Professional Documents

Culture Documents

Technical Specs Externally Finned Tubes

Uploaded by

yulianus_srOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specs Externally Finned Tubes

Uploaded by

yulianus_srCopyright:

Available Formats

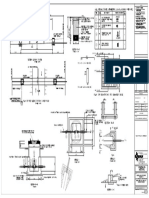

TECHNICAL SPECIFICATION EXTERNALLY FINNED TUBES MB21-5F PAGE 1 OF 4

DATE: 25 MAR 2003

ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC.

TABLE OF CONTENTS Section 1. 1.1 1.2 2. 2.1 2.2 3. 3.1 3.2 3.3 4. 4.1 4.2 4.3 4.4 4.5 Title Page No. GENERAL ......................................................................................................................................1 Scope..............................................................................................................................................1 KBR Documents, Codes, and Industry Standards. ........................................................................1 COMPONENTS AND MATERIALS ...............................................................................................2 Tubes ..............................................................................................................................................2 Fin Material .....................................................................................................................................2 FABRICATION ...............................................................................................................................2 General ...........................................................................................................................................2 Manufacture ....................................................................................................................................2 Welding ...........................................................................................................................................3 TESTING AND INSPECTION ........................................................................................................3 General ...........................................................................................................................................3 Tube Material ..................................................................................................................................3 Fin Material .....................................................................................................................................3 Finned Tubes ..................................................................................................................................3 Samples ..........................................................................................................................................4

1. GENERAL 1.1 Scope 1.1.1 This Specification, KBR Purchasing Standards MB2-1PS and SDR-2MB-2, cover the requirements for shop fabrication, testing, and inspection of externally finned tubes, where the fin material is either solid or segmented. Exceptions to this specification, if any, and abbreviations are in accordance with KBR Technical Standard MB15-1TS (Note: KBR will be referred to as the Purchaser). 1.1.2 The Purchaser will specify materials, shape, and dimensions of fins required to be furnished by the Supplier. 1.1.3 This specification covers tolerances and tests, as required to control the quality of the finished finned tube and assure compliance with the Purchaser's requirements. 1.2 KBR Documents, Codes, and Industry Standards The following documents are referenced herein and form part of the Order. Additional KBR documents, when applicable, will be listed in the Requisition. Applicable dates of issue of industry standards and codes shall be as indicated in the KBR Technical Standard MB15-1TS. KBR DOCUMENTS MB2-1PS, "Purchasing Requirements for Furnace Materials, Components and Equipment" MB15-1TS, "General Furnace Specification" SDR-2MB-2, "Supplier Data Requirements-Fabricated Furnace Components" AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) ASME Boiler and Pressure Vessel Code: Section I, Section VIII, ASME B31.3, "Power Boilers" "Pressure Vessels" Division 1 "Process Piping"

TECHNICAL SPECIFICATION EXTERNALLY FINNED TUBES MB21-5F PAGE 2 OF 4

DATE: 25 MAR 2003

ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC.

AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) ASTM A167, "Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip" ASTM A176, "Stainless and Heat-Resisting Chromium Steel Plate, Sheet, and Strip" ASTM A1008, "Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy with Improved Formability" 2. COMPONENTS AND MATERIALS 2.1 Tubes Unless otherwise noted on the Purchase Order, all materials designated by mark numbers on design drawings and listed in the Bill of Material, will be supplied by the Purchaser and shipped to the finning fabricator. The balance of materials needed to complete finned tube assembly shall be supplied by the finning fabricator unless noted (N.F.). Material supplied shall conform to the Specifications stated on the design drawings. (Note: "N.F." denotes Not Furnished by the fabricator.) 2.2 Fin Material 2.2.1 Nominal fin material thickness shall be specified by the Purchaser. The minimum thickness shall be as specified, 0.005 inch (0.127 mm) mill tolerance. 2.2.2 The fins will be manufactured from carbon steel (ASTM A1008, Type B), 11-13Cr (ASTM A176, TP 410), 18Cr-8Ni (ASTM A167, TP 302B), or 25Cr-20Ni (ASTM A167, TP 310) stainless steel in accordance with the Purchaser's requirements. TP 409 material may be used for 11-13Cr fins provided mill test reports confirm the chemical composition meets the Purchaser required minimum chromium content of 11%. ASTM A240 is acceptable alternate to ASTM A167 and ASTM A176. 2.2.3 Mill test reports shall be supplied for fin material. 3. FABRICATION 3.1 General 3.1.1 The finner shall submit an established finning procedure for Purchaser acceptance. No deviation from the accepted procedure is allowed without Purchaser concurrence. 3.1.2 Fabrication of tubes shall meet the requirements of the applicable Purchaser specifications noted in the Inquiry. 3.2 Manufacture 3.2.1 Prior to the application of fins, the exterior of the tubes shall be properly cleaned to remove scale, rust, oil, grease and other deleterious foreign materials. 3.2.2 The fin shall be solid or segmented, as specified, and wound helically around the tube in such a manner as to leave the major height of the fin in a position 90o (10o) to the tube. 3.2.3 For segmented fins, the maximum distance between the outside diameter of the tube and the base of the segmented portion of the fin shall not exceed 0.25 inch (6.4 mm). 3.2.4 The fin is considered to be a nonpressure part attachment having no load carrying function joined to a pressure part by a machine welding process. The fin-to-tube weld is not to be considered a strength or pressure containing weld.

TECHNICAL SPECIFICATION EXTERNALLY FINNED TUBES MB21-5F PAGE 3 OF 4

DATE: 25 MAR 2003 3.3 Welding

ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC.

3.3.1 Fins shall be attached by the high frequency resistance welding method. The following additional requirements shall apply: a. Moderate interruptions of the weld are permissible providing the sum total length of such interruptions does not exceed 2.0% of the total length of the weld on any tube. The maximum permissible length of an interrupted weld at a break in the fin strip shall be a function of the pipe diameter: for a NPS 2 pipe, the maximum interrupted weld length shall be 5 wraps of the tube; for a NPS 3 or NPS 4 pipe the maximum interrupted weld length shall be 4 wraps of the tube; and for a NPS 5 or NPS 6 pipe the maximum interrupted weld length shall be 3 wraps of the tube. The distance between two interruptions shall not be less than 6 inches (150 mm). Other than at a break in the fin strip, the maximum interrupted weld length shall not exceed two (2) linear inches (50 mm). The fin height after welding shall be as specified 1/32 inch (0.8 mm) as measured from the base tube to the fin tip. Warping of tubes due to finning shall not exceed 3/16 inch (4.8 mm) in any 10 feet (3.0 m) section of tube. Length of nonfinned portions on the finished finned tube shall be as specified 1/4 inch (6.4 mm).

b. c. d.

3.3.2 Weld reinforcement shall be ground smooth and level with the adjacent tube or pipe prior to attachment of fins. 4. TESTING AND INSPECTION 4.1 General The inspector representing the Purchaser shall have entry at all times, while work on the contract of the Purchaser is being performed, to all parts of the manufacturer's works that concern the manufacture of the material ordered. The manufacturer shall afford the inspector all reasonable facilities to ensure that the material is being furnished in accordance with this specification. All required tests and inspection shall be made at the place of manufacture prior to shipment unless otherwise specified and will be conducted so as not to interfere unnecessarily with the operation of the works. 4.2 Tube Material Upon arrival at the finner, tubes shall be visually inspected to verify dimensions and correct material identification. Tube will also be inspected for obvious defects including dents, laminations, gouges, out-of-roundness and surface finish. Any condition considered deleterious to the end use of welding of the fins to the tube shall be reported to the Purchaser for disposition. 4.3 Fin Material 4.3.1 Fin material shall be inspected upon receipt to verify dimensions and proper material identification. Fin material shall also be inspected for corrosion and lamination. 4.3.2 During finning, fin material shall be inspected to verify proper material identification, dimensions and integrity prior to being welded to the tube. 4.4 Finned Tubes 4.4.1 During finning, the welding operator may stop the machine and physically remove a short portion of the fin to verify the presence of an adequate weld.

