Professional Documents

Culture Documents

Design of Water Treatment Plant

Uploaded by

Vasanthakumar VenkatesanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Water Treatment Plant

Uploaded by

Vasanthakumar VenkatesanCopyright:

Available Formats

r ~"'.~IIIIIIIItQIIP'''''''''llqliill1"mllftllllJl'l'*~''''IIIIJPP~IIIIIIfIP"III QDI.IIIIIIIIIIIJI"II~ CIVIL ENQINEERING STUDIES . d !

I Ii ENVIRONMENTAL ENGINEERING i Ii PROJECT REPORT ON G " , J 8 DESIGN OF WATER TREATMENT PLANT ~ACULTY ADVISOR 4 d ii I= .. 111 . ;:..,. !!II PREPARED BY 1 II , t . i I i I I i I i JAIN. NIKHIL.R. , . ~ ii .. ~ 4 . ii

!!II I I I . DEPARTMENT OF CIVIL ENGINEERING Sardar Vallabhbhai RegionalCollege of Engineering c" Technology Surat-395007. [G ujarat) . . . 1 i = 5' !!II I ~18I1IIJ.1I""""IIIIIIIIJ.~II111IIih.Ila8l11l1l111111bDml1odDballll"'Cllldlllblld llllJb. .. = =

DEPARTMENT OF CIVIL ENGINEERING SARDAR VALLABHBHAI REGIONAL COLLEGE .OF ENGINEERING & TECHNOLOGY SURAT - 395007 CERTIFICA TE This is to certify that the project,entitled "Design of Water Treatment has been preparedby $-,./A. IJC~~./;/. 71. Roll. No 26. Plant", a final year student of Civil Engineering, during the year 1998-99, as a partial fulfillment of the requ irement for the award of Bachelor of Engineering Degree in Civil Engineering of SOUTH GUJARAT UNIVERSITY, SURAT. His work has been found to be satisfactory. . ---------. GUIDED BY: ~~'-' . of B. K. Samtani) ( Dr. B. K. K'atti)

Acknowledgment Right from the procurement of material to the cleaning of conceptual difficultie s, we cannot withhold our sincerest thanks to Prof. B.K.Samtani, Civil Engineeri ng department, SVRCET, Surat, without whose invaluable guidance and cooperation the project would not have been accomplished. we would also like to thank Dr. B. K. Katti, Prof. and Head, Civil Engg. Departm ent, whose support and encouragement are transparent in the work it self. Lastly, we would like to thank Mr. SUNIL MISTRY (Navsari) for preparing the repo rt. I" DEEPAK V.M. (15) DESAI DHARMESHM. DHAMI VIJAY M. DINTYALA SRINADH DIWANJI NIBHRVTA R. G. CHANDRAM OHAN GAJJAR TEJAL S. GAlJRAV PARASHAR (16) (17) (18) (19) (20) (21) (22) (23) (24) (25) (26) (27) GHADIYALI MINESH S. GHOSH lITPAL GOPALAKRISHNAN R. JAIN NIKHIL R. JAJlJ PRADEEP R.

CONTENTS Sr.No. 1.0 2.0 INTRODUCTION BASIC DATA FOR THE DESIGN OF WATER SUPPLY SYSTEM 3.0 4.0 5. 0 5.1 5.2 5.3 5.4 5.5 6.0 6.1 6.1.1 6.1.2 6.1.3 6.1.4 6.1.5 6.1.6 6.2 6.2.1 6.2. 2 6.2.3 6.2.4 6.2.5 6.2.6 6.3 7.0 SALIENT FEATURES OF WATER TREATMENT PLANT POPU LATION FORECASTING CALCULATION OF WATER DEMAND Calculation of different drafts D esign capacity of various components Physical and chemical standards of water Co mparison of given data and standard data Suggested units of treatment plant DESI GN OF UNITS Collection units Design of intake well Design of pen stock Design of gravity main Design of jack well Design of pumping system Design of rising main Treatment units Design of aeration unit Design of chemical house and calculatio n of chemical dose Design of mechanical rapid mix unit Design of cIarifiocculato r Design of rapid gravity filter Disinfection unit Storage tank CONCLUSION REFER ENCES: Title

-.= lUG (fr INTRODUCTION Water, undubiously is a basic human need. Providing safe and adequate quantities of the same for all rural and urban communities, is perhaps one of the most imp ortant undertaking, for the public works Dept. Indeed, the well planned water su pply scheme, is a prime and vital element of a country's social infrastructures as on this peg hangs the health and wellbeing of it's people. The population in India is likely to be Hundred crores by the turn of this century, with an estima ted 40% of urban population. This goes on to say that a very large demand of wat er supply; for Domestic, Industrial, Firefighting, Public uses, etc.; will have to be in accordance with the rising population. Hence, identification of sources of water supply, there conservation and optimum utilization is of paramount imp ortance. The water supplied should be 'Potable' and 'Wholesome'. Absolute pure w ater is never found in nature, but invariable contains certain suspended, colloi dal, and dissolved impurities (organic and inorganic in nature, generally called solids), in varying degree of concentration depending. upon the source. Hence t reatment of water to mitigate and lor absolute removal of these impurities (whic h could be; solids, pathogenic microorganisms, odour and taste generators, toxic substances, etc.) become indispensable. Untreated or improperly treated water, becomes unfit for intended use proves to be detrimental for life. The designed w ater treatment plant has a perennial river as the basic source of water the type of treatment to be given depends upon the given quality of water available and the quality of water to be served. However such an extensive survey being not po ssible in the designed water treatment plant. It is assumed that all kinds of tr eatment processors are necessary and an elaborate design. 1

The design of water treatment plant for Mandvi situated in district Surat of Guj arat has been done. Mandvi is located on the bank of river Tapti. The latitude a nd longitude of the town corresponding 21.61 N, 73.118E respectively. The popula tion of the given year 2031 will be 61400. There are many industries like diamon d industries and chemical industries in the town so, treated water supply for do mestic and industrial uses are very essential. ...

" [I_ (ir BASIC DATA FOR THE DESIGN OF WATER SUPPL V SVSTEEM The given problem includes the design of water treatment plant and distribution system and also the preparation of its Technical Report and Engg. Drawings showi ng the required details of collection and treatment units. The following Table g ives the basic necessary data required for the design of water treatment plant. (Table No. 2.1) No. 1. 2. 3. Name of the place District Location (a) About 27 mi le (43.2 kms) away from Kim railway station of western railway. (b) Nearest rail way station is Mandvi station (9 mile, 14.4 kms) on Tapti valley railway (c) On the right bank of Tapti. 4. 5. Latitude (Lat.) Longitude (Lon) 21.61 N 73.18 E Description - Mandvi - Surat (Table No. 2.2) Sr.No. 1. 2. 3. 4. Design Considerations Design period (years) Average rate of water supply (Ipcd) Industrial demand (MLD ) Quality of raw water I) Ph Values 30 135 0.6 7.5 ..

II) III) IV) V) VI) VII) VIII) 5. Turbidity (mg/L) Total Hardness (mg/L) [as CaC03] Chlorides (mg/L) Iron (mg/L) M anganese (mg/L) Carbonates (mg/L) M.P.N. (No.l100ml) 50 550 200 2.5 3.5 110 3.5 I Population of past four decades (In thousand) Year 1961 Year 1971 Year 1981 Ye ar 1991 I F.S.L. of river (R.L. in mts.) I Ground level at ; (R.L. in mts.) a) b ) Jack well site Location of aeration unit 28 29 07 12 15 22 27 6. 7. 8. I Invert level of raw material gravity intake pipe (R.L. in mts. ) 24200 9. 10. I Length of raw water rising main (mts.) I Source supply: A river with sufficien t perennial flow to satisfy the required demand. 11. 12. 13. 14. I Highest G. L. in (m) I Lowest G. M. in (m) I Bed level of river (m) I H.F.L. o f river (m) I I 34 28 22 32 3

~r::tr SALIENT FEATURESOF WATER TREATMENT PLANT 3.1. ~ General Populationof the town (In thousand) Year 1991 Year 2031 :22 : 61.4 : 8.89 : 13.33 : 30 2. Average daily draft (M.L.D.) Maximum daily draft (M.L.D.) 3. Design period (Y ears) 3.2 Intake Works Intake Well No. of units 2. Dia. Of well (m) 3. Ht of intake well . R.L. of bottom well (m) 5 R. L. of top of well (m) time (min) Collection Works :1 : 5.5 :4 : 24 : 28 :10 ... Detention Penstock ~ No. of penstockwell :2 : 400 2. Dia. Of penstock (mm) Bell mouth strainer 01 No. of bell mouth strainer 2. Dia. (m) :2 : 0.9 4

I Gravity main No. of units '" Dia. (mm) 3 Invert level (m) ~ slope Jack well No. of units Dia. (m) 3 Depth of water :1 : 6.15 : 3.12 : 10 :1 : 550 : 23.88 : 1:86 2 . Detention time (min) Rising main and pumping units Rising : ~ Dia. (m) : 0.45 :1 2 Velocity of flow (m/s) Pumping unit: Capacity of eachpump(HP) 2. No. of pumps : 60 :1 3.3 Aeration unit ~ Treatment works R.L. of aeration unit (m) (top) (Bottom) : 31.40 :29.40 :1 :5 :1 : 0.4 : 0.5 : 1.0 :5 5 2. Dia. Of top tray (m) 3. Dia. Of bottom tray (m) 4 Dia.of each tray decreasing by(m) 5. Rise of each tray (m) 6. Tread of each tray (m) Dia.of central rising main pipe (m) 8 No. of trays

