Professional Documents

Culture Documents

Cheap Wind Water Pump

Uploaded by

SeanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cheap Wind Water Pump

Uploaded by

SeanCopyright:

Available Formats

A project of Volunteers

in Asia

How to Construct a Cheap Wind Machine moing Water Do-It-Yourself Leaflet No. L-5 Published by: Brace Research Institute MacDonald Ccllege McGill University Ste. Anne de Bellevue 800 Quebec, Canada H9X 1CO Paper copies are $ 1.50.

for

Available from: Brace Research Institute MacDonald College McGill University Ste. Anne de Bellevue 800 Canada H9X 1CO yuekJf?c, Reproduced Institute, by permission the Brace Research McGill University.

Reproduction of this microfiche document in any as those form is subject to the same restrictions of the original document.

McGill University Faculty 00 Engineering BRACE ZESEARCH INSTITUTE

HowTo Construct A CHEAPWINDMACHINE FORPUMPING WATER

Do-it-Yourself Leaflet No. L-5

February Revised

1965 February 1973

BRACE RESEARCH INSTITUTE

MocDONALD COLLEGE OF MCGILL UNIVERSITY STE ANNE DE BELEVUE QUEBEC, CANADA 800

--

How To Construct A CHEAP WIND MACHINE FOR PUM ING WATER

instructions for building a Savonius Rotor for Water Bumping

The Savonius Hotor is a vertical-shaft winddevelcrpetl by the Finish engineer. machine, S. J. Savonius, during the years 1925-28. A test program was carried out on this typr cf machine by the Bract &search Institute to find out its potentialities for low Cost water pumping. From the tests the following conclusions can The Savonius Rotor, although not be drawn: as efficient as a windmill of comparabte size, lends itself to water pumping for irrigation in areas due to its low initial underdeveloped cost, simplicity of materials and construction. and low maintenance cost. It will successfully operate in areas whert* the wind speeds are in the region of 8 to 12 mph. and above, and the water level is not more than 10 to 15 ft. below ground. The rotor, drive and yuml~ are eminently suitable for home construction by the handyman with but a few tools and access to a welding set. It can be made from a variety of materials at low cost since no critical machining is necessary. The only important points to be observed in erecting such a machine is the proper choicr of the site and careful assessment of the average wind-speeds. From this information the tlrouer pump size and stroke can be Chosen from the graphs at the back of this pamphlet. It will also be necessary to provide some sort of water storage into which water can be pumped at good wind-speeds aud later used for irrigation when needed. The bigger tbe storage capacity the more flexible the system becomes. The rotor described here is the one used for all the tests carried out at the Brace Research Institute and was built from locally (Barbados) available materials in a small workshop with unskilled labor at very low cost. The whole pumping system comprises 3 units: The rotor, the drive and the pump. Each unit will be dealt with separately. These instructions apply to the type built at Brace, but it is left to the builders ingenuity to subatitute other materials or processes of ronstruction to suit local conditions. The only important measurements to be adhered to are the proportions in of the rotor itself. as shown Fig. 1.

1. The Rotor

tt Consists of two 45 gallon uit drums, bisected leugthwise and welded together to form two troughs. (Fig. 2). These two troughs arc mounted betwetn two end plates, made from of

Fig.

plywood, 48 diameter. They can both be cut frbni one siuglc sheet of standard plywood. which measures 48 ins. by 9ti ins. The dimensions for mounting the drum halves are given in Fig. 1. The ends of the oil drums are simply bolted to the wooden disks with 3/8 in. stnve and nuts. The shaft through bolts, washers the renter of the rotor is l-1/4 in. It) water pipe, which should extend about (i ins. beyond either end of the rnd plates. To secure the shalt to the end plates two flanged collars arc used, as shown in Fig. 3. They should bc ;I snuct fit on the outside of the shaft. They :IW btrltc*tl to the plywood witlr 4 bolts, and after inserting the shaft, are drilled and secured to it with :I S/4 in. bolt. spring wnshcr and nut. To sutrtmrl

.. METWOO !%R BALAYCY~ Fig. 3.

Fijr.

Romp.

5 .

Fig. 4,

Before nrounting this rutor in tlir franlv il mud be rarefully balanced to itvoid vibriilions at high speeds. This is easily rlun~ by pluciw the assembled rotor horixontallp on twit Irvel tirarght a%&% aad adding wei@& to the circomference in the center of the rotor, until prdect balance is achieved. (See Fig. 5).

THE FRAME The frame consisls of four pieces of 4 in, by as shown in Fig. 6. The joints 2 in. timber, should be securely bolted with gusset plates, to make it as stiff as possible. It must be steadied with wire guys, securely anchored to the ground and tensioned by turnbuckles. The lower cross member should be about 6 ft. above the ground, but can be Inore if practicable.

k--RAhE 4~

Fig. 6.

WtREs

2.

The

Drive

-__ -Colwrcmc ROD

~XCCNI

YB

DPIVE Asscien Fig. 7.

