Professional Documents

Culture Documents

Name of The Factory

Uploaded by

Al AminOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Name of The Factory

Uploaded by

Al AminCopyright:

Available Formats

Name of the Factory:

Chaity Composite Group Limited.

Location of the Factory:Village: New Tipuddy. P.S.: Sonargoan. P.O.: Boro Nogor. District: Narayonganj.

Production flow chart:Yarn Fabric Dyeing Finishing Garments Packing Delivery for shipment

Lay out plan of knitting section:-

Machine list:1) 2) 3) 4) 5) 6) 7) Gouding (cotton s/j-15, Micropolar-6) Fukuhara (Rib-9, s/j-10) Orizio (Rib-4, Interlock-4, s/j-8) Sun Da (s/j-40, Rib-2, interlock-1) Sun Da [open width] (s/j-8) Pailung[open width] (s/j-3) Kauo-Heng (V-bed rib-7)

Difference between different machine:Cylinder Needle Feeder No. of Cam Box Diameter Gauge Needle Guoding M/C Taiwan 30 18 96 1696 32 Co. Ltd.(cotton) Gouding M/C Taiwan 60 19 60 30 Co. Ltd(polyester) ORIZIO Italy 26 24 104 1620 88 Sun Da Taiwan 34 24 90 2260 34 FUKUHARA Japan 36 18 64 4070 16(Cylinder)+16(Dial) Sun Da (open Taiwan 30 24 90 2256 30 width) Pailung Auto Taiwan 64 24 308 4824 154 strip) Brand Origin

Flat Knitting Machinery list:Brand KauoHeng1 KauoHeng6 Origin Machine Width Taiwan 54 Taiwan 80 Needle gauge 14 14 No. of Needle

Yarn to fabric path diagram of Guoding s/j m/c:Package (cone form) Yarn guide Tension device Yarn guide Auto stopper Yarn guide Positive feeder Yarn guide Auto stopper Yarn guide Feeder Needle Fabric Squeezing roller Fabric roll

Yarn to fabric path diagram of Double jersey (FUKUHARA m/c):-

Package (cone form) Yarn guide Active guide Tension device Auto stopper Yarn guide Positive feeder Auto stopper Yarn guide Guide Feeder Needle Fabric Squeezing roller Fabric roll

Yarn to fabric path diagram of V-bed Double jersey (Kauo-Heng m/c):-

Package (cone form) Yarn guide Tension device (spring type) Yarn guide Auto stopper Yarn guide Guide Guide Guide Feeder Auto stopper Guide Guide Guide Feeder Needle Fabric (collar, cuff)

Maintenance Tools: 1) 2) 3) 4) 5) 6) 7) 8) 9) Thread tape(taflon tape) Hexo blade Pile Dhali( Plain, Ring) L.L. key T.L. key Q.P. key Gauge meter Tension meter

Name of the Knitted Fabrics:1) 3T fleece 2) Baby Tarry 3) Lacoste( s/j, d/j) 4) Pica( s/j, d/j) 5) Single jersey 6) Thermal(rib) 7) Opcl(rib) 8) Tarry(coolmax) (rib) 9) Interlock 10) Plain s/j 11) Full feeder lycra

Derivatives of the Fabrics:1) 2) 3) 4) 5) 6) 11 S/j 11 Rib 11 Interlock 33 Rib 31 Rib 21 Interlock

Production per Day:Average: 18-20tons per day Highest: 28tons per day

Types and causes of Faults:1) Lycra drop: if Lycra yarn tron it makes a gap line in the fabric. 2) Star mark: if yarn thorn and join it by knotting then a knot spot shows in the fabric which looks like star. 3) Hole: if m/c not works properly, for G.S.M. cutter. 4) Long loop: if cam not works properly or cam breaks. 5) Needle breakage Line: if needle breaks. 6) Count Mix: if different types of yarn are feed to the m/c. 7) Knot spot: if knot is not given properly. 8) Sate up: if more than one needle breaks it creates sate up. 9) Oil mark: when any hole is creating on oil pipe and fall onto the fabric it creates oil spot. 10) Edge mark: when squeezing rollers pressure is so high, it creates EDGE mark on the edge of the fabric. 11) Band line: if yarn thorns from width wise it calls Band line. 12) Wrong Design: if knitting m/c runs with the construction of a fabric which is not required for that m/c it creates wrong design. 13) G.S.M. variation: this type of fault mainly creates by operator. If operator give different count of yarn in the creel. 14) Sinker mark: when fabric is take down from sinker it creates a line. This is visible after dyeing. 15) Abrasion mark: it mainly create in Compaction m/c. There is some blade which makes the fabric smooth. If the blades are dirty it makes abrasion mark. 16) Stripe: if yarn or Lycra missed it creates stripe.