Chemical storage house : 20 : 12 : 3.0 1. Length (m) 2. Breadth (m) 3. Height (m) Chemical Dissolving Tank 1. No. of Tank 2. Length (m) 3. Breadth (m) 4. Depth (m) Flash Mixer :1 :3 :2 : 1.5 1 No. of units 2. Dia. (m) 3. Detention time (min) 4. Height (m) 5. Depth of wat er (m) Clariflocculatoi :1 : 1.6 : 0.5 : 2.6 : 2.37 Flocculator : 1. No. of units 2. Dia. (m) 3. Dia. of Inlet pipes (m) 4. Depth of water flow (m ) 5. Velocity of flow (m/s) 6 :1 : 10.16 :0.45 : 3.5 : 1.0

Clarifire : 1. No. of units 2. Dia. (m) 3. Depth of water (m) 4. Overall depth of tank (m) 5 . Slope of bottom Rapid Sand Filter 1. No. of units 2. Surface area (Sq. m) 3. D imension of unit (m x m) 4. Thickness of sand bed (m) 5. Thickness of gravel bed (m) 6. Dia. of manifold (m) 7. Laterals: (a) No's (b) Dia. (mm) (c) Length (cm) (d) Spacing (cm) 8. No. of orifices 9. Dia. of orifice (mm) 10.Wash water tank : 86 : 90 : 2.9 : 20 :16 : 13 :1 :2 :58.48 : 8.6 x 6.8 : 0.6 : 0.5 :1 :1 : 23 : 4.4 : 4.7 :8% Disinfection House 1. ChlorinerequiredIday (kg) 2. CylinderrequiredIday (no.) : 18.662 :2 3.4 Storage Units Underground Reservoir 1. No. of units 2. Length (m) 7 1 14.>

3. Breadth (m) 4. Depth (m) Elevated Service Reservoir 1. No. of units 2. Dia. ( m) 3. Height (m) 4. Capacity (Cu. m) -14 : 4.5 :1 : 12 : 4.3 : 450 8 .. ;

~ lUG (ir POPULATION FORECASTING 4.1 Desian Period .. ,'a:er supply project may be designed normally to meet the requirements : 6'" a 30 years period after there completion. The time lag between :esgn and c ompletion should be also taken into account. It should not :'"C'1arily exceed 2 years and 5 years even in exceptional circumstances. -~e 30 years period may how ever be modified in regard to specific :C"'lponents of the project particularly the conveying mains and trunk ~a "'ISof the distribution system depending on the ir useful life or the facility ;::~carrying out extension when required, so that expenditure far ahead of _:. ty is avoided. However in our case the design peri od has been ~"'1sidered as 30 years per given data. . 4.2 General Considerations POlJulation Forecast ~e population to be served during such period will have to be estimated .,:..t.~ due regard to all the factors governing the future growth and :e/elopment of th e city in the industrial, commercial, educational, social a"d administrative sph eres. Special factors causing sudden immigration or ~ux of population should als o be foreseen to the extent possible. 9

Calculation Of Population With Different Methods (TableNO.4. 1) Sr. No. 1 1. Year Population (thousand) 3 7.48 Increase (thousand) 4 Increase In creament % al increase 5 (thousand) 6 Decreas ein% increase 7 2 1961 4.52 03 07 14.52 4.84 60.45 25 46.67 132.12 44.04 -1.52 4.0 2.48 1.24 35.45 -21.67 13.78 6.89 2. 3. 4. 1971 12 15 22 1981 1991 Total Average Arithmetical Increase Method Using the relation Po Where, Po Pn n c P2031 = Pn + nc = Initial population; = Population in dh decade; = No. of decades; = Average inc rease (refer table 2.1, col. 4) = 36521+ 4840.33 = 41361.33 Geometrical Increase Method Using the relation Pn Where, Pn Pn IG N =Po(1+IG/100)n = Population in the dh de cade; = Population any decade ; = Percentage increase ( Ref. Table 4.1, col. 5 ) = No. of decade P2031 = 65744.86 + ( 44.04 /100 x 65744.86) = 94698.17 10

Incremental Increase Method Using the relation Pn Where, r = Po + ( r + i )n = Average rate of increase in p opulation per decade (Ref. Table 4.1, Col. 5) ; = Average rate of incremental in crease per decade (Ref. Table 4.1, Col. 6) ; Po Pn = Populationin any decade; = Populationin n decade; = 46319.32 P2031 = 40239.49+ ( 4840.33+ 1239.5) Decrease Rate Of Growth Method Year 2001 2011 2021 2031 Expected population 22000 + 39.78/100 x 22000 30751 + 32.39/100 x 30751 40865 + 26/100 x 40865 51490 + 19.11/100 x 51490 = 30751 = 40865 = 51490 = 61330 4.3 Description Of The Various Methods Arithmetic Increase Method ~'"'lSmethodis basedupon assumptionthat the populatio nincreasesat a ~stant ~e_ rate and rate of growth slowly decreases. In our case also :;opulationis increasingat a constantrate with slight decreasein growth -=-. this method is more suitable for. very big and older cities whereas in so = case it is relatively smaller and new town. S: results by this method is although good but not as accurate as desired. 11 . .. -

Geometrical Increase Method In this method the per decade growth rate is assumed to be constant and which is average of earlier growth rate. The forecasting is done on the basis that the percentage increases per decade willremain same. This method would apply to cities with unlimited scope for expansion. Incremental In crease Method This method is an improvement over the above two methods. The aver age increase in the population is determined by the arithmetical increase method and to this is added the average of the net incremental increase, once for each future decade. This method would apply to cities, likely to grow with a progres sively i,creasing or decreasing rate rather than constant rate. Decreasing Rate Of Growth Method As in our case the city is reaching towards saturation as obvio us from the graph and it can be seen that rate of growth is also decreasing. Thu s this ."ethod which makes use of the decrease in the percentage increases is "l ore suitable. This method consists of deduction of average decrease in percentag e increase from the latest percentage increase. ""'lus this gives weightage to t he previous data as well as the latest trends. Decrease in percentage increase i s worked out average thus giving ...,portanceto whole data. 12

Logical Curve Method This is suitable in cases where the rate of increase of dec rease of population with the time and the population growth is likely to reach a saturation limit ultimately because of special local factors. The city shall grow as per the logistic curve, which will plot as a straight lin e on the arithmetic paper with the time intervals plotted against population in percentage of solution. Simple Graphical Method Since the result obtained by this method is dependent up on "'luch reliable. the '1telligence of the designer, this method is of empirical nature and not Also this method gives very approximate results. Thus this method is useful only to verify the data obtained by some other method. Graphical Comparison Method ~is involves the extension of the population time cu rve into the future :)ased on a comparison of a similar curve for comparable cities and ~odified to the extent dictated by the factors governing such predictions. 13

Logical Curve Method This is suitable in cases where the rate of increase of dec rease of population with the time and the population growth is likely to reach a saturation limit ultimately because of special local factors. The city shall gr ow as per the logistic curve, which will plot as a straight line on the arithmet ic paper with the time intervals plotted against population in percentage of sol ution. Simple Graphical Method Since the result obtained by this method is dependent up on "'luch reliable. the 'r'1telligenceof the designer, this method is of empirical nature and not Also this method gives very approximate results. Thus this method is ...sefulonl y to verify the data obtained by some other method. Graphical Comparison Method ~is involves the extension of the population time curve into the future :)ased on a comparison of a similar curve for comparable cities and "'-'odifiedt o the extent dictated by the factors governing such predictions. 13 ...

-= lUe (jj= CALCULATION OF WATER DEMAND 5.1 Calculation Of Different Drafts = 61400 = 135 LPCD Expected population after 30 years Average rate of water supply (Including domestic, commercial, public and wastes) Water required for above purposes for whole town Industrial demand = 61400 x 135 = 8.289 MLD = 0.6 MLD Fire Requirement : It can be assumed that city is a residential town (low rise buildings) Water for fire = 100 P x 10-3MLD = 100 61.4 X 10-3MLD = 0.78 MLD (i) Average daily draft = 8.289 + 0.6 = 8.889 (ii) (iii) Maximum daily draft Coincident draft = 1.5 x 8. 889 = 13.33 = maximum daily draft + fire demand = 13.33 + 0.78 = 14.11 MLD (Coin cident draft < maximum hourly draft) 14 .. ..

