Professional Documents

Culture Documents

Reactive - Adv Dye

Uploaded by

kanji63Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reactive - Adv Dye

Uploaded by

kanji63Copyright:

Available Formats

Advances in Colour Scienceand Technotogy Volume 7 Number 1January.

2004 @ Universrtl- of Leeds

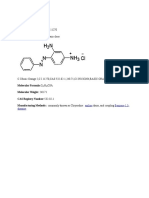

Iron complexes of reactive azo dyes

R Hrdina*, D LuStinec, P Stolin, L Burgert, S Lun6k Jr. and M Holdapek Faculty of chernical rechtr.ology, uniuersity of Pardubice, czech Republic

* Author for cor r espot tdence: Radim. H r din a@upce.cz

A set of reactive mordant azo dyes was prepared by diazotisation of aromatic amines and their subsequent couplingreactionwith secondarycomponents. The reactivedyes thus formed contained2-sulfatoethyl-sulionyl (-SO2CH2CH2OSO3Na), N-methyl-N-carboxymethyl-2-aminoethyl-sulfonyl (-SO2CH2CH2N(CH3)CH2COOH) and 2,3-dibromopropionamidyl (-NHCOCH(Br)CH2Br) groups,capableof liberating reactive reactive vinyi groupsin the application dyebath.Negative-lon Electrospray lonisation Mass Spectrometry, UVA/ISspectroscopy and eiemental analysisconfirmed the structureof the prepareddyes. Dyed wool samples (combination of acid'and reactive dyeing conditions) were treated (mordanted) with iron salts (Fe(ll), Fe(lll)) and a chromiumsatt (CrF3). The iron mordantdyeingshowedacceptable wash fastnessand lightfastnesscomparable with chromiumcomplexed dyes. Keywords: azo dyes, reactivedyes, iron mordantdyes, wool, wash fastness,light fastness

INTRODUCTION Metal complex dyes play very a important role in the textile industry. Chromium Cr(IID and cobalt Co(III) complexes are used most frequently for the dyeing of wool and synthetic polyamides. Metal complex dyes are applied to the wool either in the pre-metallised form or a complex is prepared "in situ" in the fibre by the treatment of dyed wool with chromate or dichromate (CrflII)) salts It, Z]. The aim of our work was to prepare iron mordant azo dyes in order to replace the ecologically and toxicologically problematic chromium and cobalt dyes [3-5]. Traditionally used cobalt and chromium complex dyes have very good wet fastness (rating 4 - 5 in ISO five member "grey scale") and also light fastness (rating 6 - 7 in ISO eight member "blue scale") [6]. It is known [7-16] that some iron (Fe(II), Fe(III)) complex dyes have comparable fastness properties. Since iron salts are not considered toxic, they present little or no pollution problems for the users [17 - 2Il.In spite of this, mordant dyes are used still for "deep" black shades, because they exhibit extremely high wash fastness (all wet fastness have grade 5) and are practically irreplaceable (l\dordant Black 9, 1f). These remarkable fastness properties arise from the oxidation of the mordant dye by the Cr(\rI) salt, whereby a new molecule (chromophore)comes into existence. Probably, the key fact is, that the sulfo group rs eliminated during the oxidation, so that this new chromophore and subsequently its chromium complex are insoluble in water (formation of black pigment) 122- 251. For this reason, a reacti.ve group was incorporated into the dye molecule, able to react with a nucleophilic group of animal fibre (mainly with amino group) forming a fast covalent bond between dye and fibre. In this way, the intention was to prepare dyes with excellentwash fastness, and by consequentiron treatment (mordanting) to increasethe light fastness significantly. Thus, the prepared dyes in this work contained in the molecule three different types of reactive group (Table l), where RGl and RG2 were precursorsof the vinylsulfonyl group (-SOzCH=CHz) and RGe was a precursor of the a-bromoacryloamidyl (-NH COCH(Br;=911r,reactive group. Vinylsulfonyl dyes (VS) in the protected form (as p-sulfatoethyl sulfones) were originally developed for the reactive dyeing of wool by Hoechst [26]. They are storage stable under standard conditions, and the reactive vinylsulfonyl dye (chromophoreSOzCH=CHz) is liberated by reaction with an alkali in the dyebath. The vinylsulfonyl dye reacts subsequentlywith a nucleophilic group in the fibre by Michael addition (Figure 1). Hoechst also invented derivatives of VS dyes forming the reactive vinylsulfonyl group in an acid dyebath. A water soluble secondary amine such as N-methyltaurin is used for protection of the vinyl sulfonyl group and the fixation reaction described by Zollinger [27],In this work sarcosine(N-methyl glycine) was used. This type of reactive group has been developed in previous work [28] and the reaction with the wool fibre is shown in Figure I. Dyes based on the 2,3-dibromo-propionamidyl reactive group were introduced to the dyestuff market by BASF [29] and Ciba-Geigy[30], and the fixation reaction with wool has been explained in the literature [31, 32].

