Professional Documents

Culture Documents

GT Lab Manual 21061

Uploaded by

Anonymous lUiVjgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GT Lab Manual 21061

Uploaded by

Anonymous lUiVjgCopyright:

Available Formats

1

GEOTECHNICAL

ENGINEERING

LABORATORY MANUAL

GEOTECHNCIAL ENGINERRING LABORATORY

DEPARTMENT OF CIVIL ENGINEERING

PONDICHERRY ENGINEERING COLLEGE

PONDICHERRY - 605014

2

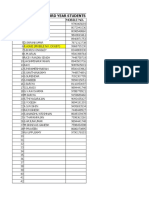

INDEX

S.No Name of Experiment

1 Visual Soil Identification as per IS Code 3

2 Specific Gravity 10

3 Grain Size Analysis Mechanical Method

Dry Sieve Analysis / Wet Sieve Analysis

12

4 Grain Size Analysis Sedimentation Analysis

Hydrometer Method

14

5 Atterberg Limits: Liquid Limit Test and Plastic Limit Test 18

6 Atterberg Limit: Shrinkage Limit Test & Free Swell Test 24

7 Laboratory Permeability Test: Constant and Variable Head 29

8 Standard Proctor Compaction Test 32

9 Direct Shear Test 36

10 Unconfined Compression Test 39

11 Triaxial Shear test UU Test 41

12 Triaxial Shear test CU Test with PWP measurement

(Demonstration)

13 Consolidation Test (Demonstration)

14 Vane Shear Test (Demonstration)

3

EXPERIMENT 1

FIELD IDENTIFICATION AND CLASSIFICATION PROCEDURE AS PER IS 1498 - 1970

AIM :

1. The field method is used primarily in the field to classify and describe soils.

2. Visual observations are employed in place of precise laboratory tests to define the basic soil

properties. The procedure is, in fact, a process of elimination beginning on the left side of

the classification chart (Table 2) and working to the right until the proper group name is

obtained.

TERMINOLOGY:

As per IS : 2809-1972 Glossary of terms and symbols relating to soil engineering ( first revision ).

1. Clay An aggregate of microscopic and sub-microscopic particles derived from the chemical

decomposition and disintegration of rock constituents. It is plastic within a moderate to wide

range of water content.

2. Silt A fine-grained soil with little or no plasticity. If shaken in the palm of the hand, a part

of saturated inorganic silt expels enough water to make its surface appear glossy. If the pat is

pressed or squeezed between the fingers, its surface again becomes dull.

3. Sand and Gravel Cohesionless aggregates of angular, subangular, sub-rounded, rounded,

flaky or flat fragments of more or less unaltered rocks or minerals.

4. Coarse-Grained Soils In these soils, more than half the total material by weight is larger

than 75-micron IS Sieve size. The coarse-grained soils shall be divided into two subdivisions,

namely:

a) Gravels (G) In these soils, more than half the coarse fraction (+ 75 micron) is larger than

4.75-mm IS Sieve size. This subdivision includes gravels and gravelly soils.

b) Sands (S) In these soils, more than half the coarse fraction (+ 75 micron) is smaller than

4.75-mm IS Sieve size. This subdivision includes sands and sandy soils.

5. Fine-Grained Soils In these soils, more than half of the material by weight is smaller than

75-micron IS Sieve size. The fine-grained soils shall be further divided into three subdivisions

on the basis of the following arbitrarily selected values of liquid limit:

a) Silts and clays of low compressibility (L) having a liquid limit less than 35,

b) Silts and clays of medium compressibility (I) having a liquid limit greater than 35 and

less than 50.

c) Silts and clays of high compressibility (H) having a liquid limit greater than 50.

Note: Soil particles finer than 2-micron may, however, be designated as clay-size particles (C) and

the particles between 75-micron and 2-micron as silt-size particles (M)

4

6. Highly Organic Soils and Other Miscellaneous Soil Materials - These soils contain large

percentages of fibrous organic matter, such as peat, and particles of decomposed vegetation.

Nomenclature Symbol Classification Size

Gravel G

Course 75 mm 20mm

Fine 20mm 4.75mm

Sand S

Course 4.75mm 2mm

Medium 2mm - 425

Fine 425 - 75

Silt M High Compressible (H),

Medium Compressible (I) ,

Low Compressible (L)

75 - 2

Clay C > 2

PROCEDURE :

1) A representative sample of the soil is selected which is spread on a flat surface or in the palm of

the hand. All particles larger than 75 mm are removed from the sample. Only the fraction of the

sample smaller than 75 mm is classified. The sample is classified as coarse-grained or fine-grained

by estimating the percentage by weight of individual particles which can be seen by the unaided

eye.

INFERENCE:

Soils containing more than 50 percent visible particles are coarse-grained soils, soils containing

less than 50 percent visible particles are fine-grained soils.

NOTE :

If it has been determined that the soil is coarse grained, it is further identified by estimating and

recording the percentage of:

(a) Gravel sized particle, size range from 75 mm to 4.75-mm IS Sieve size (or approximately 5 mm

size);

(b) Sand size particles, size range from 4.75 to 75-micron IS Sieve size;

(c) Silt and clay size particles, size range smaller than 75-micron IS Sieve.

Descriptive Information for Coarse-Grained Soils

The following descriptive information shall be recorded for coarse-grained soils:

a) Typical name:

b) Maximum size, and fraction larger than 75 mm in the total material;

c) Percentage of gravel, sand and fines in the soil or fraction of soil smaller than 75 mm;

d) Description of average size of sand of gravel;

e) Shape of the particles angular, sub-angular, sub-rounded, rounded;

5

f) The surface coatings, cementation and hardness of the particles and possible breakdown,

when compacted;

g) The colour and organic content;

h) Plasticity of fines;

i) Local or geologic name, if known; and

j) Group symbol.

Descriptive Information for Fine Grained Soils

If it has been determined that the soil is fine-graincd, it is further identified by estimating the

percentage of gravel, sand, silt and clay size particles and performing the manual identification

tests for dry strength, dilatancy, and toughness. By comparing the results of these tests with the

requirements given for the nine fine-grained soil groups, the appropriate group name and symbol

is assigned. The same procedure is used to identify the fine-grained fraction of coarse-grained soil

to determine whether they are silty or clayey.

Manual Identification Tests

The following tests for identifying the fine-grained soils shall be performed on the fraction of the

soil finer than the 425-micron IS Sieve:

a) Dilatancy (reaction to shaking)

Take a small representative sample in the form of a soil pat of the size of about 5 cubic centimetres

and add enough water to nearly saturate it. Place the pat in the open palm of one hand and shake

horizontally, striking vigorously against the other hand several times. Squeeze the pat between

the fingers. The appearance and disappearance of the water with shaking and squeezing is

referred to as a reaction. This reaction is called quick, if water appears and disappears rapidly;

slow, if water appears and disappears slowly; and no reaction, if the water condition does not

appear to change. Observe and record type of reaction as descriptive information.

b) Toughness (consistency near plastic limit)

Dry the pat used in the dilatancy test by working and moulding, until it has the consistency of

putty. The time required to dry the pat is the indication of its plasticity. Roll the pat on a smooth

surface or between the palms into a thread about 3 mm in diameter. Fold and re-roll the thread

repeatedly to 3 mm in diameter so that its moisture content is gradually reduced until the 3 mm

thread just crumbles. The moisture content at this time is called the plastic limit and the resistance

to moulding at the plastic limit is called the toughness. After the thread crumbles, lump the pieces

together and continue the slight kneading action until the lump crumbles. If the lump can still be

moulded slightly drier than the plastic limit and if high pressure is required to role the thread

between the palms of the hand, the soil is described as having high toughness. Medium toughness

is indicated by a medium thread and a lump formed of the threads slightly below the plastic limit

6

will crumble; while low toughness is indicated by a weak thread that breaks easily and cannot be

lumped together when drier than the plastic limit. Highly organic clays have very weak and

spongy feel at the plastic limit. Non-plastic soils cannot be rolled into thread of 3 mm in diameter

at any moisture content. Observe and record the toughness as descriptive information.

c) Dry strength (crushing resistance)

Completely dry the prepared soil pat. Then measure its resistance to crumbling and powdering

between fingers. This resistance, called dry strength, is a measure of the plasticity of the soil and is

influenced largely by the colloidal fraction content. The dry strength is designated as low, if the

dry pat can be easily powdered; medium, if considerable finger pressure is required and high, if it

cannot be powdered at all. Observe and record the dry strength as descriptive information.