5.2 (i) (ii) (iii) Desian CaDacitv For Various ComDonents = 13.33 MLD Intake structure daily draft Pipe main = maximum daily draft = 13.33 MLD Filters and other units at treatment plant = 2 x Average daily demand =2x8.889 = 17.778 MLD (iv) Lift pump = 2 x average daily demand = 17.778 MLD 5.3 Phvsical And Chomical Standards Of Water Sr. No. 1. 2. 3. . . . . - . - ., Characteristics Turbidity (units on J.T.U. scale) Color (units on platinum cobal t scale) Taste and odour Acceptable 2.5 5.0 Unobjection able 7.0 to 8.5 500 200 200 200 1.0 45 75 30 0.1 0.05 0.05 5 .0 Cause for Rejection 10 25 Unobjection able 6.5 to 9.2 1500 600 1000 400 1.5 45 200 150 1.0 0.5 1.5 1 5.0 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. PH Total dissolved solids (mg/L) Total hardness (mg/L as CaC03) Chlorides (mg/L as C1) 8ulphates (mg/L as 804) Fluorides (mg/L as F) Nitrates (mg/L as N03) Calc ium (mg/L as Capacity) Magnesium (mg/L Mg) Iron (mg/L Fe) Manganese mg/L as MnO Copper (mg/L Cu) Zinc (mg/L as Zn) 15

17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. Phenolic Compounds (mg/L as phenol) Anionic Detergents (mg/L as MBAS) Mineral oi l (mg/L) TOXIC MATERIALS Arsenic (mg/L as As) Cadmium (mg/L as Cd) Chromium (mg/ L as Hexavalent Cr) Cyanides (mg/L as Cn) Lead (mg/L as Pb) Selenium (mg/L as Se ) Mercury (mg/L as Hg) Polynuclear (mg/L) RADIO ACTIVITY Aromatic 0.001 0.2 0.01 0.05 0.01 0.05 0.05 0.1 0.01 0.001 0.002 1.0 0.3 0.05 0.01 0.05 0.05 0.1 0.01 0.001 0.2 Hydrocarbons 0.2 28. GROSS Alpha Activity in pico Curie 3 (pCi/L) 30 3 29. Gross Beta Activity (pCi/L) 30 Notes : . . The figures indicated under the column 'Acceptable' are the limits upon which wa ter is generally acceptable to the consumers. Figures in excess of those mention ed under 'Acceptable' render the water not acceptable, but still may be tolerate d in the absence of alternative and better source upon the limits indicated unde r column 'Cause for Rejection' above which the supply will have to be rejected. . It is possible that some mine and spring waters may exceed these radioactivity l imits and in such cases it is necessary to analyze the individual radio nuclides in order to assess the acceptability for public consumption. 16

5.4 ComDarison Of Given Data And Standard Data (Table No. 5.2) Sr. No. 1. 2. Particulars pH Turbidity Actual 705 50 Standard Difference Means 7 to 8.5 2.5 O.K. 47.5 Not for Treatment necessary Clarifier & rapid sand filter 3. 4. 5. 60 70 Total (mg/L) Hardness 550 200 2.5 3.5 200 200 0.1 0.05 350 50 2.4 3.45 Softening Chlorides(mg/L) Iron (mg/L) Manganese (mg/L) Aeration Aeration Carbonate (mg/L) MPN (no.100) 110 3.5 0.0 3.5 Softening Chlorination 8. 17

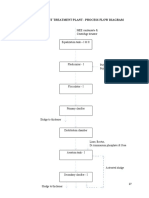

5.5 Suaaested Units Of Treatment Plant J ue to previous analysis following units are required to be designed for ,',Iat ertreatment plant. ~) Intake Structure : (a) Intake well (b) Gravity main (c) Ja ck well (d) Rising main (e) Pump 2I Treatment unit: (a) Aeration unit (b) Coagul ant dose (c) Lime soda dose (d) Chemical dissolving tank (e) Chemical house 'f) Flash mixer (g) Clariflocculator (h) Rapid sand filter (i) Chlorination unit .. Storage unit: fa) Underground storage tank b) Elevated storage ,.:.. ~ematic diagram of each of the unit is shown. 18 .... .

-=lu0 ~ DESIGN OF UNITS 6.1 Collection units 6.1.1 (a) Design Of Intake Well Intake Well Intakes consists of the opening, strainer or grating through which the water ent ers, and the conduct conveying the water, usually by gravity to a well or sump. From the well, the water is pumped to the mains or treatment plants. Intakes sho uld also be so located and designed that possibility of interference with the su pply is minimized and where uncertainty of continuous serviceability exists, int akes should be duplicated. The following must be considered in designing and locating the intak es. The source of supply, whether impounding reservoir, lake or river (including the possibility of wide fluctuation in water level). The character of the intake su rrounding, depth of water, character of bottom, navigation requirements, the eff ect of currents, floods and storms upon the structure and in scouring the bottom . The location with respect to the sources of pollution. The prevalence of floatin g materials, such as ice, logs and vegetation. Types of Intakes : Wet Intakes: Water is up to source of supply. Dry Intakes: No water inside it ot her than in the intake pipe. Submerged Intakes: Entirely under the water. Movabl e and Floating Intakes: Used where wide variation in surface elevation with slop ing blanks. 19

Location Of Intakes : . . . . . . The location of the best quality of water available. Currents that might threate n the safety of the intake structure. Navigation channels should be avoided. Ice flows and other difficulties. Formation of shoals and bars. Fetch of the wing a nd other conditions affection the weight of waves. Ice storm. Floods. Power avai lability and reliability. Accessibility. Distance from pumping station. Possibil ities of damage by moving objects and hazards. . . . . . . The intake structure used intake our design is wet-type. (b) 1. 2. Design Criter ia Detention time Diameter 5 to 10 min. 5 to10 m(maximum 15m) 3. 4. 5. 6. Depth Velocity of flow Number of units Free board 4 to 10m 0.6 to 0.9 m/s 1 to 3 (maxi mum 4) 5m (c) Design Assumptions =27m =28m Given F.S.L. Minimum R.L. Given invert level of gravity main = 24 m Detention time = 10 min. 20

Design Calculation Flowof water required Volume of well = 13.33 MLD 13600 x 24 = 0.1543 m3/sec. = 0.1543 x 0 x 60 = 92.57 m3 Cross-sectional area of intake well = 92.57 14 = 23.14 m2 diameter of intake well (d) = ...J4 23.14 In x = 5.42 < 10 m (O.K.) provide 1 intake well of diameter 5.42 m == 5.5 m (e) 1. 2. 3. 4. Summary Number of intake wells Diameter of intake well Height of well R.L. of bottom of well 1 unit 5.5m 4.0m 24m 6.1.2 Design Of Pen stock And Bell Mouth Strainer (a) Pen stock This are the pipes provided in intake well to allow water from water body to int ake well. These pen stocks are provided at different levels, so as to take accou nt of seasonal variation in water level (as H.F.L., W.L., L.W.L.). Trash racks o f screens are provided to protect the entry sizeable things which can create tro uble in the pen stock. At each level more than one pen stock is provided to take account of any obstruction during its operations. These pen stocks are regulate d by valves provided at the top of intake wells. (b) Design Criteria Velocity through pen stock Diameter of each pen stock Number of pen stock for ea ch intake well 21 = 0.6 =2 t01.0 m/sec. = less than 1 m

.~ ., .. MANHOLE .".-. . R. L. .2B M T F.S.L..-I.-,. .L.J:N R .--------.- ( -----..--:0=M1" . .' . 3MT Lw.L. -) '17 . .. ,.-GRJ\VIIY MAIN (0..55) MT .. -.;----.. "... . .. ..... :NT!-\I-<C \VrLL

(c) Design Calculation =1 =2 = 0.75 m/sec. (assumed) = 0.1543/0.75 x 2 = 0.1029 m2 Number of intake well Number of pen stocks at each level Velocity CIS area of ea ch pen stock Diameter = 0.3619 m == m 0.4 (d) 1. 2. 3. Summary Number of pen stock 1well At each level Diameter of pen stock 2 units 1m 0.4 m Design Of Bell Mouth Strainer: (a) Design Criteria = 0.2 to 0.3 m/s = 6 to 12 mm = 2 x diameter of holes Velocity of flow Hole diameter Area of strainer (b) Assumptions = 0.25 m/s = 10 mm Velocity of flow Hole diameter (c) Calculation 1t d2 Area of each hole Area of collection 0.1543 = = 0.7853cm2 4 = Area of pen stock = 0.7853 x N 0.25 x 2 N = 3929.7 Area of Bell mouth strainer= 2 x area holes 22

(c) Design Calculation =1 =2 = 0.75 m/sec. (assumed) =0.1543/0.75x2 = 0.1029 m2 Number of intake well Number of pen stocks at each level Velocity C / S area of each pen stock Diameter = 0.3619 m == m 0.4 (d) 1. 2. 3. Summary Number of pen stock / well At each level Diameter of pen stock 2 units 1 m 0.4 m Design Of Bell Mouth Strainer: (a) Design Criteria = 0.2 to 0.3 m/s = 6 to 12 mm = 2 x diameter of holes Velocity of flow Hole diameter Area of strainer (b) Assumptions = 0.25 m/s = 10 mm Velocity of flow Hole diameter (c) Calculation 1t d2 Area of each hole Area of collection 0.1543 = = 0.7853cm2 4 = Area of pen stock = 0.7853 x N 0.25 x 2 Area of Bell mouth strainer = 2 x area holes 22