Advances in Colour Scienceand Technology VoI 7 No 1 Jan 2OO4

Figure1: Reactions of reactive dyesin dyebath

Dyes with RGI dye-SOpHpHp'SO3Na + OH- + dye-SOpH=CH2 + H2O+ NaSOo

dye-SOpH=CHz+ Dyeswith RG2 CH. dve-SOCHCH;NH t t l

r

wool-NH2

dye-SOpHfHfH-wool

?rl

coo-

dye-SOpH=CH, +

Dyes with RG3

?rl Tt'

cooH

d y e - N H - C - ? t-? *, + On O B T B T

d ye- NH- C- ?:"t, + Br - * Hr o

O B T

dye-NH-C-?:"*, O Br

*2wool-NHr*

oH +

NH-wool I dye-NH-C-CH-CH2 + O NH.wool

Br-*

Hro

The idea to prepare reactive iron complex dyes is not new [33-36], but it is believed that the area of mordant dyes can bring new opportunities to solve environmental problems without compromising fastness properties. EXPERIMENTAL

Preparation chloride

Diazotisation

of

2,3-dibromo-propionyl

Acrylic acid (99%, 13.9 cm3,0.2 moi, p 1.051B.cm'r, MW 72.06) was cooled (external cooling bath with ice) to 15 "C and bromine (11.3 cm3, 0.22 mol, MW 79.90) was slowly added dropwise under stirring and cooling. The reaction temperature ranged between 15 - 20 "C. When all the bromine was added, the reaction mixture became slightly red and solid. The solid (2,3-dibromo-propionic acid) was dissolved in thionylchloride SOCIz (29.4cm3, 0.4 mol, MW 118.96)and FeCIa (1 cm3 40% aqueous solution) was added. The reaction mixture was refluxed for 8 hours and then the excess of thionylchioride was removed by distillation (b.p. 79 oC).Raw 2,3-dibromo-propionyl chloride was purified by vacuum distillation (4.9kPa, 97-99 'C). The yield of 2,3-dibromopropionyl chloride was 22.9 cm3 (purity 98%, 0.19mol, p 2.1 g.cm-3, MW 250.31).

of 2-arninophenol 2-Aminophenol(26.2 g,0.24 mol, MW 109.12)was dissolved in 20 cm3 water, 20 g crushed ice and 53 cm3 concentratedHCI (35%, 0.6 mol). Then an aqueous solution of NaNOz (4N, 60 cm3, 0.24 mol) was slowly added dropwise under intensive stirring and external cooling (ice, acetone). The diazotisation tenperature was 0 - 5 'C, and the reaction time was approximately 10 minutes. When the reaction was completed (checked by iodine starch paper), the small excessof HNOz was removed by the addition of NHzSOIH. The solution of diazonium compound was used for the next coupling reaction. Diazotisation of 2-[(4-aminophenyl)hydrogen sulfonyll ethyl sulfate 73.6 g, 0.25 mol, MW 8r.29, PAFSES (95.5o/o, commercial sample fro'.n Spolek pro chemickou a hutni vyrobu, a.s. Usti nad Labem, Czech Republic) was mixed with 40 cm3 water, 10 g ice and 55.2 cm3HCI (35%,0.625 mol) under intensive stirring and external cooling (ice, acetone). Then NaNOz (4N, 62.5 cm3,0.25 mol) was slowly added dropwise. The diazotisation temperature was 0 - 5 'C, and the reaction time was approximately 40 minutes. When the reaction was completed (checkedby iodine starch paper), the small excess of HNOz was removed by the addition of NHzSOsH. The solution of diazonium compound

