Professional Documents

Culture Documents

Solidification Son Dagıt (28.04.2013)

Uploaded by

Utku Orçun GeziciOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solidification Son Dagıt (28.04.2013)

Uploaded by

Utku Orçun GeziciCopyright:

Available Formats

1

Mid-term exam -1 : %20

Mid-term exam -2 : %20

Final exam : %60

%100

SOLIDIFICATION

Prof. Dr. . Aydn ATASOY

Department of Metallurgical and

Materials Engineering

Technical University of stanbul

2

141p

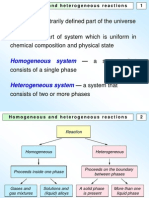

THERMODYNAMIC EQUILIBRIUM

The Sum of a) mechanical, b) chemical and c) thermal equilibrium

Net forces on the ball are zero

(Constant pressure)

A ball at the bottom

of the valley -

minimum

potential energy

position

Mechanical equilibrium

Si Ge

T ~ 1000 C

Chemical Equilibrium

C

Si

C

Ge

t = 0

t =

x

x

t =

t = 0

Potential energy for a given

atom in the system is the same

everywhere and will remain

fixed in time. (Constant

chemical composition)

Thermal equilibrium

+

=

Hotter (T )

Colder (T )

1

2

Isothermal (T)

T > T > T

1 2

Temperature is

the same

everywhere

in the system

(Constant temperature)

t = 0

t =

0

0

0 < t <<

0 << t <

0 << t <

0 < t <<

Complete dissolution

3

141r

GIBBS FREE ENERGY

For reactions at constant temperature and pressure

the relative stability of a system is determined by its Gibbs free energy:

H : enthalpy (heat content) of the system

T : absolute temperature (Kelvin)

E : internal energy of the system (kinetic energy from atomic vibrations +

potential energy from bonds between the atoms)

p : pressure

v : volume

S : entropy (measure of the randomness of the system; degree of disorder)

T S : mixing energy

p v : For condensed systems (i.e. solids and liquids) p v is relatively small

T = constant

p = constant

S T H G =

v p E H + =

S T E G ~ E H~

Liquid - Solid Phase Transformation 141-0

Liquid Solid For T = T , G = G

T

L s

,

G

T

G G

L

Temperature

G = G G

L s

A

G = E T AS A

= 0

A

T< T For

AG =

AE AT

T

Undercooling

AT= (T T) > 0

AE < 0 AG < 0

Solidification Nucleation + Growth

v

v

v v

m

m

m

v

m

AS =

AE

T

m

v

v

v v

v

s m

T

AT

AT = T T

T

T

Solid grains

Time

T

e

m

p

e

r

a

t

u

r

e

0

141-1

Cooling Curve and Nucleation

m n

m

n

Liquid

Liquid + First nuclei

n

4

141b

r

A Spherical solid particle called embryo forms homogeneously

from the liquid

Liquid atoms

Embryo/liquid interfacial

area :

A= 4t r

2

Volume of a spherical

embryo of radius r :

3

4t r

3

V=

DEFINITION OF THE VOLUME FREE ENERGY CHANGE

Solid (s)

Liquid()

: volume of liquid phase : volume of solid phase

Free energy of the system : Free energy of the system:

Total free energy change of the system after the solidification of a solid phase

Volume free

energy change =

free energy change

per unit volume

: free energy per unit

volume of liquid phase

: free energy per unit

volume of solid phase

141aa

: Solid-liquid interfacial area

: Solid-liquid interfacial free energy

Liquid ()

G

v

G

s

v

) v v (

s

v

s

o + + =

s s

s

v s v s 2

A G v G v v G ) (

G v A G v G ) v v ( G G G

v s s

s

v s v s 1 2

o + + = = A

A

s

o

s

G G G

v

s

v v

= A

o + A = o + =

s s v s s s v

s

v s

A G v A ) G G ( v

) v (

G v G

v 1

=

T

n

1 2

Homogeneous NUCLEATION in Liquids 141

Liquid Solid For T =T AG = AE T AS

v

= 0

r* = critical size For T< T AG =(AE AT

n

) / T

undercooling

AG

AG

r*

r (radius of particle)