= 2 x 3929.7 x 0.7853 = 6171.98 Diameter of Bell-mouth strainer = 88.64 Provide diameter of 0.9 m for bell mouth strainer. 6.1.3 Design Of Gravity Main (a) Gravity Main The gravity main connects the intake well to the jack well and water flows though it by gravity. To secure the greatest economy, the diameter o f a single pipe through which water flows by gravity should be such that all the head available to cause flow is consumed by friction. The available fall from t he intake well to the jack well and the ground profile in between should general ly help to decide if a free flow conduit is feasible. Once this is decided the m aterial of the conduit is to be selected keeping in view the local cost and the nature of the terrain to be traversed. Even when a fall is available, a pumping or force main, independently or in combination with a gravity main could also be considered. Gravity pipelines should be laid below the hydraulic gradient. (b) Design Criteria = 0.3 to 1 m = 0.6 to 0.9 m/s =1 = 0.7 m/s Diameters of gravity main Velocity of water Number of gravity main = number of i ntake well Assumption velocity (c) Design Calculation R.C.C. Circular pipe is used. Conduit velocity Area of conduit required Diameter of the conduit = 0.7 m/s (assumed) = 0.1543 I (0.7) = 0.2204 m2 = 0.5297 m == 0 .55 m 23

Using Manning's formula, 1 V= R 2138112n 8n2V2 R413 (0.013)2 X (0.7)2 (0.55/4)413 = 1.59 x 10-4 8 = 1 : 862 Headloss = 100 / 862 = 0.116 R.L. of gravity main = 27 - 3 =24m R.L. of gravity main at jack well = 24 - 0.116 = 23.88 m (d) 1. 2. 3. 4. Summary Number of gravity intake Diameter of gravity intake Invert level at inta ke well Invert level at jack well 1 unit 0.55m 24m 23.88 m 6.1.4 Design Of Jack Well (a) Jack Well This structure serves as a collection of the sump well for the incoming water fr om the intake well from where the water is pumped through the rising main to the various treatment units. This unit is more useful when number of intake wells are more than one., so that water is collected in one unit and then effected. The jack well is generally lo cated away from the shore line, so that the installation of pumps, inspection ma intenance is made easy. 24

(b) Design Criteria . Detentiontime = 0.5 x detention time of intake well.(3 to 15 min.}. =0.5)( 10 =5min. . . (c) Suction head < 10m. Diameter of well < 20m. Design Calculation Detention time =5m. = Assumingsuctionhead Bottomclearance Top clearance 8 m. = 1.0 m. = 0.5 m. Maximum depth of water that can be stored in condition when water is minimumin r ive 26 22.88 =3.12 m =0.1543x10x60 = 92.58 m3 = 92.58/3.12 = 29.67 m2 Capacity of well C / S area of well Diameter of well R.l. of bottom of jack well R.l. of bottom o f jack well when full = 6.14 m = 22.88 m = 22.88 + 7 = 29.88 m (d) Summary Diameter of jack well R.l. of bottom of jack well R.l. top of jack well Suction depth Top clearance Bottom clearance r:c3. 4. 6.15m 22.88 m 29.88 m 2.12m O.5m 1m .25 tE 6.

/.... k'.. --... J' .' I I I REGULAI\NG' ; I :-0:.. ..... . I' I I. . VALVE~ :'-1' .. .I :.-'Ii :: :: ~,.: ;>-~-r'- _ _._l~:,,.._. : to.. I_~"",I_J _'." _ 4' "_"_... _ " : .. .. -_" I PIAn RISING _ MAIN ( 0- 45) >B ,." "iT . T ,.~.:~ .. ...: .".: . " :'~~;~ . _.

,s R.L. ... 4.2,q. -", .. 0':~"',: .:., ','j: V" ,. ,', . , " I~ ;I1l' ~{ !iG ,co R!:G ULATt"'GVALVE GRAVITY MAt/'oJ MT . . ..' ~-:--;":1. . ~. ~'L.' li.iY~ cu\VrLL AND PUMPJ-JOUf

5.1.5 Design Of Pumping System (a) Pumps in the water treatmentplant, pumps are used to boost the water from thejack well to the aerationunits. The followingpoi ntsare to be stressedupon. The suction pumpingshould be as short and straight as possible. It should not be greaterthan 10m,for centrifugalpump. If head is more . i +n ""' ..v... i '' ~ +h, ,... i "' i n~ , n + Lhan 10 m V g ter Is converte d , n I I, ILV yg poU r g, '''' LIIU,", I n pI te VI LA v atlng ''"' water head, vapour head is created and pump ceases to function. . . . . The suction pipe should be of such size that the velocity should be about 2m / s ec. . The delivery pipe should be of such size that the velocity should be about 2.5m. /sec. The fonowing four to/pes of pumps are generally used. . . . Buoyancy operated pumps impuise operated pumps Positive displac.ementpumps Veloc ity adoptions pumps . The following criteria govern pump selection. . Type of duty required. Present and projected demand and pattern and change in de mand. The details of head and flow rate required. Selecting the operating speed of the pump and suitable drive. . o The efficiency of the pumps and consequent influence on power consumption and the running costs. (b) Diameter Of Rising Main Q = 0.1543m3/sec. Economical diameter = 0.97 --.fato 1.22 --.fa

= 0.97 "';0.1543to 1.22 .../0.1543 =0.38 to 0.48 m Provide D = 0.45 m (c) . Design Criteria Suction head should not be greater than 10m. Velocity of f low length Top clearance = 0.7 to 1.5 mts =0.5 m =1m Bottomclearance (d) Design Calculation Frictionallosses in rising main Assumingvelocity = 0.9 mtsec. F = 0.02 FPv2 hf=2gd Head loss = 0.02 x -190x (0.9)2 2 x 9.81 x 0.45 = 0.348 =0.35 Total head of pumping = hs + hd + hf + minor losses = 2.12+4.88+.35+1 =8.35 Assuming two pumps in parallel W.O.H. 1000 x 0.1543 x 8.35 W.H.P. = . = =17.17HP S.H.P. = 75 W.H.P. 75 (e) : n Summary = 17.17 0.75 =22.90 HP Provide 1 - 25 HP pump in parallel Diameter of pipe I0.45 m , 2.7

-y: 6.1.6 Design Of Rising Main (a) General These are the pressure pipes used to convey the water from the jack well to the treatment units. The design of rising main is dependent on resistance to flow, available head, al lowable velocities of flow, sediment transport, quality of water and relative co st. Various types of pipes used are cast iron, steel, reinforced cement concrete, pr e stressed concrete, asbestos cement, polyethylene rigid PVC, ductile iron fibre glass pipe, glass reinforced plastic, fibre reinforced plastic. The determinati on of the suitability in all respects of the pipe of joints for any work is a ma tter of decision by the engineer concerned on the basis of requirements for the scheme. (b) Design Criteria Velocity =0.9 to 1.5 m/sec. Diameter < 0.9 m. (c) Design Calculation = 0.97J a to 1.22.[0 = 0.38 to 0.48 m = 0.45 m Economical diameter, D Provide diameter V Summary = alA = 0.97 m/sec. Diameter of pipe I 0.45 m 28

6.2 Treatment Units The aim of water treatment is to produce and maintain water that is hygienically safe, aesthetically attractive and palatable; in an economical manner. Albeit t he treatment of water would achieve the desired quality, the evaluation of its q uality should not be confined to the end of the treatment facilities but should be extended to the point of consumer's use. The method of treatment to be employ ed depends on the characteristics of the raw water and the desired standards of water quality. The unit operations and unit processes in water treatment constit ute aeration flocculation (rapid and slow mixing) and clarification, filtration, softening, defloridization, water conditioning and disinfection and may take ma ny different combinations to suit the above requirements. In the case of ground water and surface water storage which are well protected, where the water has turbidity below 10 JTU (Jackson Candle Turbidity Units) and is free from odour and color, only disinfection by chlorination is adopted befor e supply. Where ground water contains excessive dissolved carbon dioxide and odorous gases , aeration followed by flocculation and sedimentation, rapid gravity or pressure filtration and chlorination may be necessary. Conventional treatment including prechlorination, aeration, flocculation and sed imentation, rapid gravity filtration and postchlorination are adopted for highly polluted surface waters laden with algae or microscopic organisms. Based on the data given in second chapter, the following treatment units and acc essory units are designed to meet the quality and quantity requirement of the pr oject: 29

-Aeration unit Coagulant dose Lime soda dose Chemical dissolving tank Chemical h ouse Flash mixer Clariflocculator Rapid sand filter Chlorination unit The detail design of the ab ove units are discussed in subsequent sections. 6.2.1 Design Of Aeration Unit Aeration Unit Aeration is necessary to promote the exchange of gases between the water and the atmosphere. In water treatment, aer ation is practiced for three purposes : To add oxygen to water for imparting fre shness, underground sources devoid of or deficient in oxygen. Expulsion of C02, H2S and other volatile substances causing taste and odour, e.g. water from deepe r layers of an impounding reservoir. To precipitate impurities like iron and man ganese, in certain forms, e.g. water from some underground sources. The limitati on of aeration are that the water is rendered more corrosive after aeration when the dissolved oxygen contents is increased though in earlier circumstances it m ay otherwise due to removal of aggressive C02. Also for taste and odour removal, aeration is not largely effective but can be used in combination with chlorine or activated carbon to reduce their doses. 30 e.g. water from