Yarn storing system:Cone formed yarn packages are stored in cartoon and bale

Fabric storing system: Fabric stored in roll form. 1 roll = 15-20Kg.

Fiber Types:1) Cotton 2) Polyester 3) Lycra

Count Used:26s, 30s, 34s, 36s, 16s, 12s

G.S.M.:No 1 2 3 4 5 30s Fabric s/j Rib Lacoste Baby tarry Micro Polar Fleece G.S.M. 230-170 250-210 260-220 260-220 280-180 No . 1 2 3 4 34s Fabric s/j Rib Lacoste Baby tarry G.S.M. No. 1 2 3 4 26s Fabric s/j Rib Lacoste Baby terry G.S.M. 260-220 290-210 290-130 290-130

200-140 190-160 190-150 190-150

Which count of yarn is mostly used?

26s, 30s, 34s It also depends on buyers demand.

Which GSM fabric is mostly produced?

140, 150, 170, 180, 210

What type of color fabric is mostly produced?

Black, Red, White, Stripe, Gray

Which types of fault is show on fabrics?

Star mark, Hole, Sate up, Stripe, Needle Breakage line, Band line.

Yarn collected from:Thailand, Bangladesh, India, Taiwan.

You might also like

- Costing of Men's Formal ShirtDocument8 pagesCosting of Men's Formal ShirtHaqiqat Ali94% (17)

- Carding BookletDocument46 pagesCarding Bookletsitu_tex859480% (5)

- KnittingDocument15 pagesKnittingReyad Billah100% (1)

- Effect of Machine Parameters On Knit Fabric SpecificationsDocument5 pagesEffect of Machine Parameters On Knit Fabric SpecificationsGarmentLearnerNo ratings yet

- Textile Internship at VardhmanDocument60 pagesTextile Internship at VardhmanNeetek SahayNo ratings yet

- Denim - ProcessDocument28 pagesDenim - ProcessSajjad Ashraf100% (1)

- Analysis of Plain Single Jersey Fabric & Its DerivativesDocument8 pagesAnalysis of Plain Single Jersey Fabric & Its DerivativesShahadat HossainNo ratings yet

- Fiber and YarnDocument38 pagesFiber and YarnPutri Mayangsari100% (1)

- Acoustic in Plumbing - CEU208Document19 pagesAcoustic in Plumbing - CEU208Harshal ShahNo ratings yet

- Project On Knitted Fabric ParametreDocument58 pagesProject On Knitted Fabric ParametreMozzammal Hossain Shaown100% (3)

- Sewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerFrom EverandSewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerRating: 4 out of 5 stars4/5 (3)

- Vanguard SupremeDocument8 pagesVanguard SupremeEmanuel CastellanosNo ratings yet

- Thread ConsumptionDocument4 pagesThread ConsumptionMd Mamun Hosain100% (1)

- Sa 20Document46 pagesSa 20Raju Sk100% (1)

- Leaching Worked ProblemsDocument14 pagesLeaching Worked ProblemsSummer Wynn Dacwag67% (6)

- Classimate Fualt DescriptionDocument16 pagesClassimate Fualt DescriptionSaad Naseem100% (2)

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsFrom EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsRating: 3 out of 5 stars3/5 (1)

- Organic Chemistry Lesson on Cyclic HydrocarbonsDocument12 pagesOrganic Chemistry Lesson on Cyclic HydrocarbonsShamarie Love MaribaoNo ratings yet

- Fabric-Construction-Methods (Questions) PDFDocument6 pagesFabric-Construction-Methods (Questions) PDFTamer Farouk Khalifa67% (3)

- Non WovenDocument28 pagesNon WovenAl AminNo ratings yet

- Matrix Doc NIFTDocument61 pagesMatrix Doc NIFTSiddhesh GautamNo ratings yet

- Nahar PresentationDocument28 pagesNahar Presentationsurbhi168950% (2)

- Presentation ShrinkageDocument27 pagesPresentation Shrinkagemhrscribd014No ratings yet

- Knitting machine stoppages impact fabric productionDocument8 pagesKnitting machine stoppages impact fabric productionMr AdibNo ratings yet

