Professional Documents

Culture Documents

TD

Uploaded by

Jaime Arellano HuertaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TD

Uploaded by

Jaime Arellano HuertaCopyright:

Available Formats

TRANSMISSION PRODUCTS

INDEX

DAMPERS/SPACERS

Aluminum 607...................... VIBRATION DAMPER 4R STOCKBRIDGE.................................................... TD-2

January 2012

HUBBELL Power Systems

DAMPERS/SPACERS VIBRATION DAMPER 4R STOCKBRIDGE

TD-1

Fargo 4-R vibration dampers effectively prevent fatigue damage to conductor and static wires caused by windinduced aeolian vibration. The 4-R concept improves on the design of the basic Stockbridge damper, significantly increasing the efficiency of converting wind-induced energy into heat. The improved design employs unequal weights on messengers of unequal length. This config- uration doubles the number of resonant peaks from two generated by the old-style Stockbridge damper to four in the improved Fargo 4-R. These additional resonant peaks create an envelope of dynamic response that protects the conductor through the en- tire range of dangerous vibration frequencies. To assure maximum performance, Fargo utilizes a sophisticated computer simulation whose development has been verified by decades of testing and field measurements. This computer model identifies the optimum damper placement on the span. FARGO 4-R VIBRATION DAMPER SYSTEM PROVIDES YOU...

Maximum Protection From WindInduced Conductor Bending Strain The four-resonant peaks include two separate cantilever response modes and two separate rotational response modes of the weight and messenger cable. These peaks also provide maximum energy dissipation to reduce strain over the entire spectrum of dangerous wind velocities Wide frequency response range optimizes protection of your system Large 19 strand wire and tight strand lay dissipate energy more efficiently Press fit permanent weight attachment technique assures long-term performance Contoured surfaces prevent corona discharge

Comprehensive Application Program For Optimum Performance Provides precise selection and placement through our proprietary computer simulation Computer program based on a mathematical model verified by decades of laboratory testing and field vibration measurements Precisely identifies the vibration performance characteristics of transmission lines Determines dangerous frequencies for existing or proposed spans Identifies the frequency range requiring damper protection Identifies proper damper placement for required energy dissipation Optimizes placement based on tension and span length Vibration analysis, with damper size and placement recommendation, provided on request. Contact your Hubbell Power Systems sales representative for details.

ANDERSON

HUBBELL POWER SYSTEMS

FARGO

JANUARY 2012

ALUMINUM

607

DAMPERS/SPACERS VIBRATION DAMPER 4R STOCKBRIDGE

Fargo 4-R vibration dampers effectively prevent fatigue damage to conductor and static wires caused by windinduced aeolian vibration.

TD-2

Messenger Cable: Materials and stranding are selected to obtain the best energy absorption characteristics. The galvanized steel messenger is manufactured to rigid engineering standards.

Weights: Uniquely shaped so that the resonant peaks are effectively distributed over the desired frequency range. All weights are given a corrosion-resistant finish and have smooth surfaces and rounded edges to eliminate possible corona discharge.

Clamp: The bolted clamp permits easy installation on a wide range of conductor sizes. Minimum distortion of conductor strands is controlled by careful anvil and keeper design.

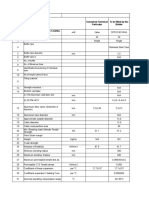

DAMPER SELECTION CABLE DIA. RANGE (2) CATALOG NUMBER(1) IN. MM 607048 607051011 6070511 6071012 6071513 6072014 0.250 to 0.438 0.439 to 0.858 0.610 to 0.858 0.859 to 1.130 1.131 to 1.425 1.426 to 1.770 6.35 to 11.12 11.12 to 21.8 15.5 to 21.8 21.8 to 28.7 28.7 to 36.2 36.2 to 44.9

CLAMPING BOLT TORQUE FT-LB 20 25 25 25 25 40

DIMENSIONS IN (MM) A 11.1 (282) 16.1 (409) 16.1 (409) 20.0 (508) 21.9 (556) 24.0 (610) B 2.38 (60) 2.69 (68) 3.18 (81) 2.91 (74) 3.78 (96) 5.92 (150) C 1.75 (44) 1.75 (44) 1.75 (44) 2.26 (57) 2.82 (72) 3.54 (90)

WEIGHT EACH LB (KG) 2.8 (1.3) 4.8 (2.2) 4.8 (2.2) 9.0 (4.1) 15.7 (7.1) 22.0 (10)

STD PKG 10 6 6 6 4 3

(1) To specify Torque Head / Break Away bolt option, add suffix O to catalog number. (2) Optimum cable range limits. Physical clamp range slightly larger.

