Professional Documents

Culture Documents

NAFEMS Auto Unified CAE Analysis For A Leaf Spring Type

Uploaded by

Indranil BhattacharyyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NAFEMS Auto Unified CAE Analysis For A Leaf Spring Type

Uploaded by

Indranil BhattacharyyaCopyright:

Available Formats

A UNIFIED CAE ANALYSIS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

A UNIFIED CAE ANALYSIS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Youngwon Hahn Engineering Specialist, Dassault Systmes Simulia Corp, USA THEME Multi-body simulation KEYWORDS Vehicle suspension, leaf spring, kinematics, compliance, vibration, durability, unified CAE SUMMARY A vehicle suspension is an important subassembly connecting the vehicle body with the tires. It requires high performance and durability since the road force from the tires is transmitted through it to the vehicle body and passengers. Commonly, CAE analyses for the suspension, such as kinematic, vibration, and durability analyses, are performed separately due to the lack of a unified analysis tool. Specifically, it is difficult to analyze the dynamic behavior of a leaf spring type suspension with flexible panels because of nonlinear effects such as those due to contact, residual stress caused by the U-bolt assembly, and rigid body motion caused by the shackle. This flexible dynamic behavior makes it difficult to perform a unified analysis for the handling, vibration, and durability of the suspension. In this study, a unified CAE analysis for a leaf spring type suspension vehicle is performed using Abaqus. The analysis sequence includes a kinematic and compliance analysis to identify the suspension characteristics, a modal and frequency response analysis to determine the vibration behavior, and four post-load simulator analyses to examine the durability response. Two models which have a flexible leaf spring suspension are considered; one has a rigid frame and the other has a flexible frame. The models are obtained from the archive of the National Crash Analysis Center. Both models use a rigid upper body for convenience. In order to easily create the models, a plug-in for Abaqus/CAE was developed. With this plug-in, each analysis model can be generated using pre-existing finite element models of the suspension components. The resulting Abaqus model allows the user to consider the unloaded shape of the leaf spring and to position the leaf spring after the U-bolt assembly. Various vehicle positions can also be considered by changing the mass of the vehicle.

A UNIFIED CAE ANALYSIS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

1: Introduction CAE (Computer Aided Engineering) is one of the powerful design tools available today given its ability to handle many complex engineering problems in the automotive industry. However, CAE analyses, such as kinematic, vibration, and durability analyses, are performed separately due to the lack of a unified CAE analysis tool. Since this increases time and cost, automotive product developers would benefit from a unified CAE procedure [1]: one model for different analyses. In particular, it is difficult to find a unified CAE tool for a vehicle suspension system due to its complexity. A vehicle suspension is an important subassembly in an automotive vehicle. Since the road load is transferred to the vehicle body through the suspension, the suspension should be well designed with respect to handling, NVH, and durability. There are many different types of suspension. The Macpherson type or Double Wishbone type of suspension is commonly used for passenger vehicles. This type of suspension can be modeled as rigid links in a CAE analysis. However, a leaf spring type suspension (Hotchkiss type suspension), which is used for trucks or heavy duty vehicles, requires that the flexibility of the leaf spring panels be considered in the CAE analysis. As shown in Figure 1, the leaf spring suspension consists of leaf spring panels, the axle, and other components, such as bolts. The spring stiffness is based on the bending and contact behaviors of leaf spring panels. In order to capture the physical behavior of the leaf spring suspension, a flexible body should be modeled in the CAE analysis. In this paper, a unified CAE analysis using Abaqus is proposed for leaf spring type suspension vehicles in order to check various vehicle performances, such as handling, NVH, and durability.

Figure 1:

Leaf spring type suspension.