It consists of the krcentric. horizontal conneoting rod, brll rrank and vertical pun~p rod. See Fig. 7. tilt* rccc~nlril~ 14 ;I t)irc*c* 4&f sl~c*l. Imrmt 141fil flw c-utl of I!w 1owc.r ;ulal)tor aucl sccurc+d to it by II Illrough boll. liu~ frlrc* is clriltrd and Iaptml 141reccGvc* ii holl which must br a good fit in the bore* of lhc tmtt bearing, forming the is 7/32 ins. which big encl. Thr erceutricity gives H htrokc ~tf i/l(i in. !-he blg ecr! of the connecting rod is ;I ball bearing, *h in. bore, which is held in a split fitting attached to the or rod. The ronnecting rod of a motorcycle small c:lr &gine \vill do nicely for this purpose. Cut the sbarrk off i~nrl weld a piecc Of 1 in. Ill the tubihg lo it. about ti ins. long to receive wooden ronnpc4iug rtr~l. (Fig. XC).

a.

ADXJSTABLE

PUMPS

t?H?K~hlb

&

CONNECTING ROD FOW lh.

c.

CONNECTING

Rob t% Fig. N

END

S~IICT 11~~putnp is :I 5iuglr uVt1ug diaphragm pulll(~. the two actuating rods arr only in tcnn~nde of ~ootl. I in. sirm, ;Incl :IW thrrmcfow SIIIU!~ c*crrutricit?; :rnd the lhr S~lUi~lY. \Villi fiesitrility td !h wocbli il is nut necessary to I~:IVV :I univc~rsal joint ilt the beI1 crank counccting rod carries a woollall iWil. :hi wifh :I good fitting pin fork on its wdl rntl. of I& in. tli;l. through ;I hole in the upper arm The pump rod is a similar of the bell crank. oiecc of 1 is. square \voort with an adjustab!e fork zsd on top. Refer to Figs. 8A and 86, which are self-explanatory. The bell crank is made from a piece of l/4 in. steel plate, cut as shown in Fig. 9. The with welded bosses :IS holes are reinforced and drilled after welding. If possible shown these bearing holes should be bushed with a bronze bush, this will increase the lit% of the pin ;rncl tirevent the system from developing

backlash. lhpre should also be an oil hose for Thr overall lubrication. width of the hushes must be a closr fit in thP fork to preevnt any side play.

3. The PlJrnD

II-it! pullIt) sheeted for this applicaliou is a single acting diaphragm pump. This design has been chosen because it is simple to build, with tllil~llillilig rc:tuirrd. It is pmctical!v Iriiniliiuiil nl:iilitenaiirc II-CT :IIICI it is cehrap. All pipe eoniic~clicms ilW stantl;irci 1 inch watrr-pipe uipples kklbnws. Th? valves can be any com:llltl nlerci;lllu ;Ivailable type of non-return valve. The pump itself is mounted just below wutrl level I fully subrurrgetl) so that there is no cwlllprcssitrn in the rod on the suction stroke. .\ srrwn slmr~l~l bc* fitted on the intake valve to prt~verlt foreign malt~~r entering the pump. The cliafihragui is ~.~actefruur a piece of inner trite, t/32 to l/U in. thick. Ihc flange should bv at

Fig

9.

._._-_PUMP ROD

Fig . Iti ltwsl l-l/4 in. witlc :mcl lakri: # bolts around the circunlfwrnw, to enswe n good senl. As cm be .see11 in Figs. 10 unrl 11. the PUIIIP is inverted, the diaphragm being operated throutfh a stirrup attached to the pump rod. This gives the tnuutr greater flexibility and is siiuplcr than Icarlinrc the rod through the puurt~

c~ll;lllllIw.

fhc tliwrnhions of thr lmmp arc not tuo witic3l cmcc* the ttianwtcr and strtrkrn havr been detcrtninecl. The stirrut) must he itimen ~ionc~l SO that it provides H definite stop cm the up ;Intl cl6bwn strakr. This will prevent damage 10 the cli:lptrrtigm during hnnclling and instab laticrn.

---- SHEET

HET~C BRAC.KET,

WEIDEDT~ STIRQUP.

A.055

D &MN.

FiH. II.

The main body of the pump consists of u piece of pipe or welded ring, closed at one end :I welded flange on the other. A and having flange ring povides the clamping of the rubber diaphragm. See Fig. 11. Two 1 inch water-pipr nipples arc welded on each side for thr inlet and outlet valv(*s. The two discs supportiug the rubber diaphragm -were made from Tufnol. impregnated fnbrir, hul any :I hard, resin similar hard r~ialcrial can be used, f*ven I~arflwood will do. if nothing else ran hr- lwwurett. Thr cleamncr between discs and putnl~-body is 0.055D and thr inside corners of tbc discs must be well rounded to prevent cutiixg tlrt* rubber on thr up and down sir&e. This is very inlportant. When nsscmbling the pump, sealingcompound is applied to the rubber between the discs and the flanges to assure a good seal. The mounting bar on top of the housing must be very stiff and can be (tither welded or bolted to the top platr. If bolts are used they must he a good fit and should have copper washers to insure against leaks. it is most important when mounting the pump in the well, to secure the mounting bar vtary firmly either by concreting, or bolting to :t couple of cross-timbers in lhc well. lhe tension forces in the pump-rod are in the rcginn of 21Ml Ihs. and at high revolutions this hanlnlrring will SOOII shake loose a weak The pump-rod should be left longer mounting. h-fortmounting thr than Ihr required lrngth After the lmn11, h:is been pump in tlie well. installctl am: the bell crank is nlountrtl on thr frame, lhe i*rll crank is brought to its neutr;lI position awl the adjustable fork end of the pump-rod to hallway on the thread. The rod is now cut so that it will fit fully into the tube of the fork, drilledaud secured with 4 holts, ah shown in Fig. 8A. Now the pun~p-rod is pulled up against the stop, the eccentric tnrnrcl to full stroke and the fork adjusted so thal the pin goes freely lhrough the hole in 111~ Iwll Crth. Now turn the fork nnnthrr one and a half turns

