0.831771

0.769311

0.706851

0.644392

0.581932

0.519472

0.457012

0.394553

0.332093

0.269633

0.207173

0.144714

0.0822538

60 70 80 90 100 110

X/C

Velocity Magnitude

315.443

294.414

273.384

252.355

231.325

210.296

189.266

168.236

147.207

126.177

105.148

84.1182

63.0887

42.0591

21.0296

0 50 100 150

x/c

Mach Number

1.14005

1.07398

1.0079

0.94183

0.875758

0.809685

0.743613

0.677541

0.611468

0.545396

0.479323

0.413251

0.347178

0.281106

0.215033

70 80 90 100 110

x/c

Velocity Magnitude

363.187

342.579

321.972

301.364

280.756

260.148

239.541

218.933

198.325

177.717

157.109

136.502

115.894

95.2862

74.6784

0 50 100 150

X/C

Mach Number

1.08923

1.02109

0.952959

0.884826

0.816692

0.748559

0.680425

0.612292

0.544158

0.476025

0.407891

0.339758

0.271624

0.203491

0.135357

60 70 80 90 100 110

X/C

Velocity Magnitude

349.876

326.551

303.226

279.901

256.576

233.251

209.926

186.6

163.275

139.95

116.625

93.3002

69.9752

46.6501

23.3251

Fig.14a velocity magnitude

contours at Mach number 0.7for

Spalart- Allmaras flow and =0.0

degree

Fig 14 Mach number contours (free

stream at Mach number 0.7 for

Spalart-Allmaras flow and =0.0

degree

Fig.15a velocity magnitude

contours at Mach number 0.729 for

inviscid flow and =0.0 degree

Fig 15 Mach number contours

(free stream at Mach number 0.729

for inviscid flow) and =0.0 degree)

Fig.16a velocity magnitude contours at

Mach number 0.729 for k-epsilon RNG

flow and =0.0 degree

Fig 16 Mach number contours (free

stream at Mach number 0.729 for k

epsilon RNG flow and =0.0 degree

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

185

0 50 100

X/C

Mach Number

1.0883

1.01874

0.949177

0.879616

0.810055

0.740494

0.670933

0.601372

0.531811

0.46225

0.392688

0.323127

0.253566

0.184005

0.114444

70 80 90 100

X/C

Velocity Magnitude

349.918

326.59

303.262

279.935

256.607

233.279

209.951

186.623

163.295

139.967

116.639

93.3115

69.9836

46.6558

23.3279

0 50 100

X/C

Mach Number

1.37883

1.301

1.22316

1.14533

1.06749

0.989656

0.91182

0.833984

0.756148

0.678313

0.600477

0.522641

0.444805

0.36697

0.289134

70 80 90 100

X/C

Velocity Magnitude

425.15

401.96

378.769

355.579

332.388

309.198

286.007

262.817

239.626

216.436

193.245

170.055

146.864

123.674

100.483

0 50 100

X/C

Mach Number

1.3464

1.27038

1.19437

1.11836

1.04234

0.966329

0.890316

0.814302

0.738289

0.662275

0.586262

0.510248

0.434235

0.358221

0.282207

70 80 90 100

X/C

Velocity Magnitude

394.762

368.445

342.127

315.81

289.492

263.175

236.857

210.54

184.222

157.905

131.587

105.27

78.9525

52.635

26.3175

Fig.17a velocity magnitude contours at

Mach number 0.729 for Spalart Allmaras

flow and =0.0 degree

Fig 17 Mach number contours (free

stream at Mach number 0.729 for Spalart

Allmaras flow and =0.0 degree

Fig.18a velocity magnitude contours at

Mach number 0.8 for inviscid flow and

=0. 0 degree

Fig 18 Mach numbercontours(free

stream at Mach number 0.8 for

inviscid flow and =0.0 degree)

Fig.19a velocity magnitude contours at

Mach number 0.8 for k-epsilon RNG flow

and =0.0 degree

Fig 19 Mach number contours (free

stream at Mach number 0.8for k

epsilon RNG flow and =0.0 degree)