JANUARY 2012

ANDERSON

HUBBELL POWER SYSTEMS

FARGO

39

4-R DAMPER INSTALLATION INSTRUCTIONS FOR VIBRATION DAMPERS

TD-3

1. Dampers shall be located from the center of the damper clamp to either the dead end or the suspension support as shown above. 2. The orientation of the damper weights along the conductor is optional. For convenience, orient the damper such that the clamp bolt head faces the installer. 3. When only one damper is required per conductor per span, it can be installed at either span extremity when the support hardware is identical. When support hardware differs, place the damper at the suspension structure. 4. When two dampers are required per conductor per span, the preferred placement is one at each span extremity.

ANDERSON

40

HUBBELL POWER SYSTEMS

FARGO

JANUARY 2012

You might also like

- VORTXcatpgDocument5 pagesVORTXcatpgJaime Arellano HuertaNo ratings yet

- Spiral Vibration Damper (PSVD)Document4 pagesSpiral Vibration Damper (PSVD)Jesus VaraNo ratings yet

- Plastic Tubings and ConnectorsDocument44 pagesPlastic Tubings and ConnectorskingoglobalNo ratings yet

- HECO ESIM 7th EditionDocument127 pagesHECO ESIM 7th EditionChristopher J LovettNo ratings yet

- Metal Conduits and ConnectorsDocument28 pagesMetal Conduits and ConnectorskingoglobalNo ratings yet

- Insulated and Non-Insulated Cable ConnectorsDocument24 pagesInsulated and Non-Insulated Cable ConnectorskingoglobalNo ratings yet

- Cable GlandsDocument22 pagesCable GlandskingoglobalNo ratings yet

- Dampers and Preformed RodsDocument8 pagesDampers and Preformed RodsJaime Arellano HuertaNo ratings yet

- Cable Joints, Terminations, Bushings & AccessoriesDocument2 pagesCable Joints, Terminations, Bushings & AccessoriesAnonymous N13JdnNo ratings yet

- Burndy Substation Catalog-Copper ProductsDocument185 pagesBurndy Substation Catalog-Copper Productsyesrty100% (1)

- Current Cycle Data SheetDocument7 pagesCurrent Cycle Data SheetJosé Antonio Segura SalgadoNo ratings yet

- Figure 8 Cable AccessoriesDocument5 pagesFigure 8 Cable AccessorieskingoglobalNo ratings yet

- Tubing AccessoriesDocument29 pagesTubing AccessorieskingoglobalNo ratings yet

- Is 4759 1996 PDFDocument12 pagesIs 4759 1996 PDFSandeep SundriyalNo ratings yet

- WA Distribution Connections ManualDocument318 pagesWA Distribution Connections ManualAllyMyallNo ratings yet

- Aluminium Compression Lugs and JointsDocument8 pagesAluminium Compression Lugs and JointskingoglobalNo ratings yet

- Ribe S D P Y I: Pacer Ampers Rotect OUR NvestmentDocument8 pagesRibe S D P Y I: Pacer Ampers Rotect OUR NvestmentArchit JhunjhunwalaNo ratings yet

- WGR 273 1Document5 pagesWGR 273 1jan rogerNo ratings yet

- ASTM A656 Grade 50: General Product DescriptionDocument1 pageASTM A656 Grade 50: General Product DescriptionHarsh ChopraNo ratings yet

- PLP - Dogbone Vibration DamperDocument5 pagesPLP - Dogbone Vibration DamperHFandino1100% (1)

- BS 64 1992Document15 pagesBS 64 1992gt24designerNo ratings yet

- CSA FastenersDocument7 pagesCSA FastenersBarnabás KissNo ratings yet

- 3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPDocument24 pages3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPAnonymous 4kYNmixNo ratings yet

