Professional Documents

Culture Documents

Pump Standards Comparison

Uploaded by

Anish DaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Standards Comparison

Uploaded by

Anish DaniCopyright:

Available Formats

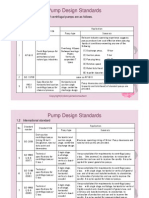

Pump Design Standards

The design standards of centrifugal pumps are as follows. 1.1 International standard

No. Standard number Application Standard title Pump type Summary Relevant industry operating experience suggests pumps produced are cost effective when pumping liquids at conditions exceeding any one of the following: Centrifugal pumps for petroleum, petrochemical and natural gas industries Overhung : 6types Between bearings: 5types Vertically suspended 7 types (1) Discharge press. (2) Suction press. (3) Pumping temp. (4) Rotative speed (5) Rated total head 19 bar 5 bar 150 3600 min-1 120 m

API 610

(6) Impeller diameter, overhung pumps 330 mm 2 ISO 13709 ANSI B 73.1 Specification for horizontal end suction centrifugal pumps for chemical process same as API 610 Horizontal, end suction single stage, centerline discharge design Pump dimensions and approximate performance (capacity and total head) of standard pumps are provided.

Copyright(C)SotoyamaConsultant

Pump Design Standards

1.2

No.

International standard

Standard number Application Standard title End-suction centrifugal pumps (rating 16 bar) Designation, nominal duty point and dimensions Technical specifications for centrifugal pumpsClass I Technical specifications for centrifugal pumpsClass Pump type Horizontal, end suction single stage, centerline discharge design Single stage, multistage, horizontal, vertical, closedcoupled Single stage, multistage, horizontal, vertical, closedcoupled Single stage, multistage, horizontal, vertical, closedcoupled Summary

ISO 2858

Maximum operating rating of 16 bar. Pump dimensions and nominal duty points are provided.

ISO 9905 (JIS B 8307)

It was established for requirements to centrifugal pump class (the severest), to standardize, to rationalize of production and use and to improve the quality. It may be applied for power generation pumps. It was established for requirements to centrifugal pump class with single stage, horizontal or vertical of general use, and all drives and installed methods, to standardize, to rationalize of production and use and to improve the quality. It may be applied for chemical pumps. It was established for requirements to centrifugal pump class with single stage, multistage, horizontal or vertical (rigidly coupled and closed-coupled) of general use, and all drives and installed methods, to standardize, to rationalize of production and use and to improve the quality. It may be applied for commercialized pumps.

ISO 5199 (JIS B 8308)

ISO 9908 (JIS B 8309)

Technical specifications for centrifugal pumpsClass

Copyright(C)SotoyamaConsultant

Pump Design Standards

2.1 JIS standard

No. Standard number Standard title Application Pump type Summary It was established for general use, small centrifugal pumps with single stage and end suction, applied for maximum working pressure 1 MPa and fresh water temperature 0 to 40, and coupled with 50Hz/60Hz and 2P/4P three-phase induction motor through flexible couplig on common baseplate. It was established for general use, small centrifugal pumps with multistage (2-15 stages), applied for maximum working pressure 2.75 MPa and fresh water temperature 0 to 40, and coupled with 50Hz/60Hz and 2P/4P three-phase induction motor through flexible couplig on common baseplate. It was established for general use, centrifugal pumps with single stage and double suction, applied for maximum working pressure 1.4 MPa and fresh water temperature 0 to 40, and coupled with 50Hz/60Hz and 4P/6P/8P three-phase induction motor through flexible couplig on common baseplate.

JIS B 8313

End suction centrifugal pumps

Small size, end suction centrifugal pumps

JIS B 8319

Small size multistage centrifugal pumps

Small size, single suction multistage centrifugal pumps

10

JIS B 8322

Double suction volute pumps

Horizontal, single stage, double suction volute pumps

Copyright(C)SotoyamaConsultant

Pump Design Standards

2.2 JIS standard

No. Standard number Application Standard title Pump type Summary It was established for general use, water ring vacuum pumps with suction bore size 20-50mm, and coupled with 50Hz/60Hz three-phase induction motor through flexible couplig or V-belt on common baseplate. It was established for single suction, centrifugal or mixed flow, submersible motor pumps for deep well with bore size 20-200mm, suspended on well top or under column pipe, applied for water temperature 10 to 25, coupled with 50Hz/60Hz and 2P submersible three-phase induction motor through couplig, and submerged within 100m deep. It was established for single suction, centrifugal, submersible motor pumps for sump, applied for sewage temperature 0 to 45, pH 5-9 and solids less than 20mm, suspended in the storage tank or set on it, coupled with 50Hz/60Hz and 2P/4P submersible three-phase induction motor through common shaft or couplig.