Advances in Colour Scienceand Technology Vol 7 No 1 Jan2OO4

was immediately reaction.

used for the next coupling

Bis-diazotisation of 4-arnino-N-(4-arninophe nyl) be nzene su lfonarnide DASA (94.Oo/o, 9.8 C, 0.035 mol, MW 263.31, sample from [28]) was dissolved in a mixture of 30 cm3 water, 5 g ice and 15 cm3 HCI (35%, 0.17 mol) under intensive stirring and external cooling (ice, acetone). Then NaNOz (4N, 17.5 cms, 0.07 mol) was slowly added dropwise. The diazotisation temperature was 0 - 5 'C, and the reaction time was approximately 10 minutes. When the reaction was completed (checked by iodine starch paper), the small excess of HNOz was removed by the addition of NHzSOgH.The solution of bis-diazonium compound was immediately used for the next coupling reactions.

Preparation of 4-hydroxy-5-(4-nitrobenz oylarnino)-naphthalene-2, 7-di sulfoni c acid (rnonosodiurn salt) H-acid (83.5%, 15.3 g, 0.04 mol, MW 319.3)was mixed with 100 cm3 water and cooledto 0 - 5 'C. Then sodium acetate (20% aqueous solution) was added to maintain pH 2 - 3. Following this the solution of 4-nitrobenzoyl chloride (7.42 g dissolved in 28 cm3 dipropylene glycol monomethyl ether Dowanol DPM, 0.04 mol) was slowly added dropwise to the suspension of H-acid under intensive stirring and cooling. The reaction temperature was 5 - 10 "C, and the reaction pH 2 - 3 was maintained by the addition of sodium acetate over the reaction time of 2 hours. Following this the cooling bath was removed and the suspension was stirred overnight (approx. 16 hours) at the laboratory tenperature (approx. 20 "C). Then 4-nitrobenzoyl chloride (1 g dissolved in 5 cm3 of Dowanol DPM, 0.0054 mol) was added again and the suspension stirred for 3 hours, the reaction pH being held at 3.5 (with the addition of 5N NaOH). Yellow product was then filtered off and dried at 80 oC. The yield was 17.5 C monosodrum salt (0.036mol, MW 490.39).

cooled to 20 "C and iron oxides were filtered off (clearing), The fiItrate was acidified rvirh concentrated HCI to pH 1 and the precipitated white product was frltered off and dried at 60 .C. The yield was 4.0 g (0.0091mol, MW 438.42). Preparation of Dye I Resorcinol (25.3 e, 0.23 mol, MW 110.1f) was dissolvedin 30 cms water and the solution pH was maintarned at value &9 by the addition of 4N NaOH. Then the diazoruum salt of 2-aminophenol (0.23 mol) was slowly poured in under rntensive stirring and external cooling (reaction temperature l0 oC,reaction pH 8-9, reaction time 4 hours). The coupling reaction was checked by TLC (Silufol UV 254, mobile phase: water/ethylacetate/propan-1oVpropan-2-ol= 3lll4l2). When the first coupling reaction was completed, the diazonium salt prepared from PAFSES (0.25 mol) was slowly added under stirring and cooling (reaction temperature 5 oC, reaction pH 8-9, reaction time 12 hours). The target dye was salted out of solution using 40 g NaCI and dried (60 "C). The yield was 120 g crude Dye I. Preparation of Dye V H-acid (15 g, 68.65%,0.032 mol, MW 319.3) was mixed with 50 cm3water and 10 g crushedice. The diazonium salt prepared from PAFSES (0.035 mol) was then slowly added dropwise under intensive stirring and cooling (reaction temperature 5'C). The reaction pH was brought to 1 by addition of an aqueoussolution of CHaCOONa (20% solution) and the reaction mixture stirred for 24 hours. When the first coupling reaction was completed (checked by TLC as above), the pH was maintained at 6 (addition of 5N NaOH) and the bis-diazonium salt prepared from DASA (0.034mol) was added all at once. The reaction pH 6-7 was maintained by the addition of 5N NaOH. The reaction temperature was 5 'C. The reaction mixture was stirred for 10 minutes (formation of bis-azo dye) and then an alkaline solution of salicylic acid (0.035 mol, 4.8 g dissolvedin 10 cm3 water and 14 cm3 5N NaOH) was added all at once. The reaction mixture was stirred for t hour at reaction pH 8-9 and reaction temperature 5 'C. The target dye was salted out of solution using 40 g NaCl and dried (60 'C). The yield was 34 g crude Dye V. Preparation of Dye VI phenyll -3-methyl-51-[- [(2-Hydroxyethyl)sulfonyl] (15 g, pyrazolone 83.2o/o, 0.044 mol, MW 282.31, sample from [28]) was dissolved in 20 cm3 water, 15 g crushed ice and 9 cma 5N NaOH. The diazonium salt prepared from 2-aminophenol (0.046 mole) was then added dropwise to the solution under intensive stirring, with reaction pH 8-9 and reaction temperature 5 "C (external cooling). TLC was used to check the coupling