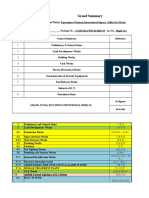

sch.1 the head of wzitcr to i:; 11~~ vcrtirnl tlist:l:i~*c~ IJCt\wt*ll the water Iwc4 ili the Wdl. ;rnd the oiillct in the rcscrvo,ir. lhc grilpll is alrcacly c*cbrrected for the dynamic head. which inc!uf!rs the friclion in thr pipe ibnd thtb va1~cx From t!lr head of wuter on the left scale drtiv: a horizontal linr until it intersects, the apl>ropri;ltr wind speett corye and draw :I sertirnl line through lhis point. This will intersect eve of the fmw straight lines marked: Pump 1. 2, 3. and 4. Each is !;or one IJUIIII, of a given tiiametm and gives on the right hand scalr the proper stroke for this particular I~III~~J and I:PYI combination.

OH gr:Iph So. 1.

be pumped.

This

Eruniple: (Follow dotted iinr 011 graph) He:id 15 ft. windspeed 10 III~*I. Draw liorizontal line at 15 ft. head. with 10 Illlrh. rnrve draw At intrsection

VcrtiCill

line.

It intersects str;iight liiw of pump 2 l+orn this poinl llril\V horizont;ll line to the right hand. stroke-?.ciilc. This gives 4 stroke of 0.M in. The pump has to operate at thi:: stroke bw give the best clffirienry of the rotor. To obtain this stroke from the bell crank, pmcced as follows: lhc ratios of strnkc ?nrl distancr from pivot are rqii:il. I).J.?75:~I-=O.M:x I?creforf* :

s--(ixll..Xi (L.4375 ; 77 .

rhe horizontal :\rnI of the! hell crank will have to be 7.7 ins long to give :I pump stroke nf 0.56 in. Fig 9. The bntlom scale of Graph Ne!. 1 gives the xtuai volume in cubic* ins. per stroke pumped at various wind spcctls. This inakrs il pf~ssihlc tn tlcterminr the size iIII(I stroke of any other :lVilihbk Imlnp, such ns ;I piston pump. Find the* hcatl to 1)~ l~u~nprrl and Ihe wind draw :I vertical line from this speefl as hcfore, point tu the bottom w11e and read the volume per stroke. Divide Illis volume hy Ihe piston area and this will hr the stroke required. lf. fnr t~Xillllpl~. a piston ~JUIII~ of 2 in. diaincter 1~ cix a~nilat~lc thr hc;ld is again I.i ft. r:>d the \vinrl SIYCCC~ IO lrlph.. cnntir?rrt: the

vertical dotted lint tcl fhe base scalr and read 13.3 divided by 3.14 off 13.3 Cu. ins./strokc. (artla of piston) gives a sforke of 4.23 ins. 11) obtain this slrokc III 1.23 ins. from Ihe hrll rrank. il ~trultl IW ;ItlVisablr to alter the er:.clnlricily 10 NISI 11 IIIWC suitnblr radio :\I fho Itc41 (*rank. If 1h(* carrrntricity is marIt* Si in.. Ihen the stroke of the ccmnccting rod bcromrs I in. This leavrs A ratio of 1 4.23 at the bell crank, which could br divided intct in vertical leg of, say, 2?4 ins., and a Iiorizontal leg of IO.58 ins. long. The hell crank would have to be shaped to conform to these measurements. If a piston, pump is used for this purpose. it must be a single arting pump, mounted below water level and operated so that the pump rod is only in tension. This will assure that there are no problems either due to buckling of the pump rod and connecting rod, or trouble with priming of the pump.

Estimating

the Output

of the Pump

(iraph No. 2, Curve A. gives the output of thr pu111p at the srlcctrtl (rated) windspcrtl for the sitr in clueslion, when pumping against H head of 111feet. Tlic output ;8t the rat14 wintlspee(l pumrtina ilpainsl a hcatl dthrr than when II! feet may bk calrUliltt*tl from (:urvc X by simlllr proportion. For rxaniplc, the piiml~ (iraph which has already heen selected from No. 1, to pump against a bead of 15 fee1 most efficiently in a windspeed of 10 mph.. will have an output at 10 mph. of 10 \V := 272 X. - = 181 Inlprrial ~:;lll~Jns l,lr 15 hour. Note that. at windspeeds other than the rated windspeed, the pump will give,=an output SOIIWwhat lower than the figure read froul Curve A of Graph No. 2. :IS it will no longrr be operating at its best efficiency. For rxample. the performance of a particular pump is indicated hy Curve B on Graph No. 2, which refers to a putnl, with a bore of 7-l/4 in. and :I stroke of 7/1fi in. The stroke has bern selcrtrd to give optimum performance at -a windspeed of 9.2 and Cnrve B coincides with Curve A pt wh., this windspeed. However. as thv wintlspced increases (or decreasrs) progressively beyond the rated windspeed of Q.2 mph.. the rclativc performance of ?hr pump drops off and the actual output, read from Curve 8, becomes $1 progressively smaller fraction of lhe optimum output. read from Curve A.

