Professional Documents

Culture Documents

Angle Probe

Uploaded by

Jeevanandam ShanmugasundaramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angle Probe

Uploaded by

Jeevanandam ShanmugasundaramCopyright:

Available Formats

Angle beam probe : Angle probes are used for detecting flaws oriented at an angle to the material surface.

They will miss flat reflectors, parallel or perpendicular to the scanning surface. The angled beam must hit the reflecting plane of the discontinuity at 900 for maximum reflection. Angle beam reflects well from corners but may undergo wave mode conversion. Usually shear wave probes are used in angle beam testing, because the refracted longitudinal wave probe will have a shear wave component of weaker intensity in the test material. Longitudinal wave angle probes are specially useful for testing austenitic stainless steel welds and inside surface of highly curved hollow parts and welds. Shear wave probes are used for testing welds, material defects in pipes, tubes, plates and sheets and in irregular shapes where full contact testing area is not available. Angle beam probes use the principle of refraction and mode conversion to produce refracted longitudinal and shear waves in the test part. In an angle beam probe, longitudinal wave is converted to refracted longitudinal or shear wave by means of an angled plastic wedge. The wedge is cut at an angle to provide an incident beam angle to produce refracted longitudinal or shear wave at the desired angle in Steel, because steel is tested in most applications. For designing small crystal low frequency probes, incident angle calculation based on snells law fails because of wider beam spread associated with these probes. The refracted angles will change in other materials because of velocity difference. A probe of 450 in steel will equal 430 in aluminum. The wedges have serrations cut on the front surface and fitted with absorbing medium to prevent internal reflections from producing unwanted echoes but some spurious echoes are often detectable just after the initial pulse. The wedge can be an integral part or can be detachable. In detachable system, a single transducer can be configured to different angles by changing the wedge and is economical. The detachable wedges are bigger and absorbs more energy. The detachable type requires couplant between the transducer and the wedge to permit transmission of ultrasound into the wedge. Standard angles are 35, 45, 60, 70 and 800 in steel. 800 and 350 probes have limited applications due to prevalence of surface waves from 800 and presence of longitudinal waves from 350 probes. Crystal sizes around 10 mm for miniature and 20 mm for bigger probes are most popular. Probes with 12.5 mm crystal size is normally recommended for standard test applications. Rectangular crystals are often used. Bigger probes have higher sensitivity and sharply focused sound beam and permit flaw detection at higher depth but cannot be placed very close to the weld edge. 4 MHz, 8 X 9 / 10 mm probes are very popular for their small contact area, high resolution and sharp echoes and are used up to a test distance of 200 mm in steel. Larger probes are mostly used for thick welds and for applications where sufficient probe contact area is available and a large area is to be scanned. A 20 X 22 mm, 2 MHz probe can detect a 2 mm reflector up to a distance of 700 mm. Twin crystal angle probes, longitudinal and shear, are available for direct scanning on ground weld surfaces and low thickness materials. These probes are more suitable for testing stainless steel and sound absorbing materials. With use, the beam exit point and the refracted beam angle will change with acrylic wear and should be checked before each use. The beam angle change should be controlled within + / - 20. New acrylic soles can be pasted with araldite to repair the wear. The front corner of the sole should be shaped to reduce spurious echoes. Performance : A good angle probe with a standard flaw detector, should produce a minimum 75% signal from the 100 mm radius of a standard IIW - V1 block with a minimum of 40 dB gain reserve. The probe should resolve at least three of the five holes [ clearly detectable peaks ] in the IOW beam profile block. Noise from internal reflections should not exceed 5% screen height, at all the working test sensitivity levels. Beam axis abnormality should be checked by maximizing a signal and moving the probe forward and backward and rotating left and right, while monitoring the falling signal. The signal should fall continuously without any sudden rise in signal height. Compiled by K. Chatterjee, 75643 Center for NDT P 00 Rv 05 Self study material.

