Professional Documents

Culture Documents

Ijcet10011 20111108 182246 5432 45

Uploaded by

Narayana Sarma MarthiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijcet10011 20111108 182246 5432 45

Uploaded by

Narayana Sarma MarthiCopyright:

Available Formats

Journal of Control Engineering and Technology (JCET)

Failure Diagnosis System of Continuous Miner Walking System Base on HOFNN

Li Xiaohuo1, Wang Chao2, Zhang Jinghui3*, Du Wei4, Liu Shuming5

College of Mechanical Engineering, Liaoning Technical University, Fuxin, China 3 Sany Heavy Equipment Co., Ltd, Shenyang, China 1 2 lixiaohuo@163.com, wangchaopower@126.com, 3*etet-1234@163.com, 4dwsyau@163.com, 5liushuming@163.com

1,2,4,5

Abstract In order to diagnose quickly and effectively fault state, reduce failure rate, save maintenance time of a continuous miner walking system and improve the reliability and productivity, enhance performances of a continuous miner, the GA-PSO hybrid optimization method of fuzzy neural network(ie HOFNN) is used in fault diagnosis of a walking system in the paper, a intelligent fault diagnosis expert system of a continuous miner walking system is designed by means of taking VC 6.0 as the programming platform, using SQL SERVER 2000 as database, embedding MATLAB7.1 in the internal. The system is simple in manmachine interface and good in man-machine conversation, capable of analyzing accurately and judging properly failures of a continuous miner walking system. Keywords Continuous miner; walking system; fuzzy neural network; fault diagnosis; GA-PSO; HOFNN

yi =

Where, is a speed factor of sigmoid function. well as threshold 2 k is The relation between net values n 2 k and weights

1 , (i = 1.2... j ) n 1 + e ij

(2)

vik as

= n2 k

These output values are

v

i =1

ik

yi 2 k

(3)

oi =

1 , (i = 1.2...k ) 1 + e n2 k

(4)

I.

INTRODUCTION

Because of poor working conditions [1, 2], complex loads [3-11] of a continuous miner, there are high demands for its reliability. A walking system is an important part of a continuous miner, if it fails, the whole continuous miner will stop working, which affect seriously woke and productivity of the machine [12, 13]. Therefore, study of a fault diagnosis for a continuous miner walking system is very important. A GAPSO hybrid optimization method of BP neural network (abbreviated as HOFNN) is put forward in the paper, a fault diagnosis system of a continuous miner walking system is researched and established, which lay the foundation for determining sites and causes of the system failures [14-17], giving diagnosis conclusions and repair suggestions, achieving intelligent diagnosis in expert level for a continuous miner. II. ESTABLISHING MODEL

Let output values of the training sample be Yi , by selflearning cycle training of the BP neural network, the network output error is

1 k 2 (5) (Yi oi ) 2 i =1 A knowledge base of a continuous miner walking system is set up by adjusting weights v ik and threshold 2 k from the ij hidden layer to output layer, weights and threshold 1 j from the input layer to output layer by gradient algorithm. E=

III. HYBRID OPTIMIZATING Because of fast convergence rate, short training time, high precision and small error of the BP neural network optimization of the GA [18], the method is used in the paper, the specific process is followed: A Initializing swarm. Taking population size m = 60 , by generating randomly weights ij ( 10 10 random matrix) and thresholds 1 j ( 10 1 random matrix) from input layer to output layer, weights v ik 10 14 random matrix) and thresholds 2 k ( 1 14 random matrix) from the hidden layer to output layer, there is n = { ij , 1 j , v ik , 2 k } . B. Striking fitness value. Striking fitness value of particle at new location

According to fault symptom numbers and fault numbers of the system, a 3-layer BP neural network optimized hybrid with genetic algorithm (GA) and particle swarm optimization (PSO) is formed; the net input values from input layer to hidden layer of the neural network are