(4/3)t rAG

V

4t ro

s

surface

free energy

change

volume free energy change

Total free energy change

a < r < r* embryo

r > r* stable nucleus (cAG

T

/ cr) = 0

0

For r = r*

T

m

m

m

*

m v

v v

v

T T T

n m n

= A

: Latent heat of solidification 0 L E

m v

< ~ A

(AG

T

)

o t + A t = A

s

2

v

3

T

r 4 G r ) 3 / 4 ( G

T E

T 2

r

n v

m s *

A A

o

=

T E 3

) T 16 (

G

2

n

2

v

2

m

3

s

*

A A

o t

=

A

a

0

5

141 aaa

of radius r*

Stable embryo( nucleus)

of radius (r* + A r)

1 atom

from the liquid

]

[

] [

+

AG < 0

T

Unstable embryo

+

[ ]

141a

The number of critical nuclei per unit volume of liquid , n*,

at any temperature is given by

n* = N exp(

AG*

k T

)

N : the number of atoms per unit volume of liquid

(The number of sites available for nuclei formation in the liquid)

L

L

Two-dimensional representation of an

instantaneous picture of the liquid

structure. Many close-packed

crystal-like embryos(coloured) are

present

B

6

141e

Homogeneous Nucleation Rate in Liquids

N

=

N v

L

exp(

A

AG*

k T

G

D

k T

) exp( )

N

L

: Number of available nucleation sites ( here; each atom)

in the unit volume of the liquid.(The number of atoms per

unit volume of the liquid.)

v : Thermal vibration frequency of the atoms in the liquid

AG

D

: Activation free energy for the diffusion of atoms in the

liquid

The addition of one more atom to each of the critical-sized embryos

will convert them into stable nuclei :

hom.

hom.

B B

0 K

T

m

n*

N

n*

N

T

T

4 3

2

1

T

T

T

AT

T : For small undercoolings AG* is large

but the rate of diffusion is rapid

and hence number of critical nuclei (n*)

is small. (Large grains)

1

T

3

:

For large undercoolings A G* is small

but the rate of diffusion is very slow

and hence the nucleation rate is again

low.

T

4

: At intermediate undercoolings, diffusion

rate is fairly rapid and AG* is not too large

and there is a maximum in the nucleation

rate. (Small grains)

T :

2

For very large undercoolings,

the diffusion rate and A G* are

extremely small and hence no embryo

can reach the crystal unit cell size (r*< a )

(Amorphous solid)

141d

0

7

8

100 m

Hyper-eutectic Al-wt%15Si alloy

Primary dendrites of oAl

Primary dendrites of Si

Fine eutectic

microstructure

grows on

primary

dendrites of o Al

9

10

11

HETEROGENEOUS NUCLEATION IN LIQUIDS

Nucleation rather occurs heterogeneously on the walls of the container or foreign particles (substrate)

acting as a site for nucleation in the melt during solidification. In commercial practice heterogeneous

nucleation is often enhanced by the addition of inoculants ( VC , TiC , TiB , AlB , ZrC , NbC , W C

powders ) to the melt in order to refine the final grain size.

2 2 2

u

Liquid

Substrate

Crystal embryo

Liquid

Crystal

embryo

o

o

LC

LS

A

CS

A

LC

h

Substrate r

o

CS

u

The shape of the crystal

embryo is a spherical cap

Volume =

t

3

r ( 2 3 Cos u + Cos u )

3 3

A = 2 t r (1 Cos u)

LC

2

A = t r (1 Cos )

CS

2 2

u

u : wetting angle

Interfacial tensions balance in the plane of the substrate:

LS

o = o + o Cos u

CS

LC

Cos u =

o

LC

LS

o

CS

o

141 i

Heterogeneous nucleation in liquids ...

141j

If o < o

CS

LS

, then the crystal embryo precipitates on

the substrate, because the average surface

energy of the crystal embryo decreases.

AG = 2tr (1 Cos u)

2

T

o

LC

o

t

3

r (2 3 Cos u + Cos u) AG +

3

3

v

t r (1 Cos u)(

2

2

o

CS

o )

LS

For

c(AG )

T

cr

= 0

r* =

2o

LC

AG

v

het.

AG* =

het.

4t

3

LC

( 2 3Cosu + Cos u)

3

3AG

v

2

AG* < AG*

het. hom.

(o

CS

o ) < 0

LS

12

141m

= N v exp( ) exp( )

Heterogeneous Nucleation Rate in Liquids

het.

s

D

D

AG*

k T

AG

k T

N : Number of sites available for heterogeneous nuclei

formation per unit volume of the liquid

s

v : Thermal vibration frequency of the atoms in the liquid

AG : Activation free energy for the diffusion of atoms in the

liquid

N

het.