11

JIS B 8323

Water ring vacuum pumps

Water ring vacuum pumps

12

JIS B 8324

Submersible motor pumps for deep well

Single suction, centrifugal or mixed flow, submersible motor pumps for deep well

13

JIS B 8325

Submersible motor pumps for sump

Single suction, single stage, centrifugal, submersible motor pumps for sump

Copyright(C)SotoyamaConsultant

You might also like

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- API Vs Non-API PumpsDocument4 pagesAPI Vs Non-API Pumpssyedahmedmasood100% (3)

- Making Sense of Pump Testing Standards - How Understanding Standards Can Impact The Bottom Line PDFDocument24 pagesMaking Sense of Pump Testing Standards - How Understanding Standards Can Impact The Bottom Line PDF1sympatyagaNo ratings yet

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- Ansi Hi Pumps Standards 2006pdf PDFDocument12 pagesAnsi Hi Pumps Standards 2006pdf PDFAbhi NandanaNo ratings yet

- ANSI-HI Centrifugal PumpsDocument74 pagesANSI-HI Centrifugal Pumpsvicky88100% (5)

- 2858 021975Document4 pages2858 021975jskrippa100% (1)

- API Vs ANSI PumpsDocument6 pagesAPI Vs ANSI PumpsRS100% (2)

- API vs ANSI Pumps: Key Differences Explained in 40 CharactersDocument9 pagesAPI vs ANSI Pumps: Key Differences Explained in 40 CharactersRogerNo ratings yet

- ANSI HI 1 6 2000 M104 HI 1-6 PreDocument9 pagesANSI HI 1 6 2000 M104 HI 1-6 PreyuchiayiNo ratings yet

- Type VS1 and VS6 Vertical Turbine Pumps Wet Pit and Double CasingDocument76 pagesType VS1 and VS6 Vertical Turbine Pumps Wet Pit and Double CasingVgvr Gvlsv100% (2)

- Centrifugal Pumps: Training Program at Petronet LNGDocument30 pagesCentrifugal Pumps: Training Program at Petronet LNGAditya Mahajan100% (1)

- Comparación B73.1 Vs ISO 5199Document2 pagesComparación B73.1 Vs ISO 5199AlvialvarezNo ratings yet

- Spec For Centrifugal Pumps - APIDocument12 pagesSpec For Centrifugal Pumps - APIjowar100% (1)

- Materials of Construction ConstructionDocument6 pagesMaterials of Construction ConstructionIlkuNo ratings yet

- Positive Displacement Rece Pump FundamentalsDocument14 pagesPositive Displacement Rece Pump FundamentalsAnjan BanerjeeNo ratings yet

- HIS 1.4 Centrifugal Pumps Installation OperationDocument66 pagesHIS 1.4 Centrifugal Pumps Installation OperationAyon Bose100% (2)

- ISO 5199 Pump Data SheetDocument2 pagesISO 5199 Pump Data SheetAndry Setiawan100% (2)

- Mag Drive PumpsDocument5 pagesMag Drive PumpsakkineniNo ratings yet

- API Reciprocating Pump TheoryDocument31 pagesAPI Reciprocating Pump TheoryFidezuri Yemen80% (5)

- Asme b73.1 PDFDocument48 pagesAsme b73.1 PDFGerencia Rigar Colombia SAS100% (3)

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- API 685 Vs API 610Document5 pagesAPI 685 Vs API 610sandeep100% (1)

- Centrifugal Pumps Vibration Causes and LimitsDocument5 pagesCentrifugal Pumps Vibration Causes and LimitsTheophilus ThistlerNo ratings yet

- 013-Ansi Vs API PumpsDocument6 pages013-Ansi Vs API Pumpsrtorabi80No ratings yet

- Write Up On PumpsDocument74 pagesWrite Up On PumpsGopal Reddy100% (1)

- HI 1.3 For Design and Application PDFDocument96 pagesHI 1.3 For Design and Application PDFmbgs31100% (2)

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- Ansi Hi 9 6 1Document24 pagesAnsi Hi 9 6 1Maqsood Ibn Shaikhul Arfeen100% (2)

- HIS 1 4 Centrifugal Pumps Installation OperationDocument66 pagesHIS 1 4 Centrifugal Pumps Installation OperationSherif Adel100% (1)