= n1 j

Where,

i =1

ij

X i 1 j

(1)

are weights and thresholds from input layer X i to output layer; are fault values input training sample. Bring net input values values of the hidden layer are

ij 1 j

,

n1 j

into the sigmoid function, the

f =

1 k 2 (Yi oi ) 2 i =1

(6)

JCET Vol.1 No.2 October 2011 PP.95-99 www.ijcet.org C World Academic Publishing

Journal of Control Engineering and Technology (JCET)

C. Renewing minimum. Renewing individual and global minimum values according to particle fitness. D. Renewing speeds and positions. Take learning factors c1 and c 2 as 2, weighted coefficient as 1, let N i , x i and N i +1 , x i +1 be respectively a current speed, location and a new speed, location, there are

port of the system, the working state and the damage extent of the continuous miner walking system are analysed by the failure diagnosis expert system.

N i +1 = c0 N i + c1[ Pi xi ] + c2 [Gi xi ] , (i = 1.2...m)

(7)

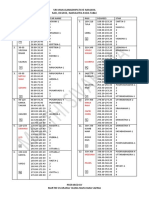

(8) E. Determining initial population. Taking half of larger fitness population as the initial population of genetic algorithm (GA), binary code, operations of selection, crossover and mutation genetic are repeatedly down, it jumps out the circulation once meeting a required accuracy, becomes a new particle population. The other half of the smaller fitness populations is as the next new particle generation. F. Substituting. Bring the new particle swarm into formula , repeat i ng l oop unt i lt o m eet preci si on and j um pi ng ij 1 j v ik out the loop, taking , , and 2 k as the initial values of the BP neural network, the self-learning cycle training is carried on, a knowledge base of a continuous miner walking system is established. IV. ESTABLISHING EXPERT SYSTEM A. Main System Interface Because MATLAB has a powerful computing power and graphics capabilities, and can easily do wavelet transform by using its wavelet toolbox functions, a continuous miner walking system fault diagnosis system is established by means of VC + +6.0 and MATLAB7.1 mixed programming, the main system interface is shown in Figure 1. B. Database Management System Figure 2a and 2b are fault diagnosis expert system databases for neural network 1 and 2 of a continuous miner walking system. Database form consists of SQL SERVER 2000. The table is database objects that contains all the data in the database, uses primarily to store the information needed to input the sample table, output sample table, a failure phenomenon table, a failure reason table, a weight table from the input layer to hidden layer, weight tables from the hidden layer to the output layer and a historical fault table. Each column (field) in tables is corresponding to the corresponding data in the database. The connection of VC + +6.0 and SQL SERVER 2000 is through this latest ADO database access technology. Because of simple and flexible, a List Control controls provided by VC + +6.0 is used to connect to the database in the paper. C. Fault Diagnosis Program Signals at key points (locations) in the continuous miner walking system are picked up with corresponding sensors, they are connected to a A/D converter of a microcontroller via MUX after pre-treatment to collect these data, then these analogy signals are transformed into digital signals, and transmitted these data into the expert system through a serial

Fig.1 Interface of expert systems

xi +1 = xi + N i +1

You can enter the neural network fault diagnosis interface after clicking on "Neural Network Fault Diagnosis" button on the main interface of the expert system, obtain processed signal characteristic values (in the from of channel data graph) when clicking on "Connection Data" after selecting sub-neural network, enter a neural network knowledge base as clicking on "Start Diagnostics", the possibility of failure (in the form of graphs that the probability of failure) is calculated. Numerical results are translated into Chinese characters (ie, fault reasons) by membership of fuzzy theory when licking on the "Explanation". Diagnosis results are stored in diagnosis fault history table once you click "Save Data" button. V. CONCLUSIONS