B

B

u

u

u =0

r~

(excellent wetting)

AG* = 0

0<u<180

(partial wetting)

AG* < AG*

het. hom.

u = 180

(no wetting)

AG* = AG*

het.

hom.

141k

0

N

A T

het.

hom.

13

T

Water

V

Water Water

M

e

t

a

l

l

i

c

s

u

b

s

t

r

a

t

e

(

c

h

i

l

l

)

a

b

H

e

a

t

e

r

C

o

o

l

e

r

H

e

a

t

i

n

s

u

l

a

t

o

r

z

T

I

T

E

V

T A

0 (t) V > = f

T

q

Liquid

Liquid

0

0

T

ss

T

fs

W

a

t

e

r

G

~

G

C C

E 1

=

) t ( T

I

f =

0

0 (t)

T

G

q

> =

(

(

c

c

~

0 . onst C G

z

T

G

0 z

q

> = =

(

(

c

c

~

=

0 C > = ~ . onst V V

pot

. Const T

I

=

V

pot

V

con

T

ft

T

ct

) t ( V f =

Liquid

cru.

V

cru

Basic Techniques of Directional Solidification

Bridgman technique Directional casting technique

: System coordinates

: Coordinate system moving with the solid-liquid interface y x

V : Rate of interface movement

T

q : Temperature imposed by the temperature gradient (G) arising from

the heat flow occurring in the casting.

14

15

b

T T

k k

A < A

- -

T T

k k

A >> A

-

5nm

2 ) T k ( /

I B

= 10 ) T k ( /

I B

~ 12 ) T k /( L

I B f

=

16

141

At equilibrium the free energy reaches an absolute minimum

and the entropy reaches the maximumvalue that the system can exhibit.

Free energy change for the reaction:

T= constant

G

l

E

G

s

E

S S

AG = G G =

s l

AE = E E =

AS = S S =

All spontaneous reactions occur when the system can lower its free energy

l s

Free energy change

Activation energy

Entropy change

In an isolated system:

For condensed systems (i.e. solids and liquids) Av is relatively small

H H AH = H H

=

Entalpy change

E v p E H A ~ A + A = A

l

l

l

s

s

s

s

s

s

l

l

l

0 S T E S T H

G G

G

s

< A A ~ A A = = A

l

141t

REACTION RATE (How fast does a reaction occur?)

1 2 3

An atom is vibrating about the position 1

To lower the free energy the atom

must move into position 3 (free energy

change : AG)

But it must first overcome the energy

barrier which is called as

activation free energy barrier

Activation free energy to overcome the energy barrier can be supplied to

the atom as thermal energy in the form of atomic vibrations.

G

a

A

G

a

A

Arrangement of atoms

a

2

3

Stable

solid

Unstable

G

s

G

l

G

*

G

i

b

b

s

f

r

e

e

e

n

e

r

g

y

1

0 )

G G

(

G

*

a

> =

A

l

AT > 0

0

G G

G

s

< = A

l

T T

I

=

AG

Meta-

stable

Liquid Solid

G

0

17

141u

Statistical Thermodynamics

Probability that atom has sufficient thermal energy to overcome

the barrier of AG :

R = molar gas constant = 8.314 J/(mol K) = 1.98 cal/(mol K)

k = Boltzmanns constant =

N = number of Avogadro

A

Here, the particle is an atom!

Joule 10 6 . 1 eV 1

18

=

) K particle /( J 10 38 . 1 N / R

23

A

=

) K particle /( cal 10 3 . 3

24

=

mol / particles 10 02 . 6

23

=

|

|

.

|

\

|

=

A

T k

I B

G

a

exp P

a

141

v : vibration frequency of an atomin a system (number of

attempts per unit time to overcome the energy barrier;

typically

The rate at which the atoms overcome the barrier (number of

successful jumps per unit time):

s 10

1 13

|

|

.

|

\

|

A

v =

T k

r

I B

a

) hkl ( ) s (

G

exp

f

l

|

|

.

|

\

|

A +

A

v =

T k

r

I B

a

) hkl ( ) (s

G

G

exp

f

l

v

v v

= ~

s

f

) hkl (

: Crystallographic factor; the ratio of the number of

growth sites occupied by the liquid atoms to the number

of sites available in the solid at interface.

