Professional Documents

Culture Documents

Proteccion de Almacenaje de Plasticos

Uploaded by

Jose Gregorio Prada RodriguezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proteccion de Almacenaje de Plasticos

Uploaded by

Jose Gregorio Prada RodriguezCopyright:

Available Formats

Sprinkler Protection Criteria for Exposed Expanded Group A Plastics Project Summary Background NFPA 13, Standard for

the Installation of Sprinkler Systems, has limited information regarding protection criteria for Exposed Expanded Group A plastic commodity stored on racks. There is an important present need for protection criteria for this type of commodity, since it presents a significant fire hazard and is stored in many warehouse and retail buildings. At the 2008 meeting of the Foundations Automatic Sprinkler Research Planning Council, this topic was identified as an area where additional research is needed to inform provisions of NFPA 13. At the Councils 2011 meeting, the topic was identified at or near the top of the priority list of projects with a particular focus on results needed for the next edition of the Standard. Although there is a broad range of criteria needed, the particular focus of this project was rack storage of this commodity with protection solutions which do not involve in rack sprinklers, to improve the flexibility of this storage protection configuration. Previous testing by Viking Corporation in Europe showed successful performance with ceiling only K19 sprinkler protection at 40-50 psi design pressure for 40 foot storage of actual mixed commodity (candles, foam slabs, cardboard boxes) in a non standard rack configuration with vertical barriers interspersed in the rack at approximately 20 foot on center.

Research Objective To develop cost effective sprinkler protection criteria for rack storage of exposed expanded Group A plastic commodity with a particular focus on ceiling only protection.

Project Execution A Project Technical Panel was formed and met four times during 2012 to develop a proposed test plan and review and revise that plan during the course of its conduct. Project Technical Panel Ken Linder, Swiss Re (Chair NFPA Sprinkler System Discharge Criteria Technical Committee) Rich Pehrson, (International Fire Marshals Association) Jason Huczek, Southwest Research Institute John Denhardt, Strickland Fire Protection Steve Wolin, Code Consultants, Inc. Matt Klaus, NFPA Staff Liaison Project Contractor Underwriters Laboratories Dan Steppan, Kerry Bell Project Sponsor Representatives IKEA - Tom Pedersen, Jan Lagerblad Viking Sprinkler Scott Franson Reliable Sprinkler Tom Multer Tyco Fire and Building Products James Golinveaux XL Insurance Pete Willse Property Insurance Research Group Rich Gallagher (Zurich Insurance) P&G - Christina Francis Target Karen Rebman Aon Insurance Tom Lentz

Discussion of Results

In total, six full scale tests were conducted with various combinations of ceiling and commodity height, horizontal transverse flue space blocking, placement and type of vertical barriers, sprinkler type, and ignition location. All tests used standard exposed expanded Group A plastic commodity (expanded polystyrene meat trays) stored in

plastic bags and resting on two-way entry, hardwood pallets). With the horizontal blocking of transverse flue spaces, the length of the main storage arrays was extended beyond the normal 32 ft. to obtain useful data relative to evaluating the potential for horizontal travel of fire to the extremities of the test array. Table 1 summarizes the test parameters and the test results. A fully detailed test report has been prepared by UL LLC and is available on the Foundations website. Innovative testing methods were used to conserve the costly standard expanded plastics commodity. Two of the six tests conducted met the pre established criteria of prevention of fire spread to the end of the array or to the target array. (All of the tests met the pre established criteria for peak steel temperature above the ignition source.) The following observations were made during the test program which may inform future work: Vertical barriers in the commodity had a significant positive impact by limiting the horizontal spread of fire along the commodity array. Both non combustible and combustible (3/8 plywood) barriers demonstrated the ability to maintain their integrity during the fire test series. The fire in the main test bay breached at least one of the vertical barriers placed closest to the ignition location in each test by travelling around the barrier at the aisle face where the commodity extended approximately 4 inches beyond the face of the barriers. However, the horizontal progress of the fire down the length of the racks was delayed by the barriers and helped enable the sprinkler system to control the fire spread. The horizontal blocking of transverse flue spaces reduced the ability of the sprinkler system to effectively discharge water into the blocked flue spaces and limit the horizontal travel of fire. 8 foot aisle widths were a significant factor in the prevention of aisle jump in the first four tests; a wider aisle width (as used in the previous European test series) may have a further positive effect. In the tests where aisle jump occurred, the sprinkler activation pattern contributed to fire spread across the aisle. Other variables observed to significantly impact the performance of the protection scheme include: o sprinkler type which influenced penetration in the commodity and activation sequence; o ceiling height and clearance to the commodity which did not influence actuation time significantly but did influence water penetration and number of operated sprinklers; and o ignition location relative to the sprinklers, which significantly influenced activation pattern and fire control.