TECHNICAL SPECIFICATION EXTERNALLY FINNED TUBES MB21-5F PAGE 4 OF 4

DATE: 25 MAR 2003

ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC.

4.4.2 To verify the extent and quality of the fin to tube bond, a small portion of fin shall be removed from the end of every 5th tube and the surface visually inspected. The average width of the white metal exposed by removing the fin shall be a minimum of 90% of the original thickness of the fin, and generally continuous over the whole length exposed. 4.4.3 The maximum amount of corrugation of a solid fin at the attachment to the tube shall be 3 times the original thickness of the fin, measured from out to out of the corrugations in the plane of the fin. 4.4.4 The inside surface of all finished finned tubes shall be visually inspected. The outside shall be free from injurious defects and have a workmanlike finish. 4.5 Samples 4.5.1 A minimum of two (2) welded fin tube samples shall be submitted with the quotation. The samples will be used for bid evaluation and will be retained by Purchaser for future inspection/rejection comparison purposes. 4.5.2 The size of each sample shall measure 6 inch (150 mm) long by 120 degrees. One sample shall represent the minimum acceptable standard and the other shall represent the normal standard. 4.5.3 The actual number of sample pairs submitted with the quotation will suit the range of materials in the Inquiry and ensure the provision of future inspection tools for the materials in the Purchase Order. Any problems in providing the sample pairs; or of the selection of sample equivalent materials; shall be discussed with Purchaser, prior to the submission of the quotation. 4.5.4 Subject to the approval of the Purchaser, additional samples may not be required if Supplier has submitted samples with a previous quotation.

You might also like

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- CPI Steam Heated BoilerDocument4 pagesCPI Steam Heated BoilerGTpianomanNo ratings yet

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 pagesInvestigation and Repair of H (1) - E.R Flange LeakriysallNo ratings yet

- Weld Repair of Grade 91 Piping and Components in PDocument27 pagesWeld Repair of Grade 91 Piping and Components in PKyi HanNo ratings yet

- Small Diameter Boiler Tube Butt Weld Acceptance Criteria - Arnold - 20 May 2015 PDFDocument8 pagesSmall Diameter Boiler Tube Butt Weld Acceptance Criteria - Arnold - 20 May 2015 PDFAnaximenes 12No ratings yet

- Titanium Cladded Sheet Welding ProcedureDocument4 pagesTitanium Cladded Sheet Welding ProcedureNaveenNo ratings yet

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNo ratings yet

- MRPL NHT Heater DecokingDocument7 pagesMRPL NHT Heater DecokingsmrndrdasNo ratings yet

- STD 133Document37 pagesSTD 133ck19654840No ratings yet

- Weld Built-Up ProcedureDocument1 pageWeld Built-Up ProcedureMohd Shafuaaz KassimNo ratings yet

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Document28 pages16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- API 570 Pipeline Inspection PDFDocument1 pageAPI 570 Pipeline Inspection PDFKhalidMoutarajiNo ratings yet

- A Brief Synopsis ofDocument54 pagesA Brief Synopsis ofNO ONENo ratings yet

- Industrial Plant Inspection GuideDocument5 pagesIndustrial Plant Inspection GuideMohamedNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- BPDocument36 pagesBPThiruvenkatasamy Elangovan100% (2)

- British Standard 5289: 1976: Visual InspectionDocument10 pagesBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNo ratings yet

- Corrosion Evaluation of Reboiler Tube PDFDocument11 pagesCorrosion Evaluation of Reboiler Tube PDFOwais MalikNo ratings yet

- API 653 - ASME Section V - NDE Practice Questions - 68 TermsDocument7 pagesAPI 653 - ASME Section V - NDE Practice Questions - 68 TermsSERFORTEC CIA. LTDA.No ratings yet

- Collar Bolts in Shell and Tube Heat ExchangersDocument3 pagesCollar Bolts in Shell and Tube Heat ExchangersBaher ElsheikhNo ratings yet

