Professional Documents

Culture Documents

Product Catalogue 2008

Uploaded by

Mircea TomusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Catalogue 2008

Uploaded by

Mircea TomusCopyright:

Available Formats

New in 2008

TERA Joint

PRODUCT CATALOGUE

2008 2009

2

PEIKKO GROUP

Peikko Group, a Finnish family-owned

company, is a pioneer in the fastening

technology of concrete structures.

The company was founded in 1965 by the name

of Terspeikko, which translates into Steel troll.

Peikkos rst product, diagonal tie for sandwich

panel, was the rst industrial product of that

category at the time. The company has ever since

remained forward-looking and innovative. It has

been able to continuously launch new products

together with its customers and successfully

implement modern and cost-efcient production

technologies.

One of the leading companies in Europe

with a goal to continue to be local

Peikko Group operates in more than 20 countries in

Europe and has started activities in North-America

and Middle-East. With more than 800 employees

and with estimated net sales of 120 million EUR in

2008, the company is well-positioned to serve its

customers. Peikko Group serves its customers locally

via vast network of subsidiaries.

www.peikko.com

SALES, DISTRIBUTION AND PRODUCTION

SALES AND DISTRIBUTION

SALES

Contact information

Peikko Group

Peikko Group

P.O.Box 104

Voimakatu 3

FIN - 15101 Lahti

Tel. +358 3 844 511

Fax +358 3 733 0152

www.peikko.com

3

CONTENTS

Approvals

Our products have approvals in various countries

including Finland, Germany, Poland, Russia, Great

Britain and Sweden. See details in product sections.

Quality and environment

The results of the work in quality and environment

are inspected regularly by external audits carried

out by Inspecta Certication, VTT Technical Research

Centre, SITAC Swedish Institute for Technical

Approval in Construction, Schweitechnische

Lehr- und Versuchsanstalt SLV Hannover and

Ministry Of Construction Russia Federal Centre

Of Certication / OS Svzapstroisertikatsiya St.

Petersburg.

Technical information

Detailed technical information and limitations for

application, requirements for the concrete and

correction factors for capacities can be found in

products technical manual. The technical information

is available in our website or as printed manuals on

request.

5. REINFORCEMENT

PRODUCTS

28

4. TIES

26

3. CORBELS, HANGERS

18

2. BOLTS,

COLUMN SHOES

12

1. FASTENING PLATES

4

6. LIFTING SYSTEMS

36

7. BALCONY JOINTS

44

8. EXPANSION JOINTS

46

9. DELTABEAM,

PEIKKO FRAME

50

4

1. FASTENING PLATES

KIINNITYSLEVYT

Betoniyhdistyksen kyttselosteet 230, 242 ja 243 Korvaa esitteet 8/02, 11/92 ja 9/91 vli 1, 9/2007

FASTENING PLATES

Standard fastening plates have

protective painting 40 m. Also

available in epoxy coating or hot

dip galvanized.

SBKL fastening plates

KL fastening plates

JPL fastening plates

PKL fastening plates

P2KL fastening plates

P3KL fastening plates

Plate thickness 8 - 15 mm.

Headed studs. For lighter

loads. Especiallly for walls

and thin structures.

Plate thickness 8 - 15 mm.

Straight ribbed bars as

anchors. Welded on surface.

Especially suits well on

dynamic anchoring

Long fastening plate.

Standard lenght 2 m. Plate

thickness 12 mm and headed

studs welded on surface.

Long fastening plate.

Standard lenght 2 m. Plate

thickness 15 or 20 mm and

headed studs welded on hole.

Long fastening plate. Plate

thickness 25 mm and headed

studs welded on hole.

Plate thickness 25 or 30 mm.

Ribbed bars with headed

studs. Standard fastening

plate for demanding xings.

Collection of fastening items for

standard elements. Mainly for

prefabricators

Corner protector. Anchors

welded on surface. 25 mm

chamfer on corner. Delivered

painted A40 m, hot dip

galvanized or stainless.

KS corner protector

TR fastening items

Corner protector. Standard

lenght 6m. Anchors are welded

on surface. Is being used in

columns, oors and walls.

Delivered painted A40m, hot

dip galvanized or stainless.

Fastening angle bar for

opening or corner. Anchors as

in UKT. Standard lenght 6 m.

To edge of openings in which

the cover plate is installed.

Standard lenght 6 m.

Standard lenght 6m. Headed

for anchors.Standard angles

50, 80 and 100 mm.

UKT fastening angle bar

SKT fastening angle bar

KKT fastening angle bar

Support for chequered plate

5

www.peikko.com

F

a

s

t

e

n

i

n

g

p

l

a

t

e

s

AxDxt H d a N

Rd

V

Rd

M

RdD

M

RdA

T

rd

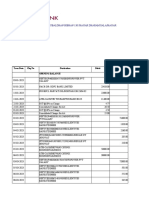

JPL

[mm] [kN] [kNm] [kg]

JPL 150x150 150x150x25 220 90 90 16 177 61,0 15,1 15,1 4,8 5,9

JPL 150x200 150x200x25 220 120 100 20 295 96,7 31,4 23,6 8,9 8,3

JPL 150x250 150x250x25 220 190 100 20 316 101,0 49,7 23,6 12,5 9,8

JPL 200x200 200x200x25 220 120 120 20 314 100,4 31,4 31,4 10,0 10,3

JPL 200x250 200x250x25 220 190 120 20 339 103,0 49,7 31,4 13,3 12,2

JPL 250x250 250x250x25 220 190 190 20 369 107,0 49,7 49,7 15,9 14,7

JPL 200x300 200x300x25 280 200 120 25 533 161,0 81,8 49,1 21,6 16,6

JPL 300x300 300x300x25 280 200 200 25 584 168,0 81,8 81,8 26,2 22,5

JPL 400x400 400x400x30 280 300 300 25 646 173,0 123,0 123,0 39,3 44,0

JPL 500x500 500x500x30 280 400 400 25 682 176,0 164,0 164,0 52,3 63,7

JPL 600x600 600x600x30 280 500 500 25 705 178,0 205,0 205,0 65,4 89,6

plate anchor

JPL S355J0 A500HW

JPLR 1.4301 A500HW

JPLRr 1.4301 hot-rolled stainless rebar*

JPLH 1.4401 A500HW

*= strenght equal to A500HW

N

Rd

V

Rd

M

RdD

M

RdA

T

rd

TT

[kN] [kNm]

177 61,0 15,1 15,1 4,8

295 96,7 31,4 23,6 8,9

316 101,0 49,7 23,6 12,5

314 100,4 31,4 31,4 10,0

339 103,0 49,7 31,4 13,3

369 107,0 49,7 49,7 15,9

533 161,0 81,8 49,1 21,6

584 168,0 81,8 81,8 26,2

646 173,0 123,0 123,0 39,3

682 176,0 164,0 164,0 52,3

705 178,0 205,0 205,0 65,4

H

t

D

A

d

a

JPL

For xings where great

capacities are needed.

JPL is painted A40 m. We also manufacture completely stainless and acid-proof JPL fastening plates.

JPL fastening plates

Materials of JPL

APPROVALS:

ETA 04/0056,

BY243 Finland,

3403/89 Sweden,

AT-15-5256/2002 Poland,

POCC FI.C19.H00289 Russia.

6

AxDxt H d a N

Rd

V

Rd

M

RdD

M

RdA

T

Rd

SBKL

[mm] [kN] [kNm] [kg]

SBKL 50x100 50x100x8 68 60 - 12 7,7 9,8 0,38 0,28 0,49 0,5

SBKL 100x100 100x100x8 68 60 60 12 13,7 19,3 0,68 0,68 1,38 0,9

SBKL 100x150 100x150x10 70 90 60 12 18,4 19,3 1,20 0,91 1,76 1,5

SBKL 150x150 150x150x12 162 90 90 12 39,6 22,6 2,57 2,57 2,10 2,7

SBKL 100x200 100x200x12 162 120 60 12 37,2 19,3 2,96 1,86 2,15 2,5

SBKL 200x200 200x200x12 162 120 120 16 82,8 43,5 6,62 6,62 4,92 4,9

SBKL 250x250 250x250x15 165 170 170 16 91,7 45,0 8,70 8,70 6,0 8,6

SBKL 100x300 100x300x15 165 180 60 16 72,3 34,8 7,94 3,61 5,50 4,7

SBKL 200x300 200x300x15 165 180 120 16 90,3 43,5 9,94 7,22 6,28 8,2

SBKL 300x300 300x300x15 165 180 180 16 98,5 47,5 10,80 10,80 7,38 11,9

AxDxt H d a N

Rd

V

Rd

M

RdD

M

RdA

T

Rd

KL

[mm] [kN] [kNm] [kg]

KL 50x100 50x100x8 218 60 - 12 7,7 9,8 0,38 0,28 0,49 0,7

KL 100x100 100x100x8 218 60 60 12 13,7 19,3 0,68 0,68 1,38 1,4

KL 100x150 100x150x10 220 90 60 12 18,4 19,3 1,20 0,91 1,76 2,0

KL 150x150 150x150x12 222 90 90 16 39,6 22,6 2,57 2,57 2,10 3,6

KL 100x200 100x200x12 222 120 60 16 37,2 19,3 2,96 1,86 2,15 3,3

KL 200x200 200x200x12 312 120 120 20 82,8 43,5 6,62 6,62 4,92 6,9

KL 100x300 100x300x15 315 180 60 20 72,3 34,8 7,94 3,61 5,50 6,7

KL 200x300 200x300x15 315 180 120 20 90,3 43,5 9,94 7,22 6,28 10,3

KL 300x300 300x300x15 315 180 180 20 98,5 47,5 10,80 10,80 7,38 13,9

plate anchors

KL S355J0 A500HW

KLR 1.4301 A500HW

KLH 1.4401 A500HW

plate anchors

SBKL S355J0 S235J2+N/S355J2+N

SBKLR 1.4301 S235J2+N/S355J2+N

SBKLRr 1.4301 1.4301

SBKLH 1.4401 S235J2+N/S355J2+N

N

Rd

V

Rd

M

RdD

M

RdA

T

Rd

[kN] [kNm]

7,7 9,8 0,38 0,28 0,49

13,7 19,3 0,68 0,68 1,38

18,4 19,3 1,20 0,91 1,76

39,6 22,6 2,57 2,57 2,10

37,2 19,3 2,96 1,86 2,15

82,8 43,5 6,62 6,62 4,92

91,7 45,0 8,70 8,70 6,0

72,3 34,8 7,94 3,61 5,50

90,3 43,5 9,94 7,22 6,28

98,5 47,5 10,80 10,80 7,38

N

Rd

V

Rd

M

RdD

M

RdA

T

Rd

[kN] [kNm]

7,7 9,8 0,38 0,28 0,49

13,7 19,3 0,68 0,68 1,38

18,4 19,3 1,20 0,91 1,76

39,6 22,6 2,57 2,57 2,10

37,2 19,3 2,96 1,86 2,15

82,8 43,5 6,62 6,62 4,92

72,3 34,8 7,94 3,61 5,50

90,3 43,5 9,94 7,22 6,28

98,5 47,5 10,80 10,80 7,38

t H

D

A

a

d

H

t

A

D

a

d

SBKL fastening plates

KL fastening plates

SBKL is painted A40m. SBKL 50/100 and SBKLR 50/100 are packed 40 pcs / box.