It is rxtrctnrly tliflirul1 18, tlrfinc the ;ic2ual rest of ;I prcljccnl II~V this in tlclll;irs ;1nd c-ruts. As in an> l)o.lt-\l,rll.srlf llrnj,~rl, the biqcrsl part nf the job is the labour. which is assu~rd lo bc frw. Drlwl~tlirlg OII tllc skill, I)atirrCc and resources 4 the home-l:uild~~r. even the Cost of tllr Inatc*rials can v:lrv ronGdrmbly. In thr prolotypr clc~srribrd hcrr. only the ball bearings, WKMI Ior thr lramr, and plywond for the rotor WPW purchased nrw. All nthrr :lrnund the p!nrr. The bark matrrial was fwntl of a garage or sm:~ll machinp shop is usually :I good place to look for things like pircrs of If rrn wrlding equippipe. angles, bolls, etr. ment is at hand, all the pirres to hr welded should be carrfully prcpnred. wired or clamped nearest welding and taken tn thr togetlirr ~1101. If cvcrything is properly prepared, the actual welding for thr whole iob will nc,t take longer than I hour. rhc only parts rrcluirinil machining :I.(* thr Shilft ad:il)tors, the etrentric flanges and tlisrs for thr for the* rotor, thr rbthrr work requirrn a diaphia~m ~111111~I. Ail drill only. Finally, fit give :I rougl~ idpa of the r:nst. the main ih~ms ;Irc listecl hrrt* as purchased in U;irbadoh, in thr cquivalcnt of I!.!? TIoll:irs:$4 2.m . 2 Oil tlrums (gnod condition) 2 Self-alignin;! Hall Wirings. flange 14.m .. .. type 7.50 .. .. Mi ft. 2 s 4 Timber

1 ~lwc*l s in. Plywvcwrl (4 ft. R 8 ft.) 12.50 .30 3.30 2.70

Pumping at Heads of More Than 30 Feet

In this :eaflct consideration has brrn t-cstrirted to a very low cost pump) :~ntl thr simplest farm of power transmission system. The equipment described ubovc has been tested when pumping against hinds of up to 30 feet.

30 ft. l/R tliilmetcnr (;:ilvanizrd Stcrl .. .. .. Wire .. .. 6 l/J s 4 ius. I~II.II I+uckles 7 ft. l-I/J 1.1). \V;itrr Iipc (Elotrrr .. .. .. .. shaft) 1 $4 in. I~(IIY 11itll ILring (big-*ml I . 1:) ft. Il;lS:iC Iipc~ (rl?*livcry~

Rolts. Nuts. \~;~sll~l~s. c4r. Tot,11 . . : . . U.S.

1.60 4.1Q

2.00 9 51.00

TECHNICAL NOTESON THE DIAPHRAGMPUMP 1. The diaphragm should be of fairly thick rubber - rubber from heavy truck or tractor inner tube is good - rubber that is too thin or too flexible is not satisfactory since under a large head the deformation of the diaphragm to negate the full diaphragm displacement,

tends

2.

The stroke may well have to be increased to one or tw> inches, depending on the rubber flexibility, In order to effect this, it may be necessary to increase the clearance between the discs and the pumpbody. It was found, in practice in very remote conditions, that a fair bit of experimentation was needed in order to determine the best location of the pump relative to both the source and the discharge. This pump is most efficient when immersed, however the pressure head then becomes too great and diaphragm deformation becomes very significant, For our 4+" pump, a suction head of about 6 to 8 feet with a pressure head of some 8 to 10 feet was felt to be about thelimiting conditions, The pump rod and connecting rod end connections should be firm. Any play in these takes away from the length of stroke,

3.

4.

MOL'fNO CAKX~SlhCUA

Cada akb se prescnta una tragcdin en 10s Llanos Orientales dc Colombia cuando SC muercn milts de vocas pot fnlta de ngua. rln Casanare las distancias entre 10s rios y cailos (que son las tinicas fuentcs de agua durante el verano) son largas y el ganado se ve obligado a mantencrse cerca al agua, y por lo tanto se acabnn 10s pastos aledafios al agua, o a caminar dis tancias demasiado grandes. En Meta y Vichada, 10s canes y rlcs veraneros son mucho tis abundantes pero a medida que el agua baja se aumenta ei riesgo de qua el ganado (especialmente las vacas viejas) se entierre. en busca de aqua y ei no lo sacan dentro de pocas horas de haberse enterrado, se muere. La tragcdia descrita parece absurda al darse cuenta que en todas estas regiones existe agua subterranea abundante a muy pocos metros de profundfdad.