The concentration of gases in a liquid generally obeys Henry's Law which states that the concentration of each gas in water is directly proportional to the part ial pressure, or concentration of gas in the atmosphere in contact with water. T he saturation concentration of a gas decreases with temperature and dissolved sa lts in water. Aeration tends to accelerate the gas exchange. The three types of aerators are : Waterfall or multiple tray aerators. Cascade aerators. Diffused a ir aerators. Design Criteria For Cascade Aerators Number of trays Spacing of trays Height of the structure Space requirement Design Calculation Qmax Provide area at tray Dia meter of bottom most tray Rise of each tray Tread of each tray = 0.1543 m3/sec. = 17 m2 =5m = 0.4 m =50cm = 4 to 9 = 0.3 to 0.75 m c/c =2m = 0.015 - 0.045 m2/m3 /hr 31

CASCADE. i. (A. ~> ~ -.-1" . L.{Jt.OO) R CA~CA[)E CASC.AbE 3. ~.Ct ~ - R.'L(30t'c.:) ~ " R.. ., :roe ~C.) L R.l(,2(h8~ R'L: 29; ( ,-, It 0) . ,C-ASCADE f4 ~ .~) (3qSJ <:'ASCI'obE ~ ~(5# 2Cf -OD , . 1N LE'T =-G : I Rl SING MAIN (0..1.,;:) MT : I ,r R..L. IN MTS PIA M ETE-R CAse ADt; Of: ~r<J MT5 AE RA\IQ\J UN\-r ~

Summary Sr. No. 1. 2. 3. 4. 5. Cascade First Second Third Fourth Fifth Diameter of tray (m) 1 2 3 4 5 R.L. (m) 31.00 30.60 30.20 29.80 29.40 R.L. of ground at site = 29.00 m Design Of Chemical House And Calculation Of Che mical Dose The space for storing the chemicals required for the subsequent treat ment of water consists of determining space required for storing the most common ly used coagulant alum, lime, chlorine, etc. for the minimum period of three mon ths and generally for six months. The size of unit also depends upon the locatio n, transport facilities, weather conditions, distance of production units and availability of chemicals. Chemical house should be designed to be free from moisture, sap, etc. These shou ld be sufficient space for handling and measuring chemicals and other related op erations. It should be located near to the treatment plant and chemicals should be stored in such size of bags that can be handled easily. Alum Dose: Coagulation The terms coagulation and flocculation are used rather indiscriminat ely to describe the process of removal of turbidity caused by fine suspension co lloids and organic colors. 32

Coagulation describes the effect produced by the addition of a chemical to a col loidal dispersion, resulting in particle destabilization. Operationally, this is achieved by the addition of appropriate chemical and rapid intense mixing for o btaining uniform dispersion of the chemical. The coagulant dose in the field should be judiciously controlled in the light of the jar test values. Alum is used as coagulant. Design Criteria For Alum Dose Alum required in particular season is given below: Monsoon Winter Summer = 50 mg/L = 20 mg/L = 5 mg/L Alum required Let the average dose of alum required be 50 mg/L, 20mg/L, 5 mg/L i n monsoon, winter and summer, respectively. Per day alum required for worst seas on for intermediate stage = 50 x 10-6x 555.48 X 103x 24 = 666.58 kg/day For six months (180 days) = 666.58 x 180 = 119984.40 kg Number o f bags whence 1 bag is containing 50 kg = 2400 If 15 days in each heap = 160 hea ps If area of one heap be 0.2 m2,then total area required = 80 m2. Lime-Soda Pro cess: Softening A water is said to be hard, when it does not form leather readil y with soap. The hardness of water is due to the presence of calcium and magnesi um ions in most of the cases. The method generally used are lime-soda 33

process. Softening with these chemicals is used particularly for water with high initial hardness ( > 500 mg/L) and suitable for water containing turbidity, col or and iron salts. Lime-soda softening cannot, however, reduce the hardness to v alues less then40 mg/L. Design Criteria For Lime-Soda Process It should be possible to remove 30 mg/L ca rbonate hardness and 200 mg/L total hardness by this process. Lime And Soda Requ ired Lime required for alkalinity Molecular weight of CaC03 = 40 + 12 + 48 = 100 = 40 + 16 = 56. CaO 100 mg/L of CaC03alkalinity requires 110 mg/L of CaC03 requires = 56 mg/L of CaO = (56/100) x 110 = 61.6 mg/L of CaO Lime Required For Magnesium 24 mg/L of magnesium requires 1 mg/L of magnesium re quires 3.5 mg/L of magnesium requires Hence, the total pure lime required = 56 m g/L of CaO. = 56/24 mg/L of CaO. = (56/24) x 3.5 = 8.2 mg/L of CaO. = 61.6 + 8.2 = 69.8 mg/L Also 56 kg of pure lime (CaO) is equivalent to 74 kg of hydrated li me. Hence, hydrated lime required Soda (Na2C03) : Soda is required fir non-carbo nate hardness, as follows. = (69.8 x 74)/56 = 92.23 mg/L. 3+

100 mg/L of NCH requires 161.6 mg/L of NCH requires = 106 mg/L of Na2C03 = ( 106/100) x 161.6 =65.59 mg/L of Na2C03 Total quantity of lime =(92.23 x 555.5 x 180 x 24 x 103) =221329.86 kg One bag contains 50 kg. Number of bags required If 15 bags in each heap, number of heaps If area of one heap is 0.2 m2. Total quantity of soda required = 4426 = 295 = 295xO.2 = 59 m2 = 65.59 x 10-6 555.5x103x 24 x 180 x = 157400.25 kg. = 3148 = 209.86 heaps. = 0.2 x 209.86 = 41.97 m2 = 80 + 59 + 41. 97 = 180.97 m2 Number of bags If 15 bags in each heap Total area of heap Total area for all che micals Add 30 % for chlorine storage, chlorine cylinders etc. Total area Provide room d imension = 235.26 m2 = 20 x 12 = 240 m2 = 20mx 12m = 119984.4 +221329.86 +157400 = 498714.26/180 =19394.44 day =387 bags =25.8 heap s provide dimension Chemical Dissolving Tanks : Total quantity of alum, lime and soda Area required Dimensions = 5.16 m2 = 3.0 m x 3.0 m 35

Chemical Solution tanks: Total quantity of alum, lime and soda required per day = 2770.63 kg/day Hence solution required per day = 2770.63 x 20 =55412 Lit/day = 38.48 Lit/min Quantity of solution for 8 hours = 38.48 x 8 x 60 = 18470 Lit = 1 8.47 m3 Assuming depth of tank (1.2m) and 0.3m free board Dimension of solution tank Summary = 4.5 x 3.5 x 1.5 1. 2. 3. 4. Per day alum required Hydrated lime required Soda required tanks 666.58 k/j 92.23 mql 65.59 'M/A.Size of chemical dissolving 3x3 5. Size of chemical solution tanks 4.5 x 3.5 x 1.5 Design Of Mechanical Rapid Mix Unit Flash Mixer Rapid mixing is and operation by which the coagulant is rapidly and uniformly dispersed throughout the volume of water to create a more or less homogeneous single or multiphase system. This helps in the formation of micro floes and results in proper utilization of chemical coagulant preventing localization of connection and premature formation of hydroxides which lead to less effective utilization of the coagulant. The ch emical coagulant is normally introduced at some point of 36

. hIIi gh .. ,..h u1ence "nI +h" ..vater U..l11.I I LIIO Y' . T II " 10 he SV u"c " OfI vnol P"u,,,.. ' f".. ..~ .d miv l IVI IQ pl iliA ng to create the desired intense turbulence are gravitational and pneumatic. T " 110 h In+ens ~' LILY ' "f VI .vi I III All " n,.. Iis d0 pendent ~ I I '" UpO II th LII " " e tvllll-'VIQ , m" anI Iv ""' OCi+u YOI ILY gradient 'G'. This is defined as the rate of change of velocity per unit distanc e normal to a section. The turbulence and resultant intensity of mixingis based on the rate of power input to the water. Flash mixture is one of the most popula r methods in which the chemicals are dispersed. They are mixed by the impeller r otating at high speeds. Design Criteria For Mechanical Rapid Mix Unit Detention time =30 to 60 sec. Velocity of flow Depth Power Required Imeeller 8eeed . . Loss of head = 4 to 9 m/sec. = 1 to 3 m cu.m/day = 0.041 'r<J/vi"1000 = 100 to 250 rpm

=O.4to;.O Mixing device be capable of creating a velocity gradient = 300m/sec/m depth Rati o of impeller diameter to tank diameter = 0.2 to 0.4 : 1 D I' a +in uv VI .. I , nf t ank h""!g I It to rfi amo tor \..II '"' ". O . -I J"+0 ':! v. . -I I (C) Design Calculation = 13331.52 m3/day = Design flow Detention time Ratio of tank height to diameter Ratio of impeller di ameter to tank diameter Rotational speed of impeller Assume temperature 30 sec. = 1.5:1 = 0.3:1 = 120 rem . =200