KL is painted A40m. KL 50/100 and KLR 50/100 are packed 30 pcs / box. KL 100/100 and KLR 100/100 are

packed 20 pcs / box. We also manufacture completely stainless or acid-proof KL fastening plates.

Materials of KL

Materials of SBKL

APPROVALS:

ETA 04/0056,

BY266 Finland,

3403/89 Sweden,

AT-15-5256/2002 Poland,

POCC FI.C19.H00289 Russia

APPROVALS:

BY266 Finland,

3403/89 Sweden,

AT-15-5256/2002 Poland,

POCC FI.C19.H00289 Russia

7

www.peikko.com

F

a

s

t

e

n

i

n

g

p

l

a

t

e

s

A H a t c/c N

Rd

V

Rd1

V

Rd2

weight

[mm] [kN] [~kg/m]

PKL 100 100 70 50 12 10 150 15,2 14,4 13,4 9

PKL 150 150 70 90 12 10 150 22,7 14,4 13,8 13

PKL 200 200 70 100 12 10 150 24,4 14,4 13,9 17

Prices are for the lenght L=2000 mm

A H a t c/c N

Rd

V

Rd1

V

Rd2

weight

[mm] [kN] [~kg/m]

P2KL 100 100 115 50 16 15 200 35,6 24,9 24,8 14

P2KL 150 150 115 90 16 15 200 44,4 25,0 24,8 20

P2KL 200 200 115 100 16 15 200 45,7 25,0 24,8 26

P2KL 300 300 115 200 16 15 200 53,3 25,4 24,8 38

P2KL 400 400 115 200 16 20 200 53,3 25,4 24,8 66

Prices are for the lenght L=2000 mm

A H a t c/c N

Rd

V

Rd1

V

Rd2

weight

[mm] [kN] [~kg/m]

P3KL 300 300 220 200 20 25 200 143,5 57,6 56,8 68

P3KL 400 400 220 300 20 25 200 143,5 58,3 56,8 88

P3KL 500 500 220 400 20 25 200 143,5 59,1 56,8 108

P3KL 600 600 220 500 20 25 200 143,5 59,7 56,8 128

plate anchors

PKL, P2KL, P3KL S355J0 S235J2+N/S355J2+N

PKLR, P2KLR, P3KLR 1.4301 S235J2+N/S355J2+N

PKLH, P2KLH, P3KLH 1.4401 S235J2+N/S355J2+N

APPROVALS:

BY230 Finland,

3403/89 Sweden,

AT-15-5256/2002 Poland,

POCC FI.C19.H00289 Russia.

N

Rd

V

Rd1

V

Rd2

[kN]

35,6 24,9 24,8

44,4 25,0 24,8

45,7 25,0 24,8

53,3 25,4 24,8

53,3 25,4 24,8

N

Rd

V

Rd1

V

Rd2

[kN]

15,2 14,4 13,4

22,7 14,4 13,8

24,4 14,4 13,9

N

Rd

V

Rd1

V

Rd2

[kN]

143,5 57,6 56,8

143,5 58,3 56,8

143,5 59,1 56,8

143,5 59,7 56,8

a

t

H

A

c/c

a

t

H

A

c/c

t H

a

A

c/c

PKL fastening plates

P2KL fastening plates

P3KL fastening plates

Materials of PKL, P2KL, P3KL

Long fastening plates (PKL, P2KL ja P3KL) capacities are per one row of

anchors.

8

H D t V

Rd

weight

[mm] [kN] [kg]

TR 15 570 455 8 10 34,6 2,5

TR 16 675 480 10 12 50,4 3,9

D A angle N

1Rd

N

2Rd

V

Rd

M

Rd

weight

[mm] [kN] [kNm] [kg]

TR 23 270 100 60x60x6 6 (7) 13,8 3,6 6,0 0,53 0,8

TR 24 350 100 80x80x8 8 (9) 24,8 6,4 10,7 1,26 1,5

H D A angle N

Rd

V

1Rd

V

2Rd

weight

[mm] [kN] [kg]

TR 25 350 315 150 80x80x8 8 83,7 16,0 7,2 2,0

TR 26 450 415 150 100x100x10 10 117,5 28,5 14,1 3,2

H D A angle N

Rd

V

Rd

M

Rd

weight

[mm] [kN] [kNm] [kg]

TR 36 200 210 80 60x60x6 6 (7) 8,7 6,0 0,65 0,9

TR 37 250 270 100 80x80x8 8 (9) 18,0 10,7 1,80 1,6

angle anchors std. packaging

TR 23/ TR 24 S235JR A500HW 20 pcs / box

TRR 23/ TRR 24 1.4301 A500HW 20 pcs / box

TRRr 23/ TRRr 24 1.4301 B600KX 20 pcs / box

plate anchors std. packaging

TR 15 S355J0 A500HW 150 kpl / FIN-pallet

TR 16 S355J0 A500HW 100 kpl / FIN-pallet

angle anchors std. packaging

TR 25/ TR 26 S235JR A500HW 150 kpl / FIN-pallet

angle anchors std. packaging

TR 36/ TR 37 S235JR A500HW 30 / 20 pcs / box

TRR 36/ TRR 37 1.4301 A500HW 30 / 20 pcs / box

TRRr 36/ TRRr 37 1.4301 B600KX 30 / 20 pcs / box

V

Rd

[kN]

34,6

50,4

N

1Rd

N

2Rd

V

Rd

M

Rd

[kN] [kNm]

13,8 3,6 6,0 0,53

24,8 6,4 10,7 1,26

N

Rd

V

1Rd

V

2Rd

[kN]

83,7 16,0 7,2

117,5 28,5 14,1

N

Rd

V

Rd

M

Rd

[kN] [kNm]

8,7 6,0 0,65

18,0 10,7 1,80

D

H

t

D

A

H

A

H

H

D

A

TR 15 and TR 16 support for square panels

TR 23 and TR 24 anchors for edges

TR 25 and TR 26 counter supports for square panels

TR 36 and TR 37 angle bars

APPROVALS:

BY247 Finland,

POCC FI.C19.H00289 Russia

FASTENING ITEMS

Fastening items are steel plates or angle bars, which

transfers the loads with the help of the anchors to

the concrete.

TR 15 and TR 25

9

www.peikko.com

F

a

s

t

e

n

i

n

g

p

l

a

t

e

s

H D A t N

Rd

V

Rd

M

Rd

weight

[mm] [kN] [kNm] [kg]

TR 38 45 560 100 10 8 (9) 14,4 13,7 0,89 1,5

plate anchors std. packaging

TR 38 S355J0 A500HW 100 pcs / FIN-pallet

TRR 38 1.4301 A500HW 150 pcs / pallet

TRRr 38 1.4301 B600KX 100 pcs / FIN-pallet

H D A t N

Rd

V

Rd

weight

[mm] [kN] [kg]

TR 39 40 309 150 6 8 16,7 10,7 0,8

plate anchors std. packaging

TR 39 S355J0 A500HW 20 pcs / box

H D A t N

Rd

V

1Rd

V

2Rd

M

1Rd

M

2Rd

weight

[mm] [kN] [kNm] [kg]

TR 43 45 340 150 8 8 (9) 5,0 29,0 10,7 0,23 0,56 1,4

TR 45 45 340 100 8 8 (9) 4,3 23,0 10,7 0,18 0,41 1,4

plate anchors at steel std. packaging

TR 43/ TR 45 S355J0 A500HW S235JR 20 pcs / box

TRRr 43/ TRRr 45 1.4301 B600KX 1.4301 20 pcs / box

H D A t N

Rd

V

Rd

weight

[mm] [kN] [kg]

TR 44 530 350 100 8 10 44,9 16,8 1,2

plate anchors std. packaging

TR 44 S355J0 A500HW 150 pcs / FIN-pallet

TRR 44 1.4301 A500HW 150 pcs / FIN-pallet

TRRr 44 1.4301 B600KX 150 pcs / FIN-pallet

N

Rd

V

Rd

M

Rd

[kN] [kNm]

14,4 13,7 0,89

N

Rd

V

Rd

[kN]

16,7 10,7

N

Rd

V

1Rd

V

2Rd

M

1Rd

M

2Rd

[kN] [kNm]

5,0 29,0 10,7 0,23 0,56

4,3 23,0 10,7 0,18 0,41

N

Rd

V

Rd

[kN]

44,9 16,8

A

A

D

H

t

H

49

t

D

A

H

D

A

A

D

t

H

TR 38 anchor for slab

TR 39 anchor for double T-slab

TR 43 and TR 45 anchors for edges

TR 44 fastening part for double T-slab

10

angle c/c weight

[mm] [~kg/m]

SKT 50 50x50x5 6 300 4,2

SKT 70 70x70x7 6 300 7,8

UKT 40 40x40x4 6 300 2,8

UKT 50 50x50x5 6 300 4,2

UKT 60 60x60x6 6 300 5,9

UKT 70 70x70x7 6 300 7,8

UKT 80 80x80x8 6 300 10,2

UKT 100x50 100x50x8 6 300 9,6

UKT 100 100x100x10 6 300 16,0

Lenghts are L=6000 mm

angle anchors

SKT / UKT S235JR A500HW

SKTRr / UKTRr 1.4301 B600KX

SKTHr / UKTHr 1.4401 B600KX

L AxDxt c/c weight

[mm] [~kg/m]

Corner protector KS 1800 60x60x4 8 400 4,0

angle anchors

KS S235JR A500HW

KSRr 1.4301 B600KX

KSHr 1.4401 B600KX

L c/c weight

[mm] [~kg/m]

Support for chequered plate 6000 6 300 5,0

angle anchors

Support for chequered plate S235JR A500HW

c/c

SKT

c/c

UKT

4

0

21

8

1

1

0

c/c

c/c

20

30

7

50

SKT and UKT fastening angle bars

KS corner protector

Support for chequered plate

KS corner protector; to protect chamfered

corners of columns.