- LS Catalogue HCCDocument10 pagesLS Catalogue HCCVICTOR JOSE VILORIANo ratings yet

- AAAC - All Aluminum Alloy 6201 Conductor PDFDocument1 pageAAAC - All Aluminum Alloy 6201 Conductor PDFsualehnavedNo ratings yet

- Aluminium Uses in Electrical EngineeringDocument7 pagesAluminium Uses in Electrical EngineeringTigrilloNo ratings yet

- ANSI-NEMA GR1-2007 - FinalDocument27 pagesANSI-NEMA GR1-2007 - FinalJunior AvalosNo ratings yet

- AISI 1038 Carbon Steel Properties GuideDocument3 pagesAISI 1038 Carbon Steel Properties Guidesingaravelan narayanasamy100% (1)

- Transpowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-StrandedDocument18 pagesTranspowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-Strandedravi474No ratings yet

- Al-Mg-Si Alloy Wire PDFDocument12 pagesAl-Mg-Si Alloy Wire PDFgvsbabu63No ratings yet

- Sanjay Conductors & Cables: An ISO: 9001: 2008 Certified CompanyDocument5 pagesSanjay Conductors & Cables: An ISO: 9001: 2008 Certified CompanySanjay ConductorsNo ratings yet

- Line Materials & Stringing in 400KV LinesDocument20 pagesLine Materials & Stringing in 400KV LinesbijoyNo ratings yet

- Bimetallic Compression Lugs and JointsDocument11 pagesBimetallic Compression Lugs and JointskingoglobalNo ratings yet

- Arial Bunch ConductorDocument10 pagesArial Bunch Conductorbbakari2000No ratings yet

- SANS-1431 Withdrawal (2010)Document1 pageSANS-1431 Withdrawal (2010)Darryl007No ratings yet

- Olex Arial CatalogueDocument15 pagesOlex Arial CatalogueMike WesleyNo ratings yet

- Trefoil and Single Cable Cleats Type SmartcleatDocument12 pagesTrefoil and Single Cable Cleats Type SmartcleatfndprojectNo ratings yet

- Aluminium Conductor Composite Core ACCCDocument5 pagesAluminium Conductor Composite Core ACCCAmlanshankar Deb BarmaNo ratings yet

- AL59 157 SQMM Transmission Line SpecificationDocument2 pagesAL59 157 SQMM Transmission Line SpecificationMohamed RafiNo ratings yet

- Lecture 1-Introduction To Structural Steel Sections and PropertiesDocument20 pagesLecture 1-Introduction To Structural Steel Sections and Propertiesrenjith037No ratings yet

- Lightning Protection SystemDocument5 pagesLightning Protection SystemRifki FathurrahmanNo ratings yet

- IS 802 Part-1 Sec-1 DRAFT 12oct11 PDFDocument24 pagesIS 802 Part-1 Sec-1 DRAFT 12oct11 PDFRohit DeraNo ratings yet

- astm (미국재료표준협회) 분류표 - 부분10 PDFDocument2 pagesastm (미국재료표준협회) 분류표 - 부분10 PDFJaeup YouNo ratings yet

- Oman Cable Over Head Cable Spec 20-4Document34 pagesOman Cable Over Head Cable Spec 20-4harishpandyanNo ratings yet

- (Catalogue) HTLSC Ver.2Document28 pages(Catalogue) HTLSC Ver.2Huy Thông NguyễnNo ratings yet

- A 108 - 99 - Qtewoc05oqDocument4 pagesA 108 - 99 - Qtewoc05oqvhenriquezmNo ratings yet

- 1LCA000003-LTE SinglePh Overhead 10kVA 167kVA Rev01Document4 pages1LCA000003-LTE SinglePh Overhead 10kVA 167kVA Rev01thapa786mNo ratings yet

- PLP INDONESIA Product - Showcase - April - May - 2020 - 2 Edit55Document11 pagesPLP INDONESIA Product - Showcase - April - May - 2020 - 2 Edit55Turinto MarjonoNo ratings yet

- Overhead Conductors Trefinasa 2016webDocument52 pagesOverhead Conductors Trefinasa 2016weboaktree2010No ratings yet

- OPGW GTP of Various VendorsDocument19 pagesOPGW GTP of Various VendorsRamphani Nunna100% (1)