NOTE The presence of high-strength water soluble cementing materials, such as calcium

carbonates or iron oxides may cause high dry strength. Non-plastic soils, such as caliche, coral,

crushed lime stone or soils containing carbonaceous cementing agents may have high dry

strength, but this can be detected by the effervescence caused by the application of diluted

hydrochloric acid.

d) Organic content and colour

Fresh wet organic soils usually have a distinctive odour of decomposed organic matter. This

odour can be made more noticeable by heating the wet sample. Another indication of the organic

matter is the distinctive dark colour. In tropical soils, the dark colour may be or may not be due to

organic matter; when not due to organic matter, it is associated with poor drainage. Dry organic

clays develop an earthy odour upon moistening, which is distinctive from that of decomposed

organic matter.

e) Other identification tests

1) Acid test Acid test using dilute hydrochloric acid (HCl) is primarily a test for the presence of

calcium carbonate. For soils with high dry strength, a strong reaction indicates that the strength

may be due to calcium carbonate as cementing agent rather than colloidal clay. The results of this

test should be

included in the soil description, if pertinent.

2) Shine test This is a quick supplementary procedure for determining the presence of clay. The

test is performed by cutting a lump of dry or slightly moist soil with a knife. The shiny surface

imparted to the soil indicates highly plastic clay, while a dull surface indicates silt or clay of low

plasticity.

3) Miscellaneous test Other criteria undoubtedly may be developed by the individual as he

gains experience in classifying the soils. For example, differentiation between some of the fine-

grained soils depends largely upon the experience in the feel of the soils. Also wet clay sticks to

7

the fingers and dries slowly but silt dries fairly quickly and can be dusted off the fingers leaving

only a stain. Frequent checking by laboratory tests is necessary to gain this experience.

Descriptive Information for Fine-Grained Soils

The following descriptive information shall be recorded for fine-grained soils:

a) Typical name;

b) Percentage of gravel, sand and fines;

c) Colour in moist condition and organic content;

d) Plasticity characteristics;

e) Local or geologic name, if known; and

f) Group symbol.

Description of Foundation Soils

The following information shall be recorded to define the in-place condition of soils which are to

be utilized as foundation for hydraulic or other structures:

a) For coarse-grained soils:

1) Natural moisture content (as dry, moist, wet and saturated);

2) Perviousness or drainage properties in the natural condition;

3) Structure (as stratified, uniform, uncemented, lensed; and attitude, that is, strike and dip);

4) Type and degree of cementation; and

5) Degree of compactness (as loose or dense).

b) For fine-grained soils:

1) Natural moisture content (as dry, moist, wet and saturated);

2) Perviousness or drainage properties;

3) Structures (as stratified, homogenous, varved, honeycomb, root-holes, blocky, fissured, lensed;

and attitude, that is, strike and dip). The thickness of lenses, fissures, etc, shall be noted;

4) Type and degree of cementation; and

5) Consistency (very soft, soft, firm, hard, very hard, sticky, brittle, friable and spongy).

NOTE The consistency and the compactness of undisturbed soil should be defined clearly from

the consistency of the soil when disturbed and manipulated. For example, a very thick stratum of

hard, dense shale or pre-consolidated clay of high bearing capacity, not requiring piling, may be

correctly classified as fat clay (CH) of high plasticity. Obviously the classification without

description of undisturbed condition might cause the interpreter to erroneously conclude that it is

soft and plastic in its natural state.

Reference:

IS 1498-1972: Indian Standard Classification and Identification of Soils for general engineering

purposes (First Revision) Reaffirmed 2002 - Edition 2.2, (1987 09)

8

9

10

EXPERIMENT - 2

SPECIFIC GRAVITY

Specific Gravity (G) - The ratio of the weight in air of a given volume of soil solids at a stated

temperature to the weight in air of an equal volume of distilled water at that temperature.

AIM :

To determine the specific gravity of both course and fine grained soil

APPARATUS

The following apparatus is required:

1) Specific Gravity Bottle / 100ml Standard flask / Pycnometer

2) A mechanical shaking apparatus capable of rotating the gas jar, end-over-end, at about 50

rev/min;

3) Vacuum pump with Desiccator;

4) A balance readable and accurate to 0-2 g; and

5) A thermometer to cover the temperature range 0C to 50

0

C readable and accurate to 1C.

6) Distilled water / Kerosene

PROCEDURE

A) Course Grained Soil

1. Determine and record the empty weight of dry / 100ml Standard flask

2. Take about 50g of CG soil passing through 4.75mm sieve in the 100ml Standard flask and

record the exact weight

3. Add air free distilled water to the sample to of the bottle and soak for 10min.

4. Apply partial vacuum to the contents for 10 min to remove entrapped air

5. Then carefully fill with water upto the mark and determine the weight. Record it.

6. Empty the contents of the Standard flask, clean with dry cloth and fill water up to the

mark. Clean the flask with dry cloth exterior and determine the weight.

B. Fine Grained soil

1. Determine and record the empty weight of dry / 100ml Standard flask

2. Take about 20 to 30g of FG soil passing through 425micron sieve in the 100ml Standard

flask and record the exact weight

3. Add air free clean kerosene to the sample to of the bottle and soak for 10min.

4. Apply partial vacuum to the contents for 10 min to remove entrapped air

5. Then carefully fill with kerosene upto the mark and determine the weight. Record it.

6. Empty the contents of the Standard flask, clean with dry cloth and fill kerosene up to the

mark. Clean the flask with dry cloth exterior and determine the weight.

11

OBSERVATION AND TABULATION

Description

Trial I Trail II Trail III

1 Empty weight of standard flask [W1] g

2 Weight of standard flask + soil [W2] g

3 Weight of standard flask + soil + water/kerosene [W3] g

4 Weight of standard flask + water / kerosene [W4] g

5 Specific Gravity of Kerosene for FG Soil

6

Specific Gravity for CG Soil

( )

2 1

2 1 3 4

( )

( )

s

W W

G

W W W W

=

Specific Gravity for FG Soil

( )

2 1

2 1 3 4

( )

( )

k

s

W W G

G

W W W W

=

RESULT

Specific Gravity of the given Fine grained soil =

Specific Gravity of the given Course grained soil =

REFERENCE

IS: 2720 (Part III/sec 1) 1980 Part III Determination of specific Gravity Section 1 : Fine Grained

Soils

IS: 2720 (Part III/Sec 2) 1980 Part III Determination of specific Gravity Section 2 : Fine, Medium

and Coarse Grained Soils

12

EXPERIMENT III

GRAIN SIZE ANALYSIS MECHANICAL METHOD

DRY SIEVE ANALYSIS / WET SIEVE ANALYSIS

AIM :

To determine the grain size, plot gradation curve and to classify the soil as per the particle

diameter

Note : Dry sieve analysis is carried out in course grained soils mostly sands where as wet sieve analysis is

carried out in course grained soils with substantial fine grained fraction

APPARATUS:

1. Set of sieves [4.75mm, 2.8mm, 2.00mm, 1.40mm, 1.00mm, 710, 600, 500, 425, 355,

300, 180, 150, 125, 90, 75]

2. Sieve shaker, Balance, Wire brush, lid and pan.

PROCEDURE:

1. Take about 500g of course grained dry soil, find the exact weight of the soil and record it

2. Arrange the sieves in the descending order with the lid and pan

3. Pour the soil in the top sieve and fix it in the sieve shaker and sieve for 30min

4. If not sieve the soil as one or two with lid and pan manually

5. Record the exact weight of soil retained in each sieve and also in the lid in the tabular

column

6. Calculate the % retained and plot a graph between % passing in X-axis and Particle

diameter (mm) in Y-axis (log) in a semi log 3 or 5cycle graph

7. Classify the soil as per IS :1498 1970

OBSERVATIONS AND TABULATION

Weight of soil taken for sieving (W)g =

No

Sieve

Size

Particle dia

(mm)

Weight of

soil

retained (g)

% Soil

retained

Cumulative

% retained

Cumulative

% finer

4.75mm

2.8 mm

2 mm

1 mm

500

425

300

150

75

13

CALCULATION:

60

10

u

D

C

D

= =________;

( )

2

30

10 60

c

D

C

D D

= =_________

RESULT

(1) The value of Cu =______ Cc=_______

(2) The soil is classified as per IS: 1498-1970 as _________

REFERENCE

IS :2720 (Part 4) 1985 Part 4 : Grain size analysis

IS :1498 1970 Classification and identification of soils for general purpose

14

EXPERIMENT - 4

GRAIN SIZE ANALYSIS SEDIMENTATION ANALYSIS

HYDROMETER METHOD

AIM :

To determine the grain size, plot gradation curve and to classify the soil as per the particle

diameter

APPARATUS:

1. Soil Hydrometer as per IS 3104:1965 Specification for density Hydrometers

2. 1000ml Graduated measuring Jar 2 Nos

3. Porcelain Dish 1

4. Mechanical Stirrer, Weighing Machine

5. 75 sieve, spatula, Glass rod, thermometer, rubber sheet etc.