A GA-PSO hybrid optimization fuzzy neural network method is applied to fault diagnosis in this paper, a intelligent continuous miner fault diagnosis expert system of a continuous miner is established by taking VC++6.0 as a programming platform and using SQL SERVER 2000 as database and embedding MATLAB7.1 in the internal. The system interface is simple, human-computer interaction function is good, and it can accurately diagnose failures, save maintenance time of a walking system and improve the work reliability and increase productivity of a continuous miner. ACKNOWLEDGMENT The research is supported by: 1National Natural Science Foundation-funded Project (59774033); 2Project of Creative Team for Liaoning Provincial Education Office (2007T068); 3Project Guiding Scientific and Technological research of China Coal Industry Association (MTKJ-08-311); 4Liaoning Province Key Laboratory of large-scale Mining Equipment (the second batch of sci. & tech. projects of Liaoning Province (2008403010); 5Safety Production and Technology Development Project of Liaoning Provincial Work Safety Bureau ([2009] 88).

JCET Vol.1 No.2 October 2011 PP.95-99 www.ijcet.org C World Academic Publishing 96

Journal of Control Engineering and Technology (JCET)

(a)

(b) Fig.2 Management interface of neural network database

JCET Vol.1 No.2 October 2011 PP.95-99 www.ijcet.org C World Academic Publishing 97

Journal of Control Engineering and Technology (JCET)

(a)

(b) Fig.3 Interface of signal processing

JCET Vol.1 No.2 October 2011 PP.95-99 www.ijcet.org C World Academic Publishing 98

Journal of Control Engineering and Technology (JCET)

REFERENCES

[1] [2] [3] Xie Xichun, Li Xiaohuo, Mining machinery and equipment (second edition). China University of Mining Press, 2007 (In Chinese) Li Xiaohuo, Development prospects of continuous miner in China. Mining & Processing Equipment, 2007.35(12),10-12 (In Chinese) R.M. Miser, K.D. Beck, W. Ramer, Operational experience with a 30 M2 continuous miner at Wabash mine. Coal International, 2003.251(6), 242245 Li Xiaohuo, Yu Xinwei, Simulation and study of hard parcel distribution on continuous miner coalface. World Sci-Tech R&D, 2009..31(3),423424,422(In China). Li Xiaohguo, Yu Xinwei, Ma Xiaohng, Kinematics analysisi of cutting drums of a continuous miner. Journal of Liaoning Technology University (Natural Science), 2005.24(6),900-902(In China) Li Xiaohguo, Ma Xiaohng, Visual simulation study of pick loads on continuous miner. Key Engineering Materials, 2009.Vol.392-394,pp 471475 Li Xiaohuo, Ge Huaiting, Mathematic model of random loads on pick of continuous miner. Chinese Journal of construction Machinery, 2006.4(3), 262-264. Chao Yanli, Li Xiaohuo, Sha Yongdong, etc., Analysis on cutting ability of picks on continuous miner. Advanced Materials Research, 2010.Vols.97-101, pp 4470-4473. Li Xiaohuo, Ma Xiaohong and Yu Xinwei, Computer simulation of drum loads on continuous miner. Mining & Processing Equipment. 2005.33(12), 19-20(In China).

[4]

[5]

[6]

[7]

[8]

[9]

[10] Li Xiaohuo, Simulation and study of load distribution on continuous miner cutting chain. Mechanical Design. 2008.11(S),21-22 (In Chinese) [11] Li Xiaohuo, Ma Xiaohong, Yu Xinwei, Simulation study on the effect of kinematical parameters of continuous miner upon loads of cutting mechanism. Journal of Guangxi University (Natural Science Edition), Vol. 35(2010) No.6, pp967-971(In China). [12] F.F.Roxborough, E.J.Pedroncell, A practical evaluation of some coalcutting theories using a continuous miner. The Mining Engineer, 1982.142(252),145~156 [13] V.B.Achanti, A.W.Khair, Cutting efficiency through optimized bit configuration-an experimental study using a simulated continuous miner. Mineral Resources Engineering, Vol.10(2001) No.4, p427-434. [14] Xi Wanqiu, Diagnosis and maintenance system online of continuous miner. Coal technology, 1997(3): PP.19-22 (In Chinese) [15] Huang Shaofu, He Qing, Study on fault detection of continuous miner. China Measurement & Testing Technology, 2004(3):25-27(In China). [16] Li Xiaohuo, Zhang Jinghui, Failure diagnosis for transport system of continuous miner on neural network improved GA and PSO algorithm. The Proceedings of the China Associaion for Science and Technology, Science press & SCIENCE Press USA Inc.,2009 Vol.6, pp424-428 [17] Li Xiaohuo, Zhang Jinghui, Failure diagnosis expert system of continuous miner loading system. Chinese Journal of construction Machinery, 2008.6(2),233-236(In China) [18] Wang Ddaoping, Zhang Yizhong, Theory and methods of Intelligent fault diagnosis system. Metallurgical Industry Press, 2001.