1. Dimension of tank: = 4.629 m3 D Height Volume = 1.6m = 2.37 + (0.23 m free board) Total height of tank = 2.6 m 2. Power Requirement: Power spend =5.47 KW 3. Dimensions of flat blade and impeller: = 0.65 m = 4.08 m/sec. = As =:h x CDx rox As x VR3 Let CD 5.47 x i 03 As = 1.8 (Flat blad e); VR = 1.99 m2 = % XVT = % x 1.8 x i 000 XAs x % x 4.08 Diameterof impeller Velocity of tip impeller Area of blade Power spent Provide 8 blades of 0.5 x 0.5 m = 2m2 Provide 4 numbers of length 1.5 m and proj ecting 0.2 m from the wall. 4. Provide inlet and outlet pipes of 250 mm diameter. Detention Time Speed of Impeller 30 sec. 120 rpm 2.6m I Summary 11. 2. 3. I Height of Tank (0.23 m free board) PowerRequired Numberof Blade(0.5mx 0.5m) Number of baffles (length 1.5 m) Diameter of inlet and outlet 4. 5. 5.47 t<JN 8 4 250 I 16. 7. 38 - ---

Design Of Clariflocculator Clariflocculator The coagulation and sedimentation pr ocesses are effectively incorporated in a single unit in the clariflocculator. S ometimes clarifier and clariflocculator are designed as separate units. All these units consists of 2 or 4 flocculating paddles placed equidistantly. Th ese paddles rotate on their vertical axis. The flocculating paddles may be of ro tor-stator type. Rotating in opposite direction above the vertical axis. The cla rification unit outside the flocculation compartment is served by inwardly rakin g rotating blades. The water mixed with chemical is fed in the flocculator compa rtment fitted with paddles rotating at low speeds thus forming floes. The flocculated water passes out from the bottom of the flocculation tank to the clarifying zone through a wide opening. The area of the opening being large eno ugh to maintain a very low velocity. Under quiescent conditions, in the annular setting zone the floc embedding the suspended particles settle to the bottom and the clear effluent overflows into the peripheral launder. (b) Design Criteria: (Flocculator) = 3 to 4.5 m = 30 to 60 min. = 0.2 to 0.8 m/sec. = 10 to 25 % of cis of tank Depth of tank Detention time Velocity of flow Total area of paddles Range of peripheral velocities of blades = 0.2 to 0.6 m/s Velocity gradient (G) Dimension less factor Gt Power consumption Outlet velocity 39 = 10 to 75 = 104to 105 = 10 to 36 KW/mld = 0.15 to 0.25 m/sec.

-- Design Criteria: (Clarifier) Surface overflow rate Depth of water Weir loading S torage of sludge Floor slope Slope for sludge hopper Scraper velocity =40 m3/m2/day = 3 to 4.5 m =300 m3/m2/day = 25 % = 1 in 12 or 8% for mechanically cleaned tank. = 1.2:1 (v:h) = 1 revolution in 45 to 80 minutes Velocity of water at outlet chamber = not more than 40 m/sec. (c) Assumptions =2% = 566.82 m3/hr = 30 min. = 30 S-1 Average outflow from clariflocculator Water lost in desludging Design average pe riod Detention period Average value of velocity wadient Design Of Influent Pipe Assuming V = 1 m/sec. Dia = 0.447 m Provide an influent pipes of 450 diameter. Design Of Flocculator : wall Volume o f flocculator = 566.82 x 30 160 = 283.41 m3 Providing a water depth Plan area of flocculator = 3.5 m = 283.41/3.5 = 80.97 m2 D = diameter of flocculator = 10.16m Dp = diameter of inlet pipes = 0.45 m D Provides a tank diameter =10.2m of 10.2 m 40

Dimension Of Paddles: = G2X !l v x vol = 302x 0.89 x 10-3X (1tf4x 10.22x 3.5) = 229.08 Power input Cd P = % (Cd x P x Ap X (V-U)3 = 1.8 = 995 kg/m3(25c) V = Velocity of tip of blade = 0.4 m/sec. v = Velocity of water tip of blade = 0 .25 x 0.4 = 0.1 m/sec. 229.08 .. Ap = % x 1.8 x 995 x Ap x (0.4-0.1)3 = 9.47 m2 Ratio of paddles to cis of flocculator [9.47/ P (10.2 - 0.75) 3.5] x 100 Provide Ap Ap = [10.5ht (10.2-0.75) 3.5] x 100 Which is acceptable (within 10 to 25 %) Provide 5 no of paddles of 3 m height and 0.7 m width One shaft will support 5 p addles The paddles will rotate at an rpm of 4 V 0.4 r r = 2 x x x r x x/60 = 2 x x x r x 4/60 = 0.96m == 1m = distance of paddle from C1. Of vertical shaft = 9.11 % <10 to 25 % = 10.5 m2 = 10.1% ok Let velocity of water below the partition wall between the flocculator and clari fier be 0.3 m/sec. Area = 555.48/0.3 x 60 x 60 = 0.51m2 Depth below partition wall = 0.51/x x 10.2 = 0.016m Provide 25% for storage of s ludge = 0.25 x 35 = 0.875m 41

----Provide 8% slope for bottom Total depth of tank at partition wall = 0.3 + 3.5 + 0.016 + 0.875 = 4.69m ==4.7m Design Of Clarifier Assuming a surface overflow rate of 40m3/m2/day Surface of clariflocculator = 555.48 x 24/40 = 333.29m2 Oct= Dia. of Clariflocculator P/4 [Oct2 - (10.2)2] Oct = 333.29 = 22.99m ==23m = 1t X Oct Length of weir = 1tx 23 Weir loading = 72.26m = 555.48 x 24/72.26 = 184.49m3/day/m According to manual of Govt. of India. If it is a well clarifier. It can exceed upto 1500m3/day/m. Summary (Clariflocculator) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Detention Period Diameter of influent pipes Overall depth of flocculator Diamet er of tank No. of paddles (3 m height and 0.7 m width) Distance of shaft from C. L. of flocculator Paddles rotation (RPM) 30min 450mm 3.5m 10.2m 5 1m 4 Distance of paddle from C.L. of vertical shaft 1m Slope of bottom (%) Total dept h of partition wall Diameter of clariflocculator 8 4.7m 23m

CL"'~IF'e~ DR.lvE M~Ctf"NI~"': II'4AL I<... ~'f T .:--z-R.\...'2.<:\.. !;.1 f MT ~iAT\(:)NAR'f t'oI\O"\llNG FLoCC.VCATOR D I<.lIt--\ ) CLA RI f:LOCCULAOR T .-.

6.2.5 (a) Design Of Rapid Gravity Filter Rapid Sand Filter The rapid sand filter comprises of a bed of sand serving as a single medium gran ular matrix supported on gravel overlying an under drainage system, the distinct ive features of rapiq sand filtration as compared to slow sand filtration includ e careful pre-treatment of raw water to effective flocculate the colloidal parti cles, use of higher filtration rates and coarser but more uniform filter media t o utilize greater depths of filter media to trap influent solids without excessi ve head loss and back washing of filter bed by reversing the flow direction to c lear the entire depth of river. . . The removal of particles within a deep granular medium filter such as rapid sand filter, occurs primarily within the filter bed and is referred to as depth filt ration. Conceptually the removal of particles takes place in two distinct slips as transport and as attachment step. In the first step the impurity particles mu st be brought from the bulkof the liquid within the pores close to the surface o f the medium of the previously deposited solids on the medium. Once the particle s come closer to the surface an attachment step is required to retain it on the surface instead of letting it flow down the filter. The transport step may be accomplished by straining gravity, setting, impaction interception, hydrodynamics and diffusion and it may be aided by flocculation in the interstices of the filter. (a) Design Criteria: (Rapid Sand Filter) Rate of filtration Max surface area of one bed = 5 to 7.5m3/m2/hr = 100m2 . . Min. overall depth of filter unit including a free board of 0.5m = 2.6m Effectiv e size of sand = 0.45 to 0.7 Uniformityco-efficientfor sand 43 = 1.3 to 1.7

. . . . . . Ignition loss should not exceed 0.7 percent by weight Silica content should not be less than 90% Specific gravity Minimum number of units Depth of sand = 2.55 to 2.65 =2 = 0.6 to 0.75 Wearing loss is not greater than 3% . . (b) Standing depth of water over the filter = 1 to 2m Free board is not less than 0. 5m Problem Statement = 555.48m3/hr =2% = 30min. = 5m3/m2/hr = 1.25 to 1.33:1 = cent ral manifold with laterals. = 13mm Net filtered water Quantity of backwash water used Time lost during backwash Des ign rate of filtration Length - width ratio Under drainage system Size of perfor ations (c) Design Calculation Solution: required flow of water Design flow for filter Plan area for filter = 555.48m3/hr = 555.48 x (1 + 0.02) x 24/23.5 = 578.65m3/hr = 578.65/5 = 115.73m2 ==116 Using 2 units, Plan area Length x width L = 58m2 = L x 1.25L = 58 =6.8m Provide 2 filter units, each with a dimension 8.6m x 6.8m. 44