6. Dispersion agent [ 33g of sodium hexameta phosphate + 7g of sodium carbonate in 1000ml

of distilled water]

PROCEDURE

A] Preparation of Soil Sample

1. Soil fraction passing 75-micron IS Sieve during wet sieving has been collected, this can be

oven-dried and used for Hydrometer analysis. If necessary if the soil contains any soluble

salt more than 1%, the soil need to be pretreated with Hydrogen peroxide. If any calcium

compounds the soil need to be pretreated with HCL.

2. After pre treatment depending on the soil type 25 to 50 g of this soil shall be used for the

analysis.

3. Weigh and record the exact weight of soil taken for the analysis in a china dish

4. To the soil add 25ml of dispersion agent + 100ml of water and soak the soil sample for

about 15 to 30min.

5. Transfer this suspension to the dispersion cup of the stirrer by adding more water no

exceeding 250ml in total

6. Stir the soil suspension for about 15 to 20min

B] Calibration of Hydrometer

1. Sketch the hydrometer on a plain paper and record the distance between the center of the

bulb to the neck of the bulb. Make three to four trials and find the mean (h/2)

2. Measure the distance between the neck each hydrometer graduation and record (H)

3. Calculate the volume of the hydrometer from the mass of the hydrometer or by water

displacement (Vh).

15

4. Calculate the cross section area of the measuring jar in

which the soil suspension is kept (Aj).

5. Plot a graph between the hydrometer reading (Rh) and

effective depth (He in cm) where

2 2

h

e

j

V h

H H

A

| |

= +

|

|

\ .

. This

calibration curve will help to calculate the effective depth

for any hydrometer reading.

C] Conduction of Experiment

1. Transfer the suspension to 1000ml measuring flask and

make up the level to 1000ml.

2. Prepare another 1000ml distilled water + 25ml

dispersion agent solution in an another 1000ml

measuring jar so that the composite correction

(Dispersion Agent Correction + Temperature Correction) may be found from taking

another reading form this jar also when ever a reading is taken form the soil suspension

WRT time.

3. Cover the mouth of the mouth of the jar in which the soil suspension is kept with a help of

a rubber sheet tightly and shake the suspension vigorously end over end three or four time.

Allow it to stand and immediately start the stop clock.

4. Immerse the hydrometer gently and allow to float freely. Take reading for , 1, 2 and

4min.

5. Then take out the hydrometer, rinse it and take a reading in the other jar to calculate the

composite correction. Also record the temperature at each time of recoding the hydrometer

reading.

6. Hydrometer Reading to be taken for , 1, 2, 4, 8, 16, 25, 36, 49, 60 min, 2h, 4h, 8h, 16h upto

24h.

7. Continue the experiment till the prescribed time interval and duration.

Meniscus correction

The hydrometer shall be inserted in a 1000ml measuring cylinder containing about 700 ml water.

By placing the eye slightly below the plane of the surface of the. liquid, and then raising it slowly

until the surface seen as an ellipse becomes a straight line, the point where the plane intersects the

hydrometer scale shall be determined. By placing the eye slightly above the plane of the surface of

the liquid, the point where the upper limit of the meniscus intersects the -hydrometer scale shall

16

be determined. The difference between the two readings shall be recorded as the meniscus

correction Cm. This is a constant for a given hydrometer.

OBSERVATION

1. Weight of soil sample taken for analysis (Wb) gm =

2. Specific Gravity of Soil (G) =

3. Meniscus Correction (x) =

4. Specific Gravity of Water (Gw) (g/cc) =

5. Viscosity of water (poise) at 20

0

= 0.01

FORMULA

30

( )

980( )

100

( )

( 1)

e

w

h

b

H

D mm

G G t

G

W R x

W G

T

o

C (Poise) T

o

C (Poise) T

o

C (Poise)

25 0.00896 28 0.00836 30 0.00800

32 0.00767 34 0.00736 36 0.00706

38 0.00679 40 0.00654

RESULT

1. Plot a Semi-log (5 Cycles) graph between % particle finer (Y-Axis) Vs Paricle Diameter (X-

Axis)

2. Report % Clay (% Particle less than 2 ) and % Silt .

REFERENCE

1. IS :2720 (Part 4) 1985 Indian Standard Methods of Test For Soils Part 4 : Grain size

analysis

2. IS :1498 1970 Indian Standard Classification and identification of soils for general purpose

3. IS : 2720 (Part 3/Sec 1) 1980 Indian Standard Methods of Test For Soils (Reaffirmed 1987)

Part 3 Determination of specific Gravity Section 1 Fine Grained Soils

17

TABULATION

Date,

Time &

Elapsed

Time (t)

min

Temperature

T

o

C

Hydrometer

Reading

Rh

Composite

Correction

Cm

Corrected

Hydrometer

Reading

Rh

Effective

Depth

(He)

From

Graph

Coefficient

of Viscosity

of water

() at T

0

C

(poise)

Equivalent

Diameter

D (mm)

%

Particle

finer

than D

(W)

Diameter of Soil Particle ant any Time t (D)

5

10

e

H

M

t

=

% Finer on Wd

100

( ')

( 1)

d

G

N R

W G

=

18

EXPERIMENT 5

DETERMINATION OF LIQUID AND PLASTIC LIMIT

Aim:

To Determine the Liquid limit, Plastic limit , Indices and to classify the soil sample

Apparatus:

1. Mechanical Liquid Limit Device (Casagrande Apparatus) It shall conform to IS: 9259- 1979.

2. Grooving Tool (Both A & B) and Gauge Block.

3. Porcelain Evaporating Dish about 12 to 15 cm in diameter.

4. Flat Glass Plate 10 mm thick and about 45 cm square or larger (alternative to porcelain

evaporating dish for mixing soil with water).

5. Spatula flexible, with the blade about 8 cm long and 2 cm wide (for mixing soil and water in

the porcelain evaporating dish).

6. Palette Knifes two, with the blade about 20 cm long and 3 cm wide (for mixing soil and

water on the flat glass Plate).

7. Balance sensitive to 0.01 g.

8. Hot air Oven thermostatically controlled with interior of non-corroding material to maintain

the temperature between 105 and 110C.

9. Wash Bottle, Measuring Jar 10ml & 25ml.

10. Containers air-tight and non-corrodible for determination of moisture content.

11. Equipments to prepare soil sample : Mallet , Tray (30 x 30cm), 425-micron IS Sieve

12. Soil Sample

PROCEDURE

6. Preparation of Soil Sample:

1. Take oven dry soil sample of 500gms. Put the soil in the tray and break it with mallet and

sieve through 425 sieve. Prepare enough quantity of soil sufficient for Liquid limit test ,

plastic limit test, shrinkage limit test and for repeat tests if required.

19

2. A sample weighing about 120 g shall be taken from the thoroughly mixed portion of

material passing 425-micron IS Sieve.

7. Adjustment of the Mechanical Device

1. The liquid limit device shall be inspected to determine that it is clean, dry and in good working

order, that the cup falls freely and it does not have too much side play at its hinge. The

grooving tool shall also be inspected to determine that it is clean and dry.

2. Using the gauge on the handle of the grooving tool or a separate gauge and by means of the

adjustment plate of the mechanical liquid limit device, the height through which the cup is

lifted and dropped shall be adjusted so that the point on the cup which comes in contact

8. Test:

1. About 120 g of the soil sample passing 425-micron IS Sieve shall be mixed thoroughly with

distilled water in the evaporating dish or on the flat glass to form a uniform paste. (The paste

shall have a consistency that will require 30 to 35 drops of the cup to cause the required closure

of the standard groove).