- 01 Saip 38Document14 pages01 Saip 38Arjun RawatNo ratings yet

- KubotaDocument12 pagesKubotaFebri Ramdani NugrahaNo ratings yet

- API 510 PC 5mar05 Case Study 2 Thickness CalculationsDocument3 pagesAPI 510 PC 5mar05 Case Study 2 Thickness CalculationsSameh AminNo ratings yet

- Pin Brazing ManualDocument24 pagesPin Brazing ManualXiaohua ChenNo ratings yet

- Annealing (metallurgy) - Heat treatment softens metalsDocument4 pagesAnnealing (metallurgy) - Heat treatment softens metalsStephen MontelepreNo ratings yet

- Calculating Heat InputDocument5 pagesCalculating Heat InputAnonymous AlhzFE9EVNNo ratings yet

- Ansi-Aws A5 - 18-93Document37 pagesAnsi-Aws A5 - 18-93skrkulachiNo ratings yet

- CRAHF Weld OverlayDocument2 pagesCRAHF Weld OverlayGogulu KumarNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNo ratings yet

- Guide To Prepare WPQR According To Asme Section IxDocument5 pagesGuide To Prepare WPQR According To Asme Section IxHoque AnamulNo ratings yet

- New Bottom PlateDocument9 pagesNew Bottom PlateEmmanuel kusimo100% (1)

- What is InspectionDocument6 pagesWhat is InspectionRathnakrajaNo ratings yet

- BechtBlogNuclear 2-13-17 Repairs ASME XI and PCC-2 George AntakiDocument7 pagesBechtBlogNuclear 2-13-17 Repairs ASME XI and PCC-2 George AntakiStephen XuNo ratings yet

- Sandia National Laboratories API-653 In-Service Tank Inspection and Evaluation TANK ID: 981-A2-T0 (West)Document80 pagesSandia National Laboratories API-653 In-Service Tank Inspection and Evaluation TANK ID: 981-A2-T0 (West)Manokaran RamalingamNo ratings yet

- Longitudinal JointDocument26 pagesLongitudinal JointirfanNo ratings yet

- Heat Exchanger Inspection PDFDocument27 pagesHeat Exchanger Inspection PDFglazetm100% (1)

- Corrosion Monitoring Methods (Chevron)Document65 pagesCorrosion Monitoring Methods (Chevron)Sergey KichenkoNo ratings yet

- Packed Bed Performance AnalyticsDocument6 pagesPacked Bed Performance AnalyticsNITINNo ratings yet

- Ferrite Limitation For SS316LDocument12 pagesFerrite Limitation For SS316LAntonio PerezNo ratings yet

- CSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of CompetenceDocument1 pageCSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of Competenceafiq ahmadNo ratings yet

- AESW011Document50 pagesAESW011Arputharaj Maria LouisNo ratings yet

- Inspection, Maintenance and Testing of Fired HeatersDocument27 pagesInspection, Maintenance and Testing of Fired HeatersVicente Regulez FernandezNo ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- Mechanical FatigueDocument6 pagesMechanical FatigueRamyMoustafaNo ratings yet

- Tube InspDocument8 pagesTube InspsrihariNo ratings yet

- 1169 2014-BOK Rev-071014Document9 pages1169 2014-BOK Rev-071014Siva KumarNo ratings yet

- Heat Exchanger Concepts (Att. VIII)Document28 pagesHeat Exchanger Concepts (Att. VIII)Syed M. Imran Ali100% (1)

- Sec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)Document5 pagesSec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)حمودي معز100% (2)

- CLSCC LiteratureDocument62 pagesCLSCC LiteratureNakarin PotidokmaiNo ratings yet

- Interpretations ASME B31.3Document338 pagesInterpretations ASME B31.3Claudenir AlvesNo ratings yet