SKT anchor for inner corners;

to bear for example channels.

UKT anchor for outer corners;

to for example threshold for

carage, corners of stairs, cor-

ner protection and expansion

joints..

Non stainless models available as painted or hot dip galvanized.

Items available also as hot dip galvanized.

11

www.peikko.com

F

a

s

t

e

n

i

n

g

p

l

a

t

e

s

K40-1 K30-2 weight

V

Rd

N

Rd1

N

Rd2

T

Rd

M

Rd

V

Rd

N

Rd1

N

Rd2

T

Rd

M

Rd

[kN] [kNm] [kN] [kNm] [kg]

KKT 50x100 99,2 55,0 20,0 10,4 6,2 78,0 41,0 14,9 7,7 4,6 3,6

angle bar anchors

KKT 50x100 S235JR A500HW

K40-1 K30-2 weight

V

Rd

T

Rd

V

Rd

T

Rd

[kN] [kNm] [kN] [kNm] [kg]

KKJ 50x100 99,2 10,4 78,0 7,7 4,2

angle bar at steel anchors

KKJ 50x100 S235JR S235JR A500HW

angle c/c H N

Rdd

V

Rdd

weight

[mm] [kN] [~kg/m]

KKT 50 50x50x5 12 250 160 14,6 16,3 5,3

KKT 60 60x60x6 12 250 160 14,6 16,3 6,3

KKT 70 70x70x7 12 250 160 14,6 16,3 8,4

KKT 80 80x80x8 12 250 160 14,6 16,3 11,2

KKT 100 100x100x10 16 200 150 26,0 28,7 18,0

Prices are L=6000 mm

angle bar anchors

KKT S235JR S235J2+N / S355J2+N

KKTR 1.4301 S235J2+N / S355J2+N

KKTH 1.4401 S235J2+N / S355J2+N

N

Rdd

V

Rdd

[kN]

14,6 16,3

14,6 16,3

14,6 16,3

14,6 16,3

26,0 28,7

K40-1 K30-2

V

Rd

N

Rd1

N

Rd2

T

Rd

M

Rd

V

Rd

N

Rd1

N

Rd2

T

Rd

M

Rd

[kN] [kNm] [kN] [kNm]

99,2 55,0 20,0 10,4 6,2 78,0 41,0 14,9 7,7 4,6

K40-1 K30-2

V

Rd

T

Rd

V

Rd

T

Rd

[kN] [kNm] [kN] [kNm]

99,2 10,4 78,0 7,7

30

H

c/c

KKT 50 - KKT 80

H

30

c/c

KKT 100

50

1

0

0

1

6

333

170

125

50 80

1

2

5

1

6

334

170

100

125

KKT 50/100 angle bar for upper corner of beam

KKJ 50/100 exible angle bar for upper corner of beam

APPROVALS:

BY248 Finland,

POCC FI.C19.H00289 Russia

KKT fastening angle bar

APPROVALS:

BY230 Finland,

AT-15-5256/2002 Poland,

POCC FI.C19.H00289 Russia

KKT; for load bearing corner fastening

APPROVALS:

BY248 Finland,

POCC FI.C19.H00289 Russia

Non stainless models available as painted or hot dip galvanized.

12

HPM JA PPM

PULTIT

Betoniyhdistyksen kyttseloste nro 244 Korvaa esitteen 8/2002 Vli 2, 9/2007

PILARIKENGT HPKM, PPKM, PEC, PKKM

Betoniyhdistyksen kyttselosteet nro 219, 206, 224 Korvaa esitteen 11/2006 Vli 2, 9/2007

2. BOLTS, COLUMN SHOES

HPKM column shoes

PPKM column shoes

COLUMN-BOLT JOINT

Column shoes are fastening items which allow

moment stiff extensions and connections between

prefabricated columns and for example foundations.

All forces on the column are transferred with column

shoes and bolts to the bearing structure, for example

to the foundation.

Component column is possible to set at the correct

height level and vertical position. The joint between

column base and structure below should be grout as

soon as possible after instal-

lation. After that the

connection parts and

grouting will work as

reinforced concrete

structure. The above

structures may not be

installed before the

connection joints are

cast and hardened.

With the help of HPKM column

shoes, moment stiff joints can

be made.

The light weight of the HPKM

makes the handling and

installation easy and fast.

With the help of PPKM

column shoes, very high

capacity for the moment

stiff column joints can be

made.

PEC column shoes

Easy handling, lightness

and high capacities

are combined in PEC

column shoes.

PPM anchor bolts

PPM/P bolts are used as

overlapping bolts in columns

and as basic bolts. The main

reinforcement of the basic bolt is

attached to reinforcement of the

column with an overlap.

PPM/L bolts are used as a basic

bolts and anchor bolts in founda-

tions.

HPM anchor bolts

HPM/P ribbed bar bolts are used

as overlapping bolts in pre-cast

columns and as foundation

bolts.

HPM/L are also used as anchor

bolts in foundations, and they

are suitable for bolt joints at the

top of concrete beams or on

sides of columns.

The number of column shoes in the

column depends on the dimensions of

the column, forces on the

column, concrete grade

and type of column shoe

used. Usually four col-

umn shoes are enough

to create a moment stiff

connection.

The capacities of the

joints are dened by the

bolt being used.

13

www.peikko.com

B

o

l

t

s

,

c

o

l

u

m

n

s

h

o

e

s

Column shoe and bolt used

ETA K40-1 K40-2

N

Rd

[kN]

HPKM 16 HPM 16 61.7 71.3 65.4

HPKM 20 HPM 20 96.3 111.3 102.0

HPKM 24 HPM 24 138.7 160.4 147.0

HPKM 30 HPM 30 220.4 255.0 233.7

HPKM 39 HPM 39 383.4 443.6 406.6

PPKM 36 PPM 36 435.7 519.9 476.6

PPKM 39 PPM 39 520.5 621.1 569.3

PPKM 45 PPM 45 696.5 831.1 761.8

PPKM 52 PPM 52 937.6 1118.7 1025.5

PEC 24 PPM 22 161.6 212.1 194.4

PEC 30 PPM 27 244.8 321.3 294.5

PEC 36 PPM 36 435.7 519.9 476.6

PKKM 36 PPM 36 435.7 519.9 476.6

PKKM 45 PPM 45 696.5 831.1 761.8

PKKM 52 PPM 52 937.6 1118.7 1025.5

The given capacities are according to EC2 and Finnish regulations.

CORNER CASTING BOX MIDDLE CASTING BOX

HPKM

16

CBOX

HPKM

20

CBOX

HPKM

24

CBOX

HPKM

30

CBOX

HPKM

39

CBOX

PEC

30

CBOX

PEC

36

CBOX

HPKM

16

MBOX

HPKM

20

MBOX

HPKM

24

MBOX

HPKM

30

MBOX

HPKM

39

MBOX

PEC

30

MBOX

PEC

36

MBOX

yellow blue grey green orange black red yellow blue grey green orange black red

thread M16 M20 M22 M24 M27 M30 M36 M39 M45 M52

wrench 24 30 34 36 41 46 55 60 70 80

2x50x100 3x50x100 5x50x100 8x50x100 10x50x100 15x50x100

2x100x100 3x100x100 5x100x100 8x100x100 10x100x100 15x100x100

ETA K40-1 K40-2

N

Rd

[kN]

61.7 71.3 65.4

96.3 111.3 102.0

138.7 160.4 147.0

220.4 255.0 233.7

383.4 443.6 406.6

435.7 519.9 476.6

520.5 621.1 569.3

696.5 831.1 761.8

937.6 1118.7 1025.5

161.6 212.1 194.4

244.8 321.3 294.5

435.7 519.9 476.6

435.7 519.9 476.6

696.5 831.1 761.8

937.6 1118.7 1025.5

Capacities of column connection

Wrench size

Casting box

Installation parts

Standard installation parts direct

from storage.

14

B C E H t weight color

[mm] [kg]

HPKM 16 85 75 50 740 15 27 2,1 yellow

HPKM 20 95 80 50 835 20 30 3,5 blue

HPKM 24 105 85 50 1040 30 35 6,1 grey

HPKM 30 120 90 50 1310 45 40 12,3 green

HPKM 39 150 110 60 1775 50 55 23,3 orange

B C E H t weight color

[mm] [kg]

PPKM 36 130 105 50 1890 40 50 37,8 red

PPKM 39 130 115 60 2020 40 55 45,6 brown

PPKM 45 130 123 60 2230 50 60 61,2 violet

PPKM 52 150 131 60 2560 60 70 95,2 white

plates ( 15 mm) plates (> 15 mm) ribbed bars

S355J0 S355J2+N A500HW

B C E H t weight color

[mm] [kg]

PEC 24 105 90 50 1140 30 35 10,4 light blue

PEC 30 130 105 50 1430 45 45 19,0 black

PEC 36 170 115 60 1855 50 55 30,0 red

t

H

B

C

E

B

t

H

E

C

t

B

H

C

E

HPKM column shoes

PPKM column shoes

APPROVALS:

BY219 Finland,

AT-15-5061/2001 Poland,

POCC FI.C19.H00289 Russia

HPKM column shoes are also available welded in circular bottom plate.