Note: In the case of clayey soils, the soil paste shall be left to stand for a sufficient time (24

hours) so as to ensure uniform distribution of moisture throughout the soil mass.

2. A portion of the paste shall be placed in the cup above the spot where the cup rests on the

base, squeezed down and spread into position, with as few strokes of the spatula as possible

and at the same time trimmed to a depth of one entimeter at the point of maximum

thickness, returning the excess soil to the dish.

3. The soil in the cup shall be decided by firm strokes of the grooving tool along the diameter

through the centre line of the cam follower so that a clean, sharp groove of the proper

dimensions is formed.

Note: In case where grooving tool, Type A does not give a clear groove as in sandy soils,

grooving tool Type B or Type C should be used.

4. The cup shall be dropped by turning the crank at the rate of two

revolutions per second until the two halves of the soil cake come in

contact with bottom of the groove along a distance of about 12 mm.

This length shall be measured with the end of the grooving tool or a

ruler.

5. The number of drops required to cause the groove close for the length

of 12 mm shall be recorded.

6. A representative slice of soil approximately the width of the spatula, extending from about

edge to edge of the soil cake at right angle to the groove and including that portion of the

20

groove in which the soil flowed together shall be taken in a suitable container and determine

its moisture content as described in IS : 2720 (Part 2)-1973.

7. The remaining soil in the cup shall be transferred to the evaporating dish and the cup and the

grooving tool cleaned thoroughly.

8. Remix the soil with more water and repeat as per steps 2, 3, 4. For at least three more

additional trials (minimum of four in all)

Note:

9. In no case shall dried soil be added to the thoroughly mixed soil that is being tested.

10. In each case, the number of blows shall be recorded and the moisture content determined as

before. The specimens shall be of such consistency that the number of drops required to close

the groove shall be not less than 15 or more than 35 and the points on the flow curve are

evenly distributed in this range.

11. The test should proceed from the drier (more drops) to the wetter (less drops) condition of the

soil.

9. Determination of Liquid Limit and Flow Index

Liquid Limit (wL)

1. A flow curve shall be plotted on semi-logarithmic graph (1-Cycle) representing water content

on the arithmetical scale (x-Axis) and the number of drops (Blows) on the logarithmic scale (Y-

Axis). The flow curve is a straight line drawn as nearly as possible through the four or more

plotted points.

2. The moisture content corresponding to 25 drops as read from the curve shall be rounded off to

the nearest whole number and reported as the liquid limit of the soil.

Flow Index (If )

1. The flow curve (straight line) plotted on semi-logarithmic graph shall be extended at either

end so as to intersect the ordinates corresponding to 10 and 100 drops.

2. The slope of this line expressed as the difference in water contents at 10 drops and at 100

drops shall be reported as the flow index.

3. The flow index may be calculated from the following equation also:

1 2

2

10

1

log

f

w w

I

N

N

=

| |

|

\ .

TEST FOR THE DETERMINATION OF PLASTIC LIMIT

Procedure:

1. The soil sample shall be mixed thoroughly with distilled water in an evaporating dish or on

the flat glass plate till the soil mass becomes plastic enough to be easily moulded with fingers.

Note: In the case of clayey soils, the plastic soil mass shall be left to stand for a sufficient time

(24 hours) to ensure uniform distribution of moisture throughout the soil.

21

2. A ball shall be formed with about 8 g of this plastic soil mass and rolled between the fingers

and the glass plate with just sufficient pressure to roll the mass into a thread of uniform

diameter throughout its length.

3. The rate of rolling shall be between 80 and 90 strokes / min counting a stroke as one complete

motion of the hand forward and back to the starting position again.

4. The rolling shall be done till the threads are of 3 mm diameter. The soil shall then be kneaded

together to a uniform mass and rolled again. This process of alternate rolling and kneading

shall be continued until the thread crumbles under the pressure required for rolling and the

soil can no longer be rolled into a thread.

5. The crumbling may occur when the thread has a diameter greater than 3 mm. This shall be

considered a satisfactory end point, provided the soil has been rolled into a thread 3 mm in

diameter immediately before.

Note : At no time shall an attempt be made to produce failure at exactly 3 mmm diameter by

allowing the thread to reach 3 mm then reducing the rate of rolling or pressure or both and

continuing the rolling without further deformation until the thread fails apart.

6. The pieces of crumbled soil thread shall be collected in an air-tight container and the moisture

content determined as described in IS : 2720 (Part 2)-1973.

Result

Plastic Limit:

1. The observations of the test should be recorded suitably. A recommended proforma for the

record of results is given below.

2. The moisture content determined is the plastic limit of the soil. The plastic limit shall be

determined for at least three portions of the soil passing 425-micron IS Sieve.

3. The average of the results calculated to the nearest whole number shall be reported as the

plastic limit of the soil.

Plasticity Index (Ip) :

The plasticity index is calculated as the difference between its liquid limit and plastic limit:

Plasticity index (Ip) = liquid limit (wL) plastic limit (wp).

In the case of sandy soils, plastic limit should be determined first. When plastic limit cannot be

determined, the plasticity index should be reported as NP (non-plastic).

When the plastic limit is equal to or greater than the liquid limit, the plasticity index shall be

reported as zero.

Toughness Index (IT) :

The toughness index shall be calculated as follows:

Toughness index (IT) = Ip / If where Ip = plasticity index and If = flow index.

22

Liquidity Index (IL) :

The liquidity index shall be calculated as follows:

n P

L

P

w w

I

I

= where wn = Natural Water

Content

Consistency Index (IC):

Consistency Index shall be calculated as follows :

L n

c

P

w w

I

I

=

OBSERVATIONS & TABULATION

Details of Soil Sample:

Weight of Soil Sample taken for Liquid Limit Test:

Weight of Soil Sample taken for Plastic Limit Test:

To Determine Natural Water Content (If the given Soil sample is wet):

Description Trial I Trail II Trail III

Identification of Container

Empty Weight of Container (W1)

Weight of Container + Wet Soil (W2)

Weight of Container + Dry Soil (W3)

Water Content %

2 3

2 1

( )

100

( )

W W

W W

Average Natural Water Content %

To Determine Liquid Limit

Description

Trial I Trail II Trail III Trail IV Trail V Trail VI

Range of Blows 70 - 60 60 - 50 50 - 40 40 - 30 30 - 20 20 - 10

App. amount of water added (ml)

Approximate Water Content

Number of Blows

Container No

Empty Weight of Container (W1)

Weight of Container + Wet Soil (W2)

Weight of Container + Dry Soil (W3)

Water Content %

2 3

2 1

( )

100

( )

W W

W W

23

To Determine Plastic Limit

Description Trial I Trail II Trail III

Identification of Container

Empty Weight of Container (W1)

Weight of Container + Wet Soil (W2)

Weight of Container + Dry Soil (W3)

Water Content %

2 3

2 1

( )

100

( )

W W

W W

Average Water Content %

RESULT:

1. Liquid Limit (wL) % =

2. Plastic Limit (wp) % =

3. Plasticity Index (Ip) =

4. Flow Index (If) =

5. Toughness Index (IT) =

6. Natural Water Content (wn) % =

7. Liquidity Index (IL) % =

8. Consistency Index (Ic) =

9. Classification of Soil as per IS : 1498 1970

(Reaffirmed 1987)

REFERENCE

1. IS : 2720 (Part 5) 1985 Indian Standard Methods of Test For Soils. Part 5 Determination of

Liquid Limit and Plastic Limit.

2. IS :9259 1979 (Reaffirmed 1987) Indian Standard Specification for Liquid limit Apparatus

For Soils.

3. IS :1498 1970 Classification and identification of soils for general purpose

4. IS : 2720 (Part 2) 1973 Indian Standard Methods of Test For Soils Part 2 Determination of

Water Content (Second Revision)

24

EXPERIMENT VI

A) DETERMINATION OF SHRINKAGE LIMIT

AIM: To determine the Shrinkage limit, degree of shrinkage and indices.

PROCEDURE

a) Preparation of Soil Paste-

1. Place about 30 g of the soil sample passing through 425 sieve in the evaporating dish

2. Thoroughly mix the soil with distilled water in an amount sufficient to fill the soil voids

completely and to make the soil pasty enough to be readily worked into the shrinkage dish

without entrapping air bubbles.