A UNIFIED CAE ANALYSIS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

2: Leaf Spring Type Suspension Model A leaf spring type suspension consists of leaf spring panels, a center bolt, a Ubolt, an axle, and a bushing. Multiple leaf spring panels are constrained by the center bolt and the U-bolt. The U-bolt assembly process introduces preloading stress and makes it difficult for the user to simulate leaf spring type suspensions. The preloading effect from the center bolt is assumed small in comparison with the effect from the U-bolt [2]. In order to easily build the complex leaf spring suspension system, an Abaqus/CAE plug-in is used. The plug-in requires the presence of pre-existing finite element component models such as for the U-bolt, leaf spring panels, and axle. Once the user specifies the coordinates of the joint, the connecting area information in the flexible component, and other suspension properties, the leaf spring type suspension model is automatically generated in Abaqus/CAE. Figure 2 shows a screenshot of the plug-in and finite element component models.

Figure 2:

Screenshot of the plug-in (Left) and finite element component models (Right).

In this paper, the Silverado model, which can be downloaded from the National Crash Analysis Center, is used for the leaf spring type suspension vehicle. Two models which have a flexible leaf spring suspension are considered as shown in Figure 3; one has a rigid frame and the other has a flexible frame. The joint and bushing are modeled as connector elements in the Abaqus model. The tire and upper body are defined as rigid for convenience. A contact interaction is also defined between the leaf spring panels in order to prevent their interpenetration. A rebound clip is defined as a coupling. Four posts are generated in order to apply the load at the bottom of the wheel. Between the wheel and the plate, slide-plane type connector element is used.

A UNIFIED CAE ANALYSIS ANALYS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Figure 3:

Rigid body frame model (Left) and flexible body frame model (Right).

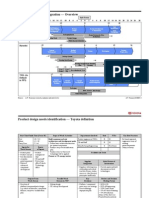

3: Analysis Procedure After building the leaf spring suspension vehicle, the following analysis procedure is required prior to the kinematics and compliance, NVH, and durability analyses: 1. U-bolt bolt assembly procedure The role of the U-bolt is to constrain the leaf spring panels by applying a bolt load. It can be modeled by applying a pre-section section force on the section surface of the U-bolt U in the Abaqus model. . In this procedure, the bushing center points at the ends of the leaf spring panels are fixed and the bolt assembly load is applied to the U U-bolts. bolts. The mass center of the upper body is also fixed. 2. Positioning procedure After the U-bolt bolt assembly load is applied, the constraints at the bushing center points at the end of the leaf spring panel should be released in order to locate the wheel in the equilibrium position. The vehicle position can be adjusted by moving the wheel upward or downward. The mass center of the upper body is also fixed. 3. Gravity procedure After positioning the wheel, the gravity force is applied to the model after removing the boundary condition on the upper body. This procedure is not required in the kinematics and compliance analysis. Figure 4 shows the Von Mises stress contours from the U-bolt bolt loading analys analysis.

A UNIFIED CAE ANALYSIS ANALYS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Figure 4:

The Von Mises stress result from U-bolt bolt assembly loading analysis analysis.

After completing the above procedures, the following loads and boundary conditions are applied: Kinematics and compliance The center of gravity in the upper body is fixed and the plate at the bottom of the wheel is moved upward and downward. Only a double-bump test, in which the right and left wheels are simultaneously moved in the same direction, is performed in this study [3]. Vibration The frequency response analysis is performed after the gravity loading is applied. A unit load is applied at the right wheel in the front suspension and the left wheel in the rear suspension. The mode-based based steady-state steady dynamic analysis procedure available in Abaqus is used. Durability A random displacement is applied to the plate at the bottom of the wheel after the gravity loading is applied. The implicit dynamic analysis procedure proced available in Abaqus is used in this study. For the vibration and durability analyses, analys additional springs are added between the wheel and the plate in order to prevent free sliding of the wheel on the plate surface. If the wheel model is replaced with a flexible FE tire model and contact is defined between the flexible tire and the plate, the additional spring springs are not needed. The results from each analysis are discussed next.

A UNIFIED CAE ANALYSIS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Kinematics and Compliance For the double-bump test, the suspension characteristics can be extracted. Figure 5 shows the toe, camber and vertical force change versus vertical displacement of the wheel for the rigid frame model. For the rear toe result, hysteretic behavior is observed due to the contact interaction. However, it is not significant since the toe value is small.

Figure 5:

Toe at double-bump mode (Left: Front, Right: Rear).