18

(

(

|

|

.

|

\

|

A

|

|

.

|

\

|

A

v = =

T k T k

r r

I B I B

a

) hkl ( s

G

exp 1

G

exp a ) ( a V

f

l s l

a

D

T k

G

exp

2

I

I B

a

I

=

|

|

.

|

\

|

A

v =

v

(

(

|

|

.

|

\

|

A

~

(

(

|

|

.

|

\

|

A

=

T k T k

I B

D

I B

I

) hkl (

G

exp 1

V

G

exp 1

a

D

V

f

a

D f

a

D

a

D

V

0

I ) hkl (

0

I I

D

~ ~ =

Continuous growth

19

20

21

22

23

24

1.5

T k N

G

A B s

C

A

f

) hkl (

5 = o

3 = o

2 = o

5 . 1 = o

1 = o

a

0

2

1

0.5

0.5

10 = o

0.2 0 0.4 0.6 0.8 1.0

0

o = 10

o = 5

o = 3

o = 1

b

f

) hkl (

)

T k N

( /

G

A B s C

A

25

26

27

a-4

7

a1

b

c

kiz dzlemleri

219 141

) 0 1 10 (

) 0001 (

{

1

1

1

}

{

1

1

1

}

{

1

1

1

}

<

1

1

2

>

219

141

a2

r 4

c

t r 2

c

r

c

r 19

c

(0001)

c

(0001)

a1

b

c

kiz dzlemleri

219 141

) 0 1 10 (

) 0001 (

{

1

1

1

}

{

1

1

1

}

{

1

1

1

}

<

1

1

2

>

219

141

a2

r 4

c

t r 2

c

r

c

r 19

c

(0001)

1

a-1

b

b

r

C

y

0

V

b-1 b-2

1

2

3

4

5

6

a-2

a-3

.

b

.

b

141

141

219

219

(

1

1

1

)

kiz dzlemleri

B

A

| |A 2 1 1 | |A 1 2 1

| |A 1 1 2

| | B 2 11

(

1

1

1

)

A

(

1

1

1

)

B

B

) 111 (

| | 2 1 1

| | 1 2 1

| | 1 1 2

| | 2 11

| | 1 2 1

| | 11 2

Twin planes

Repeatable growth defects in faceted crystals : Screw dislocation with a spiral ramp,

twinning with re-entrant corner, and twist boundary with steps. Depending upon

the type of defect present, the faceted crystal can exhibit various morphologies:

needles in the case of screw dislocations, or plates in the case of twinnings (Si in Al-Si)

or twist boundaries (graphite in cast iron).

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

You might also like

- Boiling Heat Transfer and Two-Phase Flow PDFDocument441 pagesBoiling Heat Transfer and Two-Phase Flow PDFll_pabilonaNo ratings yet

- ChemistryDocument7 pagesChemistrySankar SasmalNo ratings yet

- Fluid 11Document210 pagesFluid 11Omolafe Olawale SamuelNo ratings yet

- First Law of ThermodynamicsDocument27 pagesFirst Law of ThermodynamicsJanith DushyanthaNo ratings yet

- Models For Nonideal ReactorsDocument41 pagesModels For Nonideal ReactorsStanley SibandaNo ratings yet

- Problem Solving PhysicsDocument6 pagesProblem Solving PhysicsrobertzenbuiserNo ratings yet

- Chapter 2b KineticsDocument11 pagesChapter 2b KineticsSankar SasmalNo ratings yet

- Chemical, Biochemical, and Engineering ThermodynamicsDocument37 pagesChemical, Biochemical, and Engineering Thermodynamicsdeepak pandeyNo ratings yet

- Introduction To Vapor Liquid EquilibriumDocument35 pagesIntroduction To Vapor Liquid Equilibriumshiv007anshNo ratings yet

- Ch20 Young Freedman2Document28 pagesCh20 Young Freedman2Andrew MerrillNo ratings yet

- Applications: Chemical and Phase Equilibria: 5.60 Spring 2008 Lecture #29Document6 pagesApplications: Chemical and Phase Equilibria: 5.60 Spring 2008 Lecture #29sgybleeNo ratings yet

- Heat Transfer Coefficient and Nusselt CorrelationDocument22 pagesHeat Transfer Coefficient and Nusselt CorrelationThulasi Ram100% (1)