Potential Future Studies Future protection options which may be explored are lower storage and ceiling heights, larger aisle widths, reduced transverse flue space blocking, a more limited set of exposed expanded Group A plastic commodities, and other protection schemes including the option of a single horizontal barrier within the rack with enhanced in-rack sprinkler protection at one level immediately below the barrier.

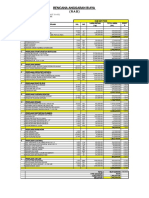

Table 1. Test Parameters and Results

FIRE TEST NUMBER Test Date Storage Type Commodity Type Pallet Type Vertical Barriers Horizontal Blocking of Transverse Flues in Main Array (noncombustible) Length of Main Storage Array, ft. Nominal Storage Height, ft. Ceiling Height, ft. Nominal Clearance, ft. Aisle Width, ft. Ignition Location Sprinkler Systems Sprinkler Orientation Deflector to Ceiling, in.

Sprinkler Spacing, sprinkler by branchline ft. by ft.

16 ft. on center Main Array (Noncombustible)

18 flues inside vertical barriers

Test 1

July 9, 2012

Test 2

July 13, 2012

Test 3

July 18, 2012

Test 4

July 25, 2012

Test 5

October 31, 2012

Test 6

November 8, 2012

Test Parameters Double Row Rack Exposed Expanded Group A Plastic

(Bagged Meat Trays on Hardwood Pallets)

2 way entry, stringer, hardwood

16 ft. on center - Main Array (Noncombustible)

12 flues inside vertical barriers None at uprights

16 ft. on center - Main Array (Noncombustible)

72 flues - None at the uprights and vertical barriers

20 ft. on center - Main Array (Noncombustible)

60 flues - None at the uprights and vertical barriers

24 ft. on center - Main Array (3/8 in. plywood)

98 flues - None at the uprights and vertical barriers

16 ft. on center Main Array (3/8 in. plywood)

60 flues - None at the uprights and vertical barriers

32 20 40 20

32 20 40 20

56 35 40 5

68 30 35 5

56 40 45 5

56 30 40 10

8 Between 2 Sprinklers (offset) Under 1 Sprinkler (offset) Ceiling Only (no in-rack sprinklers) Pendent 14 10 by 10 212 22.4 1.58 50 214 25.2 1.95 60 Test Results 214 25.2 1.95 60 212 ESFR 16.8 1.19 - 0.99

50 psig first 6 sprinklers then 35 psig for remainder of operating sprinklers

Temperature Rating, F Sprinkler Type

Nominal Sprinkler Discharge Coefficient K, gpm/psig 0.5

214 25.2 1.95 60

214 25.2 1.95 60

Nominal Discharge Density, gpm/ft2 Nominal Discharge Pressure, psig

Length of Test, minutes First Sprinkler Operation Time, min:sec Last Sprinkler Operation Time, min:sec Number of Operated Sprinklers

Peak Gas Temperature at Ceiling Above Ignition, F Maximum 1 minute Average Gas Temperature at Ceiling Above Ignition, F Peak Steel Temperature at Ceiling Above Ignition, F Maximum 1 minute Average Steel Temperature at Ceiling Above Ignition, F

31 0:39 8:23 12 564 255 126 124

None Yes (East and West end of Main)

31 0:44 3:21 6 558 220 119 117

None Yes (West end of Main)

31 0:52 1:45 10 1138 353 145 141

None

31 0:47 2:44 16 1163 496 164 164

None

31 0:47 1:39 18 1002 489 160 156

1:01 (North Target)

Yes (North Target Array Burned Through to Extremities)

31 0:48 4:35 11 241 151 129 127

1:27 (South Target)

Yes (South Target Array Burned Through to Extremities)

Ignition Time of Target Array, minutes:seconds Fire Travel to Extremities of Test Array

No

No

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PRICE ACTION PROTOCOL SifuDocument283 pagesPRICE ACTION PROTOCOL SifuMuhammad Khairul Anwar100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Solution Wilkerson CompanyDocument10 pagesSolution Wilkerson CompanyHIMANSHU AGRAWAL67% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 27 Pratap Waghmare Zerodha Case StudyDocument20 pages27 Pratap Waghmare Zerodha Case Studypratap waghmare0% (1)

- Bollinger BandsDocument6 pagesBollinger Bandsvvpvarun0% (1)