Vibration After a frequency extraction step using the AMS eigensolver, a modebased steady state dynamic analysis is performed. As shown in Figure 6, the wind-up mode can be observed at around 43 Hz in the rigid frame model. The flexible frame model shows the wind-up mode at

A UNIFIED CAE ANALYSIS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

approximately 47 Hz, as shown in Figure 7. The flexible frame effects can also be observed in the wind-up mode in Figure 7.

Figure 6:

Vibration result from rigid frame model.

Figure 7:

Vibration result from flexible frame model.

Durability For the durability analysis, random displacement history is generated with MATLAB and applied to the plate attached to the post at the bottom of the wheel. The stresses on the leaf spring panel can be observed in the rigid body model, as shown in Figure 8 (Top). In the flexible frame model, a small local area of high stress is also observed at the front suspension as shown in Figures 8 (Bottom) and 9 (Top (black arrow)).

A UNIFIED CAE ANALYSIS ANALYS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Figure 10 shows the time history of the Von Mises stress around a point in the high stress area (indicated as point A in Figure 9 (Bottom)).

Figure 8: Stress contour contours at time = 0.53 sec in the rigid (Top) and flexible (Bottom (Bottom) frame models.

A UNIFIED CAE ANALYSIS ANALYS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Figure 9: Stress contour contours at the front (Top) and rear (Bottom) suspension in the flexible frame model.

A UNIFIED CAE ANALYSIS ANALYS FOR A LEAF SPRING TYPE SUSPENSION VEHICLE

Figure 10: Stress history tory at point A on the 3rd leaf spring panel (point A indicated in Figure 9).

4: Conclusions A unified CAE analysis is performed for a leaf spring type suspension vehicle using Abaqus. With ith one model, three different analyses (kinematics and compliance, frequency, , and durability) durability are performed in order to evaluate the vehicle performance. The toe suspension parameter, the wind-up up mode, and the high stress area/stress time history can be obtained for each analysis. analysis In this paper, a rigid tire model is used for convenience. The author expects that more reliable results can be obtained if a flexible tire model is used. 5: Acknowledgments The author would like to express his gratitude to the NHTSA for use of the Silverado finite element model and also a thank Pierre Burgers and Fernando Carranza of SIMULIA for their kind advice. REFERENCES 1. El Khaldi, F., Ni, R., Culiere, Culiere P., Ullrich, P., and Terres Aboitiz, C., 2010, Recent Integration Achievements in Virtual Prototyping for the Automobile Industry, FISITA, May 31. 2. Qin, P., Dentel, G., and Mesh, M., 2002, Multi-Leaf Spring and Hotchkiss Suspension CAE Simulation, Abaqus Users Conference 3. Hahn, Y., 2010, Kinematics and Compliance (K&C) Simulation Simulation Using a Nonlinear Finite Element Model, Model SAE 2010-01-0951 4. Abaqus 6.10 Analysis Users Manual, Dassault Systmes, 2010.

You might also like

- Modal and Stress Analysis of Lower Wishbone Arm Along With TopologyDocument7 pagesModal and Stress Analysis of Lower Wishbone Arm Along With TopologyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Fatigue Strength Analysis On The Automobile Stabilizer BarDocument5 pagesFatigue Strength Analysis On The Automobile Stabilizer BarSantiago UrgilesNo ratings yet

- Fatigue Analysis of An Automotive Stabilizer BarDocument4 pagesFatigue Analysis of An Automotive Stabilizer BarAbhay KhotNo ratings yet

- A Literature Review On Collapsible Steering ColumnDocument9 pagesA Literature Review On Collapsible Steering ColumnIJIRSTNo ratings yet

- Chassis Mulitleaf Auc02 ChryslerDocument14 pagesChassis Mulitleaf Auc02 ChryslerIndranil BhattacharyyaNo ratings yet

- Research Article: Explicit Nonlinear Finite Element Geometric Analysis of Parabolic Leaf Springs Under Various LoadsDocument12 pagesResearch Article: Explicit Nonlinear Finite Element Geometric Analysis of Parabolic Leaf Springs Under Various LoadsraajaahNo ratings yet