- Warp KnittingDocument44 pagesWarp KnittingEngineer WaleedNo ratings yet

- Spinning Department Hierarchy and Process FlowDocument14 pagesSpinning Department Hierarchy and Process FlowWaqas AkramNo ratings yet

- Comparative Analysis of Fabrics Made From Eli-TwisDocument5 pagesComparative Analysis of Fabrics Made From Eli-TwisMễro ĢANo ratings yet

- Study on Usable and Unusable Cotton Waste Produced in Spinning MillsDocument34 pagesStudy on Usable and Unusable Cotton Waste Produced in Spinning Millsmortuza hasanNo ratings yet

- A Study On Sewability On Denim FabricsDocument6 pagesA Study On Sewability On Denim FabricsgraceNo ratings yet

- Textile Training-Maintannance+knittingDocument60 pagesTextile Training-Maintannance+knittingAlamin KhanNo ratings yet

- M05 Weft Knitting Technologies I SWDocument10 pagesM05 Weft Knitting Technologies I SWMamun Zaman100% (1)

- Knitting: Knitting Is A Inter Locking / Inter Looping / Inter Matching of Loops Which Form ADocument30 pagesKnitting: Knitting Is A Inter Locking / Inter Looping / Inter Matching of Loops Which Form AMonirHossain100% (1)

- Learn Textile0Document208 pagesLearn Textile0Hassan ShahzadNo ratings yet

- To Study The Impact On Process Parameter of Knitted Fabric: April 2011Document20 pagesTo Study The Impact On Process Parameter of Knitted Fabric: April 2011Fahad AshfaqNo ratings yet

- Question For InterviewDocument1 pageQuestion For InterviewMs. Naznin AkterNo ratings yet

- Factory Profiles (Latest) Basic ShirtDocument3 pagesFactory Profiles (Latest) Basic ShirtSadia Sharmin NilimaNo ratings yet

- Figure Out The Weight Loss Percentage of Three Thread Fleece Fabric Composed of Different Fibres For Abrasion On The Technical Back SideDocument5 pagesFigure Out The Weight Loss Percentage of Three Thread Fleece Fabric Composed of Different Fibres For Abrasion On The Technical Back SideMahabbat HossainNo ratings yet

- Six SigmaDocument6 pagesSix Sigmasayeef khanNo ratings yet

- Common Faults in Knitting FabricsDocument19 pagesCommon Faults in Knitting FabricsNeFariOus ArYan AraFat AnikNo ratings yet

- Weft Knit DesignDocument6 pagesWeft Knit DesignAhmed AksarNo ratings yet

- Special Fabric Lab (Group) PDFDocument39 pagesSpecial Fabric Lab (Group) PDFShah Abir MustabNo ratings yet

- Sewn Products and Machinery Equipments Jury AssignmentDocument24 pagesSewn Products and Machinery Equipments Jury AssignmentSreejita MahapatraNo ratings yet

- Aim & Objective of Project: Richa & CoDocument31 pagesAim & Objective of Project: Richa & CoRanvijay Singh RathoreNo ratings yet

- Textile Spinning To Finishing Process: Business English ProgramDocument41 pagesTextile Spinning To Finishing Process: Business English ProgramM.TauqeerNo ratings yet

- Knitted Spacer Fabric - Manufacturing Techniques and ApplicationDocument8 pagesKnitted Spacer Fabric - Manufacturing Techniques and ApplicationomiNo ratings yet

- Advancements in Garment Manufacturing TechnologyDocument19 pagesAdvancements in Garment Manufacturing TechnologyShanmugeshwari MuthiahNo ratings yet

- Experiment No. 01 Experiment Name: Study On Layout Plan of ApparelDocument7 pagesExperiment No. 01 Experiment Name: Study On Layout Plan of ApparelTanzila Nusrat100% (2)

- Exp. No. 01 Name of The Exp: Study On Layout Plan of Knitting Shade ObjectsDocument7 pagesExp. No. 01 Name of The Exp: Study On Layout Plan of Knitting Shade ObjectsAriful Islam Tonmay0% (1)

- Weft Knitting (Suza)Document16 pagesWeft Knitting (Suza)Suza Ahmed AuporboNo ratings yet

- Basic Garments Information.Document5 pagesBasic Garments Information.Aamir AhmedNo ratings yet

- Spinning Final Questions by Satex NewDocument10 pagesSpinning Final Questions by Satex Newsaif rajNo ratings yet