- Vertical Turbine PumpsDocument171 pagesVertical Turbine PumpsAnonymous CMS3dL1T100% (1)

- API 682 GuidelinesDocument28 pagesAPI 682 GuidelinesSergio Solano100% (3)

- Hi 1.6 (2000)Document46 pagesHi 1.6 (2000)mishraengg100% (2)

- HIS For Vertical PumpDocument72 pagesHIS For Vertical PumpVaibhavSharma100% (2)

- Durco Mark 3 ISO: Chemical Process PumpDocument28 pagesDurco Mark 3 ISO: Chemical Process PumpAnonymous CMS3dL1TNo ratings yet

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDocument53 pagesОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- API 610 12th Edition Major ChangesDocument4 pagesAPI 610 12th Edition Major ChangesTyas Utami83% (6)

- BS en Iso 9905-1998+a1-2011Document72 pagesBS en Iso 9905-1998+a1-2011Tasawwur TahirNo ratings yet

- Hermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKDocument16 pagesHermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKADITYA_PATHAKNo ratings yet

- Ansi Hi 9 6 5Document40 pagesAnsi Hi 9 6 5Carlos Esaú López Gómez100% (5)

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- Ansi-Hi 9 6 3-1997 Centrifugal and Vertical PumpsDocument15 pagesAnsi-Hi 9 6 3-1997 Centrifugal and Vertical Pumpssalgora100% (1)

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Pumps definition guideDocument45 pagesPumps definition guideAbdallahNo ratings yet

- Pump Care ManualDocument3 pagesPump Care ManualGerencia Rigar Colombia SASNo ratings yet

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerDocument8 pages02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988No ratings yet

- Bombas de Cavidad ProgresivaDocument8 pagesBombas de Cavidad ProgresivaJohanna RojasNo ratings yet

- 8413Document6 pages8413FGHUIJNo ratings yet

- Indupump Process Pump Brochure SmallDocument16 pagesIndupump Process Pump Brochure SmalljasonventNo ratings yet

- High-End Metering PumpsDocument15 pagesHigh-End Metering PumpsDaniel Saenz GonzalezNo ratings yet

- Vertical Sump Pumps GuideDocument12 pagesVertical Sump Pumps GuideMiguel V. PalNo ratings yet

- Pump JTN B1Document8 pagesPump JTN B1Patricia J ÁngelesNo ratings yet

- FMC Pump Pump Engineering DatabookDocument84 pagesFMC Pump Pump Engineering DatabookAlda England100% (3)

- Rickmeier 34Document12 pagesRickmeier 34carlosNo ratings yet

- Iso Api Ansi Din Npfa BsiDocument1 pageIso Api Ansi Din Npfa BsiGhassan ABO ALINo ratings yet

- Double Pipe HEDocument1 pageDouble Pipe HEAnish DaniNo ratings yet

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- CG 03jun2013Document53 pagesCG 03jun2013Anish Dani100% (1)

- API Vs ANSI PumpsDocument6 pagesAPI Vs ANSI PumpsRS100% (2)

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- Lotus Desaru Beach ResortDocument8 pagesLotus Desaru Beach ResortAnish DaniNo ratings yet

- CG 20may2013Document50 pagesCG 20may2013Anish DaniNo ratings yet

- Pipe Reducer StandardDocument3 pagesPipe Reducer StandardSyifa Alfi HabibiNo ratings yet

- API Vs ANSI PumpsDocument6 pagesAPI Vs ANSI PumpsRS100% (2)

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- Flange and Bolt DimensionsDocument7 pagesFlange and Bolt DimensionsAnish DaniNo ratings yet

- Documentatie Sudura - Wleding NotationsDocument38 pagesDocumentatie Sudura - Wleding NotationsBorborean Andrei TiberiuNo ratings yet

- Stress Analyses of Cylindrical Vessel With Changeable Head GeometryDocument12 pagesStress Analyses of Cylindrical Vessel With Changeable Head GeometryAnish DaniNo ratings yet

- GK MaterialDocument155 pagesGK MaterialswatiemeraldNo ratings yet

- Poker General RulesDocument8 pagesPoker General RulesAnish DaniNo ratings yet

- Public Toilet GuideDocument70 pagesPublic Toilet Guideshrikant100% (1)

- Poker General RulesDocument8 pagesPoker General RulesAnish DaniNo ratings yet

- Gujarati KahevatoDocument155 pagesGujarati KahevatoDinesh Patdia67% (3)