- Api 571 PDFDocument3 pagesApi 571 PDFumnartkhNo ratings yet

- Saep 355 PDFDocument20 pagesSaep 355 PDFRami ElloumiNo ratings yet

- Exchangers: Repairing Cracks in Refinery HeatDocument4 pagesExchangers: Repairing Cracks in Refinery Heatramadoss_alwar7307No ratings yet

- Inspection Storage Tank STD 129Document10 pagesInspection Storage Tank STD 129kanip_No ratings yet

- Externally Finned TubesDocument4 pagesExternally Finned TubesAleem QureshiNo ratings yet

- Standard2 7 3Document22 pagesStandard2 7 3Chaker AmirNo ratings yet

- High-Level Efficiency: Demag Universal CranesDocument24 pagesHigh-Level Efficiency: Demag Universal Cranesyulianus_srNo ratings yet

- 3000 Litre Transcube Fuel TankDocument1 page3000 Litre Transcube Fuel Tankyulianus_srNo ratings yet

- Cafco FENDOLITE® MII - Product Datasheet PDFDocument4 pagesCafco FENDOLITE® MII - Product Datasheet PDFyulianus_srNo ratings yet

- Wire Rope ThimblesDocument1 pageWire Rope Thimblesyulianus_srNo ratings yet

- 2-1-bf6kz PDF FR 17 PDFDocument4 pages2-1-bf6kz PDF FR 17 PDFyulianus_srNo ratings yet

- Grey Water Re-Use Primary Treatment TankDocument1 pageGrey Water Re-Use Primary Treatment Tankyulianus_srNo ratings yet

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDyulianus_srNo ratings yet

- Detailed Border New Year FlyerDocument2 pagesDetailed Border New Year Flyeryulianus_srNo ratings yet

- Fixing Clips (Sket)Document1 pageFixing Clips (Sket)yulianus_srNo ratings yet

- B209M ASTM Aluminum StandardsDocument26 pagesB209M ASTM Aluminum StandardsDanny SeeNo ratings yet

- HD Jack 3-11Document1 pageHD Jack 3-11yulianus_srNo ratings yet

- Bs en Iso 15848 2pdf Ebook and ManualDocument1 pageBs en Iso 15848 2pdf Ebook and Manualyulianus_srNo ratings yet

- Cafco FENDOLITE® TGDocument4 pagesCafco FENDOLITE® TGyulianus_srNo ratings yet

- Road CrossingDocument1 pageRoad Crossingyulianus_srNo ratings yet

- Program BPJS-TK JHTDocument3 pagesProgram BPJS-TK JHTyulianus_srNo ratings yet

- Bevel and Trim Detail PDFDocument1 pageBevel and Trim Detail PDFyulianus_srNo ratings yet

- Program BPJS-TK JKKDocument3 pagesProgram BPJS-TK JKKyulianus_srNo ratings yet

- Plate Joint PDFDocument1 pagePlate Joint PDFyulianus_srNo ratings yet

- Bevel and Trim DetailDocument1 pageBevel and Trim Detailyulianus_srNo ratings yet

- Pipeline Barred TeeDocument1 pagePipeline Barred Teeyulianus_srNo ratings yet

- Uptime Brochure Tcm4-581762Document2 pagesUptime Brochure Tcm4-581762yulianus_srNo ratings yet

- Geothermal Energy For Power GenerationDocument9 pagesGeothermal Energy For Power Generationyulianus_srNo ratings yet

- Unequal Welding DesignDocument1 pageUnequal Welding Designyulianus_srNo ratings yet

- Rubber Lining SpecDocument1 pageRubber Lining Specyulianus_srNo ratings yet

- Piping Hook UpDocument1 pagePiping Hook Upyulianus_srNo ratings yet

- Weld ConnectionDocument1 pageWeld Connectionyulianus_srNo ratings yet

- Static Presssure TestDocument14 pagesStatic Presssure TestBalakumar100% (1)

- Piping Layout DrawingDocument2 pagesPiping Layout Drawingyulianus_srNo ratings yet

- Typical Road Crossing DetailDocument1 pageTypical Road Crossing Detailyulianus_srNo ratings yet