- Fabric Detail SheetDocument2 pagesFabric Detail SheetsabrygNo ratings yet

- Comparative Study of Sweater Industry in BangladeshDocument26 pagesComparative Study of Sweater Industry in BangladeshsatexNo ratings yet

- Grey Departmen & Weaving FinishingtDocument60 pagesGrey Departmen & Weaving FinishingtKomol KabirNo ratings yet

- Knit Fabric FaultDocument9 pagesKnit Fabric FaultLucas HillNo ratings yet

- Chapter-7-Knitting-MachineryDocument34 pagesChapter-7-Knitting-Machineryadib1894No ratings yet

- Apparel MerchandisingDocument29 pagesApparel MerchandisingMohammad Hossain100% (1)

- Fabric Defects & InspectionDocument23 pagesFabric Defects & InspectionYogesh SharmaNo ratings yet

- Materi PTT NewDocument25 pagesMateri PTT NewMark Riha JrNo ratings yet

- Intern ReportDocument121 pagesIntern ReportMd Chinto100% (2)

- Fabric Weight For KnitDocument36 pagesFabric Weight For KnitMohammad Zahirul IslamNo ratings yet

- Industrial Project by (Abir Das)Document70 pagesIndustrial Project by (Abir Das)Mamun IENo ratings yet

- MSK Yarn Spinning ProcessDocument31 pagesMSK Yarn Spinning ProcessZaheed RahmanNo ratings yet

- Textile Division: Knit Collar Cuff EtcDocument3 pagesTextile Division: Knit Collar Cuff EtcAl AminNo ratings yet

- Lecture-7 & 8: Handbook For Understanding and Implementation of ISO 9001:2008Document18 pagesLecture-7 & 8: Handbook For Understanding and Implementation of ISO 9001:2008Al AminNo ratings yet

- Organize and Bargain Collectively in A Lawful and Peaceful Manner Without Penalty or InterfaceDocument1 pageOrganize and Bargain Collectively in A Lawful and Peaceful Manner Without Penalty or InterfaceAl AminNo ratings yet

- Cost Analysis: Quality Comes First, Rest Are ConsequencesDocument5 pagesCost Analysis: Quality Comes First, Rest Are ConsequencesAl AminNo ratings yet

- Corporate OfficeDocument1 pageCorporate OfficeAl AminNo ratings yet

- Corporate OfficeDocument1 pageCorporate OfficeAl AminNo ratings yet

- Textile Division: Knit Collar Cuff EtcDocument3 pagesTextile Division: Knit Collar Cuff EtcAl AminNo ratings yet

- GarmentsDocument2 pagesGarmentsAl AminNo ratings yet

- Woven Fabric Design ElementsDocument236 pagesWoven Fabric Design ElementsAl Amin100% (1)

- Organize and Bargain Collectively in A Lawful and Peaceful Manner Without Penalty or InterfaceDocument1 pageOrganize and Bargain Collectively in A Lawful and Peaceful Manner Without Penalty or InterfaceAl AminNo ratings yet

- Protection of The Environment:: CHAITY GROUP Has Been Adding Dimensions To The Knitwear and Woven Garments IndustriesDocument1 pageProtection of The Environment:: CHAITY GROUP Has Been Adding Dimensions To The Knitwear and Woven Garments IndustriesAl AminNo ratings yet

- Code of ConductDocument1 pageCode of ConductAl AminNo ratings yet

- Functon of Parts in Air JetDocument2 pagesFuncton of Parts in Air JetAl Amin100% (6)

- Serial No Observations Results Obtained 1Document1 pageSerial No Observations Results Obtained 1Al AminNo ratings yet

- Woven FabricDocument1 pageWoven FabricAl AminNo ratings yet

- Batch & Lab Group: 13: Southeast University Fabric Structure & Design Job Sheet 2 (C)Document2 pagesBatch & Lab Group: 13: Southeast University Fabric Structure & Design Job Sheet 2 (C)Al AminNo ratings yet

- IR Spectroscopy Guide to Functional GroupsDocument11 pagesIR Spectroscopy Guide to Functional GroupsAl AminNo ratings yet

- MathDocument1 pageMathAl AminNo ratings yet

- SerialDocument1 pageSerialAl AminNo ratings yet

- Standard CVDocument2 pagesStandard CVAl AminNo ratings yet

- WPT 1 (Tex 2015)Document63 pagesWPT 1 (Tex 2015)Al Amin100% (1)