- L - 21 External Mass Transfer Effects: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDocument57 pagesL - 21 External Mass Transfer Effects: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyNo ratings yet

- CH 10 Entropy Free EnergyDocument2 pagesCH 10 Entropy Free Energyeongl39No ratings yet

- Metallurgical Physical ChemistryDocument45 pagesMetallurgical Physical ChemistryAlvin Garcia PalancaNo ratings yet

- Process Heat Transfer Chapter 2Document20 pagesProcess Heat Transfer Chapter 2billiam123No ratings yet

- Environmental Systems and Facility PlanningDocument33 pagesEnvironmental Systems and Facility PlanningpeagricultureNo ratings yet

- S S S S S S: EntropyDocument3 pagesS S S S S S: EntropyKyutie JaraNo ratings yet

- ME3122 Handbook of Heat Transfer Equations 2014Document22 pagesME3122 Handbook of Heat Transfer Equations 2014Nian Wee WuNo ratings yet

- Heat Flow Control From Thermal Transistor To Thermal Logic GateDocument36 pagesHeat Flow Control From Thermal Transistor To Thermal Logic GategiridharkumarabNo ratings yet

- Mel242 32Document35 pagesMel242 32Mohammad OmarNo ratings yet

- Heat Exchangers Lecture Chapter SectionsDocument44 pagesHeat Exchangers Lecture Chapter SectionsIqbal Nugroho100% (1)

- ENME 332, Spring 2013 Transfer Processes: Instructors: Reinhard Radermacher & Bao YangDocument18 pagesENME 332, Spring 2013 Transfer Processes: Instructors: Reinhard Radermacher & Bao YangZain BaqarNo ratings yet

- Free Convection: Its Free, No Operating Cost! .. Its Natural .Document34 pagesFree Convection: Its Free, No Operating Cost! .. Its Natural .zeeshanahmad111No ratings yet

- Compressible Flow PDFDocument90 pagesCompressible Flow PDFOmer TokhNo ratings yet

- Fe Chemical EngineeringDocument5 pagesFe Chemical EngineeringJudith LugoNo ratings yet

- Flow in PipesDocument35 pagesFlow in Pipesbernabas100% (1)

- Formulas For Thermo 2 QuizDocument1 pageFormulas For Thermo 2 Quizzvikush1No ratings yet

- Equilibrium in Solution: TPC TPRTC TPRT A TPDocument6 pagesEquilibrium in Solution: TPC TPRTC TPRT A TPsgybleeNo ratings yet

- 2 006 FA13 Eqn Sheet v1Document13 pages2 006 FA13 Eqn Sheet v1MH MerhiNo ratings yet

- ME623-Two Phase Flow (Part-A)Document12 pagesME623-Two Phase Flow (Part-A)jedrajNo ratings yet

- Convection Experiment: Leader: Tom Salerno Partners: Greg Rothsching Stephen Johnson Jen DiroccoDocument19 pagesConvection Experiment: Leader: Tom Salerno Partners: Greg Rothsching Stephen Johnson Jen DirocconazhakimNo ratings yet

- Formula Sheet HTDocument8 pagesFormula Sheet HTChristopher FernandesNo ratings yet

- Gas DynamicsDocument17 pagesGas DynamicsAmrMashhourNo ratings yet

- Heat Transfer BookletDocument10 pagesHeat Transfer Bookletdhilee100% (1)

- Chemistry 1st Yr 5th LectureDocument43 pagesChemistry 1st Yr 5th LectureNurul Nadia SaffariNo ratings yet

- Ph2200 Formula Sheet KnightDocument2 pagesPh2200 Formula Sheet Knightsubhash123abcNo ratings yet

- Reactor Design Sample ExamDocument7 pagesReactor Design Sample ExamAugustine BrockNo ratings yet

- Basic Equations - Heat Diff-2Document21 pagesBasic Equations - Heat Diff-2Qasim AliNo ratings yet

- Heat Engine CyclesDocument21 pagesHeat Engine CyclesMagdy RiadNo ratings yet

- CBE3508 Sp21 FinalDocument6 pagesCBE3508 Sp21 Finalsasuke uchihaNo ratings yet

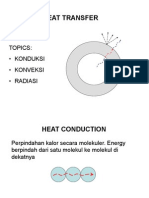

- Heat Transfer: Topics: - Konduksi - Konveksi - RadiasiDocument20 pagesHeat Transfer: Topics: - Konduksi - Konveksi - RadiasiHandita SutoyoNo ratings yet