Estimation Of Sand Depth : It is checked against breakthrough of floc. Using Hud son Formula: Q x d x h/L = 8 x 293223 11 Where, Q, d, hand 1 are in m3/m2/hr,mm, m and m, respectively. Assume, 8 = 4 X 10-4(poor response) < average degree of pre-treatment h = 2.5m (terminal head loss) Q = 5 x 2m3/m2/hr(assuming 100% over load of filter) d = 0.6mm(meandia.) 10 x (0.6)3 x 2.5/1 = 4 x 10-4x 293223 L>46m provide depth of sand bed = 60cm Estimation Of Gravel And Size Gradation: Assum ing size gradation of 2 mm at to 40 mm at bottom using empirical formula : P Whe re, R = 2.54 R (log d) = 12 (10 to 14) The units of Land dare cm and mm, respectively. Size Depth(cm) Increment 2 9.2 9 .2 5 21.3 12.1 10 30.5 9.2 20 40 9.5 40 49 9 Provide 50 cm depth of gravel. Design Of Under Drainage System : Plan area of each filter = 8.6 x 6.8 = 58.48m2 Total area of perforation = 3 x 10-3 x 58.48 = 0.17544m2 = 1754.4cm2 45 J

-Total cross section area of laterals = 3 x area of perforation = 3 x 1754.4 = 5263.2cm2 Area of central manifold = 2 x area of lateral = 2 x 5263.2 = 10526.4cm2 Diameter of central manifold = ..J10526.4 x 4hc = 115.76cm Providing a commercially available diameter of 100 cm. Assuming spacing for late rals Number of laterals = 43 on either side = 20cm = 8.6 x 100/20 D = ..J61.2 X 4ht = 8.83cm == 90mm Number of perforations /Iaterals = 86 units Length of one lateral = % width of filter % dia. of manifold = %x6.8-%x = 2.90 m 1 Let n be total no. of perforation of 13mm dia. .. Total area of perforation = n x 1t/4 x (1.3)2 = 1754.4 .. n = 1321.76 == 1322 No. of perforation /Iateral = 1322/86 = 15.37 ==16 Spacing of perforations = 2.90 x 100/1.6 = 181.25cm clc Provide 16 perforations of 13 mm diameter at 180 cm clc.

46

Computation of wash water Troughs: Wash water rate Wash water discharge for one filter = 36m3/m2/hr = 36 x 58.48 = 2105.28m3/hr = 0.5848m3/sec. Assuming a spaci ng of 1.8 m for wash water trough which will run parallel to the longer dimensio n of the filter unit. No. of trough = 6.8/1.8 =3.78=:4 discharge per unit trough = 0.5848/4 = 0.1462m3/sec. For a width of 0.4 m the water depth at upper end is given by Q = 1.376 b h312 0.1462 h Freeboard = 1.376 x 0.4(h)312 = 0.41 = 0.1m Provide 4 troughs of 0.4 m wide x 0.5 deep in each filter. Total Depth Of Filter Box: Depth of filter box = depth of under drain + gravel + sand + water depth + free board = 900 + 500 + 600 + 2200 + 300 = 4500mm Design Of Filter Air Wash : Assume rate at which air is supplied Duration of air wash = 1.5m3/m2/min. =3min. Total quantity of air required per unit bed = 1.5 x 3 x 8.6 x 6.8 = 263. 16m3 47

HE"Ab L.o~S \N[)\C.ATbA. ~ I I : . I i I I I : I . " I, I' . "- - - . I I I , - 1 . , . . -. , I I I I, _ _ J _,_ _ _ '-._ _ _ .. ~ _ . ... I I I I I ~ I I I t I I I I I I "..: I I I ' I I I::; .I . I ' , ~._ i ,- - - I,.,- - . . , - - , .'-,- - - -'. . ' , , . . I I

1 - - -' - - '. : , I I I, I I 'I. 'I I I T ,.12.~,MT I' t., I' : .. 1 Ic:t 17 -- - - - '"""""' ---

(d) 1. 2. 3. 4. 5. 6. 7. 8. 9. Summary Number of units Size of unit Depth of sand bed Depth of gravel Diameter of perfo ration Diameter of central manifold Spacing for laterals Number of laterals Diam eter of laterals 2 8.6 x 6.8m 60cm SOcm 13mm 100cm 20cm 86 90mm 16 4 0.4 x 0.5m 4500mm 3min. 263. 16m;:! 10. Number of perforations 11. Number of troughs 12. Size of trough 13. Total de pth of filter box 14. Duration of air wash 15. Total quantity of air required pe r unit bed 6.2.6 (a) Disinfection Chlorination Unit Treatment method such as aeration, plain sedimentation, coagulation, sedimentati on, filtration, would render the water chemically and aesthetically acceptable with some reduction in the pathogenic bacterial content . However, the foregoing treatment methods do not ensure 100% removal of pathoge nic bacteria, and hence it becomes necessary to 'disinfect' the water to kill th e pathogenic bacteria. Disinfection should not only remove the existing bacteria from water but also en sure their immediate killing even afterwards, in the distribution system. The ch emical which is used as a disinfectant must, therefore be able to give the "resi dual sterilising effect" for a long period, thus affording some protection again st recontamination. In addition to this, it should be 48

cI. CHLORINE GAS L.IQUID C1.1 c. YLINCEPTO CI~TRI~IJTION MAIN ~ ~ o 1 tJ $\-IUT oP'f: YALVE VALliE ~ o I-( WEIGHING .sCALE ..J SC.HeCK ~ Pl1~p .. OVER r:/..f:)/N To t:>AA/fIJ STRoNG CJ.,). SOLUTION I TflEAT EJ> WATeR 70 13 LINE FEED DIAGRAM OF A. 'YPICAl CHLORINA70R .5oLUTION INSTALJ..ATloN I I I I I

harmless, unobjectionable to taste, ecomomical and measurable by simple tests. ' Chlorine' satisfies the above said more than any other disinfectant and hence is widely used. (b) Design Criteria (chlorination) Chlorine dose . = 1.4mg/L (rainy season) = 1mg/L (winter season) = 0.6mg/L (summer season) (c) Residual chlorine Contact period = 0.1 to 0.2 mg/L (minimum) = 20 to 30min. Design Caculations Rate of chlorine required, to disinfect water be 2 p.p.m. Chlorine required. Per day = 13.33 x 106x 1.4 x 10-6 = 18.662kg For 6 months = 18.662 x 180 = 3359.16k g Number of cylinder (one cylinder contain 16 kg) = 3359.16 x 2/16 = 419.895 Num ber of cylinders used per day (d) 1 2 Summary Chlorine required per day Number o f cylinder required per day 18.662kg 2 of 16kg =2 cylinders of 16kg 6.3 General Storaae Tank Distribution reservoirs also called service reservoirs are the storage "eservoir s which store the treated water for supplying the same during emergencies and al so help in absorbing the hourly fluctuations in water demand. Depending upon the ir elevation with respect to the ground they 49

are classified as under ground reservoir and elevated reservoir both of these re servoirs designed for this project. Storage Capacity Ideally the total storage capacity of a distribution reservoir is the summation of (i) balancing reserve (ii) breakdown reserve and (iii) fire reserve. The balancing storage capacity of a reservoir can be worked out from th e data of hourly consumption of water for the town/city by either the mass curve method or analytical method. In absence of availability of the data of hourly d emand of \AJaterhe capacity of reservoir is usually 114 1/3 t to of the daily av erage supply. Underground Storage Reservoir (U.S.R.) : (a) General The reservoir is used for storing the filtered water which is now fit for drinki ng. From this, the water is pumped to E.S.R. normally the capacity of this type of reservoir depends upon the capacity of the pumps and hours of pumping during a day. If the pumps work for 24 minutes then the capacity of this reservoir may be between 30 minutes to 1 hour. (b) Design Criteria (U.S.R.) (i) (ii) Detention time Freeboard = 1 to 4hr = 0.4 to 0 .6m (c) Design Calculations Assuming that all pumps are working for.hours Capacity of underground reservoir = 6hr capacity of average demand = Qavg. x detentiontime = 18 MLD x 4 x 106x 10-3/24 = 4500 m3 50 .........