JCET Vol.1 No.2 October 2011 PP.95-99 www.ijcet.org C World Academic Publishing 99

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 14 Pages English Calendar Final Small PDFDocument14 pages14 Pages English Calendar Final Small PDFNarayana Sarma MarthiNo ratings yet

- Rasi Degree Star TableDocument1 pageRasi Degree Star TableNarayana Sarma Marthi50% (2)

- Bommala Bhagavatam Telugu PDFDocument97 pagesBommala Bhagavatam Telugu PDFNarayana Sarma MarthiNo ratings yet

- Toronto Ontario Canada Sarvari 2020 2021 LagnantaKalaluDocument13 pagesToronto Ontario Canada Sarvari 2020 2021 LagnantaKalaluNarayana Sarma MarthiNo ratings yet

- Saavana Dina Pramanam Calculation NewYork Vijayawada Vikari 2019 2020Document11 pagesSaavana Dina Pramanam Calculation NewYork Vijayawada Vikari 2019 2020Narayana Sarma MarthiNo ratings yet

- " Automatic Air Suspension System ": A Seminar ReportDocument18 pages" Automatic Air Suspension System ": A Seminar ReportNarayana Sarma MarthiNo ratings yet

- Matlab Plotting For EeDocument15 pagesMatlab Plotting For EeNarayana Sarma MarthiNo ratings yet

- Mathematics InvestingDocument22 pagesMathematics InvestingNarayana Sarma MarthiNo ratings yet

- Free Space Path Loss MathlabDocument6 pagesFree Space Path Loss MathlabNarayana Sarma MarthiNo ratings yet

- Ac Servo Motor Principal PDFDocument26 pagesAc Servo Motor Principal PDFAman Deep86% (7)

- What They Don't Teach You at Harward Business SchoolDocument1 pageWhat They Don't Teach You at Harward Business SchoolNarayana Sarma Marthi0% (3)

- Maxillary & Mandibular CaninesDocument35 pagesMaxillary & Mandibular CaninesNarayana Sarma MarthiNo ratings yet

- Internal Combustion EngineDocument16 pagesInternal Combustion EngineNarayana Sarma Marthi0% (1)

- Maxillary & Mandibular Lateral IncisorDocument38 pagesMaxillary & Mandibular Lateral IncisorNarayana Sarma MarthiNo ratings yet

- Maxillary & Mandibular CaninesDocument35 pagesMaxillary & Mandibular CaninesNarayana Sarma MarthiNo ratings yet

- Wireless USB Is A Short-Range, High-BandwidthDocument7 pagesWireless USB Is A Short-Range, High-BandwidthNarayana Sarma MarthiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Internal Audit Checklist of Garments Manufacturing Industry - Garments AcademyDocument6 pagesInternal Audit Checklist of Garments Manufacturing Industry - Garments AcademyAriful HasanNo ratings yet

- Astm F 595 - 96Document8 pagesAstm F 595 - 96Stephanie SiahaanNo ratings yet

- ASCE Manuals and Reports On EngineeringDocument108 pagesASCE Manuals and Reports On EngineeringPabloGarciaNo ratings yet