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

186

0 50 100

X/C

Mach Number

1.33213

1.25009

1.16804

1.086

1.00395

0.921903

0.839857

0.757811

0.675765

0.593719

0.511673

0.429627

0.34758

0.265534

0.183488

70 80 90 100

X/C

Velocity Magnitude

394.796

368.476

342.157

315.837

289.517

263.197

236.878

210.558

184.238

157.918

131.599

105.279

78.9592

52.6395

26.3197

0 25 50 75 100

X/C

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

P

r

e

s

s

u

r

e

C

o

e

f

f

i

c

i

e

n

t

for inviscid flow

for K-epsilon RNG

for Spalart-Allmaras

0 25 50 75 100

X/C

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

P

r

e

s

s

u

r

e

C

o

e

f

f

i

c

i

e

n

t

for inviscid flow

for K-epsilon RNG

for Spalart-Allmaras

0 25 50 75 100

X/C

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

P

r

e

s

s

u

r

e

C

o

e

f

f

i

c

i

e

n

t

for inviscid flow

for K-epsilon RNG

for Spalart-Allmaras

0.2 0.4 0.6 0.8

X/C

1

2

3

4

5

6

7

L

i

f

t

F

o

r

c

e

C

o

e

f

f

i

c

i

e

n

t

inviscid flow

k-epsilon RNG flow

spalart-Allmaras flow

Fig.20a velocity magnitude contours

at Mach number 0.8 for Spalart-

Allmaras flow and =0.0 degree

Fig 20 Mach number contours

(free stream at Mach number 0.8 for

Spalart-Allmaras flow and =0.0 degree)

Fig.22 Comparison of Pressure

Coefficient Distribution (Free stream

Mach number 0.729)

Fig.21 Comparison of Pressure

Coefficient Distribution (Free

stream Mach number 0.7)

Fig 24Lift force coefficient (CL)

at Mach numbers from (0.1 to 0.9)

for inviscid and viscose flow

Fig23 Comparison of Pressure

Coefficient Distribution (Free

stream Mach number 0.8)

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

187

Fig.25 Drag force coefficient (CD)

at Mach numbers from (0.1 to 0.9)

for inviscid and viscose flow

.

0.2 0.4 0.6 0.8

X/C

1

2

3

4

5

6

7

L

i

f

t

F

o

r

c

e

C

o

e

f

f

i

c

i

e

n

t

inviscid flow

k-epsilon RNG flow

spalart-Allmaras flow

Journal Of Engineering And Development, Vol. 15, No.4, Des 2011 ISSN 1813- 7822

188

References

1. Omar Badran, Regis Quadros and Fettah Aldudak Two-Equation Turbulence

Models for Turbulent Flow over a NACA 4412Airfoil at Angle of Attack 15 Degree

Mechanical Engineering Department Faculty of Engineering technology, Al-Balqa`

Applied University, P.O.Box 331006, Amman 11134 Jordan (2003)

2. Serhat Duran Computer-Aided Design Of Horizontal-Axis Wind Turbine Blades

Partial Fulfillment of the requirements for the Degree of Master of Science in

Mechanical Engineering, Middle East Technical University (2005).

3. B. Greschner, C. Yu, S. Zheng, M. Zhuang, Z. J. Wang and F. Thiele* Knowledge

Based Airfoil Aerodynamic and Aeroacoustic"Hermann-Foettinger-Institute of Fluid

MechanicsBerlin University of Technology, Mueller-Breslau-Str. 8, D-10623

Berlin, Germany(2005).

4. Manish K. Singh, K. Dhanalakshmi and S. K. Chakrabartty" Navier-Stokes Analysis

of Airfoils with Gurney Flap" Computational and Theoretical Fluid Dynamics

Division National Aerospace Laboratories P. B. 1779, Bangalore 560 017,

India(2005).

5. Ali Al-Hussaini.: Computational Study of Supersonic Flow Over Aerodynamic

Configurations Department of Mechanical Engineering of the University of

Technology,(2006).

6. V. Yakhot and S. A. Orszag. Renormalization Group Analysis of Turbulence: I.

Basic Theory. Journal of Scientific Computing,1(1):1{51, 1986.

7. D. Choudhury. Introduction to the Renormalization Group Method and Turbulence

Modelling Fluent I nc.Technical memorandum TM-107, 1993

8. S. Sakar and L. Balakrishhnan. Application of a Reynolds stress Turbulence Model to

the Compressible shear layer ICASE Report 90-18, NASA CR 182002,1990.

9. Chen H. C. and V. C. Patel. Near-Wall Turbulence Models for Complex Flows

I ncluding Separation. AIAA Journal,26(6):641{648, 1988.