Four column shoes / bottom plate. Sizes 280, 380 and 480.

Materials HPKM, PEC and PPKM

APPROVALS:

BY206 Finland,

S/N 020363 Germany

POCC FI.C19.H00289 Russia

Capacities on page 13.

Capacities on page 13.

Capacities on page 13.

APPROVALS:

BY219 Finland,

S/N 070017 Germany,

AT-15-5061/2001 Poland,

POCC FI.C19.H00289 Russia

PEC column shoes

15

www.peikko.com

B

o

l

t

s

,

c

o

l

u

m

n

s

h

o

e

s

L A washer N

Rd

weight

[mm] [kN] [kg]

HPM 16L 280 140 16 38-6 61,7 0,9

HPM 16P 810 140 16 38-6 61,7 1,7

HPM 20L 350 140 20 46-6 96,3 1,4

HPM 20P 1000 140 20 46-6 96,3 2,9

HPM 24L 430 170 25 56-6 138,7 2,1

HPM 24P 1160 170 25 56-6 138,7 4,9

HPM 30L 500 190 32 65-8 220,4 4,4

HPM 30P 1420 190 32 65-8 220,4 9,4

HPM 39L 700 200 40 90-10 383,4 9,0

HPM 39P 2000 200 40 90-10 383,4 21,1

L A washer N

Rd

weight

[mm] [kN] [kg]

PPM 22L 510 160 220 56-6 161,6 3,2

PPM 22P 1190 160 220 56-6 161,6 6,0

PPM 27L 650 170 225 65-8 244,8 5,7

PPM 27P 1415 170 225 65-8 244,8 11,5

PPM 30L 670 190 225 65-8 299,2 6,2

PPM 30P 1705 190 225 65-8 299,2 14,1

PPM 36L 740 190 420 80-8 435,7 9,4

PPM 36P 1450 190 420 80-8 435,7 15,7

PPM 39L 880 190 325 90-10 520,5 12,6

PPM 39P 1815 190 325 90-10 520,5 23,5

PPM 45L 980 220 425 100-10 696,5 18,2

PPM 45P 1825 220 425 100-10 696,5 31,1

PPM 52L 1140 250 432 100-12 937,6 32,3

PPM 52P 1930 250 432 100-12 937,6 50,0

PPM 60L 1330 310 432 115-15 1259,7 41,9

PPM 60P 2490 310 432 115-15 1259,7 70,9

ribbed bars A500HW / BSt500S

washers S355J0

nuts property class 8

thread bar imacro M

ribbed bars A500HW

washers S355J0

nuts property class 8

N

Rd

[kN]

61,7

61,7

96,3

96,3

138,7

138,7

220,4

220,4

383,4

383,4

N

Rd

[kN]

161,6

161,6

244,8

244,8

299,2

299,2

435,7

435,7

520,5

520,5

696,5

696,5

937,6

937,6

1259,7

1259,7

L

A

HPM L

A

L

HPM P

L

A

PPM L

L

A

PPM P

APPROVALS:

HPM L:

ETA-02/0006,

BY244 Finland,

AT-15-5060/2001 Poland,

POCC FI.C19.H00289 Russia

HPM P:

BY244 Finland,

AT-15-5060/2001 Poland,

POCC FI.C19.H00289 Russia

APPROVALS:

PPM L:

BY244 Finland,

Z-21.5-1706 Germany,

AT-15-5060/2001 Poland,

POCC FI.C19.H00289 Russia

PPM P:

BY244 Finland,

AT-15-5060/2001 Poland,

POCC FI.C19.H00289 Russia

PPM bolts also available as hot-dip galvanized.

HPM bolts also available as hot-dip galvanized.

HPM anchor bolts

PPM anchor bolts

Materials of HPM

Materials of PPM

16

H B L t h b a weight color

[mm] [kg]

PSK 16 580 80 141 30 80 2x16 36 76 4,4 yellow

PSK 20 850 90 146 35 90 2x16 40 80 6,1 blue

PSK 24 960 120 166 35 100 2x20 44 84 10,1 grey

PSK 30 1170 120 185 45 120 2x25 50 90 16,8 green

PSK 36 1755 150 212 60 130 2x32 56 96 36,2 red

PSK 45 1940 180 252 80 160 4x32 65 105 75,8 violet

PSK 52 2520 200 288 80 185 4x32 72 112 102,3 white

plates ( 15 mm) plates (> 15 mm) box ribbed bars

S355J0 S355J2+N S235JR A500HW

H L B t E K weight

[mm] [kg]

PKKM 36 1912 245 130 60 50 50 130 40,3

PKKM 45 2380 250 180 60 60 60 140 72

PKKM 52 2900 280 210 80 60 70 150 115,1

bottom plate box ribbed bars

S355J2+N S235JR A500HW

t

H

h

L

a b

B

H

K

L

B

E

t

PKKM middle shoes

SPECIAL COLUMN SHOES

PSK wall shoe

PSK wall shoes are designed for tension splicing of

wall-like precast elements. Wall shoes are used in

e.g. buildings stiffening walls.

The loads are transferred from wall to load bearing

structures with the help of wall shoes and anchoring

bolts.

Wall shoes are used with HPM and PPM anchoring

bolts. With wall shoes PSK AL -washers must be

used.

Capacities on page 13.

Capacities on page 13.

APPROVALS:

BY273 Finland,

S/N 020505 Germany

AT-15-5395/2002 Poland

POCC FI.C19.H00289 Russia

APPROVALS:

BY224 Finland

PSK wall shoes

Materials of PSK

Materials of PKKM

PKKM middle shoe

Middle shoes can be used on the sides of wall-like

columns.

PSK SEINKENK

Betoniyhdistyksen kyttseloste nro 197 Korvaa esitteen 3/2003 Vli 2, 11/2006

17

www.peikko.com

B

o

l

t

s

,

c

o

l

u

m

n

s

h

o

e

s

standard sizes

180/180 280/280 380/380

PPK 16 - - -

PPK 20 - - -

PPK 22 - - -

PPK 24 X X -

PPK 27 - - -

PPK 30 - X X

PPK 36 - - X

PPK 39 - - -

PPK 45 - - -

PPK 52 - - -

L A washer N

Rd

weight

[mm] [kN] [kg]

HPM 20YP-1500 1500 140 20 46-6 96,3 4,1

HPM 24YP-2400 2400 170 25 56-6 138,7 9,8

HPM 30YP-2400 2400 190 32 65-8 220,4 16,1

HPM 30YP-3000 3000 190 32 65-8 220,4 19,9

rebars A500HW / BSt500S

washers S355J0

nuts property class 8

L M A weight

[mm] [kg]

A500HW 16 1490 16 140 16 2,4

A500HW 20 1850 20 140 20 4,6

A500HW 25 1300 24 170 25 5,0

A500HW 25 1700 24 170 25 6,6

A500HW 25 2060 24 170 25 7,9

A500HW 32 1950 30 190 32 12,3

A500HW 32 2560 30 190 32 14,8

N

Rd

[kN]

96,3

138,7

220,4

220,4

A

L

HPM YP

A

L

PPK installation frame

INSTALLATION FRAME

Assembling the bolts as boltgroubs can be made with the help of PPK installation frames.

Correct c/c distances and vertical straightness of the bolts can be ensured by using the PPK installation frame.

Centerlines have been marked to the installation frame to help the positioning of the bolt group. Installation

frames can be re-used c/c dimensions and thread sizes are suitable for the use.

Coming: HPM YP bolts

Materials of HPM YP

A500HW anchor bolts

A500HW anchor bolts

without nuts and

washers.

Also available as hot-

dip galvanized.

Extra long HPM-bolts

are used for example

in column-beam-

column connections,

where bolts extend

trough a beam to the

upper column.

Other sizes manufac-

tured by order.

18

PCs KONSOLI

Betoniyhdistyksen kyttseloste nro 276 Korvaa esilleen 5/2006 Vli 3, X/2003

3. CORBELS, HANGERS

Light corbel system

CORBEL SYSTEMS

PCs corbel system

PCs corbel system is designed

to support steel, composite and

reinforced concrete beams to

reinforced concrete columns and

walls.

Light corbel system

Light corbel system can be used in

e.g. supporting exterior wall, intermediate landing

and balcony elements. Elements can be supported

from in-situ cast or element frame.

System parts:

- corbel box

- corbel at steel

- support part for wall element

- or support for oor slabs

(KL 120/190 pictured)

PCs corbel system

Connection consists of:

- A column part and cor-

bel parts

- A link in

beams end

plate

(PC 3-H pictured)

Light corbel in sandwich-element (above) support and in

intermediate landing (below).

19

www.peikko.com

C

o

r

b

e

l

s

,

h

a

n

g

e

r

s

L B H weight

[mm] [kg]

K120 120 60 130 2,2

K190 190 60 153 3,7

K120PUR 120 140 146 4,4

Surface treatment options: paint / hot dip galvanized

L B H H2 weight

[mm] [kg]

KS120 80 100 90 80 1,6

KS190 80 120 110 80 1,9

(includes bolt, nut and two washers), always hot dip galvanized

L B B2 H weight

[mm] [kg]

KL120/190 567 158 170 200 6,0

Surface treatment options: paint / hot dip galvanized

L B H weight

[mm] [kg]

KA120 236 12 90 2,1

KA190 304 16 110 4,5

plates ( 6 mm) plates (> 6 mm)

at steel / square

section

ribbed bars

S235JR S355J0+N S355J0+N A500HW

in KS also neoprenes

H

L

B

L

H2

H

B

L

B B2

H

H

L B

Light corbel K (corbel box)

Light corbel KS (for wall element)

Light corbel KL 120/190 (for oor slab)

Remember also square sections!