4-hydroxy-5-(4-arninoof benz oylarnino)-naphth alene-2,7di sulfonic acid (Becharnp reduction) Iron filings (2.6 S, 0.047 mol) were mixed with 30 cm3 water and 0.26 cm3 concentrated HCI (35o/o). The mixture was heated to the boiling point and stirred for 10 minutes. Then the mixture was cooledto the temperature 65 "C and the solution of 4-hydroxy-5-(4-nitro-benzoylamino)-naphthalene2,7-disulfonic acid (4.9 S dissolved in 30 cm3 water, pH maintained at value 8.5, 0.01 mol) was slowly added. After all the nitro compound had been added, the reaction mixture was stirred for 2 hours. When the reduction was completed (colourless solution). the reaction mixture was

Preparation

Advances in Colour Scienceand Technology VoI 7 No I Jan20O4

reaction, The reaction mixture was stirred for 4 hours and the dye was salted out of solution using 20 g NaCl and dried (80 "C). The yield was 1T g crude mono-azodye. Dry mono-azo dye (15 C) was slowly added (partwise) to stirred and externally cooled HSOaCI (50 cma). The formed solution was stirred for 2 hours at 25 "C. Then the solution was added dropwise to a mixture of 50 cm3 water and b0 g crushed ice. The precipitated dye was filtered off and carefully dried (IR lamp). The yield was t4 g ofcrude reactive dye. Reactive dye (14 g) was mixed with 30 cm3 water and with N-methyiglycine (3.6 g, 0.04 mol, MW 89.09) under intensive stirring. Then bN NaOH was added to obtain pH 8-9 and the reaction mixture was stirred for 2 hours at the reaction temperature 50 "C. The dye was salted out of solution using 20 g NaCI and dried (G0 .C). The yield was 17.5 g crude Dye VI. Preparation of Dye X 4-Hydroxy5-(4-amino-benzoylamino)-naphthalene2,?-disulfonicacid (10 g, 0.023 mol, MW 438.42) was mixed with 20 cm3 water. The diazonium salt prepared from 2-aminophenol (0.024 mol) was then slowly added under intensive stirring and external cooling. The reaction pH was maintained at 6 by the addition of 5N NaOH. The reaction temperature was 5 oC and the reaction time was 4 hours. When the coupling reaction was completed (checked by TLC) the formed azo dye was salted out of reaction mixture using 15 g NaCl and dried (80'C). The yield of azodye was 12 g. 12 g of azo dye was mixed with 20 cm3 water and l0 cm3 phosphorus buffer added (buffer: 1 cm3 concentrated HsPOq diluted with 9 cm3 water and neutralised with 5N NaOH at pH 6). The solution was externally cooled to I "C and 2,3-dibromopropionyl chloride (98%, 2.7 cm3, 0.022 mol) was slowly added under intensive stirring. The reaction pH was kept at 4-5 using 5M NaOH. When the reaction was completed, the dye was salted out of solution using 15 g NaCl. The yield was 18 g crude Dye X. Application procedures (Dyeing) Dyeings of wool with reactive mordant dyes I - XII were carried out from an acid dyebath (pH 3, acetic acid), with liquor ratio 20:1 and 4% mass concentration of dye (on mass of fabric) using a Linitest laboratory dyeing machine (Hanau, FRG). The dyeing cycle was 30 min from 20 oC to 100 "C, 60 min at 100 "C, 15 min cooling to 70 "C. After this the metal salt was added (metallisation factor Crf was 0.35; mass of metal salt = mass of dye x Crf) and the dyebath heated to 100 oC over 15 min, held for 45 min at 100 "C. and cooledover 15 min to 25 "C. The fabrics were removed and treated