- Wall S T. CH Eat Sheet: Q&A SeriesDocument7 pagesWall S T. CH Eat Sheet: Q&A Seriessuryareet22No ratings yet

- Evaporation Rate of SolventsDocument2 pagesEvaporation Rate of SolventsLjupco Aleksov88% (8)

- PROJECT REPORT OF Angel BrokingDocument57 pagesPROJECT REPORT OF Angel BrokingChandrakant80% (5)

- Novice HedgeDocument97 pagesNovice Hedgevamsi kumar100% (2)

- Sprinkler Protection For High Bay and Automated Storage in Warehouse Type Storage FacilitiesDocument11 pagesSprinkler Protection For High Bay and Automated Storage in Warehouse Type Storage FacilitiesJose Gregorio Prada RodriguezNo ratings yet

- Smith - 2017 - The Concepts of Devaluation, Valorization and DeprDocument16 pagesSmith - 2017 - The Concepts of Devaluation, Valorization and DeprRMADVNo ratings yet

- RAB Rumah Subsidi Type 30Document1 pageRAB Rumah Subsidi Type 30Soerja Soengoehta100% (4)

- UNIT II Exercises SolutionsDocument8 pagesUNIT II Exercises Solutionsvajra1 1999No ratings yet

- Model ESFR 25 - PR 11 16 12Document1 pageModel ESFR 25 - PR 11 16 12Jose Gregorio Prada RodriguezNo ratings yet

- 150 H ESFR Early Suppression Fast ResponseDocument2 pages150 H ESFR Early Suppression Fast ResponseJose Gregorio Prada RodriguezNo ratings yet

- Rociadores k25 en Techos Hasta 18mtsDocument11 pagesRociadores k25 en Techos Hasta 18mtsJose Gregorio Prada RodriguezNo ratings yet

- Chapter Ten: Derivative Securities MarketsDocument22 pagesChapter Ten: Derivative Securities MarketsknicknicNo ratings yet

- Part2-EquityInvestmentsAsAHedgeAgainst LazardResearchDocument7 pagesPart2-EquityInvestmentsAsAHedgeAgainst LazardResearchLen RittbergNo ratings yet

- Managerial EconomicsDocument3 pagesManagerial EconomicsRushi GawasNo ratings yet

- LME Steel Scrap FactsheetDocument2 pagesLME Steel Scrap FactsheetMark D.No ratings yet

- Entry Point Take Profit and Stop LossDocument2 pagesEntry Point Take Profit and Stop LossJay R Fuenzalida ValerosoNo ratings yet

- Revenue Curves Under Perfect CompetitionDocument10 pagesRevenue Curves Under Perfect CompetitionGhalib HussainNo ratings yet

- Broken by Broker While Trading? Don'T Worry, Zerodha Is Here !!!Document2 pagesBroken by Broker While Trading? Don'T Worry, Zerodha Is Here !!!faradayNo ratings yet

- Historical DataDocument48 pagesHistorical DataNouman ShafqatNo ratings yet

- Cambridge-IELTS Test Practice 1Document4 pagesCambridge-IELTS Test Practice 1Nisaul FadillahNo ratings yet

- Pivot Point Trading Strategy GuideDocument12 pagesPivot Point Trading Strategy Guideforstermakhado492No ratings yet

- Chem 1 - APIC Phenol Presentation May 2014Document27 pagesChem 1 - APIC Phenol Presentation May 2014singhkamalpNo ratings yet

- Bfa Free Ebook - ClassDocument19 pagesBfa Free Ebook - ClassAdeayo SegunNo ratings yet

- Tutorial 1 QuestionsDocument3 pagesTutorial 1 Questionsguan junyanNo ratings yet

- Chemical Conversion Factors TecnonDocument4 pagesChemical Conversion Factors TecnontotpityiNo ratings yet

- ICT Forex - The Weekly Bias - Excellence in Short Term TradingDocument8 pagesICT Forex - The Weekly Bias - Excellence in Short Term TradingOG BerryNo ratings yet

- Logistics Assignment 2.0Document6 pagesLogistics Assignment 2.0yonelaNo ratings yet

- Market Demand, Market Supply, and Market Equilibrium: What I KnowDocument2 pagesMarket Demand, Market Supply, and Market Equilibrium: What I KnowLaarnie QuiambaoNo ratings yet

- Light Sweet Crude Oil (WTI) Futures and Options: How The World AdvancesDocument16 pagesLight Sweet Crude Oil (WTI) Futures and Options: How The World AdvancesDark CygnusNo ratings yet

- Interthane 990 BM PrintDocument9 pagesInterthane 990 BM Printmiqa sunaloiusNo ratings yet