- Batch & Lab Group: 13: Southeast University Fabric Structure & Design Job Sheet 2 (C)Document2 pagesBatch & Lab Group: 13: Southeast University Fabric Structure & Design Job Sheet 2 (C)Al AminNo ratings yet

- Great News For Teletalk 3g UsersDocument2 pagesGreat News For Teletalk 3g UsersAl AminNo ratings yet

- Different Types of Industrial Sewing MachineDocument1 pageDifferent Types of Industrial Sewing MachineAl AminNo ratings yet

- Yarn Count ConverterDocument2 pagesYarn Count ConverterAl AminNo ratings yet

- Apparel TestingDocument9 pagesApparel TestingAl AminNo ratings yet

- Utf 8''sensornotesDocument10 pagesUtf 8''sensornotesAl AminNo ratings yet

- Neutralization: PH Control: ProblemsDocument3 pagesNeutralization: PH Control: ProblemsAl AminNo ratings yet

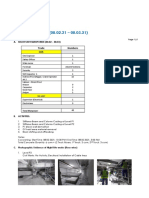

- Night Shift Report 08.02.21-08.03.21Document7 pagesNight Shift Report 08.02.21-08.03.21Julius Ceasar SanorjoNo ratings yet

- Inorganic NomenclatureDocument65 pagesInorganic NomenclatureCalm your MindNo ratings yet

- Furnace Technology Argon PurgingDocument7 pagesFurnace Technology Argon Purgingvasanthi100% (1)

- Temparature Sensor. CompleteDocument15 pagesTemparature Sensor. CompleteMarvin BenedictoNo ratings yet

- Techniques For Controlling Pathogenic MicroorganismsDocument17 pagesTechniques For Controlling Pathogenic MicroorganismsMäê MedrosoNo ratings yet

- A New Lead Alloy For Automotive Batteries Operating Under High TemperatureDocument7 pagesA New Lead Alloy For Automotive Batteries Operating Under High Temperatureehsan453No ratings yet

- Lab GTM A1Document5 pagesLab GTM A1Rheymar Serote TomasNo ratings yet

- C 3 StoichDocument38 pagesC 3 StoichJay-Rald LammataoNo ratings yet

- Synova ChemicalsDocument201 pagesSynova ChemicalsInnovation InnovationNo ratings yet

- Products of CombustionDocument5 pagesProducts of CombustionAJ SiosonNo ratings yet

- Raw Materials and Reactions for Urea ManufactureDocument2 pagesRaw Materials and Reactions for Urea ManufactureTusharNo ratings yet

- DS - 1070 Eco - 09.07.2018Document4 pagesDS - 1070 Eco - 09.07.2018spencerNo ratings yet

- Chapter 6 - Multiphase Systems: CBE2124, LevickyDocument27 pagesChapter 6 - Multiphase Systems: CBE2124, LevickyRimmonNo ratings yet

- Graphical Representation of Mineral CompositionDocument8 pagesGraphical Representation of Mineral CompositionMaMtNo ratings yet

- BF ThermoDocument5 pagesBF ThermoLucky AliNo ratings yet

- MUlecular Distilation UnitDocument6 pagesMUlecular Distilation UnitElly SufriadiNo ratings yet

- Shortcrete PDFDocument4 pagesShortcrete PDFhelloNo ratings yet

- Effect of Surface Pre-Treatments on Adhesive Bond StrengthDocument6 pagesEffect of Surface Pre-Treatments on Adhesive Bond StrengthMuhammad Abbas MehdiNo ratings yet

- Geography Year 4 TestDocument2 pagesGeography Year 4 TestladeahmagdalyneNo ratings yet

- Refined Rice Bran Oil MSDSDocument3 pagesRefined Rice Bran Oil MSDSvickyNo ratings yet

- Gummy Bear LabDocument3 pagesGummy Bear Labapi-266459443No ratings yet

- 15-Ktp PRR PipesDocument46 pages15-Ktp PRR PipesmohammedNo ratings yet

- Recommended Performance Guideline Micro Surfacing: NoticeDocument17 pagesRecommended Performance Guideline Micro Surfacing: NoticeRaAl GaRuNo ratings yet

- Stromme Cement & Rust Remover: Product DescriptionDocument1 pageStromme Cement & Rust Remover: Product Descriptiona.khinkiladze86No ratings yet

- Catalog Rigole WAVINDocument12 pagesCatalog Rigole WAVINAdelina PristavuNo ratings yet