- Presented By:: Dr. Mukulesh DebnathDocument28 pagesPresented By:: Dr. Mukulesh DebnathSACHIN100% (2)

- A Review On Independent Suspension System of Light Commercial VehicleDocument6 pagesA Review On Independent Suspension System of Light Commercial VehicleKiru CherryNo ratings yet

- Vehicle Chassis-Suspension Dynamics Analysis PDFDocument5 pagesVehicle Chassis-Suspension Dynamics Analysis PDFSuhash MediboinaNo ratings yet

- Solidworks Simulation ProjectDocument51 pagesSolidworks Simulation ProjectAlper KutluyuvaNo ratings yet

- Rnl-A-10 Rollover of Bus SML IsuzuDocument13 pagesRnl-A-10 Rollover of Bus SML IsuzuNavas AzeezNo ratings yet

- Research On Axle HousingsDocument7 pagesResearch On Axle HousingsTushar ChughNo ratings yet

- Automobile Suspension Detailed Analysis PDFDocument19 pagesAutomobile Suspension Detailed Analysis PDFalpNo ratings yet

- Auto Full Vehicle NVH Analysis With Rolling Tires 11Document4 pagesAuto Full Vehicle NVH Analysis With Rolling Tires 11Dmitry GrenishenNo ratings yet

- Design UprightDocument5 pagesDesign UprightJohn HopkinsNo ratings yet

- Design and Analysis of Front Axle of Heavy Commercial Vehicle 4 GNR PDFDocument34 pagesDesign and Analysis of Front Axle of Heavy Commercial Vehicle 4 GNR PDFKoyyada Kranthikumar100% (1)

- Abstracts Ks TechnologiesDocument20 pagesAbstracts Ks TechnologiessosaseNo ratings yet

- Abstract-B Tech LevelDocument11 pagesAbstract-B Tech LevelDhanish KumarNo ratings yet

- Impact Driver SimulationDocument15 pagesImpact Driver SimulationSNN77No ratings yet

- Tow HookDocument8 pagesTow HookAmulya ManthaNo ratings yet

- Structural Analysis of Double-Wishbone Suspension SystemDocument7 pagesStructural Analysis of Double-Wishbone Suspension SystemIJRASETPublicationsNo ratings yet

- METU ME 465 (Automotive) - ch5Document73 pagesMETU ME 465 (Automotive) - ch5Tt OwnsqqNo ratings yet

- Vivek Adap SuspDocument21 pagesVivek Adap SuspMohammed Asif NNo ratings yet

- 12 Things To Know About Lifted' Suspension EngineeringDocument7 pages12 Things To Know About Lifted' Suspension EngineeringPeter SchmidtNo ratings yet

- Cheri An 2009Document24 pagesCheri An 2009Shriyash KamatNo ratings yet

- Implementation of Pacejka's AnalyticalDocument42 pagesImplementation of Pacejka's AnalyticalRenan AlvesNo ratings yet

- Integrated Landing Gear System PDFDocument14 pagesIntegrated Landing Gear System PDFMario Di PisaNo ratings yet

- Abaqus Technology BrifDocument6 pagesAbaqus Technology BrifFARZADFGNo ratings yet

- A Comparative Study of The SuspensionDocument7 pagesA Comparative Study of The SuspensionSivadanusNo ratings yet

- Experimental and Finite Element Stress Analysis of Three Wheeler Front FenderDocument7 pagesExperimental and Finite Element Stress Analysis of Three Wheeler Front FenderNithin SunnyNo ratings yet

- Design, Analysis and Manufacturing A Double Wishbone Suspension System With Variable Camber Angle by Pneumatics MechanismDocument8 pagesDesign, Analysis and Manufacturing A Double Wishbone Suspension System With Variable Camber Angle by Pneumatics MechanismTristan GrossNo ratings yet

- PW 200 Dy 2Document9 pagesPW 200 Dy 2marten_zitNo ratings yet

- DimensionnementDocument10 pagesDimensionnementSliim AmiriNo ratings yet

- Methods To Determine Torsional Stiffness in A Semi-Trailer Chassis FrameDocument9 pagesMethods To Determine Torsional Stiffness in A Semi-Trailer Chassis Frameognen88No ratings yet