with alkali (NaHCOr) for lb min at 40 oC in a wash-bath, at pH 8.5, and then the fabrics were removed, washed with water at 20 oC and airdried at room temperature. Comparison dyeings of wool with Mordant Black g and Mordant Black 11 were carried out from an acid dyebath (pH 3, acetic acid), with liquor ratio 20:1 and 4% mass concentration of dye (on mass of fabric) using a Linitest laboratory dyeing machine (Hanau, FRG). The dyeing cycle was 30 min from 20'C to 100 "C, 60 min at 100 "C, lb min cooling to 70 'C. Then HCOOH (2 % on mass of fabric) was added and the dyebath heated 100 "C over lb min, held for 15 min at 100 oC, and cooledover 15 min to 70 "C. After this KzCrzOz was added (metallisation factor Crf was 0.25) and the dyebath heated over 15 min 100 "C, held for 45 min at 100'C, and cooled over 15 min to 25 "C. The fabrics were removed and washed with warer ar 20 "C and air-dried at room temperature. Measurements of absorption spectra of the dyes and of the exhaustion of dye from the dyebath were carried out using an HP 8453 diode array absorption spectrophotometer(Hewlett Packard). Fastness tests The wash fastness at 60 oC was tested according to the ISO 105-A10S/C03(1994) procedure. The wash fastness - potting - was tested according to the ISO 105-A10S/809(1994) procedure. Light fastness was evaluated on Xenotest 450 (Hanau, FRG) according to the ISO 105:802 (method 2) (normal climate conditions) procedure. Electrospray ionisation

(ESr-MS)

mass spectrometry

Mass spectra were measured on an ion trap analyser Esquire 3000 (Bruker Daltonics, Bremen, Germany). The samples were dissolved in 50% aqueous acetonitrile and analysed by direct infusion at flow rate 3 Fl.min-l. Mass spectra were recorded in the range mlz 50 1000 using electrospray ionisation (ESI) in the negative-ion mode and averaged over 10 scans. The mass spectrometer was tuned to obtain an optimum response for mlz 500 (except for dye XII, where the spectrometer was tuned to mlz 800). The pressure and flow rate of nitrogen were 10 psi and 4 dm3.min-l, respectively. The isolation width of the precursor ion for MS' measurements was Lmlz=4 (except for bromine containing compounds, where the isolation width was Lmlz=6). For measurement of dye XII, the tuning parameter "compound stability" was set to a lower value (50%) to increase the relative abundance of the deprotonated molecule.

Advances in Colour Scienceand Technology Vol 7 No I Jan 2004

RESULTS AND DISCUSSION Synthesis ofthe dyes All dyes I - XII were prepared by diazotisation of the primary component (aromatic amine) followed by coupiing with the secondary component under weak alkaline conditions. The synthetic route for each dye is in Table I and the structures of the prepared dyes are summarised in Table 2. The dyes are drawn in the azo form in spite of the fact that the hydrazone form probably dominates [4347).

Dyes I - V were prepared from Z-[(1aminophenyl)suifonyllethyl hydrogen sulfate (PAFSES) as the primary componenr,which was diazotised with an aqueous solution of NaNO:r rn the presence of diluted mineral acrd. The secondarycomponent for the coupling reaction was a monoazo or disazo dye prepared by standard procedures [37]. The preparation of Dye I is described in Figure 2; Dyes II - ry were prepared in a similar way. Since the preparation of Dye V is more complicated, its synthesis is shown separately in Figure 3.