- Electrochemirstry ConceptsDocument48 pagesElectrochemirstry ConceptsgyirgaNo ratings yet

- EntropyDocument54 pagesEntropyvarshabachchas1302No ratings yet

- Summary Sheets Complete Version F2013Document58 pagesSummary Sheets Complete Version F2013Minjae LeeNo ratings yet

- DM M M DT: KG Where, KDocument3 pagesDM M M DT: KG Where, KhamadabashaaNo ratings yet

- Week 2. Chemical Kinetics Analysis of Rate EquationDocument31 pagesWeek 2. Chemical Kinetics Analysis of Rate EquationYuni ApriyaniNo ratings yet

- Lecture 2Document21 pagesLecture 2Ahmed SajjadNo ratings yet

- Statistical ThermodynamicsDocument22 pagesStatistical ThermodynamicshanyassawyNo ratings yet

- Introduction To Fluid DynamicsDocument76 pagesIntroduction To Fluid DynamicsRajrdbNo ratings yet

- I. First-Order Circuits Overview: 1. RC Natural ResponseDocument6 pagesI. First-Order Circuits Overview: 1. RC Natural ResponsechauNo ratings yet

- Control Lec 2Document9 pagesControl Lec 2mamnd tahaNo ratings yet

- Convection Heat Transfer: Reading ProblemsDocument16 pagesConvection Heat Transfer: Reading ProblemspcelumalaiNo ratings yet

- Flow in Circular Pipes: ObjectiveDocument35 pagesFlow in Circular Pipes: ObjectivemamunruetNo ratings yet

- Chapter 8. Internal Flow (Bounded, Forced)Document31 pagesChapter 8. Internal Flow (Bounded, Forced)wadec24No ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- Random Fourier Series with Applications to Harmonic Analysis. (AM-101), Volume 101From EverandRandom Fourier Series with Applications to Harmonic Analysis. (AM-101), Volume 101No ratings yet

- HORIZON Ebook SMCs Awareness StageDocument13 pagesHORIZON Ebook SMCs Awareness StageUtku Orçun GeziciNo ratings yet

- Class Notes Fall 2021: ME:5160 Intermediate Mechanics of FluidsDocument35 pagesClass Notes Fall 2021: ME:5160 Intermediate Mechanics of FluidsUtku Orçun GeziciNo ratings yet

- Theano Lasagne Keras-MarceloDocument27 pagesTheano Lasagne Keras-MarceloUtku Orçun GeziciNo ratings yet

- Chap 3Document63 pagesChap 3snupisnupNo ratings yet

- Ionic Liquid Energy MaterialsDocument50 pagesIonic Liquid Energy MaterialsUtku Orçun GeziciNo ratings yet

- TanakaDocument14 pagesTanakaUtku Orçun GeziciNo ratings yet

- Underground Bodyopus Militant WeightLoss RecompositionDocument142 pagesUnderground Bodyopus Militant WeightLoss RecompositionDaniel Kocmiel100% (2)

- Nanohydr Final Exam 18 - 19Document1 pageNanohydr Final Exam 18 - 19Utku Orçun GeziciNo ratings yet

- 03Document6 pages03Utku Orçun GeziciNo ratings yet

- Proceedings PDFDocument879 pagesProceedings PDFUtku Orçun GeziciNo ratings yet

- Deformati̇on Behavi̇our of Polymeri̇c MaterialsDocument27 pagesDeformati̇on Behavi̇our of Polymeri̇c MaterialsUtku Orçun GeziciNo ratings yet

- Powder MetallurgyDocument17 pagesPowder MetallurgyMuktesh SinghNo ratings yet

- ch3 AshbylecturesDocument21 pagesch3 AshbylecturesUtku Orçun GeziciNo ratings yet

- Interpreting Phase DiagramsDocument131 pagesInterpreting Phase Diagramsweltwind100% (2)

- Class 02 IDocument12 pagesClass 02 IUtku Orçun GeziciNo ratings yet

- System of UnitsDocument15 pagesSystem of UnitsUtku Orçun GeziciNo ratings yet

- The Islam Question - Should I Become A Muslim?Document189 pagesThe Islam Question - Should I Become A Muslim?Aorounga100% (1)