- Dynamic Load and Stress Analyis of CrankshaftDocument8 pagesDynamic Load and Stress Analyis of Crankshaftsathya_rangaNo ratings yet

- Suspension FEA AnalysisDocument153 pagesSuspension FEA AnalysishellomyfriendsNo ratings yet

- Random Vibration Analysis For The Chassis Frame of Hydraulic Truck Based On AnsysDocument4 pagesRandom Vibration Analysis For The Chassis Frame of Hydraulic Truck Based On Ansysbilal sarfrazNo ratings yet

- Notes Unit 4 AEN 22656 AY 2023-24Document18 pagesNotes Unit 4 AEN 22656 AY 2023-24yashwaghmare674No ratings yet

- Suspension AnalysisDocument11 pagesSuspension Analysisanmol6237No ratings yet

- Kinematic and Dynamic Analysis of Independent Suspension SystemDocument9 pagesKinematic and Dynamic Analysis of Independent Suspension Systemsiddhartha180987100% (3)

- 1 Final Technical Report Mini BajaDocument14 pages1 Final Technical Report Mini BajaLucasNo ratings yet

- Ijfatigue S 07 00263Document40 pagesIjfatigue S 07 00263ekremNo ratings yet

- Adams Car AnalysisDocument146 pagesAdams Car AnalysisAnderson MoribeNo ratings yet

- Stress Distribution Analysis of Rear Axle Housing by Using Finite Elements AnalysisDocument10 pagesStress Distribution Analysis of Rear Axle Housing by Using Finite Elements AnalysisrubantoNo ratings yet

- ES140205 - Sujit Parmeshwar Narwade 72-80Document9 pagesES140205 - Sujit Parmeshwar Narwade 72-80Kubilay AçıkgözNo ratings yet

- Shaft Alignment Guide - E-Jan05Document21 pagesShaft Alignment Guide - E-Jan05Brian FreemanNo ratings yet

- Topological Optimization of Steering Knuckle by Using Additive Manufacturing ProcessDocument6 pagesTopological Optimization of Steering Knuckle by Using Additive Manufacturing ProcessdhruvNo ratings yet

- DESIGN AND ANALYSIS OF AL 7075 Steering Knuckle PDFDocument7 pagesDESIGN AND ANALYSIS OF AL 7075 Steering Knuckle PDFsanjeev105No ratings yet

- Design and Optimization of Hub and Knuckle For Formula SAE CarDocument5 pagesDesign and Optimization of Hub and Knuckle For Formula SAE CarTalles OliveiraNo ratings yet

- Rollover Analysis of Bus Using Body SectionDocument5 pagesRollover Analysis of Bus Using Body SectionPrathamesh PatikNo ratings yet

- New Automotive Suspension SystemsDocument30 pagesNew Automotive Suspension SystemsAbubaker MuzayinNo ratings yet

- Double Wishbone SuspensionDocument2 pagesDouble Wishbone SuspensionAkash MahajanNo ratings yet

- Synthesis and Analysis of The Five-Link Rear Suspension System Used in AutomobilesDocument18 pagesSynthesis and Analysis of The Five-Link Rear Suspension System Used in AutomobilesManish RajNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Vehicle Handling Dynamics: Theory and ApplicationFrom EverandVehicle Handling Dynamics: Theory and ApplicationRating: 5 out of 5 stars5/5 (2)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Planar Linkage Synthesis: A modern CAD based approachFrom EverandPlanar Linkage Synthesis: A modern CAD based approachNo ratings yet

- Tribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingFrom EverandTribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingRating: 1.5 out of 5 stars1.5/5 (2)

- Kinematic Analysis of Roll Motion For A StrutSLA Suspension SystemDocument5 pagesKinematic Analysis of Roll Motion For A StrutSLA Suspension SystemIndranil BhattacharyyaNo ratings yet

- Experiences Tuning An Augmented Power Unit Sound System For Both Interior and Exterior of An Electric CarDocument7 pagesExperiences Tuning An Augmented Power Unit Sound System For Both Interior and Exterior of An Electric CarIndranil BhattacharyyaNo ratings yet