Square section 120 12x12x115 HDG

Square section 190 16x16x185 HDG

Materials of light corbel system

APPROVALS:

BY280 Finland

LIGHT CORBEL

SYSTEM

Light corbel KA (corbel piece)

Always hot dip galvanized

20

3

4

0

d

=

2

8

0

APPROVALS:

BY276 Finland,

POCC FI.C19.H00289 Russia

APPROVALS:

BY210 Finland,

POCC FI.C19.H00289 Russia

PCs corbel

PC beam shoe

PCs CORBEL SYSTEM

PCs corbel

There are several types of corbels:

PCs basic model

PCs UP for columns upper end

both before mentioned also double sided

all before mentioned with LOCK-corbel parts

PC beam shoe

There are two types of beam shoes:

PC L for beams with low ange (anges

height < 60 mm) (e.g. PC 3-L)

PC H for beams with high ange (anges

height 60 mm) (e.g. PC 3-H)

The beam shoe type differs in height. Type L ts

better low beams with steel ange and type H ts

better beams with concrete ange. In the case of a

beam without a ange the shoe type and its location

must be considered separately.

PCs UP (left) and

PCs (right).

PCs corbels also available

double sided.

PC H beam shoe on the left and PC L on the right.

Installation of PCs

The column part is

installed to the casting

mould together with

reinforcements.

The corbel parts (a

corbel plate, washers

and bolts) are attached

to the column after the

element has been cast.

A link has to be made

to the end plate of

steel or composite

beam for the corbel.

The beam is installed on the corbel by lowering the

beam so that the corbel goes into the link in the

beams end plate.

When using LOCK-corbel, the vertical thread bars

should t through holes made for the LOCK-corbel

in the beams top plate. Thread bars have to be long

enough so that washers and nuts can be tightened

properly after the beam is installed.

The whole height of the joint between the column,

the beam and the space around the corbel parts is

grouted at the same time as the joints of the slabs.

PCs 5-2 / d=280 UP

LOCK 290 + LOCK 350

corbels load class

double sided console (-2 /)

round column (d=)

diameter / side length of column

model for negative support reaction (LOCK) and length of

the vertical bar (see page 21)

Sections marked with blue, red

and green are optional and

independent from one another.

Double-sided corbel is indi-

cated with -2 followed by the

diameter or side length of the

column. In the case of a rectangu-

lar column, =d is left off. If more

than one LOCK-corbel part is needed

(double-sided corbel), each is marked

separately.

For example. pictured on right is

PCs 3-2 / d=280 UP LOCK 340

How to form the product code for the

PCs corbel

model for columns

to end (UP)

21

www.peikko.com

C

o

r

b

e

l

s

,

h

a

n

g

e

r

s

plates (> 25 mm) plates ( 25 mm) ribbed bars screws washers

S355J2+N S355J0 A500HW property class 10.9 property class 10.9

thread H6 color

PCs 2 LOCK M16 31 red

PCs 3 LOCK M22 39 grey

PCs 5 LOCK M22 39 yellow

PCs 7 LOCK M22 39 green

PCs 10 LOCK M27 50 blue

PCs 15 LOCK M27 50 black

H1 L1 B1 H2 H3 L4 B2 d3 V

Rd

T

Rd

weight color

[mm] [kN] [kNm] [kg]

PCs 2 UP 155 76 60 210 397 125 116 16 220 8 12,2 red

PCs 3 UP 155 92 80 235 386 200 135 20 350 15 21,5 grey

PCs 5 UP 205 112 90 315 430 250 150 25 580 30 37,3 yellow

PCs 7 UP 225 112 110 350 423 210 212 32 715 55 57,3 green

PCs 10 UP 280 117 145 380 578 260 222 32 1015 75 84,5 blue

H1 L1 B1 H2 H3 L3 B2 d3 V

Rd

T

Rd

weight color

[mm] [kN] [kNm] [kg]

PCs 2 155 76 60 210 397 125 116 16 220 8 12,8 red

PCs 3 155 92 80 235 386 140 135 20 350 15 21,9 grey

PCs 5 205 112 90 315 430 150 150 25 580 30 38 yellow

PCs 7 225 112 110 350 423 145 212 32 715 55 58,4 green

PCs 10 280 117 145 380 578 160 222 32 1015 75 85,0 blue

PCs 15 280 122 220 380 578 260 282 32 1500 190 127,5 black

V

Rd

T

Rd

[kN] [kNm]

220 8

350 15

580 30

715 55

1015 75

1500 190

V

Rd

T

Rd

[kN] [kNm]

220 8

350 15

580 30

715 55

1015 75

B1

H

2

H

3

H

3

t2

d3

H

1

L1 L3

B2

H

2

H

3

B1

t2

L4 L1

H

1

d3

B2

1

0

0

L

=

H6

V

ud, neg

PCs corbel

PCs UP corbel

Materials of PCs ja PCs UP

Lenght L must be given at the code of the console

(see page 20)

Lenght H6; see the PCs corbel manual

V

ud,neg

= 80 kN in all sizes of console

LOCK corbel parts

PCs corbel delivery includes column part, console

plate, washer plate, nuts and HV -washers.

22

plates ribbed bars

PRK S355J0 A500HW

PRK stainless 1.4301 A500HW

PRK fully stainless 1.4301 B600KX

H1 H2 weight

[mm] [kg]

PRK 200 200 162 12 (11) 13,5

PRK 265 265 162 12 (11) 15,3

PRK 320 320 282 12 (11) 17,3

plates ribbed bars

S355J0 A500HW

H1 B1 B2 L1 L4 t1 V

Rd

weight color

[mm] [kN] [kg]

PC 3-L 270 150 150 110 1115 20 350 15,6 grey

PC 5-L 300 150 150 130 1175 25 580 23,7 yellow

PC 7-L 340 240 152 130 1270 25 715 35,0 green

PC 10-L 410 240 187 135 1290 25 1015 56,5 blue

H1 B1 B2 L1 L4 t1 V

Rd

weight color

[mm] [kN] [kg]

PC 3-H 310 150 118 110 1115 20 350 16,1 grey

PC 5-H 340 150 128 130 1175 25 580 24,3 yellow

PC 7-H 380 240 152 130 1270 25 715 35,7 green

PC 10-H 450 240 187 135 1290 25 1015 59,6 blue

V

Rd

[kN]

350

580

715

1015

V

Rd

[kN]

350

580

715

1015

100

H1

H2

1190

300

12

H1

t1

L1

L4

B1

B2

PC 3-L

PC 5-L

PC 7-L

PC 10-L

B1

B2

H1

t1

L1

L4

B1

B2

PC 3-H

PC 5-H

B1

B2

PC 7-H

PC 10-H

weight

[kg]

PRK

PRK edge hanger for hollow core slabs

With the help of PRK edge hanger for hollow core slabs can e.g.

balcony element be supported to hollow core slabs.

PC H beam shoe

PC L beam shoe

Materials of PC L beam shoe ja PC H beam shoe

Upcoming new sizes: PC 2-L and PC 15-L

Upcoming new sizes: PC 2-H and PC 15-H

Materials of PRK

23

www.peikko.com

C

o

r

b

e

l

s

,

h

a

n

g

e

r

s

plates ribbed bars

S355J2+N A500HW

h1 h2 b1 b2 L2

[mm]

POK 150 150 150 120 100 130

POK 175 175 175 120 100 130

POK 200 200 200 120 100 130

POK 265 265 265 120 100 150

POK 320 320 320 140 100 150

POK 370 370 370 140 100 150

POK 200/370 200 370 140 100 150

POK 400 400 400 140 100 150

POK 500 500 500 140 100 150

L

h1 h2

b2

b1

L2

105

85

20

185

95150

70

POK

ONTELOLAATTAKANNAKE

Betoniyhdistyksen kyttseloste nro 189 Korvaa esitteen 5/2003 Vli 3, 11/2006

POK slab hanger

POK

POK slab hanger for hollow

core slabs has an L-shaped

steel section, which is de-

signed to to bear hollow core

(HC) slab units around a oor

opening.

In the erection stage, before grout-

ing, POK slab hangers distribute loads from the

supported HC slab to the units each side of it. After

concreting the oor, the load from the HC slab is

transferred by the POK slab hanger and also by the

Part weights 1,1 kg.

Material is S355J0 and it is hot dip galvanized.

APPROVALS::

BY263 Finland,

AT-15-5360/2002 Poland,

POCC FI.C19.H00289 Russia

Peikkohanger

PEIKKOHANGER

Peikkohanger is used in e.g. elevator shafts, stairways etc.

Hanger acts as a fast support for handrails, working oors and riggers.

Capacity curves can

be found at POK slab

hangers manual.

Materials of POK

grouting joints between the units. POK hangers re

resistance is up to 60 minutes. If higher re resist-

ance ratings are needed, additional re protection

has to be used.

Standard lengths

(all models):

L=1200

L=1800

L=2400

24

520

210 210 50

80

2

0

h

s

h

l

v

80

ts

ds

90

120

50

hs ts h lv* ds

V

Rd, assem-

bling

**

[mm] [kN]

PBH 1 100 15 460 360 10 80

PBH 2 100 20 470 370 12 100

PBH 3 120 15 580 460 12 125

PBH 4 120 20 600 480 14 150

* lv can be adapted to constructive details and design

** In case hs 50 cm, V

Rd, assembling

should be lowered according design

values in PBH brochure

V

Rd, assem-

bling

**

[kN]

80

100

125

150

PBH corbel

Peikko PBH corbels are used to connect prefab

TT elements to beams or to connect secondary

to primary beams - without any additional and

cost intensive concrete console.

Usually special supports are not needed, either.