3. Weight and Volume of the Shrinkage Dish- Determine the weight of the clean empty

shrinkage dish and record.

4. Determine the capacity of the shrinkage dish in cubic centimetres, which is also the volume

of the wet soil pat, by filling the shrinkage dish to overflowing with mercury, removing the

excess by pressing the plain glass plate firmly over the top of the shrinkage dish in such a

way that the plate is flush with the top of the dish and no air is entrapped, weighing the

mercury held in the shrinkage dish to an accuracy of 0.1 g and dividing this weight by the

unit weight of mercury to obtain the volume.

5. Record this volume as the volume of the wet soil pat ( Vo)

B) Filling the Shrinkage Dish

6. Coat the inside of the shrinkage dish with a thin layer of silicone grease or Vaseline or some

other heavy grease to prevent the adhesion of soil to the dish.

7. Place in the centre of the shrinkage dish an amount of the soil paste equal to about one-

third the volume of the shrinkage dish, and allow the paste to flow to the edges by tapping

the shrinkage dish on a firm surface cushioned by several layers of blotting paper, rubber

sheet or similar material.

8. Add an amount of the soil paste approximately equal to the first portion, and tap the

shrinkage dish as before until the paste is thoroughly compacted and all included air has

been brought to the surface.

9. Add more soil paste and continue the tapping until the shrinkage dish is completely filled

and excess soil paste stands out about its edge. Then strike off the excess soil paste with a

straight edge, and wipe off all soil adhering to the outside of the shrinkage dish.

10. Weigh immediately the shrinkage dish + wet soil and record the weight.

25

11. Allow the soil pat to dry in air until the colour of the pat turns from dark to light. Then

oven-dry the pat in the shrinkage dish for 24 hours, cool in a desiccator and weigh

immediately after removal from the desiccator.

12. Record the weight as the weight of shrinkage dish and dry soil.

C) Volume of the Dry Soil Pat

13. Determine the volume of the dry soil pat by removing the pat from the shrinkage dish and

immersing it in the glass cup full of mercury.

14. Fill the glass cup to overflowing with mercury and remove the excess mercury by pressing

the glass plate with the three prongs (see Fjg. 1 ) firmly over the top of the cup, collecting

the excess mercury in a suitable container. Carefully wipe off any mercury which may be

adhering to the outside of the cup.

15. Place the cup, filled thus with mercury, in the evaporating dish taking care not to spill any

mercury from the glass cup, and place the oven-dried soil pat on the surface of the mercury

in the cup.

16. Then carefully force the pat under the mercury by means of the glass plate with the same

prongs (see Fig. 1) and press the plate firmly over the top of the cup, the displaced mercury

being collected in the evaporating dish without spilling out of it. Care shall be taken to

ensure that no air is trapped under the soil pat.

17. Weigh the mercury so displaced by the dry soil pat to an accuracy of 0.1 g and determine

its volume by dividing this weight by the unit weight of mercury. Record this volume as

the volume of the oven-dry soil pat, Vd.

Formulas:

( ) *100

( )

( ) ( )

1

( ) *100

o d

s

d

d

d w

s

d

d

V V

Shrinkage Limit w w

W

W

Shrinkage Ratio SR

V

Volumetric Shrinkage VS w w SR

V

Shrikage Limit UDS

W G

(

=

(

=

=

| |

=

|

\ .

TABULATION OF OBSERVATION:

o

d

Wt. Of mercury filling shrinkage limit

Volume of Wet Soil Pat (V ) =

Sp. Gr. of Mercury (13.6)

Wt. Of mercury displaced by the dry soil pat

Volume of Dry Soil Pat (V )=

Sp. Gr. of Mercury (13.6)

Shrinkage Li

( )

( )

1

1

100

o d w

s

d

d

d w

s

V V

mit w w

W

W

Shrikage Ratio SR

V

Volumetric Shrikage VS w w SR

(

=

(

=

=

26

No Observations Trial I Trial II

1. Shrinkage Dish Number

2 Empty Weight of Shrinkage Dish (gm)

3. Weight of Shrinkage Dish + Wet soil (gm)

4 Weight of Shrinkage Dish + Dry Soil (gm)

5 Weight of Dry Soil Pat (W

d

)

6 Water Content of Soil Pat (w

1

)

7 Weight of container / Evaporating Dish

8 Weight of container + Mercury filling the

shrinkage Dish

9 Weight of Mercury Filling the Shrinkage

dish only.

10 Volume of Wet Soil pad (v)= (9) / 13.6

11 Weight of container / Evaporating Dish

12 Weight of container + Mercury replaced by

the dry soil pad

13 Weight of Mercury replaced by the soil pad

only

14 Volume of dry Soil pad (V

d

) = (13) / 13.6

15 Shrinkage Limit (w

s

)

REFERENCE : IS : 2720 (Part 6) 1972 Indian Standard Methods of Test For Soils Part 6

Determination of Shrinkage Factors.

27

28

EXPERIMENT VI

B) DETERMINATION OF FREE SWELL INDEX

Aim

To determine free swell index of soil which helps to identify the potential of a soil to swell which

might need further detailed investigation regarding swelling and swelling pressures under

different field conditions.

Apparatus:

1. Sieve - 425-micron IS Sieve.

2. Glass Graduated Cylinders - Two, l00ml capacity (IS : 878- 1956. ).

Procedure:

1. Take two 10g soil specimens of oven dry soil passing through 425-micron IS Sieve.

a. NOTE - In the case of highly swelling soils, such as sodium bentonites, the sample size may be 5

g or alternatively a cylinder of 250 ml capacity may be used.

2. Each soil specimen shall be poured in each of the two glass graduated cylinders of 100 ml

capacity. One cylinder shall then be filled with kerosene oil and the other with distilled writer

up to the 100 ml mark.

3. After removal of entrapped air (by gentle shaking or stirring with a glass rod ), the soils in

both the cylinders shall be allowed to settle.

4. Sufficient time (not less than 24 h) shall be allowed for the soil sample to attain equilibrium

state of volume without any further change in the volume of the soils.

5. The final volume of soils in each of the cylinders shall be read out.

Calculation

The level of the soil in the kerosene graduated cylinder shall be read as the original volume of

the soil samples, kerosene being a non-polar liquid do not cause swelling of the soil. The level

of the soil in the distilled water cylinder shall be read as the free swell level. The free swell

index of the soil shall be calculated as follows:

Where Vd = the volume of soil specimen read from the graduated cylinder containing distilled

water, and Vk = the volume of soil specimen read from the graduated cylinder containing

kerosene.

Reference :

IS : 2720 (Part 40) 1972 : Indian Standard Methods of Test For Soils Part 40 Determination of

Free Swell Index of Soils.

29

EXPERIMENT- VII

PERMEABILITY OR HYDRAULIC CONDUCTIVITY

Purpose:

The purpose of this test is to determine the permeability (hydraulic conductivity) of a sandy soil

by the constant head test method. There are two general types of permeability test methods that

are routinely performed in the laboratory: (1) the constant head test method, and (2) the falling

head test method. The constant head test method is used for permeable soils (k>10-4 cm/s) and

the falling head test is mainly used for less permeable soils (k<10-4 cm/s).

Significance:

Permeability (or hydraulic conductivity) refers to the ease with which water can flow through

a soil. This property is necessary for the calculation of seepage through earth dams or under

sheet pile walls, the calculation of the seepage rate from waste storage facilities (landfills,

ponds, etc.), and the calculation of the rate of settlement of clayey soil deposits.

The knowledge of the permeability is essential in the solution of many engineering problems

involving flow of water through soils such as: Dewatering and drainage of excavations, back

fills and subgrades; Determining yield of water bearing strata; Assessing seepage through the

body of earth dams; and Computing losses from canals.

In addition since the soil may be used to inhibit flow of water, the permeability of soil governs

the type of soil to be used.

Apparatus

1) The mould assembly (including drainage base and drainage cap) shall conform to IS: 11209-

1985.

2) The compaction rammer shall conform to IS: 9198-1979

(or) wooden rammer.

3) Set of Stand Pipes - Glass stand pipes for falling head

(variable head) test arrangement, varying in diameter

from 5 to 20 mm, suitably mounted on stand or otherwise

fixed on wall.