- HTLSC STACIR Rev1 PDFDocument22 pagesHTLSC STACIR Rev1 PDFShuvan MabuNo ratings yet

- Stockdamper BridgeDocument3 pagesStockdamper BridgePavan KhetrapalNo ratings yet

- LMR 600Document4 pagesLMR 600Edytryk MghbjNo ratings yet

- Electric Poker Vibrators GuideDocument8 pagesElectric Poker Vibrators GuideIgor Halterbeck HalterbeckNo ratings yet

- Our Mission: The Coax LeaderDocument3 pagesOur Mission: The Coax LeaderArindam BanerjeeNo ratings yet

- L6 L8 Spec Sheet PDFDocument4 pagesL6 L8 Spec Sheet PDFpurnimaNo ratings yet

- NAM Cat CombinedCh1Document16 pagesNAM Cat CombinedCh1Thanh Do VanNo ratings yet

- SR 4Document12 pagesSR 4Parker333No ratings yet

- Steel Wood Equivalent Catalog - ValmontDocument28 pagesSteel Wood Equivalent Catalog - Valmontmrjack1No ratings yet

- ACA DampersDocument24 pagesACA DampersHFandino1No ratings yet

- PRUEBA DIAGNOSTICO Interacción Inicial en InglesDocument2 pagesPRUEBA DIAGNOSTICO Interacción Inicial en InglesJaime Arellano HuertaNo ratings yet

- SIemens TimerDocument4 pagesSIemens Timervaithy1990No ratings yet

- 04113009Document10 pages04113009Jaime Arellano HuertaNo ratings yet

- Dampers and Preformed RodsDocument8 pagesDampers and Preformed RodsJaime Arellano HuertaNo ratings yet

- Ingles Segunda ParteDocument17 pagesIngles Segunda ParteJaime Arellano HuertaNo ratings yet

- Finite Element Analysis of A Single Conductor With A Stockbridge Damper Under Aeolian VibrationDocument135 pagesFinite Element Analysis of A Single Conductor With A Stockbridge Damper Under Aeolian VibrationMichael ClarkNo ratings yet

- 00027776Document14 pages00027776Jaime Arellano HuertaNo ratings yet

- I. Complete The Following Dialogue With YOUR InformationDocument3 pagesI. Complete The Following Dialogue With YOUR InformationJaime Arellano HuertaNo ratings yet

- Vibration Damping For Overhead LinesDocument7 pagesVibration Damping For Overhead LinesJaime Arellano HuertaNo ratings yet

- 00027776Document14 pages00027776Jaime Arellano HuertaNo ratings yet

- 04073782Document31 pages04073782Jaime Arellano HuertaNo ratings yet

- 00027776Document14 pages00027776Jaime Arellano HuertaNo ratings yet

- Stockbridge DamperDocument17 pagesStockbridge Damperjobpei2No ratings yet

- Examen Ingles SecundariaDocument32 pagesExamen Ingles SecundariaJaime Arellano HuertaNo ratings yet

- Dampers and Preformed RodsDocument8 pagesDampers and Preformed RodsJaime Arellano HuertaNo ratings yet

- Examen Ingles SecundariaDocument28 pagesExamen Ingles SecundariaJaime Arellano Huerta50% (2)

- 121 Wcndtfinal00121Document10 pages121 Wcndtfinal00121Jaime Arellano HuertaNo ratings yet

- Transmission Asia4 6Document2 pagesTransmission Asia4 6Jaime Arellano HuertaNo ratings yet

- 121 Wcndtfinal00121Document10 pages121 Wcndtfinal00121Jaime Arellano HuertaNo ratings yet

- 003 Elkin SarahDocument1 page003 Elkin SarahJaime Arellano HuertaNo ratings yet

- Transmission Asia4 6Document2 pagesTransmission Asia4 6Jaime Arellano HuertaNo ratings yet

- 659398Document8 pages659398Jaime Arellano HuertaNo ratings yet

- 121 Wcndtfinal00121Document10 pages121 Wcndtfinal00121Jaime Arellano HuertaNo ratings yet

- 94 Analysis of Vibrational DampersDocument24 pages94 Analysis of Vibrational DampersJaime Arellano HuertaNo ratings yet