10. Fluent Users Services Center,2002, WWW. fluent users. com,.

11. Al-Dulaimy, F. M. A.; Cousin, R. A CFD assessment to transonic flow around a 2822

airfoil Research Reports from Guest Scientists in the Faculties 07 and 09 in the

Academic Year 2004/2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Mirage ERP Presentation 2019 PDFDocument69 pagesMirage ERP Presentation 2019 PDFEslam NagyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Quality in Education: Shelley O'Grady, M.SDocument54 pagesQuality in Education: Shelley O'Grady, M.SEslam NagyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- BF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDDocument1 pageBF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDEslam NagyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 1 s2.0 S100093611300071X Main PDFDocument11 pages1 s2.0 S100093611300071X Main PDFEslam NagyNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Main FrameDocument9 pagesMain FrameEslam NagyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Transonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverDocument11 pagesTransonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverEslam NagyNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Aerodynamic Optimization of a Transonic Axial Compressor Rotor ThesisDocument100 pagesAerodynamic Optimization of a Transonic Axial Compressor Rotor ThesisEslam NagyNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Archshaders Vol 1Document130 pagesArchshaders Vol 1Michelle KalogerakiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Opp Rating Rating: Risk Rating Limit: 8.0 8.0 5.0Document3 pagesOpp Rating Rating: Risk Rating Limit: 8.0 8.0 5.0Eslam NagyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- BF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDDocument1 pageBF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDEslam NagyNo ratings yet

- Effects of Alloying Elements in SteelDocument3 pagesEffects of Alloying Elements in SteelEslam NagyNo ratings yet

- International Material Grade Comparison TableDocument9 pagesInternational Material Grade Comparison Tablenyamuk06100% (4)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Transonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverDocument11 pagesTransonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverEslam NagyNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Asme JT Oct2004 Part2Document11 pagesAsme JT Oct2004 Part2Eslam NagyNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- PDRDocument14 pagesPDREslam NagyNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Aiaa JPP Rotor37Document7 pagesAiaa JPP Rotor37Eslam NagyNo ratings yet

- Transonic Flow Over A RAE 2822 AirfoilDocument1 pageTransonic Flow Over A RAE 2822 AirfoilEslam NagyNo ratings yet

- 57 07-05-21 Isaif8 0021-ChenDocument10 pages57 07-05-21 Isaif8 0021-ChenEslam NagyNo ratings yet

- Tut24 Turbo PostprocessiHFHngDocument20 pagesTut24 Turbo PostprocessiHFHngEslam NagyNo ratings yet

- Tut03 Modeling External Compressible FlowDocument30 pagesTut03 Modeling External Compressible FlowEslam NagyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Airfoil optimization using CFDDocument25 pagesAirfoil optimization using CFDEslam NagyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- A Basic Experimental Investigation of Passive Control Applied To A Transonic InteractionDocument13 pagesA Basic Experimental Investigation of Passive Control Applied To A Transonic InteractionEslam NagyNo ratings yet

- A CFD Analysis of Blade Row Interactions Within A High-Speed Axial CompressorDocument195 pagesA CFD Analysis of Blade Row Interactions Within A High-Speed Axial CompressorEslam NagyNo ratings yet

- AerodynamicShapeDesign FinalReport Fall2010Document156 pagesAerodynamicShapeDesign FinalReport Fall2010benimmmNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fluent OverviewXZDocument48 pagesFluent OverviewXZEslam NagyNo ratings yet

- Wind TurbinesDocument163 pagesWind TurbinesEslam Nagy100% (1)

- Gas TurbinesDocument376 pagesGas TurbinesAlan Sala50% (2)

- MSC - Eng - Steady Three-Dimensional Shock Wave Reflection Transition PhenomenaDocument69 pagesMSC - Eng - Steady Three-Dimensional Shock Wave Reflection Transition PhenomenaEslam NagyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Blade Design Methods and IssuesDocument48 pagesBlade Design Methods and IssuesEslam NagyNo ratings yet

- Hacon TMDocument68 pagesHacon TMTiago CoutoNo ratings yet

- CH Technical Description PDFDocument19 pagesCH Technical Description PDFDANE80100% (2)

- FLR - Performance of A Tubular CondenserDocument12 pagesFLR - Performance of A Tubular CondenserNazario Emil LintagNo ratings yet

- Inc - JR Star Co Super Chaina2022-23 Physics Teaching Exam Schedule Paper Setting Allotment Upto Dusshera 29.06.225.00PMDocument31 pagesInc - JR Star Co Super Chaina2022-23 Physics Teaching Exam Schedule Paper Setting Allotment Upto Dusshera 29.06.225.00PMRobin HootNo ratings yet