You might also like

- EG II CAT 2 QPDocument1 pageEG II CAT 2 QPJeevanandam ShanmugasundaramNo ratings yet

- DESIGN AND FABRICATION OF Mini Bench Saw MachineDocument1 pageDESIGN AND FABRICATION OF Mini Bench Saw MachineJeevanandam ShanmugasundaramNo ratings yet

- Biotechnology Principles and ProcessesDocument16 pagesBiotechnology Principles and ProcesseslovehopeNo ratings yet

- Process Planning NotesDocument10 pagesProcess Planning NotesJeevanandam ShanmugasundaramNo ratings yet

- Unit II Process Planning GuideDocument16 pagesUnit II Process Planning GuideVisvas RajyaguruNo ratings yet

- Essaki Title PagesDocument16 pagesEssaki Title PagesJeevanandam ShanmugasundaramNo ratings yet

- MS Manonmani Sundaranar University BBA III Year Production ManagementDocument72 pagesMS Manonmani Sundaranar University BBA III Year Production ManagementJeevanandam ShanmugasundaramNo ratings yet

- CO PO I YearDocument8 pagesCO PO I YearJeevanandam ShanmugasundaramNo ratings yet

- VTU Project Report on Design of Multi-Purpose WheelchairDocument57 pagesVTU Project Report on Design of Multi-Purpose WheelchairsaleemNo ratings yet

- Course-PO Correlation MatrixDocument7 pagesCourse-PO Correlation MatrixJeevanandam ShanmugasundaramNo ratings yet

- Invention Disclosure Form-26.2.2020Document3 pagesInvention Disclosure Form-26.2.2020Jeevanandam ShanmugasundaramNo ratings yet

- Fundamentals of Gas Welding and CuttingDocument73 pagesFundamentals of Gas Welding and CuttingMalith Nadzy PereraNo ratings yet

- Pneumatic Systems ComponentsDocument17 pagesPneumatic Systems ComponentsJeevanandam ShanmugasundaramNo ratings yet

- CO PSO I YearDocument9 pagesCO PSO I YearJeevanandam ShanmugasundaramNo ratings yet

- Unit-Ii Flow of Fluids and Flow Through Pipes 2.1. Flow of FluidsDocument14 pagesUnit-Ii Flow of Fluids and Flow Through Pipes 2.1. Flow of FluidsJeevanandam ShanmugasundaramNo ratings yet

- Mechanical Engineering Exam Questions on Special MachinesDocument7 pagesMechanical Engineering Exam Questions on Special MachinesJeevanandam ShanmugasundaramNo ratings yet

- Unit - I Properties of Fluids and Pressure MeasurementsDocument2 pagesUnit - I Properties of Fluids and Pressure MeasurementsJeevanandam ShanmugasundaramNo ratings yet

- Values in Work LifeDocument3 pagesValues in Work LifeJeevanandam ShanmugasundaramNo ratings yet

- CADM U II 2 and 3 MarksDocument5 pagesCADM U II 2 and 3 MarksJeevanandam ShanmugasundaramNo ratings yet

- Periyar Centenary Polytechnic College: Department of Mechanical EngineeringDocument6 pagesPeriyar Centenary Polytechnic College: Department of Mechanical EngineeringJeevanandam ShanmugasundaramNo ratings yet

- First Monthly Examination: PO4 PO1 PO1 PO4Document4 pagesFirst Monthly Examination: PO4 PO1 PO1 PO4Jeevanandam ShanmugasundaramNo ratings yet

- Computer Aided Design and ManufacturingDocument161 pagesComputer Aided Design and Manufacturingsubra mani100% (5)

- Mechanical Engineering Exam on Electrical Drives and ControlDocument5 pagesMechanical Engineering Exam on Electrical Drives and ControlJeevanandam ShanmugasundaramNo ratings yet

- First Monthly Examination: PO4 PO1 PO1 PO4Document4 pagesFirst Monthly Examination: PO4 PO1 PO1 PO4Jeevanandam ShanmugasundaramNo ratings yet

- Department of Mechanical Engineering: Periyar Nagar - Vallam - 613 403 - ThanjavurDocument4 pagesDepartment of Mechanical Engineering: Periyar Nagar - Vallam - 613 403 - ThanjavurJeevanandam ShanmugasundaramNo ratings yet

- Fluid Mechanics Exam Questions on Indicator Diagrams, Negative Slip, Jet Pumps & Relief ValvesDocument5 pagesFluid Mechanics Exam Questions on Indicator Diagrams, Negative Slip, Jet Pumps & Relief ValvesJeevanandam ShanmugasundaramNo ratings yet

- Electrical Drives and ControlDocument224 pagesElectrical Drives and ControlvanthiyadevnNo ratings yet

- Periyar Centenary Polytechnic CollegeDocument2 pagesPeriyar Centenary Polytechnic CollegeJeevanandam ShanmugasundaramNo ratings yet

- Periyar Centenary Polytechnic College, Vallam Department of Mechanical EngineeringDocument2 pagesPeriyar Centenary Polytechnic College, Vallam Department of Mechanical EngineeringJeevanandam ShanmugasundaramNo ratings yet