4) Constant Head Tank - A suitable water reservoir capable or supplying water to the

permeameter under constant head for constant head test arrangement.

5) Beaker-500ml, Measuring Jar (500ml, 250ml, 100ml), Measuring Scale: 1m, 30cm, Stop

Watch, Tray & Trowel.

Preparation of Soil Sample:

1. Measure the dimension of the permeameter mould and calculate the Volume of the mould.

30

2. Weigh and take soil sample for the given unit weight or void ratio to which the soil

sample need to be prepared.

3. Wet the bottom porous stone and slide it into the base plate. Place a filter paper above the

prous stone. Fix the mould to the base plate using bolts.

4. Fill the soil in three or more layer in to the mould.

5. Place the top porous stone on the top cover of the permeameter and fix it tightly so that

there is no leakage.

6. Connect the permeability mould to the stand pipe filled with water. Open the air screw on

the lid and remove all the entrapped air.

7. After the flow has become steady, start taking reading.

A. Constant Head Method

1. For a constant head test arrangement, the specimen shall be connected through the top inlet to

the constant head water reservoir.

2. Measure the hydraulic head i.e. from the top of the water level in the stand pipe to the water

outlet in the permeameter.

3. The bottom outlet shall be opened and when the steady state of flow has been established, the

quantity of flow for a convenient time interval shall be collected and measured.

4. The collection of the quantity of flow for the same time interval shall be repeated thrice.

OBSERAVTIONS:

1. Height of Mould / Length of Sample = 2. Diameter of Sample=

3. CS Area of Sample = 4. Volume of Sample =

5. Weight of Soil Taken = 6. Unit Weight of Sample=

7. Specific Gravity of Soil = 8. Void Ratio of Sample =

9. Hydraulic Head =

Trial

Time (t)

(Sec)

Quantity of Water Collected (Q) (ml) Coefficient of Permeability

(K) cm/sec

thA

QL

K =

Trial I Trial II Trial III Average

1

2

3, 4, 5

Average K

31

B. Variable Head Method

1. For a falling head test arrangement the permeameter shall be connected to the stand-pipe.

2. Fill the stand pipe with water and the bottom outlet of the permeameter be opened

3. Tabulate the time interval required for the water level to fall from a known initial head to a

known final head

4. The stand-pipe shall be refilled with water and the test repeated till three successive

observations give nearly same time interval.

Initial

Head (h1)

cm

Final

Head (h2)

cm

Time taken for fall

in head (t) (sec)

Coefficient of Permeability

(K) cm/sec

2

1

log 3 . 2

h

h

tA

aL

K =

Trail I

Diameter of the

Stand Pipe (d) =

Trail II

Diameter of the

Stand Pipe (d) =

Average K

32

EXPERIMENT VIII

STANDARD PROCTOR COMPACTION TEST

[OR]

DETERMINATION OF WATER CONTENT-DRY DENSITY RELATION USING LIGHT

COMPACTION

AIM :

1. To determine the water content Dry Density relation using Light Compaction.

2. To determine the Optimum Water content and Maximum Dry Density of the given soil

sample.

APPARATUS:

1. Standard Proctor Compaction mould 1000cc capacity as per IS 10074-1982.

2. Light Compaction Rammer (2.6kg with height of fall 31cm)

3. Metallic Try 2 Nos (Big -1 & Small 1 No)

4. 4.75 mm IS Sieve 1 No

5. Mixing Tools T ray 2 Nos , Trowel 2 Nos to mixing the soil sample with additions of

water

6. Measuring Jar 25ml / 10ml ; Scale 30cm long ; Oil can ; Cotton Waste.

7. Container 5 Nos to determine the water content for tests conducted in the laboratory.

8. Steel Straightedge / Knife To level the soil sutface.

9. Sample Extruder (Optional) to extrude compacted specimens from the mould.

10. Weighing Balances one, of capacity 10 kg sensitive to 1 g and other of capacity 200 g

sensitive to 0.01 g.

11. Hot Air Oven.

PROCEDURE

1. A representative portion of air dried soil material approximately 2.5kg to 3kg passing

through 4.75mm sieve is prepared.

2. Find the empty weight of Proctor Mould without the collar and base plate. Also measure

the dimensions of the mould and record it.

3. Add 4 to 8% (Ref Notes) of water to the soil by weight and mix the soil thoroughly.

4. After confirming that the moisture is uniform divide the soil into 3 parts.

5. Fix the mould to the base plate and slightly spread oil inside the mould and base plate. This

will help to extract the soil easily put of mould.

6. Transfer the first part of wet soil into the mould and

33

7. Compact the soil by applying 25 blows uniformly throughout the surface of soil inside

the mould.

8. After scratching the surface of the I layer of soil, fix the collar on the mould and transfer II

part of wet soil to the mould and repeat step no (7).

9. Again as a III Stage repeat step Nos (7) & (8)

10. Remove the collar and cut of the excess soil on the mould and level the surface.

11. Then remove the base plate and find the weight of mould + wet soil.

12. Extract the soil out of mould using vertical soil extractor and collect a descriptive soil

sample for calculating the water content by oven drying method.

13. Break the soil sample and add next additional increment of water so that the water content

of the soil is increased additionally by 2% (Ref: Notes).

14. Repeat the procedure, conduct minimum of 5 trials, with 3 minimum of trials in dry side of

the proctor curve (increasing d value) and 2 number of trials in wet side (decreasing d

value).

15. Record all the observation as mentioned in the data sheet.

16. Calculate the dry density and actual water. Plot a graph between Water content in X-Axis

and Dry density in Y-Axis.

17. From the graph report the Maximum dry density and Optimum Water content.

18. Also plat a Zero Air Void Plot for 100% saturation in the same graph.

NOTE:

i) The amount of water to be mixed with air dried soil at the commencement of the test will

vary with the type of soil under test. In general, with sandy and gravelly soils a moisture

content of 4% to 6% would be suitable, while with cohesive soils a moisture content about

8% to 10% below the plastic limit of the soil (plastic limit minus 10 to plastic limit minus 8)

usually be suitable.

ii) It is important that the water is mixed thoroughly and adequately with the soil, since

inadequate mixing gives rise to variable test results. This is particularly important with

cohesive soils when adding a substantial quantity of water to the air dried soil.

iii) With clays of high plasticity, or where hand mixing is employed, it may be difficult to

distribute the water uniformly through the air dried soil by mixing alone, and it may be

necessary to store the mixed sample in a sealed container for a minimum period of about 16

hours before continuing with the test. The water added for each stage of the test should be

such that a range of moisture contents is obtained which includes the optimum moisture.

34

iv) In general, increments of 1% to 2% are suitable for sandy and gravelly soils and of 2% to

4% for cohesive soils. To increase the accuracy of the test it is often advisable to reduce the

increments of water in the region of the optimum moisture content

DATA SHEET

OBSERVATION

1. Empty Weight of Mould = 3. Weight of Soil Taken (gm) =

2. Dimensions of Mould

Diameter (cm)

Height (cm)

=

=

4. Initial Water content selected %

5. Quantity of water (cc)

=

=

Volume of Mould (cc) = Sp. Gr. of Soil =

TABULATION:

Trail

Approximate

Water Content

(%)

Quantity of

Water (cc)

Weight of

Mould + Wet

Soil (gm)

Weight of

wet Soil

(gm)

Bulk Unit

Weight

(kN/m

3

)

Actual

Water

Content (%)

Dry Unit Weight

(kN/m

3

)

1.

2.

3.

4.

5.

To Determine Actual Water Content:

Description Trial 1 Trail 2 Trail 3 Trial 4 Trail 5

Identification of Container

Empty Weight of Container (W1)

Weight of Container + Wet Soil (W2)

Weight of Container + Dry Soil (W3)

Water Content %

2 3

2 1

( )

100

( )

W W

W W

FORMULA:

RESULT:

i) The Maximum Dry Density of the given Soil Sample (kN/m

3

) =

ii) The Optimum Moisture Content (%) =

REFERENCE :

( )

1

1

1

d

a w

d

r

w

n G

wG

S

=

+

=

+

35

1. IS : 2720 (Part VII) 1980 (Reaffirmed 2002) Indian Standard Methods for Soils Part VII

Determination of water content Dry Density relation using Light Compaction. (Second

Revision)

36

EXPERIMENT 9

DIRECT SHEAR TEST

AIM:

To determine shear strength of soil with a maximum particle size of 4.75 mm in undrained,

consolidated undrained

APPARATUS:

1. The shear box (2 halves), base plate, grid plates, porous stones and loading pad with steel

ball, 2 Nos of alignment screws.