- Mokveld Product Sheet Axial Control Valve 1Document2 pagesMokveld Product Sheet Axial Control Valve 1Belos SahajiNo ratings yet

- Steel DesignDocument180 pagesSteel DesignAndrick Alvarez100% (2)

- Simple and Fractional DistillationDocument5 pagesSimple and Fractional DistillationAlliah VegaNo ratings yet

- Review On Shear Thickening Fluids and ApplicationsDocument13 pagesReview On Shear Thickening Fluids and ApplicationsSEP-PublisherNo ratings yet

- ECSS E HB 32 20 - Part2A PDFDocument434 pagesECSS E HB 32 20 - Part2A PDFVesa RäisänenNo ratings yet

- ThermoCond 19 enDocument4 pagesThermoCond 19 enAnonymous 7z6OzoNo ratings yet

- Mech 3 Sem Strength of Materials c16 Apr 2018Document4 pagesMech 3 Sem Strength of Materials c16 Apr 2018Sundarasetty HarishbabuNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Psychrometry ProblemsDocument33 pagesPsychrometry Problems19R21A0334 MATTA SHASHANKNo ratings yet

- ITG43r - 07 Report On Structural Design andDocument66 pagesITG43r - 07 Report On Structural Design andHarun AlrasyidNo ratings yet

- Ressa Reslope and MsewDocument2 pagesRessa Reslope and Msewchehalis0% (1)

- Lab 7Document23 pagesLab 7Zorin RealceNo ratings yet

- Analysis Methods For Leakage Rates in Pressurized ComponentsDocument20 pagesAnalysis Methods For Leakage Rates in Pressurized ComponentsGeorgiosLupusMogueidaNo ratings yet

- Ceramic InternationalDocument11 pagesCeramic InternationalMohsin KhanNo ratings yet

- Construction and Building Materials: Sukhoon Pyo, Mo Alkaysi, Sherif El-TawilDocument10 pagesConstruction and Building Materials: Sukhoon Pyo, Mo Alkaysi, Sherif El-TawilKashif NaukhezNo ratings yet

- Optimal Cooling of a Tubular ReactorDocument24 pagesOptimal Cooling of a Tubular Reactorkingsley peprahNo ratings yet

- Radiation Heat Transfer Analysis in High EmissivitDocument7 pagesRadiation Heat Transfer Analysis in High EmissivitashvinNo ratings yet

- PRINCIPLES OF SEDIMENTATIONDocument7 pagesPRINCIPLES OF SEDIMENTATIONAhmad SalihNo ratings yet

- Modeling Oxidative Pyrolysis of WoodDocument11 pagesModeling Oxidative Pyrolysis of WoodJoel Bernardo ZavaletaNo ratings yet

- Heat ConductionDocument25 pagesHeat ConductionAnonymous z4Fe39jNo ratings yet

- Namma Kalvi 11th Physics Model Question Papers em 2020 217208 PDFDocument66 pagesNamma Kalvi 11th Physics Model Question Papers em 2020 217208 PDFvvn natrajNo ratings yet

- RiegelsAerofoilSections PDFDocument292 pagesRiegelsAerofoilSections PDFpickle77No ratings yet

- Chapter 9Document84 pagesChapter 9ERCAN ÖZERDENNo ratings yet

- Die CastingDocument267 pagesDie CastingSteel BeingNo ratings yet

- Test Question 1: Matching Items Column A 1.1 What TypeDocument3 pagesTest Question 1: Matching Items Column A 1.1 What TypeMadikgetlad376No ratings yet

- 12 - Deflection by Conjugate Beam MethodDocument7 pages12 - Deflection by Conjugate Beam MethodFrancis Ko Badongen-Cawi Tabaniag Jr.No ratings yet

- 3 - Absolute, Effective and Relative PermeabilitiesDocument34 pages3 - Absolute, Effective and Relative PermeabilitiesAhmad MammadovNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Quantum Physics: What Everyone Needs to KnowFrom EverandQuantum Physics: What Everyone Needs to KnowRating: 4.5 out of 5 stars4.5/5 (48)

- Summary and Interpretation of Reality TransurfingFrom EverandSummary and Interpretation of Reality TransurfingRating: 5 out of 5 stars5/5 (5)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessFrom EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessRating: 4 out of 5 stars4/5 (6)