al

El ICA y el CUT en su preocupacibn por encontrar una soluci6n econbmica problema de agua han instalado un molino experimental en Carimagua que El molino representa una modificacibn de un diseparece muy promisorio. fro realizado, probado y publicado por la Brace ISesearch Station" en BarSabados. ~1 diseno fue basado en un aotor inventado por el finland& vonius en 1925. El MoIIno es de construcci6n muy sencilla, bajo costo y fdcil mantenimien to. Se ha estimado que el costo de materiales, incliryendo trabajos en el campo serta de sproximadamente de tiller I. le no serlan factibles equivalentes a $125.00 U.S.) El costo esta $2.500 [! ..M colombianos de boca y tapa basado en un pozo de 9 metros de profundidad, con anillo en concrete reforzado y en una torre de 8 metros hecha de madera rollfza en forma de trIpode con bases de concrete. En la zona de Carimagua se ha estimado el cost0 del molino, hecho por contrato e incluyendo el molino, la excwacl6n de1 pozo, hechura de1 anillo y la tapa en concrcto y la torre en madera rolliza cortada en la finca en $4.500.00 ($225.00 U.S.) No cxisten datos concretes sobre rcndimiento. Se mid16 en forma bastante rlrstica un rendimiento de aproximadamente 500 galones/hora cuando el nivel dcl agua estaba a 8 metros, con un c,i.lindro dc molino de 3" y una brisa estimada de 6-8 Km/hors. La carrera de1 pistbn era de 2 cl-+. Se puede variar la carrera de1 pistbn facilmente sagtin la estaCiblC En apoca de verano cuando hay mucha brisa, parece indicado aumenEn car&lo, en &potar la carrera y asi reducir la velocidad de1 rotor. ca de Lpvierno, es convenicnte reducir la carrera, para qua el molLno COmhaw a b&bear con usu brira ollninu.

Background

Information

on the Brace Research Institute

Brace Research Institute of McGill University was founded in 1959 to develop equipment and techniques for making dry lands available and The Institute has conceneconomically useful for agricultural purposes. trated on tbe problems affecting individuals or small communities in rural areas and is one of the few organizations with this basic objective. equipment developed by this Institute utilizes as many local In general, resources as possible, whether human, energy or material, so that the As a result, the technology can be easily adapted to the local environment. Institute has concentrated on utilizing solar and wind energy as well as concentrating on the problems that simple desalination systems, specifically face isolated rural populations in developing arid areas. Instructional 1) 2) 3) 4) manuals are available describing the use of solar energy for the

heating of water for domestic and commercial use cooking of food drying of agricultural produce desalination of mter for human, animal and agricultural

use.

The adaptation of simple greenhouses combined with solar desalination systems for the production of food and water in arid areas is also being developed. The Institute is also adapting greenhouses to make better use of solar energy to reduce heating costs in colder regions. In addition, simple windmills of water have been developed. Further inquiries for the production to of elecaicity and the pumping

should be directed

Brace Research Institute, Macdonald College of McGill University, Ste. Anne de Bellevue, Quebec, H9X 3M1, Canada. Other leaflets L-l L-2 L-3 L-4 L-5 L-SF L-6 L-7 L-8 L-9 L-10 T-17 available: Make a Solar Still (plastic covered) Rake a Solar Steam Cooker Heat your Swimming Pool using Solar Energy Build a Solar Water Heater Construct a Cheap Wind Machine for Pumping Water version of L-5 Make a Solar Cabinet Dryer for Agricultural Produce Translation of L-6 Translation of L-6 Translation of L-2 Translation of L-6 Solar Still for the Production of Distilled Water* Price $1.25 $1.25 $0.75 $1.25 $1.25 $0.75 $1.25 $1.25 $1.25 $1.25 $1.25 $1.25

How to How to How to How to How to French How to Arabic Spanish French French Simple

Please remit payment with money order or add $0.25 to your cheque for bank handling charges. * Also available in French, Arabic and Spanish.

_ -.

---

You might also like

- Engineering Vol 69 1900-05-25Document31 pagesEngineering Vol 69 1900-05-25ian_newNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Build a 1:100 Scale Bailey Bridge Model in 12 StepsDocument11 pagesBuild a 1:100 Scale Bailey Bridge Model in 12 Stepsgunawan.MSJR gunawan.MSJRNo ratings yet

- TM 9-297A, 3.5 Inch Repeating Rocket Launcher M25Document110 pagesTM 9-297A, 3.5 Inch Repeating Rocket Launcher M25Dæmon PhobosNo ratings yet

- The Low Cost Wooden DuplicatorDocument25 pagesThe Low Cost Wooden DuplicatorSean100% (1)

- TM9 2320 212 10Document161 pagesTM9 2320 212 10rick.mccort2766100% (1)

- Fuel Alcohol ProductionDocument51 pagesFuel Alcohol ProductionplutocowNo ratings yet

- 01 6Document160 pages01 6Steve BarrowNo ratings yet

- PRC 10Document16 pagesPRC 10Robert LiningtonNo ratings yet

- M151 TM - 9-2920-225-34PDocument17 pagesM151 TM - 9-2920-225-34PKiwiBig_DNo ratings yet

- Vickers Automatic Rifle Gun Magazine ExplainedDocument21 pagesVickers Automatic Rifle Gun Magazine ExplainedHanseaticLeague1993100% (1)