2. Proving Ring 2 kN capacity.

3. Tools to prepare soil sample (Weighing Machine, Tray , Wooden Mallet, 30cm Scale,

Trowel)

4. Stop watch (or) Dial Gauge (LC=0.01mm) to determine strain.

5. Loading Frame with weights to apply Normal Stress.

PROCEDURE

1. Measure the dimensions of the shear box. The soil can be filled up to a maximum height of 1

cm from the top. Calculate the volume of box.

2. Record the init weight of the soil sample to which the test need to be conducted.

3. Calculate the weight of soil required to fill the shear box for the required density. Weigh the

soil and keep it ready in a tray.

4. Assemble the shear box.

Keep the two haves one over another

keep the base plate in position,

Place grid plate such that serrations of the grid plates should be at right angles to the

direction of shear

Push the alignment screws in the respective holes of the shear box assembly so that the

shear box assembly do not get distorted while handling and gap screw in position

5. Fill the soil into the shear box in layers (3 -4 layers) compacted using a wooden rammer.

6. After filling the entire amount of soil to the required height of shear box slide the top grid plate

with serration down, perpendicular to the direction of shear.

7. Place the loading pad on the top

8. Transfer shear box to the shear load frame (by holding the handle fixed to the base of the shear

box assembly) so that handle of the shear box (top part) to bear against the proving ring.

9. Adjust the loading screw so that the shear box top touches the proving ring and then slide the

lock in the loading screw.

37

10. Keep the loading yoke on the top of the loading pad on the ball. Check if the horizontal arm

of the loading yoke is horizontal. If not adjust the counter weight of the loading yoke.

11. Adjust proving ring reading to zero, pull out the large alignment screws from the shear box

12. Set the vertical load to a predetermined value by sliding the slotted weight in the loading

hanger of loading yoke (0.5, 1, 1.5, 2,2.5kg/cm

2

)

13. Apply the horizontal shear load at a constant rate of strain and strain of laoding is calculated

by the time duration.

14. Note the proving ring reading for every 30 sec.

15. The test is continued to a maximum of 20% strain or till the soil sample fails. The soil failure is

indicated by return of load reading in proving ring.

16. Record also the maximum proving reading and calculate the maximum shear stress

17. Remove the load on the soil sample both shear and vertical load, take out the shear box

carefully without spillage of soil sample.

18. Re assemble the shear box and Repeat the test for next increment of normal stress.

19. Plot a stress strain plot for each normal loading.

20. Plot the value of the maximum shear stress (Y axis) versus the corresponding vertical stress (x-

axis) for each test, and determine the angle of internal friction (|) from the slope of the

approximated Mohr-Coulomb failure envelope.

OBSERVATION:

Dimensions of Shear Box (L) cm

(B) cm

(H) cm

=

=

=

Bulk Unit Weight of Sample (kN/m

3

)

Weight of soil sample tested (gm)

=

=

Volume of Shear Box (cc) = Area of the Shear Box (Ao) (cm

2

)

Proving Ring Constant = Strain Rate of Test =

Check if the large alignment screws are pulled out from the shear box

TABULATION:

Trial I : Vertical Stress (kPa) =

Time

Lapsed

Proving Ring

reading

Displacement

(o) (cm)

Corrected Area 1

3

c o

A A

o | |

=

|

\ .

Shear

Load (N)

Shear Stress

(kPa)

Trial II : Vertical Stress (kPa) =

Time

Lapsed

Proving Ring

reading

Displacement

(o) (cm)

Corrected Area 1

3

c o

A A

o | |

=

|

\ .

Shear

Load (N)

Shear Stress

(kPa)

38

Summary of Results:

Trail Normal Stress

Applied (kPa)

Shear Stress @ Failure

(kPa)

Shear strength

parameters

I

C =

| =

II

III

IV

V

REFERENCE:

IS:2720 (Part13)-1986 ( Second Revision ), Indian Standard: Methods of testing for Soils: Part 13:

Direct Shear Test

39

EXPERIMENT X

UNCONFINED COMPRESSION TEST (UCC-TEST)

Aim :

To determine the unconfined compressive strength of clayey soil ( undisturbed / remoulded /

compacted) using controlled rate of strain.

Apparatus:

1. Soil Sample in 38mm Shelby tube 2. Split Mould with screws

3. Wire cut saw / Knife 4. Weighing Machine

5. Proving Ring (2kN) 6. Dial Gauge (L.C = 0.01mm)

7. Containers 8. Loading Frame

9. Spanner, Scale 30cm. 10. Sample extractor.

Test Procedure:

A) Preparation of Soil Specimen

1. Remoulded soil sample may be prepared by compacting the soil at the desired water

content and dry unit weight in a bigger 1500cc CBR mould and then cut by the 38mm thin

walled Shelby tube.

2. To extract the soil sample out of the Shelby tube, fix the tube horizontally in the horizontal

soil extractor. In the open end fix the assembled split mould.

3. Slowly rotate the plunger into the tube so that the sample will be pushed in the split mould.

After the sample of required length is pushed into the split mould, remove the split mould

after cutting the sample with the help of wire cur saw and unscrewing the mould from the

extractor.

4. Trim the soil sample to the exact diameter and length of split mould. Collect a descriptive

soil sample to determine the water content by oven drying method.

5. Un screw the split mould, carefully the soil specimen and measure the dimension of the

sample. Also weigh the soil sample to determine the bulk unit weight of the sample.

B) UCC Test

1. Transfer the soil sample to the centre of the bottom base plate of the loading device.

2. Fix the proving ring with the top loading plate on the loading frame.

3. Through a ball and socket system the load is transferred to the sample to avoid eccentric

loading.

4. Adjust the upper plate to make the top plate contact with the soil specimen.

5. Fix the dial gauge resting on the lower plate to determine the stain of loading.

6. Set the gear to the position such that the rate of loading is 1.25mm/min.

40

7. Switch on the machine so that the soil sample is compressed uniformly. While loading

note the Proving ring reading for every 0.25% strain in dial gauge till the soil sample fails

or to a maximum stain of 20%.

8. After the completion of the test, remover the soil sample from the loading frame and sketch

the failure pattern.

9. Calculate the stress and strain. Plot a graph between stain in X-Axis and Stress in Y-Axis.

10. From the graph calculate the UnConfined Compressive Strength of the given soil sample.

OBSERVATIONS :

1. Dimensions of the soil sample

L (cm)

D (cm)

=

=

2. Weight of Soil Sample (gm)

=

=

3. CS Area of the Soil Sample (cm

2

) = 4. Volume of Soil Sample (cc) =

5. Proving Ring Constant = 6. Bulk Unit Weight of Soil

sample

=

7. Water content of the sample =

Tabulation:

Dial Gauge

Reading

(div)

Proving Ring

Reading

(div)

Strain (c) %

Corrected Area

(cm

2

)

AC = Ao / (1-c)

Load

(KN)

Stress

(kPa)

0.25 %

0.50 %

0.75 %

1.00 %

.

.

.

20%

RESULTS

1. Failure angle from the Soil Sample (o) =

2. Angle of Internal Friction (|) =

3. Un Confined Compressive Strength (kPa) =

4. Undrained Cohesion C (kPa) =

5. Strain at failure (%) =

REFERENCE:

IS:2720 (Part10)-1991 ( Second Revision ), Indian Standard: Methods of testing for Soils: Part 10:

Determination of Un Confined Compressive Strength.

41

EXPERIMENT XI

TRIAXIAL SHEAR TEST (UU - TEST)

AIM:

Determination of the compressive strength of a specimen of saturated cohesive soil in the triaxial

compression apparatus under conditions in which the cell pressure is maintained constant and

there is no change in the total water content of the specimen.

APPARATUS:

1. Soil Sample in 38mm Shelby tube 2. Split Mould with screws

3. Wire cut saw / Knife 4. Weighing Machine

5. Proving Ring (2kN) 6. Dial Gauge (L.C = 0.01mm)

7. Containers 8. Loading Frame

9. Spanner, Scale 30cm. 10. Sample extractor.

11. Triaxial Cell 12. Cell pressure applying device

13. Membrane Stretcher. 14. Rubber membrane, O- Rings, Loading Pad, etc.

PROCEDURE:

A) Preparation of Soil Specimen

1. Remoulded soil sample may be prepared by compacting the soil at the desired water

content and dry unit weight in a bigger 1500cc CBR mould and then cut by the 38mm thin

walled Shelby tube.