-. Assuming 6 compartments Let depth = 4m = Area Area of each compartment Dimension Free board 1125 m2 = 190 m2 = 14 m x 14 m = 0.5m Provide 6 compartments of 14 m x 14 m x 4.5 m (d) 1. 2. 3. 4. 5. Summary Capacit y of reservoir Total depth Compartments Size Detention time 4500 m;1 4.5m 6 14 m x 14 m x 4.5 m 4 hr Elevated Service Reservoir (ESR) : (a) General Where the areas to be supplied with treated water are at higher elevations than the treatment plant site, the pressure requirements of the distribution system n ecessitates the construction of ESR. The treated water from the underground rese rvoirs is pumped to the ESR and than supplied to the consumers. (b) Design Calcu lations = 450 m3 Free board Overall depth Diameter Assumingcapacityof ESR= 1/10 of underground storage =0.3m =4m = "450 x 4 In X4 d = 11.96m .. Provide 1 ESR of overall height = 4.3m and Diameter = 11.96m 51

.. (b) 1. 2. 3. Summary Number of tanks Depth of tank Diameter of tank 1 4.3m 11.96m 52

_0_4.3 f_ I' ., I.. h--d~~.:!=-~:?< :1'lC - fL.oWI PIPe PIPe --j. M,. I r 1/"'fT .. .:" "..I I.. OUT LeT PIPE ]!t.-'YA-LIIE .. . .. .. . COLUMN BERMS -.I' . . ,..... I -I.- I ...;.; ~I i'" 5 c:ccion

.=lUe (iF CONCLUSION The designed project deals with the design of a conventional water treatment pla nt having a perennial river as the source. The design has been done for a predic ated population of 61400 expected after 30 (2001 to 2031) years. Although this p roject and its data is totally hypothetical, this exercise will help us when we may come across some such design in future. The above treatment of the water makes it possible to safe guard the health of t he people. 53

rJfr REFERENCES 1. 2. 3. A.G.Bhole. "Low cost package water treatment plant for rural areas"l.E. (I) Journal - EN 19 95. Birdie J.S. "Water supply and sanitary engineering", Pub.: Dhanpat Rai & Sons, New Delhi, 19 94. Fair G.M. "Water and waste water engineering" (vol.1&2) john Wiley & sons, inc. New York, 1967. 4. 5. 6. Garg S.K. Govt. of India. "Water supply engineering" Khanna pub., New Delhi, 1994. "Manual on Water Supply & Treatment", Ministry of works & housing, New Delhi, 1984. l'Water Clarificati on process: Practical Design Hudson H.E. Jr. & Evaluation" Van Norstrand Reinhold Co., New York, 1981. 7. Steel E.W. & Mcggee T.J. 8. TwartA.C. l'Water S upply & Sewerage" McGraw Hill Ltd., New York, 1981. l'Water Supply" Arnold Inter national Student Edition (AISE), Great Britain, 1985. 54

p r

------ - :: - -,~~-,~---

.;.-...... . .. l- .=-- r" ~-~ -~~ -'~ _JW:~~T'" - ~ ~ ~~ ~- ~---- .... 'II ----

..

You might also like

- Presentation On: Sewage Treatment PlantDocument8 pagesPresentation On: Sewage Treatment PlantLeo VictorNo ratings yet

- Tank SizingDocument2 pagesTank Sizingaike_5No ratings yet

- Water Treatment I Kurang KomplitDocument89 pagesWater Treatment I Kurang KomplitEndarAdeCandraNo ratings yet

- Shortcut Nitrogen Removal-Nitrite Shunt and DeammonificationFrom EverandShortcut Nitrogen Removal-Nitrite Shunt and DeammonificationNo ratings yet

- Yanbu WWTW Process Group PresentationDocument52 pagesYanbu WWTW Process Group Presentationyxp2237No ratings yet

- Concept of Zero DischargeDocument4 pagesConcept of Zero DischargeShesharam Chouhan67% (3)

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentFrom EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNo ratings yet

- Chapter 1 Basic Design ConsiderationDocument38 pagesChapter 1 Basic Design ConsiderationAce ThunderNo ratings yet

- Low Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterFrom EverandLow Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterNo ratings yet

- MM Aqua Technologies LTD.: TubedekDocument47 pagesMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- Rapid Sand Filter and Tube SettlersDocument16 pagesRapid Sand Filter and Tube Settlersnp27031990No ratings yet

- Aeration Tank and Clarifier DesignDocument6 pagesAeration Tank and Clarifier DesignRajesh NareNo ratings yet

- Chlorination Equipment & AccessoriesDocument57 pagesChlorination Equipment & AccessoriesmailmaverickNo ratings yet

- Water Supply EngineeringDocument2 pagesWater Supply EngineeringAnil Marsani50% (2)

- 250mld WTPDocument6 pages250mld WTPeepmcjayal2No ratings yet

- CEB707 - 5 - Water Treatment Plant DesignDocument18 pagesCEB707 - 5 - Water Treatment Plant Designalex100% (2)

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Document57 pagesToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891No ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationKalyca Nazhifa SalwaNo ratings yet

- SBRDocument44 pagesSBRNavneet Singh67% (3)

- SBR Sewage Treatment Plant Clear WaterDocument12 pagesSBR Sewage Treatment Plant Clear WaterAndreea CalcanNo ratings yet

- Cálculos Osmosis InversaDocument26 pagesCálculos Osmosis InversabetzabeNo ratings yet

- Slow Sand Filtration Dwfsom40 PDFDocument4 pagesSlow Sand Filtration Dwfsom40 PDFjose03No ratings yet

- Grit ChambersDocument28 pagesGrit ChambersmkkNo ratings yet

- Inclined Plate Clarifier (Parallel Plate Clarifier, Lamella Clarifier) Basic Theory of OperationDocument2 pagesInclined Plate Clarifier (Parallel Plate Clarifier, Lamella Clarifier) Basic Theory of OperationThanneeru Naga Raju100% (1)

- Sequencing Batch Reactor Technology For Biological Wastewater Treatment: A ReviewDocument9 pagesSequencing Batch Reactor Technology For Biological Wastewater Treatment: A ReviewDiliptiwariNo ratings yet

- Lesson Plan: How Do We Clean Polluted Water?Document15 pagesLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNo ratings yet

- Multimedia FiltrationDocument2 pagesMultimedia FiltrationRavNo ratings yet

- Topic 6 - Water TreatmentDocument57 pagesTopic 6 - Water TreatmentYousef ZamNo ratings yet

- Interim Report 150 MLDDocument112 pagesInterim Report 150 MLDMaqsood Ibn Shaikhul ArfeenNo ratings yet

- ClarifierDocument1 pageClarifiergroup2sd1314No ratings yet

- List of SymbolsDocument11 pagesList of SymbolsKaarthic EmayNo ratings yet

- DesalinationDocument14 pagesDesalinationmarishankar1990No ratings yet

- Coagulation and Ultrafiltration in Seawa PDFDocument227 pagesCoagulation and Ultrafiltration in Seawa PDFGigih PramonoNo ratings yet

- Activated Sludge Calcs With ExcelDocument22 pagesActivated Sludge Calcs With ExcelsahatNo ratings yet

- Activated Sludge SystemDocument50 pagesActivated Sludge SystemRind Bergh Develos0% (1)

- 432 ProjectDocument19 pages432 ProjectSahil PalNo ratings yet

- Sedimentation Tank DesignDocument23 pagesSedimentation Tank Designyash_btech100% (1)

- WATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9b - FlocculationDocument37 pagesWATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9b - Flocculationmamat88100% (2)

- Tube Settler Systems For ClarificationDocument7 pagesTube Settler Systems For Clarificationtrdakshayani100% (1)

- Inclined Plate ClarifierDocument2 pagesInclined Plate ClarifierKelvin SiewNo ratings yet

- Clarifier Recirculation2Document23 pagesClarifier Recirculation2PavithiranNo ratings yet

- STP Presentation - SBRDocument51 pagesSTP Presentation - SBRNoriel LunaNo ratings yet

- Clariflocculator TypesDocument7 pagesClariflocculator TypesdexterNo ratings yet

- Cost Analysis of Activated Sludge ProcessDocument19 pagesCost Analysis of Activated Sludge ProcessDevendra Sharma100% (1)

- Grit ChamberDocument3 pagesGrit Chambergaur_shashikant4432No ratings yet

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (1)

- Water Treatment PlantDocument5 pagesWater Treatment PlantbinukirubaNo ratings yet

- LamellaDocument5 pagesLamellaKhoa Nguyen DangNo ratings yet

- Design of Secondary ClarifierDocument7 pagesDesign of Secondary Clarifierusmansherdin100% (1)

- Rapid Sand FiltrationDocument16 pagesRapid Sand FiltrationNurul ShafinazNo ratings yet

- Effluent Treatment Plant - Process Flow DiagramDocument45 pagesEffluent Treatment Plant - Process Flow DiagramAmarnath PNo ratings yet

- Wastewater Treatment Plant Construction (Package E)Document270 pagesWastewater Treatment Plant Construction (Package E)Glen GuxhoNo ratings yet

- EE-2 Mini Project ReportDocument7 pagesEE-2 Mini Project Report63GANESH SINGHCIVILNo ratings yet

- Equipment Design - Aeration TankDocument6 pagesEquipment Design - Aeration TankKENGERALDNo ratings yet

- Complete Water Treatment Plant ProjectDocument79 pagesComplete Water Treatment Plant ProjectRAHUL MAHAJAN100% (1)

- WorkDocument43 pagesWorkAkash GundaleNo ratings yet

- Waste Water Facilities Plan UpdateDocument14 pagesWaste Water Facilities Plan Updatejobya_4No ratings yet

- Revised Material Balance of Waste Water Treatment PlantDocument28 pagesRevised Material Balance of Waste Water Treatment Plantjobya_4100% (1)

- Reverse Osmosis Membrane Design CalculatorDocument2 pagesReverse Osmosis Membrane Design Calculatorjobya_4No ratings yet

- GargDocument81 pagesGargjobya_4No ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)