- Failure Mode Effects Analysis of A Pressure TankDocument1 pageFailure Mode Effects Analysis of A Pressure TankjaleNo ratings yet

- Parts and Accessories For Protective Coatings High-Pressure EquipmentDocument16 pagesParts and Accessories For Protective Coatings High-Pressure EquipmentEngTamerNo ratings yet

- Maintenance Management Best Practice - 01 04 2014Document270 pagesMaintenance Management Best Practice - 01 04 2014Mahmoud GamalNo ratings yet

- SENG 421: Software Metrics: Goal-Based Software Measurement Framework (Chapter 3)Document139 pagesSENG 421: Software Metrics: Goal-Based Software Measurement Framework (Chapter 3)Xhy KatNo ratings yet

- Battery Preventive Maintenance Data SheetDocument2 pagesBattery Preventive Maintenance Data SheetEka Budi HendrawanNo ratings yet

- RTN Connect Dfmea PDFDocument21 pagesRTN Connect Dfmea PDFvprochockyNo ratings yet

- IKO Bearings Catalog Linear Motion Guide SeriesDocument392 pagesIKO Bearings Catalog Linear Motion Guide SeriesRafael Abraham ValNo ratings yet

- On-Site Oil Analysis ServiceDocument4 pagesOn-Site Oil Analysis ServiceAzhar AbdullahNo ratings yet

- Mil STD 331Document295 pagesMil STD 331HI HINo ratings yet

- 3DTCOS Reduces Overhead Corrosion Control CH-1960Document4 pages3DTCOS Reduces Overhead Corrosion Control CH-1960Atul ChoudhariNo ratings yet

- Specification For Fire and Gas Detection System PDFDocument48 pagesSpecification For Fire and Gas Detection System PDFgalih santoso100% (2)

- ABB Reliability Fingerprint: Identifies Opportunities For Productivity, Reliability and Cost ImprovementDocument17 pagesABB Reliability Fingerprint: Identifies Opportunities For Productivity, Reliability and Cost ImprovementAmro HassaninNo ratings yet

- Finops AzureDocument20 pagesFinops Azuresashikumar_123No ratings yet

- International Negotiation PDFDocument12 pagesInternational Negotiation PDFVanNamNo ratings yet

- Oil Analysis HandbookDocument106 pagesOil Analysis HandbookAlvaroJavierReyesNo ratings yet

- Hydraulic Uniformity Index For Water Distribution NetworksDocument10 pagesHydraulic Uniformity Index For Water Distribution NetworksDaniel Ortega AcostaNo ratings yet

- Software Quality and ReliabilityDocument25 pagesSoftware Quality and ReliabilityNikhil DangiNo ratings yet

- SL425 OhDocument263 pagesSL425 OhRicardo OByrneNo ratings yet

- C4711 RefDocument3 pagesC4711 Refamir amirNo ratings yet

- Freight Ohannes MelkamuDocument82 pagesFreight Ohannes MelkamuGirmaNo ratings yet

- Retrofit Roi CalculatorDocument9 pagesRetrofit Roi Calculatorprasad_kcpNo ratings yet

- T97 New ANSIRIAR1506 Robotand Robot System SafetyDocument28 pagesT97 New ANSIRIAR1506 Robotand Robot System SafetyGraciela RguezNo ratings yet

- SIS ESD Sistems For Process Industries Using IEC 61508 Unit7 SIL SelectionDocument100 pagesSIS ESD Sistems For Process Industries Using IEC 61508 Unit7 SIL Selection최재호No ratings yet

- Victoria Heavy Equipment LimitedDocument3 pagesVictoria Heavy Equipment LimitedChristopher KalanderopoulosNo ratings yet

- Maintenance and Reliability Best Technician PRDocument6 pagesMaintenance and Reliability Best Technician PRArmandoNo ratings yet

- Mil HDBK 472 1Document122 pagesMil HDBK 472 1ThejaswiniNo ratings yet