- TM 5-1185 1955 Galion RollerDocument449 pagesTM 5-1185 1955 Galion RollerAdvocate100% (1)

- (1944) TM 9-1829a Ordnance Maintenance Speedometers, Tachometers and RecordersDocument167 pages(1944) TM 9-1829a Ordnance Maintenance Speedometers, Tachometers and RecordersHerbert Hillary Booker 2ndNo ratings yet

- Travenol's Finest - 1981 Hays Kansas Employee CookbookDocument109 pagesTravenol's Finest - 1981 Hays Kansas Employee CookbookBeau DealyNo ratings yet

- TM 9-882 7-Ton Semi-Trailer Edwards, Gramm, NaborsDocument90 pagesTM 9-882 7-Ton Semi-Trailer Edwards, Gramm, NaborsAdvocate100% (1)

- M1916 37mm CatalogDocument14 pagesM1916 37mm Catalogtyrant88No ratings yet

- TM11-2201 Reperforator Teletypewriter Sets TG-16 and TG-17Document43 pagesTM11-2201 Reperforator Teletypewriter Sets TG-16 and TG-17david_graves_okstateNo ratings yet

- TM 9 1025 211 34Document697 pagesTM 9 1025 211 34Mark Ab100% (1)

- 42 Small Scale Irrigation DesignDocument4 pages42 Small Scale Irrigation DesignNiiteSajoNo ratings yet

- TM 9-2800 (1943)Document498 pagesTM 9-2800 (1943)degardin lucNo ratings yet

- TM9-1900 Ammunition General, June 1945Document339 pagesTM9-1900 Ammunition General, June 1945Thomas Conroy-RunyonNo ratings yet

- TM 5-3222 Tractor T-9Document298 pagesTM 5-3222 Tractor T-9AdvocateNo ratings yet

- FM 19-1 - 1966Document58 pagesFM 19-1 - 1966DongelxNo ratings yet

- Engine Removal Guide for 1/4-Ton 4x4 TrucksDocument76 pagesEngine Removal Guide for 1/4-Ton 4x4 Trucksgwa4940% (1)

- TM9-238 Deepwater Fording of Ordnance Materiel PDFDocument35 pagesTM9-238 Deepwater Fording of Ordnance Materiel PDFdieudecafeNo ratings yet

- TM-10-8340-221-13 Tent Shelter Half and MountainDocument32 pagesTM-10-8340-221-13 Tent Shelter Half and Mountainc126358100% (1)

- TM9 2320 209 34PDocument1,076 pagesTM9 2320 209 34PMichael ZimmermannNo ratings yet

- Engineering Vol 69 1900-04-06Document35 pagesEngineering Vol 69 1900-04-06ian_new100% (1)

- History Bailey BridgeDocument4 pagesHistory Bailey BridgeMai KawayapanikNo ratings yet

- General Dynamics - Hydra-70 2.75-Inch (70mm) Family of RocketsDocument2 pagesGeneral Dynamics - Hydra-70 2.75-Inch (70mm) Family of RocketsYamvea100% (1)

- TM 9 8240Document229 pagesTM 9 8240UglyGermanNo ratings yet

- Jollystolly - Alvis StalwartDocument155 pagesJollystolly - Alvis StalwarthughneveNo ratings yet

- Ops-Core Dh-132 HelmetDocument4 pagesOps-Core Dh-132 HelmetDenbe SantosNo ratings yet

- 40 MM Antiaircraft Gun - TM 9-1252Document44 pages40 MM Antiaircraft Gun - TM 9-1252tb1905No ratings yet

- Care and Use of Boyar Schultz Model 6-12 Surface GrinderDocument11 pagesCare and Use of Boyar Schultz Model 6-12 Surface GrinderRandyWilsonNo ratings yet

- History Queensland Main Roads Commission 1939-1945Document103 pagesHistory Queensland Main Roads Commission 1939-1945AuldmonNo ratings yet

- TM 9-1750J Power Unit Accessories For Medium Tanks M3A4 and M4A4 1943Document382 pagesTM 9-1750J Power Unit Accessories For Medium Tanks M3A4 and M4A4 1943RobertLockieNo ratings yet

- Del Core My ElectricalDocument56 pagesDel Core My Electricaljohanbl88No ratings yet

- American Farm ToolsDocument127 pagesAmerican Farm ToolsjimborenoNo ratings yet

- Rail Engineering 101Document131 pagesRail Engineering 101Lee WebbNo ratings yet

- 253 Trench MortarDocument56 pages253 Trench MortarkshwookNo ratings yet

- Flame, Riot Control Agent, and Herbicide OperationsDocument52 pagesFlame, Riot Control Agent, and Herbicide OperationsBig VeeNo ratings yet

- TM 9-1774 Snow Tractor M7 and Snow Trailer 1-Ton M19Document91 pagesTM 9-1774 Snow Tractor M7 and Snow Trailer 1-Ton M19Advocate100% (1)

- Ordnance Publications For Supply Index I JUL43 PDFDocument224 pagesOrdnance Publications For Supply Index I JUL43 PDFchfootball25No ratings yet