- 121 Wcndtfinal00121Document10 pages121 Wcndtfinal00121Jaime Arellano HuertaNo ratings yet

- 121 Wcndtfinal00121Document10 pages121 Wcndtfinal00121Jaime Arellano HuertaNo ratings yet

- 003 Elkin SarahDocument1 page003 Elkin SarahJaime Arellano HuertaNo ratings yet

- Complete trip-free loop, PFC and PSC testerDocument2 pagesComplete trip-free loop, PFC and PSC testerGermanilloZetaNo ratings yet

- XI-Opt. Syllabus (2023-24)Document29 pagesXI-Opt. Syllabus (2023-24)INDERDEEPNo ratings yet

- Digital Image Processing TechniquesDocument34 pagesDigital Image Processing Techniquesaishuvc1822No ratings yet

- Solidworks Flow SimulationDocument7 pagesSolidworks Flow SimulationpatrickNX94200% (1)

- Connective TissueDocument6 pagesConnective TissuecrtgyhujikNo ratings yet

- Activity No. 5 Capacitive Circuit ObjectivesDocument4 pagesActivity No. 5 Capacitive Circuit ObjectivesJohn Paul BaquiranNo ratings yet

- Arm Assembly Language ProgrammingDocument170 pagesArm Assembly Language ProgrammingAnup Kumar Yadav100% (4)

- Tutorial - Lecture 3 SolutionsDocument10 pagesTutorial - Lecture 3 SolutionsBastián Olfos MárquezNo ratings yet

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcNo ratings yet

- Compact GSM II: Installation and Application ManualDocument22 pagesCompact GSM II: Installation and Application ManualleonardseniorNo ratings yet

- Er DiagramsDocument20 pagesEr DiagramsMatthew BloomfieldNo ratings yet

- Work MeasurementDocument15 pagesWork MeasurementBalaji BabuNo ratings yet

- 3G Commands in EricssonDocument2 pages3G Commands in EricssonKeshav Singh0% (1)

- It Tigear2Document2 pagesIt Tigear2rrobles011No ratings yet

- Business Analyst TrainingDocument3 pagesBusiness Analyst TrainingMuniswamaiah Mohan100% (1)

- B. Solving Quadratic EquationsDocument23 pagesB. Solving Quadratic EquationsHasnain -GamerNo ratings yet

- Second Mid Term CE 461: Structural Analysis II: Student Name: Student No.: Section: 9 10 11 12Document4 pagesSecond Mid Term CE 461: Structural Analysis II: Student Name: Student No.: Section: 9 10 11 12David Olorato NgwakoNo ratings yet

- Waterproof BoxDocument129 pagesWaterproof BoxVenkata Narayana BoddapatiNo ratings yet

- Gpa Calculation SheetDocument1 pageGpa Calculation SheetIryna HoncharukNo ratings yet

- The BCA (1) 23Document36 pagesThe BCA (1) 23Aurobind DasNo ratings yet

- Eps Manual NissanDocument8 pagesEps Manual Nissanjoiler pajueloNo ratings yet

- Insertion Appointment of Complete Dentures: Lec 17 4 GradeDocument15 pagesInsertion Appointment of Complete Dentures: Lec 17 4 GradeSaif Hashim100% (1)

- Fulltext PDFDocument454 pagesFulltext PDFVirmantas JuoceviciusNo ratings yet

- Writing Iap Smarten Up in Maths Age 7 8Document38 pagesWriting Iap Smarten Up in Maths Age 7 8lphoune100% (1)

- Oracle Coherence Admin GuideDocument156 pagesOracle Coherence Admin Guidegisharoy100% (1)

- Analysis of Rack and Pinion Using AnsysDocument21 pagesAnalysis of Rack and Pinion Using AnsysTejas Prakash100% (1)

- Post GreeDocument15 pagesPost GreeDwi PraptiNo ratings yet

- Compressed Air Operated Vacuum Waste Removal: Systems and ComponentsDocument20 pagesCompressed Air Operated Vacuum Waste Removal: Systems and ComponentsDaniel RukawaNo ratings yet

- Design of Weirs and BarragesDocument42 pagesDesign of Weirs and BarragesDivyaSlp100% (2)