- MODEL QPDocument4 pagesMODEL QPJeevanandam ShanmugasundaramNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Australian Welding Guide 2012Document220 pagesThe Australian Welding Guide 2012notsofar100% (2)

- Understanding ASTM 335 P11 Applications & Weldabilityt Rev1Document1,059 pagesUnderstanding ASTM 335 P11 Applications & Weldabilityt Rev1庄查理No ratings yet

- Water blasting: an effective method for cleaning stainless steelDocument4 pagesWater blasting: an effective method for cleaning stainless steelAlexander OsorioNo ratings yet

- Trepanning Positioning Welding ManualDocument14 pagesTrepanning Positioning Welding ManualGovindan PerumalNo ratings yet

- BS en 13414 1 2003Document19 pagesBS en 13414 1 2003Ganesh ModiNo ratings yet

- Method Statment For Hot Water System HD XXXDocument11 pagesMethod Statment For Hot Water System HD XXXJohan YazidNo ratings yet

- Edilflex en 20160523Document13 pagesEdilflex en 20160523bbNo ratings yet

- As 60974 1 2006 Arc Welding Equipment Welding Power Sources IEC 60974 1 2000 MOD PDFDocument8 pagesAs 60974 1 2006 Arc Welding Equipment Welding Power Sources IEC 60974 1 2000 MOD PDFAnderson Puentes OsorioNo ratings yet

- 26.design and Fabrication of Wind Powered VehicleDocument9 pages26.design and Fabrication of Wind Powered VehicleDanson KeinoNo ratings yet

- Ventilation For Welding and CuttingDocument3 pagesVentilation For Welding and Cuttingirene hulkNo ratings yet

- 1 Welding SafetyDocument51 pages1 Welding SafetyAfshadNo ratings yet

- Anchor Flanges Restrain Pipeline MovementDocument4 pagesAnchor Flanges Restrain Pipeline MovementRockny2011No ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument43 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesDinesh SinghNo ratings yet

- UEP Bulletin 1724E-204Document55 pagesUEP Bulletin 1724E-204Edwin Medina TroncosNo ratings yet

- E-Splice: Reinforcing Bar Couplers Through Friction-Weld TechnologyDocument7 pagesE-Splice: Reinforcing Bar Couplers Through Friction-Weld TechnologyLeon BruceNo ratings yet

- Internship Report 11710608Document46 pagesInternship Report 11710608Janeesh Pal SinghNo ratings yet

- Bolted ConnectionDocument36 pagesBolted ConnectionMeenuNo ratings yet

- Workshop TechnologyDocument62 pagesWorkshop TechnologyMuhammadJawadNo ratings yet

- Mazda 6 Body ShopDocument155 pagesMazda 6 Body Shopvera.victorNo ratings yet

- Radiography PresentationDocument28 pagesRadiography PresentationmqasimqasimNo ratings yet

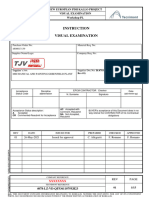

- 4078-Lz-Vd-Qp33611079xh23-Is01 Is.478.022a (PL) VT ApDocument15 pages4078-Lz-Vd-Qp33611079xh23-Is01 Is.478.022a (PL) VT Apqa-qcNo ratings yet

- Abrax 400 Data SheetDocument14 pagesAbrax 400 Data SheetJeetu GosaiNo ratings yet

- Din 1.4003Document2 pagesDin 1.4003Dhaniel100% (1)

- Sugar CaneMill V5.1Document7 pagesSugar CaneMill V5.1uksraj100% (1)

- ISOtankDocument21 pagesISOtankFernando Pereira Jr100% (1)

- Compliance Checklist of Structural Steelwork ManufacturedDocument7 pagesCompliance Checklist of Structural Steelwork ManufacturedAbdulrahman AlnasharNo ratings yet

- Wearplate en 09v5Document3 pagesWearplate en 09v5BepdjNo ratings yet

- Introduction To Phased Array Ultrasonic Technology Applications: Olympus GuidelineDocument5 pagesIntroduction To Phased Array Ultrasonic Technology Applications: Olympus GuidelineKevin HuangNo ratings yet

- Industrial Summer Training Report at ONGC Mehsana AssetDocument29 pagesIndustrial Summer Training Report at ONGC Mehsana AssetPrince PatelNo ratings yet

- HEYCO Kat 2012 EN PDFDocument218 pagesHEYCO Kat 2012 EN PDFjose03No ratings yet