- American Cars 1960-1972Document944 pagesAmerican Cars 1960-1972Caroline Bahna100% (9)

- Leaf Spring DesignDocument210 pagesLeaf Spring DesignIndranil BhattacharyyaNo ratings yet

- American Cars 1960-1972Document944 pagesAmerican Cars 1960-1972Caroline Bahna100% (9)

- Torque PendulumDocument5 pagesTorque PendulumAhmed AlaminNo ratings yet

- 0022 460x (64) 90082Document9 pages0022 460x (64) 90082Indranil BhattacharyyaNo ratings yet

- Engineering Design Handbook - Automotive SeriesDocument264 pagesEngineering Design Handbook - Automotive SeriesIndranil Bhattacharyya100% (2)

- Multi Link SimulationDocument11 pagesMulti Link SimulationIndranil BhattacharyyaNo ratings yet

- 15-Suspension Systems and Components v2Document42 pages15-Suspension Systems and Components v2Ismail AmlaNo ratings yet

- Vehicle Design and IntegrationDocument17 pagesVehicle Design and Integrationmail_sambhu0% (1)

- 211CH1257Document99 pages211CH1257Indranil BhattacharyyaNo ratings yet

- Vehicle Development ProcessDocument22 pagesVehicle Development ProcessIndranil BhattacharyyaNo ratings yet

- MotionView 11.0 TutorialsDocument371 pagesMotionView 11.0 TutorialsIndranil BhattacharyyaNo ratings yet

- 24SIGHT Case StudyDocument8 pages24SIGHT Case StudyIndranil Bhattacharyya100% (1)

- Dynamic Analysis of A Multi-Link Suspension Mechanism With Compliant JointsDocument6 pagesDynamic Analysis of A Multi-Link Suspension Mechanism With Compliant JointsDhrubajyoti DasNo ratings yet

- Dynamic Analysis of A Multi-Link Suspension Mechanism With Compliant JointsDocument6 pagesDynamic Analysis of A Multi-Link Suspension Mechanism With Compliant JointsDhrubajyoti DasNo ratings yet

- VHe New Hyundai-Kia 1,0 L Three-Cylinder Gasoline EngineDocument8 pagesVHe New Hyundai-Kia 1,0 L Three-Cylinder Gasoline EngineIndranil BhattacharyyaNo ratings yet

- Trita Ave - 2013 04Document202 pagesTrita Ave - 2013 04Indranil BhattacharyyaNo ratings yet

- Cabin ThermalDocument7 pagesCabin ThermalIndranil BhattacharyyaNo ratings yet

- Cabin NVHDocument8 pagesCabin NVHIndranil BhattacharyyaNo ratings yet

- CFDDocument95 pagesCFDIndranil BhattacharyyaNo ratings yet

- Fluent Tutorials 1Document912 pagesFluent Tutorials 1cagdasozen100% (1)

- 10 RansDocument47 pages10 RansEmad PouryazdanpanahNo ratings yet

- Master of Technology in Department of Mechanical Engineering byDocument56 pagesMaster of Technology in Department of Mechanical Engineering byIndranil BhattacharyyaNo ratings yet

- SN 05114Document14 pagesSN 05114Indranil BhattacharyyaNo ratings yet

- Fluid ManualDocument0 pagesFluid ManualIndranil BhattacharyyaNo ratings yet

- ANSYS-FLUENT Tutorial: United Arab Emirates University Spring, 2010Document57 pagesANSYS-FLUENT Tutorial: United Arab Emirates University Spring, 2010ramkumar121No ratings yet

- ANSYS-FLUENT Tutorial: United Arab Emirates University Spring, 2010Document57 pagesANSYS-FLUENT Tutorial: United Arab Emirates University Spring, 2010ramkumar121No ratings yet

- Consultancy BrochureDocument8 pagesConsultancy BrochureIndranil BhattacharyyaNo ratings yet

- Thomson BSA Grease BrochureDocument1 pageThomson BSA Grease BrochureElectromateNo ratings yet