- The Principles of AnimationDocument18 pagesThe Principles of AnimationAnish DaniNo ratings yet

- Digital Photography GuidebookDocument58 pagesDigital Photography GuidebookAnish Dani100% (1)

- Flange and Bolt DimensionsDocument7 pagesFlange and Bolt DimensionsAnish DaniNo ratings yet

- Steel I Beam SizingDocument2 pagesSteel I Beam SizingAnish DaniNo ratings yet

- WEQ1PR Answered Questionnaire V1-Main PDFDocument4 pagesWEQ1PR Answered Questionnaire V1-Main PDFJethro QuiritNo ratings yet

- Valves for water heating and cooling systemsDocument32 pagesValves for water heating and cooling systemsFeras BatarsehNo ratings yet

- FAMPDocument27 pagesFAMPChandra SekharNo ratings yet

- BEMS Point Diagram UC PG 6Document1 pageBEMS Point Diagram UC PG 6psn_kylmNo ratings yet

- I B R Material Cum Release Note Received Details (2) - RBPLDocument8 pagesI B R Material Cum Release Note Received Details (2) - RBPLManikandan elumalaiNo ratings yet

- SBD-6479 WaterCalcWorksheet 01-12Document4 pagesSBD-6479 WaterCalcWorksheet 01-12Victor ValenciaNo ratings yet

- Fundamentals of Pumps: Types and OverviewDocument25 pagesFundamentals of Pumps: Types and OverviewCristinaNo ratings yet

- Plumbing Installation QuestionsDocument5 pagesPlumbing Installation QuestionsJoshua EchavarriaNo ratings yet

- Product Catalogue 310316Document47 pagesProduct Catalogue 310316Cluis KeNo ratings yet

- 330C Excavator Hydraulic System: Fluid Power SymbolsDocument2 pages330C Excavator Hydraulic System: Fluid Power SymbolsVictor Nunez100% (1)

- (Type Here) : P H o N E: 4 8 0 - 8 2 4 - 2 7 0 0Document18 pages(Type Here) : P H o N E: 4 8 0 - 8 2 4 - 2 7 0 0arun RajannaNo ratings yet

- Plate No.3 PlumbingDocument1 pagePlate No.3 PlumbingDawat JohnNo ratings yet

- Valve Selection Handbook - Check ValvesDocument16 pagesValve Selection Handbook - Check ValvesPalazzo345No ratings yet

- Kirloskar Up Upl Uph Upt CompressedDocument16 pagesKirloskar Up Upl Uph Upt Compressededward baskaraNo ratings yet

- PARKER PS1-E11 Technical Datasheet PDFDocument1 pagePARKER PS1-E11 Technical Datasheet PDFCardoso MalacaoNo ratings yet

- Iso 9461Document7 pagesIso 9461Fabio StuiNo ratings yet

- Datasheet Si-205 EN Butterfly ValveDocument8 pagesDatasheet Si-205 EN Butterfly ValvedavidNo ratings yet

- Axial Piston Pumps for Open and Closed CircuitsDocument32 pagesAxial Piston Pumps for Open and Closed Circuitsanon_485665212No ratings yet

- Value Wise (More Then 2 Years)Document139 pagesValue Wise (More Then 2 Years)Saurabh Kumar SinghNo ratings yet

- MIKE11 Structures Definition Weirs Culverts RegulatingDocument6 pagesMIKE11 Structures Definition Weirs Culverts RegulatingAruna JayasundaraNo ratings yet

- Copy of List PA IOT Update (003)Document21 pagesCopy of List PA IOT Update (003)Anderson DelfinoNo ratings yet

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureАлексейNo ratings yet

- Hawe Rapid RangeDocument16 pagesHawe Rapid RangecinbrekNo ratings yet

- Bomba para Prueba Hidr UlicanDocument0 pagesBomba para Prueba Hidr Ulicanhtaliban100% (2)

- KR MV5 TropicalDocument2 pagesKR MV5 TropicalDjamal MohammediNo ratings yet

- 9Document140 pages9Dixon Javier Cortes TapiaNo ratings yet

- Pump BasicsDocument18 pagesPump Basicsnbharath1988No ratings yet

- Pipe Fittings GuideDocument1 pagePipe Fittings Guidesopan kharcheNo ratings yet

- Kemper Catalog FlowControl Sep2010Document16 pagesKemper Catalog FlowControl Sep2010Oswaldo VillarroelNo ratings yet

- Introduction Types of CompressorDocument2 pagesIntroduction Types of CompressorMayur NandaneNo ratings yet