- TM 9-242 Ordnance ToolsDocument427 pagesTM 9-242 Ordnance ToolsedrestNo ratings yet

- Handbook of Artillery - Including Mobile, Anti-Rcraft and Trench Matriel - United States. Army. Ordnance DeptDocument398 pagesHandbook of Artillery - Including Mobile, Anti-Rcraft and Trench Matriel - United States. Army. Ordnance DeptoraberaNo ratings yet

- Development of A Multifuel StoveDocument64 pagesDevelopment of A Multifuel StoveSimonASLNo ratings yet

- Powerengineering201512 DLDocument53 pagesPowerengineering201512 DLjosetxoxNo ratings yet

- FM55-15 Transportation Corps Reference DataDocument436 pagesFM55-15 Transportation Corps Reference DatadieudecafeNo ratings yet

- TM9 335Document240 pagesTM9 335Julio Marcelo100% (1)

- Engineering Vol 72 1901-12-13Document33 pagesEngineering Vol 72 1901-12-13ian_newNo ratings yet

- TM9-424 6inch Gun M1900 Barbette M1900Document140 pagesTM9-424 6inch Gun M1900 Barbette M1900packardv12No ratings yet

- TM 9-726 (Light Tank M3) PDFDocument253 pagesTM 9-726 (Light Tank M3) PDFferdockmNo ratings yet

- A Project of Volunteers in Asia: Yuekjf?CDocument16 pagesA Project of Volunteers in Asia: Yuekjf?CmeineanmeldungenNo ratings yet

- Metal Turning LatheDocument12 pagesMetal Turning LatheEugen50% (2)

- How To Run A Lathe 1966 Pt1 PDF1 PDFDocument22 pagesHow To Run A Lathe 1966 Pt1 PDF1 PDFSergio Gon100% (1)

- Ram Pump DTU S1Document12 pagesRam Pump DTU S1Andri Betmanto100% (1)

- Numerical Tools For The Computation of Homoclinic/heteroclinic OrbitsDocument40 pagesNumerical Tools For The Computation of Homoclinic/heteroclinic OrbitsSeanNo ratings yet

- Space Settlements: A Design StudyDocument297 pagesSpace Settlements: A Design StudySean100% (1)

- Metal - Ferrous MaterialsDocument30 pagesMetal - Ferrous MaterialsSeanNo ratings yet

- Bicycle AmbulanceDocument9 pagesBicycle AmbulanceSean100% (1)

- Small Scale BrickmakingDocument216 pagesSmall Scale BrickmakingSean100% (1)

- How To Use Metal TubingDocument8 pagesHow To Use Metal TubingSeanNo ratings yet

- Construction GluesDocument5 pagesConstruction GluesSean100% (1)

- The Design and Manufacture of Low-Cost Motorized VehiclesDocument198 pagesThe Design and Manufacture of Low-Cost Motorized VehiclesSeanNo ratings yet

- Workshop Equipment: How To Make 12 Woodworking ToolsDocument110 pagesWorkshop Equipment: How To Make 12 Woodworking ToolsSean100% (1)

- Foundry Work For The Amateur 1975Document116 pagesFoundry Work For The Amateur 1975Rob Furnald100% (3)

- 3 Welding Jigs: ITDG Complete Technical Drawing #19Document9 pages3 Welding Jigs: ITDG Complete Technical Drawing #19SeanNo ratings yet

- Cattail ChemurgyDocument6 pagesCattail ChemurgySeanNo ratings yet

- Tether Transportation StudyDocument93 pagesTether Transportation StudySeanNo ratings yet

- Manual of Information: RIFE Hydraulic RamDocument19 pagesManual of Information: RIFE Hydraulic RamSean100% (1)

- Composite Materials Handbook Mil-Hdbk-17-5 Volume 5Document260 pagesComposite Materials Handbook Mil-Hdbk-17-5 Volume 5javier_gonzalez_cid8060No ratings yet

- Simple Tin Pump - JavaDocument9 pagesSimple Tin Pump - JavaSeanNo ratings yet

- Basic Principles of Bio Filtration in AquacultureDocument38 pagesBasic Principles of Bio Filtration in AquacultureSeanNo ratings yet

- Piston Water PumpDocument10 pagesPiston Water PumpSeanNo ratings yet

- Reciprocating Wire Power Transmission For Small Water WheelsDocument5 pagesReciprocating Wire Power Transmission For Small Water WheelsSeanNo ratings yet

- The Resonant Structure of Jupiter's Trojan AsteroidsDocument21 pagesThe Resonant Structure of Jupiter's Trojan AsteroidsSeanNo ratings yet

- Strategies For Solar Sail Mission Design in The Circular Restricted Three-Body ProblemDocument141 pagesStrategies For Solar Sail Mission Design in The Circular Restricted Three-Body ProblemSeanNo ratings yet

- Bicycles: A Case Study of Indian ExperienceDocument98 pagesBicycles: A Case Study of Indian ExperienceSeanNo ratings yet

- Microgravity Combustio For Material SynthesisDocument46 pagesMicrogravity Combustio For Material SynthesisSeanNo ratings yet

- Steam Power Quarterly v-XXIXDocument46 pagesSteam Power Quarterly v-XXIXSean100% (2)