During assembling time all loads can be conducted

into the beam via the Peikko PBH corbel.

In the nal state usually the capacity of the bearing

area results from the concrete capacity (after the

additinal reinforcement has been placed and the ad-

ditional concrete ahas hardened) and the capacity of

the PBH corbel.

All sizes, weights and capacities can be found as a

printout in our PBH-brochure or as pdf-le on the

website www.peikko.com

The capacity of the bearing-area results from the

consoles capacity added to the capacity of the

ferroconcrete-corbel.

Loads, which are added after the in-situ concrete has

hardened must not exceed the values of

V

Rd

V

Rd, assembling

from the PHB-bruchures charts.

The advantages of the PBH corbel:

No consoles necessary at the beams

quick and easy formwork-process

Less reinforcement in the bearing-area

necessary

no notching of the beam

easier reinforcement

high capacities

legal security provided by the static certication

of the LGA (Landesgewerbeanstalt Bayern), a

public-law corporation based in Nuremberg,

Germany

easy dimensioning through Peikko capacity

charts

no additional support needed during assembling

PBH corbel

25

www.peikko.com

C

o

r

b

e

l

s

,

h

a

n

g

e

r

s

26

internal bar external bar diagonal

PDM B500K B500K 1.4301

PD B500K B600KX 1.4301

PDR B600KX B600KX 1.4301

PPA B600KX B600KX B600KX

The material of the pin is B600KX

ANSAAT JA PISTOKAS

Betoniyhdistyksen kyttselosteet nro 194 ja 246 Korvaa esitteet 3/03 ja 11/96 Vli 4, 5/2007

4. TIES

TIES

Ties are connecting reinforcement which allows the

joining of sandwich panels concrete layers together.

PD diagonal ties

PD diagonal ties are designed to join sandwich

panels concrete layers together in the height of the

whole component.

PPA beam ties

Beam ties can be used in low structures e.g. door

and window beams and also in low foundation ele-

ments.

Materials for ties

APPROVALS:

BY265 Finland (ties),

BY246 Finland (pin),

POCC FI.C19.H00289 Russia

PPI connector pin

PPI connector pins are used to join the

concrete layers of the sadwich element

together. The pins will not improve the

compressive capacity of the load bear-

ing concrete layer. Connector pin can be

applied for example in styrox or urethane

isolated elements edges and openings.

Material is stainless ribbed bar B600KX.

27

www.peikko.com

T

i

e

s

H L Advisable insulation thickness

[mm]

PD 150 150 2400 90

PD 180 180 2400 120

PD 200 200 2400 140

PD 210 210 2400 150

PD 220 220 2400 160

PD 240** 240 2400 180

PD 260** 260 2400 200

** = sold in 500 ties / pallet.

insulation thickness (installation angle) K25 K10

H perpendicular 45 angle N

k

N

d

N

k

N

d

[mm] [kN]

PPI 170 170 80 - 7,0 3,5 3,8 1,9

PPI 190 190 100 - 7,0 3,5 3,8 1,9

PPI 210 210 120 - 7,0 3,5 3,8 1,9

PPI 230 230 140 80 7,0 3,5 3,8 1,9

PPI 250 250 160 100 7,0 3,5 3,8 1,9

H Advisable insulation thickness

[mm]

PPA 150 150 90

PPA 180 180 120

PPA 200 200 140

PPA 210 210 150

PPA 220 220 160

PPA 240 240 180

PPA 260 260 200

PPA 280 280 220

K25 K10

N

k

N

d

N

k

N

d

[kN]

7,0 3,5 3,8 1,9

7,0 3,5 3,8 1,9

7,0 3,5 3,8 1,9

7,0 3,5 3,8 1,9

7,0 3,5 3,8 1,9

L

H

250

H

62

H

4

S

o

l

d

i

n

f

u

l

l

p

a

l

l

e

t

s

,

7

5

0

t

i

e

s

/

p

a

l

l

e

t

.

PPI connectorpin

S

o

l

d

i

n

f

u

l

l

b

o

x

e

s

,

5

0

0

p

c

s

/

b

o

x

.

PPA beam tie

S

o

l

d

i

n

f

u

l

l

p

a

l

l

e

t

s

,

5

0

0

t

i

e

s

/

p

a

l

l

e

t

.

PD diagonal tie

APPROVALS:

BY246 Finland,

POCC FI.C19.H00289 Russia

28

L1 L2 C c/c B

[mm]

TSA 8/150/42 380 380 - 8 150 42

TSA 8/300/42 380 380 - 8 300 42

TSA 10/150/42 480 480 - 10 150 42

TSA 10/300/42 480 480 - 10 300 42

TSA and TSK 8/150/95 120 400 62 8 150 95

TSA and TSK 8/300/95 120 400 62 8 300 95

TSA and TSK 8/150/120 120 400 80 8 150 120

TSA and TSK 8/300/120 120 400 80 8 300 120

TSA and TSK 10/150/120 140 500 80 10 150 120

TSA and TSK 10/300/120 140 500 80 10 300 120

TSA and TSK 8/150/150 120 400 110 8 150 150

TSA and TSK 8/300/150 120 400 110 8 300 150

TSA and TSK 10/150/150 140 500 110 10 150 150

TSA and TSK 10/300/150 140 500 110 10 300 150

L=2400 in all models

40

B

c/c

TSA xx/xxx/42

L2

C

40

B

c/c

TSA xx/xxx/xxx

L1

c/c

TSK xx/xxx/xxx

C

40 B

L2

TS TYSAUMARAUDOITE

Korvaa esitteen 5/2001 Vli 5, 11/2006

5. REINFORCEMENT PRODUCTS

Bended joint reinforcement

We also manufacture bended joint

reinforcements that goes in wall

consoles.

More information from our sales

department.

TS joint reinforcement

TS JOIN T REINFORCEMENT

TS joint reinforcement is a reinforcement block

manufactured from zinc-coated sheet metal

box and ribbed bars. It can be

used for example in in-situ

casted joints.

29

www.peikko.com

R

e

i

n

f

o

r

c

e

m

e

n

t

p

r

o

d

u

c

t

s

Concrete

grade

loop distribution c/c [mm]

250 300 350 400 450 500 550 600 650 700 750

K30 114,9 107,4 92,5 81,3 72,7 65,7 60,0 55,3 51,3 47,8 44,9

K35 124,1 116,0 99,9 87,9 78,5 71,0 64,8 59,7 55,4 51,7 48,5

K40 132,7 124,0 106,8 93,9 83,9 75,9 69,3 63,8 59,2 55,2 51,8

K45 140,8 131,5 113,3 99,6 89,0 80,5 73,5 67,7 62,8 58,6 54,9

L1 L2 B H SL

[mm]

PVL 80 160 212 50 20 80 6

PVL 100 160 212 50 20 100 6

PVL 120 190 212 50 20 120 6

loop distribution c/c [mm]

250 300 350 400 450 500 550 600 650 700 750

114,9 107,4 92,5 81,3 72,7 65,7 60,0 55,3 51,3 47,8 44,9

124,1 116,0 99,9 87,9 78,5 71,0 64,8 59,7 55,4 51,7 48,5

132,7 124,0 106,8 93,9 83,9 75,9 69,3 63,8 59,2 55,2 51,8

140,8 131,5 113,3 99,6 89,0 80,5 73,5 67,7 62,8 58,6 54,9

L2

B

SL

H

L1

PVL CONNECTING LOOP

PVL connecting loop is made of high strenght

wire cable and galvanized sheet metal box. It

can be used e.g. in conrete wall elements with

vertical casting joints.

PVL connecting loop transfers shearing forces direct-

ed to casting joint with the wire cable and concrete

dovel from one component to the other.

APPROVALS:

BY254 Finland

Capacity value for shearing force [kN/m]

PVL connecting loop

30

Item name

EFS M8x40

EFS M10x15

EFS M12x70

EFS M16x80

Item name

EFS-NP M12x70

EFS-NP M16x100

Item name

EFS-B M16x80

EFS-B M20x95

Item name

EFS-BNP M16x80

EFS-BNP M20x95

Galvanized,

M thread size x part lenght

Item name

WFS M6x35

WFS M8x40

WFS M10x40

WFS M10x50

WFS M12x60

WFS M12x70

Item name

WFS-NP M6X35

WFS-NP M8X40

WFS-NP M10X40

WFS-NP M10X50

WFS-NP M12X60

l h

s

d

h

weight

[mm] [kg]

HFS M12x50 50 41 40 0,1

HFS M12x70 70 61 40 0,1

HFS M16x50 50 39 50 0,2

HFS M16x90 90 79 50 0,2

l h

s

d

h

Galvanized,

M thread size x part lenght

EFS-B eye xing socket + bolt

Sold in 50 pcs / bag

Galvanized,

M thread size x part lenght

Galvanized,

M thread size x part lenght

HFS xing anchor

APPROVALS:

BY267 Finland

Fixing anchors

Fixing anchors are xing parts with female thread that can be used for temporary and permanent xings.

EFS eye xing socket EFS-NP eye xing socket + nail plate

EFS-BNP eye x. socket + bolt + np.