2. To extract the soil sample out of the Shelby tube, fix the tube horizontally in the horizontal

soil extractor. In the open end fix the assembled split mould.

3. Slowly rotate the plunger into the tube so that the sample will be pushed in the split mould.

After the sample of required length is pushed into the split mould, remove the split mould

after cutting the sample with the help of wire cur saw and unscrewing the mould from the

extractor.

4. Trim the soil sample to the exact diameter and length of split mould. Collect a descriptive

soil sample to determine the water content by oven drying method.

5. Un screw the split mould, carefully the soil specimen and measure the dimension of the

sample. Also weigh the soil sample to determine the bulk unit weight of the sample.

B) Triaxial Test

1. Stretch the rubber membrane in the membrane stretcher after sliding the O rings in the top

and bottom of the membrane stretcher.

42

2. Sucking the air in the membrane stretcher, push the soil sample into the stretched

membrane.

3. Slide the loading plate in to the top of the soil sample. Transfer the soil sample with the

rubber membrane to the pedestal at the base of the triaxial cell. Then slide the O ring to the

base pedestal and top loading pad and remove the membrane stretcher.

4. Fix the proving ring with the top loading plate on the loading frame.

5. Close the soil sample with the top Perspex cover and fix it tightly with the screws.

6. Transfer the triaxial cell to the loading frame.

7. Make the loading rod of the triaxial cell resting on the loading pad of the sample centrally.

Through a ball and socket system the load is transferred between the loading rod and

proving ring to avoid eccentric loading.

8. Connect the water pressure line to the triaxial cell bottom and fill the triaxial cell opening

the valve and air release valve on the top of the Perspex cover.

9. After filling the triaxial cell with water, close the air release valve and apply the required

confining pressure (o3). (100 / 200 / 300kPa)

10. Fix the dial gauge resting on the lower plate to determine the stain of loading.

11. Set the gear to the position such that the rate of loading is _________mm/min.

12. Switch on the machine so that the deviator stress is applied uniformly on the soil sample

uniformly. While loading note the Proving ring reading for every 0.25% strain in dial gauge

till the soil sample fails or to a maximum stain of 20%.

13. After the completion of the test, remover the soil sample from the loading frame and

observe the failure pattern.

14. Calculate the stress and strain. Plot a graph between stain in X-Axis and Stress in Y-Axis.

15. Repeat the procedure with 2 more specimen with different cell pressures.

16. From the Stress Strain graph calculate the maximum deviator stress at failure for the

given soil sample at a particular cell pressure.

17. Then plot the Mohr-Coulomb envelop to determine the shear strength parameters

Cohesion (C) and Angle of internal friction (|)

OBSERVATIONS :

1. Dimensions of the soil sample

L (cm)

D (cm)

=

=

2. Weight of Soil Sample (gm)

=

=

3. CS Area of the Soil Sample (cm

2

) = 4. Volume of Soil Sample (cc) =

5. Proving Ring Constant = 6. Bulk Unit Weight of Soil

sample

=

43

7. Water content of the sample =

Tabulation:

Trail 1 : Cell Pressure (o3) = 100 kPa

Dial Gauge

Reading

(div)

Proving Ring

Reading

(div)

Strain (c) %

Corrected Area

(cm

2

)

AC = Ao / (1-c)

Load

(KN)

Stress

(kPa)

0.25 %

0.50 %

0.75 %

1.00 %

.

.

.

20%

Cell Pressure

or Confining

Pressure o3

(kPa)

Deviator Stress at

Failure Aof (kPa)

Major Principal Stress

o1 = (o3 +Aof) kPa

Strain at

failure % (cf)

Principal Stress

Ratio

(o1 /o3)

Shear Strength

Parameters

C (kPa) =

| =

RESULTS

1. Angle of Internal Friction (|) =

2. Undrained Cohesion C (kPa) =

REFERENCE:

IS:2720 (Part11)-1991 ( First Revision ), Indian Standard: Methods of testing for Soils: Part 11:

Determination of Shear Strength Parameters of a specimen tested in Un Consolidated Undrained

Triaxial Compression without the measurements of Pore Water Pressure

44

45

You might also like

- Sanathkumar V: ObjectiveDocument3 pagesSanathkumar V: ObjectiveAnonymous lUiVjgNo ratings yet

- Retrofitting TechniquesDocument17 pagesRetrofitting TechniquesAnonymous lUiVjgNo ratings yet

- Full Schedules of SeminarDocument8 pagesFull Schedules of SeminarAnonymous lUiVjgNo ratings yet

- RGCET Mech - DBDocument4 pagesRGCET Mech - DBAnonymous lUiVjgNo ratings yet

- Review of LiteratureDocument10 pagesReview of LiteratureAnonymous lUiVjgNo ratings yet

- Exam Prayer Teaching NotesDocument1 pageExam Prayer Teaching NotesAnonymous lUiVjgNo ratings yet

- Painting EstimationDocument8 pagesPainting EstimationAnonymous lUiVjgNo ratings yet

- 101 Keyboard ShortcutsDocument6 pages101 Keyboard Shortcutslittle cute gurlz100% (4)

- Time Managment - Rsssj1Document45 pagesTime Managment - Rsssj1Anonymous lUiVjgNo ratings yet

- Groundwater Tracing TechniquesDocument12 pagesGroundwater Tracing TechniquesAnonymous lUiVjgNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Boiler Water TreatmentDocument7 pagesBoiler Water TreatmentJAY PARIKH100% (1)

- 2021 Jun CSEC TCF P1Document11 pages2021 Jun CSEC TCF P1Bisham SiewNo ratings yet

- Davi-BARCODE-MCB-FOUR ROLLDocument12 pagesDavi-BARCODE-MCB-FOUR ROLLبازرگانی راهیان کار و دانشNo ratings yet

- Incinerator Opermanual2 en PDFDocument22 pagesIncinerator Opermanual2 en PDFcap.mucino100% (1)

- Recarburization of Ductile IronDocument2 pagesRecarburization of Ductile IronWalton BangladeshNo ratings yet

- PF Ds The Ultimate Technology in Separation and Washing 2020 05-27-608185Document40 pagesPF Ds The Ultimate Technology in Separation and Washing 2020 05-27-608185Marcel MendivilNo ratings yet

- Roll Mill 1Document48 pagesRoll Mill 1klasiko bente tresNo ratings yet

- Valorizing Spent Coffee GroundsDocument15 pagesValorizing Spent Coffee GroundsJorge ZapataNo ratings yet

- Opal's Spectacular Colors and Properties RevealedDocument1 pageOpal's Spectacular Colors and Properties RevealedJohn Angelo Fernandez OquianaNo ratings yet

- Optimization of Electroless Copper Coating Parameters On Graphite Particles Using Taguchi and Grey Relational AnalysisDocument6 pagesOptimization of Electroless Copper Coating Parameters On Graphite Particles Using Taguchi and Grey Relational AnalysisfacebookdeepuNo ratings yet

- Fanuc Sensor65162e - 03Document659 pagesFanuc Sensor65162e - 03sicstone100% (2)

- Deutz 165 MK3 Electrial 1Document100 pagesDeutz 165 MK3 Electrial 1chrideerNo ratings yet

- The 16 Losses PDFDocument3 pagesThe 16 Losses PDFsenzo scholarNo ratings yet

- Search ResultsDocument3 pagesSearch ResultsSanjay MehtaNo ratings yet

- Book of Best PracticesDocument117 pagesBook of Best PracticesMoeen Khan Risaldar100% (2)

- Olefins Production PDFDocument64 pagesOlefins Production PDFAnonymous 0zrCNQNo ratings yet

- OxoneDocument2 pagesOxoneSha Hriyar HNo ratings yet

- PP Cast FilmDocument4 pagesPP Cast FilmMiguel MarujoNo ratings yet

- QweqDocument2 pagesQweqPraYush RajbhandariNo ratings yet

- Flue Gas Cooler Brochure - 0 PDFDocument1 pageFlue Gas Cooler Brochure - 0 PDFSriram RamanujamNo ratings yet