- "Symmetry and States of Self Stress in Triangulated Toroidal Frames" by P.W. Fowler and S.D. GuestDocument13 pages"Symmetry and States of Self Stress in Triangulated Toroidal Frames" by P.W. Fowler and S.D. GuestSeanNo ratings yet

- The Sten-Screen Making and Using A Low Cost Printing ProcessDocument18 pagesThe Sten-Screen Making and Using A Low Cost Printing ProcessAndrew AyersNo ratings yet

- Understanding Pedal PowerDocument15 pagesUnderstanding Pedal PowerSean100% (1)

- They May Be Old But They Work - A Solar Food Dryer... by JJDocument2 pagesThey May Be Old But They Work - A Solar Food Dryer... by JJSeanNo ratings yet

- An Amazing 10-Speed Bicycle Wheelbarrow Hybrid for Carrying Heavy LoadsDocument20 pagesAn Amazing 10-Speed Bicycle Wheelbarrow Hybrid for Carrying Heavy LoadsSeanNo ratings yet

- Manual Book KeboDocument42 pagesManual Book KeboUlwan FianiNo ratings yet

- Base Plate Design CapacitiesDocument4 pagesBase Plate Design CapacitiesSrishti Project Consultants0% (1)

- TargetDocument120 pagesTargetrohandiNo ratings yet

- 029D2B0002 (9000B2C) 9710astraluxDocument15 pages029D2B0002 (9000B2C) 9710astraluxAstraluxNo ratings yet

- Prozueb Msp7 Fi01 enDocument2 pagesProzueb Msp7 Fi01 enAgustin BaezNo ratings yet

- 5 Manual de Piezas Terminadora de Asfalto.....Document12 pages5 Manual de Piezas Terminadora de Asfalto.....Franco SartoriNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 pagesRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- GBR SystemDocument16 pagesGBR Systemalexandru lutaNo ratings yet

- Expansion of Osmani International AirportDocument563 pagesExpansion of Osmani International AirportJayampathi AsangaNo ratings yet

- Assistant Engineer in KamcoDocument16 pagesAssistant Engineer in KamcoLearn Mechanical EngineeringNo ratings yet

- Rope Shovels:4100: Description Part No. Bom Qty Current Stock Min Stock For 3 MonthsDocument30 pagesRope Shovels:4100: Description Part No. Bom Qty Current Stock Min Stock For 3 MonthsKobusNo ratings yet

- Caterpillar Cat 225B EXCAVATOR (Prefix 2ZD) Service Repair ManualDocument24 pagesCaterpillar Cat 225B EXCAVATOR (Prefix 2ZD) Service Repair Manualrpoy9396615No ratings yet

- Oculus: Free Plan: Oculus Supercap FFDocument68 pagesOculus: Free Plan: Oculus Supercap FFDarren-Edward O'NeillNo ratings yet

- 2512-Z900RS Frame Slider Set PDFDocument4 pages2512-Z900RS Frame Slider Set PDF孙振立100% (1)

- Laboratory Glassware CatalogueDocument52 pagesLaboratory Glassware CatalogueashkansoheylNo ratings yet

- Parker - Part List - F130CF-F130CPDocument32 pagesParker - Part List - F130CF-F130CPPOIUYTNo ratings yet

- Ugo Basile 7025/7125 Rodent VentilatorDocument38 pagesUgo Basile 7025/7125 Rodent VentilatorNikos Psihalakis100% (1)

- Cooling Gas Compressor (CG 438 J) : Detail Bill of Material (Compressor)Document8 pagesCooling Gas Compressor (CG 438 J) : Detail Bill of Material (Compressor)Haitham AbdEl-TawabNo ratings yet

- Catalogue TubtaraDocument78 pagesCatalogue TubtaraErikas AbepaNo ratings yet

- INS0008 FordAOD KickdownDocument4 pagesINS0008 FordAOD KickdownAndreas HochmeisterNo ratings yet

- Report KamcoDocument17 pagesReport Kamcoshamins123No ratings yet

- Arthrex Ankle ManagementDocument20 pagesArthrex Ankle ManagementNicusor AnghelNo ratings yet

- Bolts and NutsDocument17 pagesBolts and NutsMosa Elnaid Elnaid100% (1)

- Pier Protection Systems at Spans Over Navigable Streams - 2010Document26 pagesPier Protection Systems at Spans Over Navigable Streams - 2010Mike2322No ratings yet

- RATV - Socket Head Fasteners - MetricDocument1 pageRATV - Socket Head Fasteners - MetricGustavo CarvalhoNo ratings yet

- Swivel Flange CalculationsDocument45 pagesSwivel Flange CalculationsFaraj KhalikovNo ratings yet

- Manual de Servicio - Yamaha Fazer FZS600 (1998)Document364 pagesManual de Servicio - Yamaha Fazer FZS600 (1998)Joshua MillerNo ratings yet

- Review - ACFAS Surgical Review BookDocument90 pagesReview - ACFAS Surgical Review BookAndrew Bernhard50% (2)

- Samsung UE40EH5000WDocument49 pagesSamsung UE40EH5000WjokersuNo ratings yet

- BC03 Fire DamperDocument20 pagesBC03 Fire DamperabhishekNo ratings yet