WFS wavy end xing socket

Galvanized,

M thread size x part lenght

WFS wavy end xing socket

Galvanized, M thread size x part lenght

31

www.peikko.com

R

e

i

n

f

o

r

c

e

m

e

n

t

p

r

o

d

u

c

t

s

L1 L2 c/c material weight/pcs pcs/

[mm] [kg] bundle

5-150, 5000x2350 5000 2350 5 150 B500K 24,62 40

5-150, 4000x2920 4000 2920 5 150 B500K 24,46 40

5-200, 5000x2350 5000 2350 5 200 B500K 18,29 40

6-150, 5000x2350 5000 2350 6 150 B500K 35,50 40

6-200, 5000x2350 5000 2350 6 200 B500K 26,36 40

8-150, 5000x2350 5000 2350 8 150 B500K 63,16 25

8-200, 5000x2350 5000 2350 8 200 B500K 46,91 25

10-150, 5000x2350 5000 2350 10 150 B500K 98,66 15

10-200, 5000x2350 5000 2350 10 200 B500K 73,27 20

4-150 4000x2920 4000 2920 4 150 B600KX 15,88 50

5-150 4000x2920 4000 2920 5 150 B600KX 24,46 40

7-150 5000x2350 5000 2350 7 150 B600KX 48,30 25

available lengths

[mm]

4,0 4000

5,0 4000 and 6000

7,0 6000 and 12000

9,0 6000 and 12000

Annealed and xed, soft

[mm]

0,9 wire tie L=300, 350 and 400 mm

4,0 coil, 25 kg / coil and 10 kg / coil

4,0 masons clamp L=350, 400, 450, 500 and 600 mm

10,0 L=4000 (std. bundle 250 kg)

12,0 L=4000 (std. bundle 250 kg)

16,0 L=6000 (std. bundle 500 kg)

20,0 L=4000 and 6000

25,0 L=4000 and 6000

L2

c/c

c/c

L1

Meshes

stainless

stainless

stainless

Mesh

We make to order also

stainless special meshes.

Diameters: 4, 5, 7

and 9

Stainless ribbed and round bars

Hot rolled stainless ribbed bars

from storage: 16, 20, 25, 32

and 40. Also ribbed and round

bars cut for xed sizes.

Stainless round bar 1.4301

Stainless ribbed bar B600KX

Stainless rebar coil

Stainless rebar coils available in the following

sizes: 5, 7, 9 and 11.

Reinforcement meshes and

stainless rebar

Reinforcement meshes can be used as reinforce-

ments in oors and building facings.

Stainless rebar and meshes long-lasting reinforce-

ments for exterior structures.

Marking of rebar

Marking in rebar manufactured by Peikko (6+6+2)

32

PSB punching reinforcement

PSB elements are used as punching reinforcement. The elements consists of double headed ribbed

bar studs welded to a spacer bar. Elements are preferably put in from the top after laying the at slab

reinforcement. PSB elements are supplied as standard elements, which are available off stock or in

short delay, and as complete elements, which are manufactured to measure on demand. The standard

options are 2 stud and 3 stud elements which can be combined to form 4-, 5-, 6 stud assemblies etc.

The symmetrical arrangement of the PSB studs on each element guarantees correct installation.

Advantages:

planar ground oor

low slab thickness

applicable from 180 mm slab thickness

easy and time-saving installation

reduced mould consumption

increase of the bearing capacity

short delivery time

custom made demands

Type PSB-U: installation from the

bottom

It is possible to install the PSB elements from the

bottom, before placing the reinforcement of the slab.

In this case the type PSB-U guarantees a secure posi-

tion on the slab mould, because of the two installa-

tion bars, which are fastened on its bottom.

For more information please contact our technical

support.

PSB is made of

BSt500S

APPROVALS:

WR-Z-070705 Austria,

060-025271 Czech,

Z-15.1-201 Germany,

PSE-EME Hungary

The standard elements consist of 2 stud and 3 stud elements

PSB

The complete PSB elements are

designed with 3 and more double

headed ribbed anchors welded to a

spacer bar at individual spacings on

demand. Complete elements are ideal

for the installation from below;

i.e. the elements are placed on the

formwork by special spacers. The

lower and upper reinforcements are

then put into position.

33

www.peikko.com

R

e

i

n

f

o

r

c

e

m

e

n

t

p

r

o

d

u

c

t

s

Concentrated support of slabs

without enlarged column heads

Steel concrete at slabs without beams and without

enlarged column heads are regarded as economical

construction and provide good conditions for an

optimum use of space and an easy installation of

additional devices.

The solution: PSB PUNCHING REINFORCEMENT

The PSB punching reinforcement consists of double head studs (BSt500S) with forged heads.

An assembly bar on which the stud heads are welded combines the single studs to form

punching elements.

Inserted from the top

The PSB punching reinforcement elements are

preferably inserted from the top after laying the

reinforcement. Adjustments of the position can be

made without any problems.

The problem: Load distribution around

the columns

The load concentration around the columns

generally leads to high shear loads which are not

allowed according to DIN 1045-1.

Punching of the col-

umn head

Uneconomic

To avoid punching the choice is often uneconomic

and inconvenient solutions such as for example.

Enlargement of the

column heads (above)

and increase of the slab

thickness (below).

These measures reduce

the usable oor heights

and thus the use of

the construction is

restricted.

How to order

PSB - 14 / 265 - 3 / 552 ( 130 / 130 / 195 / 97 )

Type

Anchor [mm]

Anchor height [mm]

Anchor per element

tot.lenght of the element [mm]

Distance of the support edge/angle

Distance 1. Anchor

Distance 2. Anchor

...

Distance last Anchor dip end

34

MODIX SM Standard Muffs SM A+B

For connection of rebars with equal diameter.

Other rebar must be able to rotate free.

MODIX PM Positions Muff

Connection part for rebars which are both

xed to reinforcement. Rebars can be bent or

straight. Rebars must be axially in line.

MODIX RM Reduction Muff

For the connection of rebars with different

diameters. Other rebar must be able to rotate

free.

MODIX KM Kombination Muff

For fastening the female coupler to structures

with metric screw. KM ring is installed be-

tween the muff and the screw.

MODIX EM End anchoring Muff

Part for anchoring the coupled rebar to con-

crete without using a hook.

MODIX AM A weldable Muff

AM muff can be welded to structures to fasten

the coupled rebar.

MODIX rebar splicing system

In structures which have heavy reinforcement with small center to center distances, splicing rebars are

wasting valuable space from concrete. In concreting joints, continuing the reinforcement can be dif-

cult through the formwork, and creating rigid column to beam connections is complex with continu-

ous reinforcement. These problems can be solved by using industrially made and approved end to end

threaded connections. Peikko

MODIX system is a state of the art rebar coupling system. Check the

Approval status and supplier network from local sales.

Peikko

MODIX rebar splicing systems is available

for rebar sizes d12 - d32. System consists of female

and male thread muffs and connectors. Due to unique

design installation does not require special tools to ensure

proper tightness of the connection - normal pipe wrenches will

do the work just ne. Various lengths and bendings available

upon order.

Muff types

35

www.peikko.com

R

e

i

n

f

o

r

c

e

m

e

n

t

p

r

o

d

u

c

t

s

MODIX

size (d)

[mm]

color

Protective cap with

thread for A muff

Protective plug B muff Plastic installation plate

Magnetic installation

plate

10 orange

12 yellow

14 blue

16 white

20 grey

25 red

28 black

32 brown

Delivery: With muff With muff By order By order

Accessories

36

JENKA socket anchor lifting

system

JENKA product range consists of various Rd-

threaded socket anchors with capacities from

500 kg to 12,5 tons, threaded lifting loops and

various accessories.

JENKA -anchors are suitable also for narrow

and thin structures. WAS and WAL are for re-

duced anchoring depth, SRA for narrow struc-

tures and CSA to arrange bonding with sepa-

rate rebar. JENKA anchors are delivered with

zinc plated sockets and plain rebars.

Contact local sales for more detailed informa-

tion.

CSA crosshole socket anchor

BSA bolt socket anchor ESA eye socket anchor

PSA plate socket anchor

Item name:

CSA Rd thread size (d)

Item name:

BSA Rd thread size

Item name:

ESA Rd thread size

Item name:

PSA Rd thread size

Item name

Load class

[kg]

Length

[mm]

CSA 12 500 40

CSA 14 800 47

CSA 16 1200 55

CSA 18 1600 65

CSA 20 2000 67

CSA 24 2500 77

CSA 30 4000 105

CSA 36 6300 125

CSA 42 8000 145

CSA 52 12500 195

Item name

Load class

[kg]

Length

[mm]

BSA 12 500 60

BSA 14 800 70

BSA 16 1200 80

BSA 18 1600 90

BSA 20 2000 100

BSA 24 2500 115

BSA 30 4000 150

Item name

Load class

[kg]

Length

[mm]

ESA 12 500 60

ESA 14 800 70

ESA 16 1200 77

ESA 18 1600 85

ESA 20 2000 92

ESA 24 2500 105

Item name

Load class

[kg]

Length

[mm]

PSA 12 500 30

PSA 14 800 33

PSA 16 1200 35

PSA 18 1600 44

PSA 20 2000 47

PSA 24 2500 54

PSA 30 4000 72

PSA 36 6300 84

PSA 42 8000 98

PSA 52 12500 117

d

6. LIFTING SYSTEMS

37

www.peikko.com

L

i

f

t

i

n

g

s

y

s

t

e

m

s

Item name Load class [kg]

SRA 12X195 500

SRA 14X235 800

SRA 16X275 1200

SRA 18X305 1600

SRA 20X360 2000

SRA 24X400 2500

SRA 30X505 4000

SRA 36X690 6300

SRA 42X840 8000

SRA 52X950 12500

Item name Load class [kg]

WAS 12X105 500

WAS 14X130 800

WAS 16X165 1200

WAS 18X175 1600

WAS 20X195 2000

WAS 24X240 2500

WAS 30X300 4000

WAS 36X380 6300

WAS 42X450 8000

Item name Load class [kg]

TF 12X100 500

TF 12X150 500

TF 14X105 800

TF 14X155 800

TF 16X130 1200

TF 16X175 1200

TF 18X150 1600

TF 18X225 1600

TF 20X185 2000

TF 20X250 2000

TF 24X200 2500

TF 24X275 2500

TF 30X275 4000

TF 30X350 4000

TF 36X335 6300

TF 36X450 6300

TF 42X385 8000

TF 42X500 8000

TF 52X550 12500

TF 52X700 12500

Item name Load class [kg]

WAL 12X135 500

WAL 14X170 800

WAL 16X215 1200

WAL 18X235 1600

WAL 20X270 2000

WAL 24X350 2500

WAL 30X450 4000

WAL 36X570 6300

WAL 42X620 8000

WAL 52X880 12500

Rd thread

size

Load class

[kg]

12 500

14 800

16 1200

18 1600

20 2000

24 2500

30 4000

36 6300

42 8000

52 12500

d

h

SRA straight rebar anchor

WAS short wawytail anchor TF Trollfoot

WAL long wawytail anchor

d

h

Item name:

SRA Rd thread size (d) x length (h) [mm]

Item name:

WAS Rd thread size (d) x length (h) [mm]

Item name:

TF Rd thread size (d) x length [mm]

Item name:

WAL Rd thread size (d) x length (h) [mm]

d

h

TLL threaded lifting loop

Max. lifting agle 45. Available in

sizes TLL 12 - TLL 52. Rd thread.