- I Mold Product Overview Servomold Ver1.0 enDocument8 pagesI Mold Product Overview Servomold Ver1.0 enInderjeet SinghNo ratings yet

- Internal Protection of Three Phase Lines from Transient OvervoltagesDocument2 pagesInternal Protection of Three Phase Lines from Transient OvervoltagesD Yunos BujangNo ratings yet

- Goip Sms Interface enDocument10 pagesGoip Sms Interface enNoli Bellen RafalloNo ratings yet

- A 15Document4 pagesA 15Prem SharmaNo ratings yet

- Moat MTN NH Smoky QuartzDocument2 pagesMoat MTN NH Smoky QuartzBrian OelbergNo ratings yet

- BIMobject Revit Style GuideDocument57 pagesBIMobject Revit Style GuideCristian Lemus BorjaNo ratings yet

- Acsr Canna 933 Tip Test Raporu PDFDocument13 pagesAcsr Canna 933 Tip Test Raporu PDFelsayedNo ratings yet

- Yingli Solar PANDA YL270C 30b Data Sheet 1 PDFDocument2 pagesYingli Solar PANDA YL270C 30b Data Sheet 1 PDFCourtney MillerNo ratings yet

- Grilles and Diffusers PDFDocument149 pagesGrilles and Diffusers PDFMohammed Javid100% (1)

- Waterman AF-41 Flap GatesDocument3 pagesWaterman AF-41 Flap GatesIbnuyusoff77No ratings yet

- USMLEStep3 Certification of IdentityDocument1 pageUSMLEStep3 Certification of IdentityKrupa KarnikNo ratings yet

- Model Answer Summer 2016Document22 pagesModel Answer Summer 2016DiyaNegi0% (1)

- Cost-effective 1,500 VDC modular inverters for large-scale solar plantsDocument2 pagesCost-effective 1,500 VDC modular inverters for large-scale solar plantsGregorio VillarrealNo ratings yet

- Is - 919-Part 2Document46 pagesIs - 919-Part 2mmkattaNo ratings yet

- CASE 595 P100 Trainings Manual GB PDFDocument195 pagesCASE 595 P100 Trainings Manual GB PDFjulianmata100% (2)

- Optical Multi Service Edge NortelDocument172 pagesOptical Multi Service Edge NortelsijuicetNo ratings yet

- Dcon Utility User ManualDocument45 pagesDcon Utility User ManualPedro BortotNo ratings yet

- Specification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorDocument19 pagesSpecification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorHassen LazharNo ratings yet

- HTTrack mirroring errors of mrodrigueza websiteDocument2 pagesHTTrack mirroring errors of mrodrigueza websiteneptuno97No ratings yet

- Personal Satellite Communication SystemDocument4 pagesPersonal Satellite Communication SystemvydeoNo ratings yet

- Company BrochureDocument19 pagesCompany BrochurevbgeoNo ratings yet

- Carta FuturaDocument3 pagesCarta FuturaCarlosSánchezNo ratings yet

- Document With FeaturesDocument256 pagesDocument With FeaturesNitinNo ratings yet

- Info Install PartageDocument7 pagesInfo Install PartageAdnan MilanNo ratings yet

- InstallationDocument14 pagesInstallationwaqasNo ratings yet

- PCP-00 Rev.0 Process Control Plan AuditDocument7 pagesPCP-00 Rev.0 Process Control Plan AuditVinod SaleNo ratings yet

- Catalogo Jiskoot 210Document44 pagesCatalogo Jiskoot 210Cristian Andres Gonzalez0% (1)

- Frame Relay Benefits Over Leased LinesDocument20 pagesFrame Relay Benefits Over Leased LinesErnestoLopezGonzalezNo ratings yet

- Entry of Foreign ArchitectsDocument26 pagesEntry of Foreign ArchitectsSajju ArunachalamNo ratings yet

- ACM Data Sheet Rev 04 10 - 14 PDFDocument2 pagesACM Data Sheet Rev 04 10 - 14 PDFJosephNo ratings yet