- Infanrix Hexa RSMKL July 2023Document37 pagesInfanrix Hexa RSMKL July 2023Bayu KurniawanNo ratings yet

- GII-07 Training MaterialDocument191 pagesGII-07 Training MaterialIris Amati MartinsNo ratings yet

- SEO-optimized title for practice test documentDocument4 pagesSEO-optimized title for practice test documentThu GiangNo ratings yet

- Kurukshetra English August '17Document60 pagesKurukshetra English August '17amit2688No ratings yet

- The Republic of LOMAR Sovereignty and International LawDocument13 pagesThe Republic of LOMAR Sovereignty and International LawRoyalHouseofRA UruguayNo ratings yet

- Adjustment DisordersDocument2 pagesAdjustment DisordersIsabel CastilloNo ratings yet

- 50 Cool Stories 3000 Hot Words (Master Vocabulary in 50 Days) For GRE Mba Sat Banking SSC DefDocument263 pages50 Cool Stories 3000 Hot Words (Master Vocabulary in 50 Days) For GRE Mba Sat Banking SSC DefaravindNo ratings yet

- Think Like An EconomistDocument34 pagesThink Like An EconomistDiv-yuh BothraNo ratings yet

- Richard CuretonDocument24 pagesRichard CuretonHayk HambardzumyanNo ratings yet

- GSM ZTE Paging Feature GuideDocument17 pagesGSM ZTE Paging Feature Guidemikepadilla82100% (1)

- Ad844 PDFDocument20 pagesAd844 PDFkavi_mishra92No ratings yet

- Japanese Tea Cups LessonDocument3 pagesJapanese Tea Cups Lessonapi-525048974No ratings yet

- Comparative Ethnographies: State and Its MarginsDocument31 pagesComparative Ethnographies: State and Its MarginsJuan ManuelNo ratings yet

- Supplier Development at Honda, Nissan and ToyotaDocument28 pagesSupplier Development at Honda, Nissan and Toyotapresidonsi100% (1)

- (Cambridge Series in Statistical and Probabilistic Mathematics) Gerhard Tutz, Ludwig-Maximilians-Universität Munchen - Regression For Categorical Data-Cambridge University Press (2012)Document574 pages(Cambridge Series in Statistical and Probabilistic Mathematics) Gerhard Tutz, Ludwig-Maximilians-Universität Munchen - Regression For Categorical Data-Cambridge University Press (2012)shu100% (2)

- Perkin Elmer Singapore Distribution CaseDocument3 pagesPerkin Elmer Singapore Distribution CaseJackie Canlas100% (1)

- Code of Conduct GuidanceDocument17 pagesCode of Conduct GuidanceMuhammad RidwanNo ratings yet

- Testing Your Understanding: The Dash, Slash, Ellipses & BracketsDocument2 pagesTesting Your Understanding: The Dash, Slash, Ellipses & BracketsBatsaikhan DashdondogNo ratings yet

- Discrete Mathematics - Logical EquivalenceDocument9 pagesDiscrete Mathematics - Logical EquivalenceEisha IslamNo ratings yet

- People vs. Abad SantosDocument2 pagesPeople vs. Abad SantosTrixie PeraltaNo ratings yet

- 2018 World Traumatic Dental Injury Prevalence and IncidenceDocument16 pages2018 World Traumatic Dental Injury Prevalence and IncidencebaridinoNo ratings yet

- Pin Block Formats Explained in DetailDocument3 pagesPin Block Formats Explained in DetailJinay SanganiNo ratings yet

- MF 04Document21 pagesMF 04Carlos De la CruzNo ratings yet

- Speed of Sound and its Relationship with TemperatureDocument2 pagesSpeed of Sound and its Relationship with TemperatureBENNY CALLONo ratings yet

- Apostles CreedDocument141 pagesApostles Creedjerome mecca0% (2)

- Carb-Based-Dll No. 2 - 4th Qtr.Document5 pagesCarb-Based-Dll No. 2 - 4th Qtr.Kathrene Santos RiveraNo ratings yet

- Goan Bread Tradition Questions AnsweredDocument2 pagesGoan Bread Tradition Questions AnsweredPreeti SharmaNo ratings yet

- 17 Lagrange's TheoremDocument6 pages17 Lagrange's TheoremRomeo Jay PragachaNo ratings yet

- St. Louis ChemicalDocument8 pagesSt. Louis ChemicalNaomi Alberg-BlijdNo ratings yet