JL JENKA lifter

Only to be used with

NPP mould xing. Avail-

able in sizes JL 12 - JL 52. Rd

thread.

TLL and JL lifting

devices are com-

patible with JENKA

and PLA anchors.

Lifting devices (JENKA, PLA)

38

inner thread coupler ribbed bar

1.4301 / 1.4305 A500HW / Bst500S

D Rd ds dt e h K20 weight

[mm] F

perm

[kN] [kg]

PLA 20 30 20 20 58 35 140 20 0,3

PLA 24 35 24 20 58 43 150 25 0,4

PLA 30 40 30 25 72 56 200 40 0,6

PLA 36 50 36 32 96 68 250 63 1,3

F

perm

= permissible load

K20

F

perm

[kN]

20

25

40

63

Rd

D

e

h

ds

dt

CPP Plastic cap

For JENKA and PLA anchors.

Concrete grey color, no threads,

is pressed down. Available in

sizes CPP 12 - CPP 52. Sold in

100 pcs packages.

JID JENKA identication ring

For JENKA anchors. Colour-

coded plastic ring with the

denition of load class. Remains

visible in the element. Available

in sizes JID 12 - JID 52. Sold in

100 pcs packages.

JFR JENKA xing ring

Similar to JID, but has clips for

reinforcement. Plastic, colour-

coded. Available in sizes JFR 12

- JFR 52.

Other supplies (JENKA, PLA) Installation xings (JENKA, PLA)

Installation xings for wood and metal moulds

NPP plastic nail plate

Fixed by nailing trough the plate

into the mould. Compatible with

JL JENKA lifter. Available in

sizes NPP 12 - NPP 52 (Rd).

NNP narrow nail plate

Fixed by nailing trough the plate

into the mould. Material: plastic.

Available in thread sizes

M12 - M52 (M thread).

NPM magnetic holder

Fastens with magnet.

Available in sizes NPM 12 -

NPM 42 (Rd).

PLA lifting anchor

PLA lifting anchors are lifting parts for lifting balcony slabs from stainless thread. The

lifting is done by Rd threaded lifting loop or lifting device. Inner thread is anchored to

concrete with the help of headed stud.

After installing the element the lifting anchor needs no mortar lling. Hole can be blocked

by plastic cap.

See lifting devices on page 37.

Note: Anchors load groups/classes refer to anchors steel tensile strength. Capacity marked to the

anchor is the Safe Working Load with safety factor 3 for the steel part only. Anchors actual capacity and

safe working load when installed into concrete must be checked from user instructions available from

local sales.

PLA lifting anchor

APPROVALS:

BY233 Finland

39

www.peikko.com

L

i

f

t

i

n

g

s

y

s

t

e

m

s

ribbed bar tube pin

B600KX 1.4301 1.4301 / B600KX

at steel ribbed bar

1.4301 1.4301

L F

perm

weight

[mm] [kN] [kg]

PNLF 1 600 1 7 11,7 1,0

PNLF 2 770 1 9 19,3 1,5

PNLF 3 940 1 11 28,8 2,3

PNLF 4 920 2 9 32,8 3,2

PNLF 5 1120 2 11 48,2 5,3

PNLF 6 1350 3 11 72,0 8,7

F

perm

= permissible load

H a c K40-1* weight

[mm] F

perm

[kN] [kg]

RRPr 2 440 10 30 11 3,5 1,0

RRPr 4 550 15 40 16 10,0 2,4

* = design strenght of concrete F

perm

= permissible load

F

perm

[kN]

11,7

19,3

28,8

32,8

48,2

72,0

K40-1*

F

perm

[kN]

3,5

10,0

L

c

H

a

PNLF lifting anchor

PNLF is designed for lifting anchors of sandwich

elements. PNLF is fully stainless.

PNLF lifting anchor

RRPr columns lifting part

RRPr is stainless steel part for lifting columns. It is specially for oor heights

balcony columns.

RRPr is used for lifting up (from horizontal position) and placing smaller columns.

The part is left to the column after installation. It acts transversal anchor for balcony

slab.

RRPr columns lifting part

APPROVALS:

BY217 Finland

40

Item name Load class [tons] Unit weight [kg]

KKL 13 1,3 0.9

KKL 25 2,0 -2,5 1.5

KKL 50 4,0 - 5,0 3.2

KKL 100 7,5 - 10 9.4

KKL 200 20 20.0

KKL 320 32 45.5

Item name for load class color

KRC 13 1,3 blue

KRC 25 2,0 -2,5 yellow

KRC 50 4,0 - 5,0 blue

KRC 75 7,5 red

KRC 100 10 yellow

KRC 150 15 grey

KRC 200 20 black

KRC 320 32 grey

Item name Load class [tons] Length h [mm]

KK 1,3 1,3 40-240

KK 2,5 2,5 45-280

KK 4,0 4,0 75-420

KK 5,0 5,0 65-480

KK 7,5 7,5 95-680

KK 10 10 115-680

KK 15 15 140-840

KK 20 20 200-1000

KK 32 32 200-1200

Item name for load class

KFS 13 1,3

KFS 25 2,0 -2,5

KFS 50 4,0 - 5,0

KFS 75 7,5

KFS 100 10

KFS 150 15

KFS 200 20

KFS 320 32

h

KK lifting system

KK lifting system is a rapid release lifting anchor system consisting of anchors of load classes from 1,3

to 32 tons, lifting clutches and recess formers. It is used for lifting beams, thick slabs and wall panels

as well as concrete tubes.

Standard anchors are delivered as plain black. Hot dip galvanized (HDG) or electro galvanized mod-

els are available on customer request. Contact local sales for more detailed information.

Note: Anchors load groups/classes refer to anchors steel tensile strength. Capacity marked to the anchor is

the Safe Working Load with safety factor 3 for the steel part only. Anchors actual capacity and safe working

load when installed into concrete must be checked from user instructions available from local sales.

KKL lifting clutch

For KK-lifting anchors

KKL lifting clutch is a heady duty

lifting device for continuous use

for load classes from 1,3 32

tons.

KRC recess former

KFS recess xing screw

Color coded rubber re-

cess former for KK-lifting

system.

Available for load classes

1,3 32 tons

For xing KRC recess

former to casting mould.

Available for load classes

1,3 32 tons

KK-anchor

Available for load

classes 1,3 to 32 tons in

various lengths.

41

www.peikko.com

L

i

f

t

i

n

g

s

y

s

t

e

m

s

Item name for load class

KMR 13 1,3

KMR 25 2,0 -2,5

KMR 50 4,0 - 5,0

KMR 75 7,5

For load class Item name Color

2,5 RR-RF-2,5 Orange

5,0 RR-RF-5,0 Black

10,0 RR-RF-10,0 Green

26,0 RR-RF-26,0 Blue

For load class Item name

2,5 RR-HP-2,5

5,0 RR-HP-5,0

10,0 RR-HP-10,0

Item name for load class

KMG 13 1.3

KMG 25 2,0 -2,5

KMG 50 4,0 - 5,0

KMG 75 7.5

Load class

[tons]

Item name

2,5 RR-C-2,5

5,0 RR-C-5,0

10,0 RR-C-10,0

KMR magnetic recess former KMG magnetic recess grommet

Magnetic recess former

for KK-lifting system

Available for load

classes 1,3 7,5 tons

Magnetic recess grom-

met. For use with KMR.

Material: rubber.

RR lifting lugs

RR lifting lugs are lifting parts for precast elements. They are used together with dedicated lifting

devices.

Lifting device (RR lifting lugs)

Lifting device for RR line of

lifting lugs (including RRPr)

RR supplies

RR-RF recess former

For RR system. Color-coded.

RR-HP

For xing RR-RF into mould.

Note: Anchors load groups/classes refer to

anchors steel tensile strength. Capacity marked

to the anchor is the Safe Working Load with

safety factor 3 for the steel part only. Anchors

actual capacity and safe working load when

installed into concrete must be checked from

user instructions available from local sales.

42

Load class

[tons]

Item name

Length

[mm]

1,4 RR-HA-1,4-90 90

2,0 RR-HA-2,0-90 90

2,5 RR-HA-2,5-90 90

3,0 RR-HA-3,0-120 120

4,0 RR-HA-4,0-120 120

5,0 RR-HA-5,0-120 120

7,5 RR-HA-7,5-160 160

10,0 RR-HA-10,0-170 170

14,0 RR-HA-14,0-240 240

22,0 RR-HA-22,0-300 300

26,0 RR-HA-26,0-300 300

Load class

[tons]

Item name

Length

[mm]

0,7 RR-SA-0,7-110 110

1,4

RR-SA-1,4-110 110

RR-SA-1,4-160 160

2,0

RR-SA-2,0-130 130

RR-SA-2,0-160 160

RR-SA-2,0-210 210

2,5

RR-SA-2,5-150 150

RR-SA-2,5-200 200

RR-SA-2,5-250 250

3,0

RR-SA-3,0-160 160

RR-SA-3,0-200 200

RR-SA-3,0-280 280

4,0

RR-SA-4,0-180 180

RR-SA-4,0-240 240

RR-SA-4,0-320 320

5,0

RR-SA-5,0-180 180

RR-SA-5,0-240 240

RR-SA-5,0-400 400

7,5

RR-SA-7,5-260 260