- Lab Report 1Document26 pagesLab Report 1ParvinNo ratings yet

- Denver, H., 1985 - Settlement Calculation For Footings On SandDocument8 pagesDenver, H., 1985 - Settlement Calculation For Footings On SandbusyspiderNo ratings yet

- Wear On HOT RoLLING Mill RollsDocument15 pagesWear On HOT RoLLING Mill RollssourajpatelNo ratings yet

- Altitude Correction FactorsDocument6 pagesAltitude Correction Factorscarlos.calderonNo ratings yet

- Edgar Cayce LibraryDocument7 pagesEdgar Cayce LibrarysnemalecNo ratings yet

- Evaluation of LS-DYNA Concrete Material Model 159Document209 pagesEvaluation of LS-DYNA Concrete Material Model 159SudathipTangwongchaiNo ratings yet

- ANSI-SMACNA 2006 HvacDuctStandardsDocument64 pagesANSI-SMACNA 2006 HvacDuctStandardsErica MorrisonNo ratings yet

- Recent Progress Toward A Three-Dimensional Unstructured Navier-Stokes Flow SolverDocument21 pagesRecent Progress Toward A Three-Dimensional Unstructured Navier-Stokes Flow SolverDanielle HaysNo ratings yet

- Solution Manual For Essential University Physics 3rd Edition by Wolfson PDFDocument18 pagesSolution Manual For Essential University Physics 3rd Edition by Wolfson PDFa5496735350% (1)

- EEG BCI For Dual Task Driving DetectionDocument9 pagesEEG BCI For Dual Task Driving DetectionBudi SetyawanNo ratings yet

- An Elastic Second SkinDocument16 pagesAn Elastic Second SkinNop PiromNo ratings yet

- SeasonswebquestDocument2 pagesSeasonswebquestapi-264590160No ratings yet

- Thermodynamics MST 2011Document3 pagesThermodynamics MST 2011greenhoochyNo ratings yet

- O3 Final ReportDocument109 pagesO3 Final ReportFaizan MirNo ratings yet

- Digital Image CoorelationDocument8 pagesDigital Image CoorelationAkmal BhattiNo ratings yet

- Please Make A Note - 2Document5 pagesPlease Make A Note - 2Ishan MahtoNo ratings yet

- Soln1 PsDocument6 pagesSoln1 PsRafran Rosly100% (1)

- DESIGNDocument9 pagesDESIGNRowena Remorosa GalayNo ratings yet

- General Relativity Solutions To Exercises by Sergei WinitzkiDocument39 pagesGeneral Relativity Solutions To Exercises by Sergei WinitzkiMichael Anthony Mendoza83% (6)

- Oceanic Anoxic Events (O.a.e) Organic Rocks Deposition CretaceousDocument6 pagesOceanic Anoxic Events (O.a.e) Organic Rocks Deposition CretaceousJulian De Bedout OrdoñezNo ratings yet

- LaMotte 3176-01 Chlorine Kit InstructionsDocument4 pagesLaMotte 3176-01 Chlorine Kit InstructionsPromagEnviro.comNo ratings yet

- DIL 805 Quenching Dilatometer BrochureDocument14 pagesDIL 805 Quenching Dilatometer BrochureDeniz ShenNo ratings yet

- The Zeeman EffectDocument11 pagesThe Zeeman EffectAlex TarrNo ratings yet

- 2012, AAG, Tachi - Interactive Freeform Design of TensegrityDocument10 pages2012, AAG, Tachi - Interactive Freeform Design of TensegrityPierre ClrNo ratings yet

- Rose Diagrams Intro PDFDocument3 pagesRose Diagrams Intro PDFMahmood MuftiNo ratings yet

- Estimating The Size of Onion Epidermal Cells From Diffraction PatternsDocument5 pagesEstimating The Size of Onion Epidermal Cells From Diffraction PatternsAlexis Nathán RuedaNo ratings yet

- Algebra 2 Unit 3 StudentDocument68 pagesAlgebra 2 Unit 3 Studentapi-327127977No ratings yet

- Koncagul Predicting UCSDocument15 pagesKoncagul Predicting UCSSajid IqbalNo ratings yet