Table 1:

Dyes t- V Dyes Vl - lX

Preparation of mordantreactivedyes

Reactivegroup RG' = Reactivegroup RG2=

-SOpHTCHTO-SO.Na ,CH, -SOpHTCH;N. cH2cooH -NH C-CH CH2 O BrBr

(2-sulfatoethyl-sulfonyl)

(lV-methyl-N-carborymethyl-2-aminoethyl-sulfonyl)

Dyes X - Xll

Reactivegroup RG3=

(2,3-dibromopropionamidyl)

Dye

Synthetic route

' 2-aminophenol * t resorcinol 2 PAFSES 2 -PAFSES

1 4-amino-3-hydroxy-7-nitro-naphthalene-1-sulfonicacid+resorcinol

ill

s-aminosalicylic acid +

resorcinol + 1

2 PAFSES 2 PAFSES

2-aminophenol-4-sulfonicacid +

1 , S - d i h y d r o x y n a p h t h a l e n e-

PAFSES-l*

2-aminophenol

H-acid i

' + t PYRAZ

onsn -i*

2 1

salicvtic acid

addition of sarcosine + add t'on of sarcosine additionof sarcosine

dehydration with HSO3CI PYRAZ 2

2-aminophenol-4-sulfonic acid -

dehydration with HSqCI 1 PYRAZ 2

vill

4 - a m i n o - 3 - h y d r o x y - 7 - n i t r o - n a p h t h a l e n e - 1 - s u l f o n i c a c i d* S-aminosalicylic acid * 2-aminophenol chloride .+ 1 1 PYRAZ + 2

dehydrationwithHSO3C| .+ addition of sarctsine 2

tx

dehydration with HSO3CI -

4-hydroxy-s-(4-amino-benzoylamino)-naphthalene-2,7-dasulfonic acid 1

tredt with 2,3-dibromo-propionyl 2

2-aminoohenol-4 sulfonicacid dibromoproplonyl chloride X l f 1 + 2-amino-5-nitro-phenol dibromopropionyl chloride

4-hydroxy-5-(4-amino-benzoylamino)-naphthalene-2,7-disulfonic acid 2

treat with 2,3-

4-hydroxy-S-(4-amino-benzoylamino)-naphthalene-2,7-disulfonic acid -

treat with 2,3-

PAFSES= 2-[(4-aminophenyl)sulfonyl]ethyl hydrogensulfate = DASA 4-amino-N-(4-aminophenyl)benzenesulfonamide PYRAz = 1-[-[(2-hyd roxyethyl)sulfonyl]phenyll-3-methyl-5-pyrazolone

10

Advances in Colour Scienceand Technology Vol 7 No I Jan20O4

Table2: Molecular structure of prepared mordant dyes

Dye

Structure

Dye

Structure

\r /-*="1

J ,/-\

OH

HO

*"o.sL

/-\

fo* N=Nfuy'-RG.

( V*=* \-/

vI ot

cHt

l l l l "oAr'N

l-\ Nao,s-(

\J

orN

HO

)-*=*1

>:\

fo^ lr=N_eFRG

>r t: Il Y

RG'

ill

vlil

N--N

CH.

lv

*o{*'I

a

).

Ac'

*"-"o,$il

v

Y

h : u fNao3s-\g fi'

l,i N

I

?" T",,

OH

( V*=* \:,/

NaOrS

<-\

$.oo" OH

XI

OH J oH NHco{

F NaorS

)-r=r-,/'\

\--l

,)-RG'

Naors#so.rua

l\"

OH VI

=N

CH.

HoAru-N I

xtl

h "Y

Ac2

Advances in Colour Scienceand Technology Vol 7 No I Jan 2004

11

Figure2: Synthesis of DyeI

NH.

N,

Thirdcoupling reaction

OH I /.\-,,COOH ll I pH 8 DyeV

l l l +

a\

NaNO, *

HCI

,\ ll

tX- = SOTCHzCH2OSO3'

Y

X ,/ \

N '' = N ''\-...-.

r 2H2o I + N a c+

(r)+

\/

""!HO

A i l t +

\v

X

N,.

l-\ HX--{'

tol 'FN.

\t ro^

\:,/

.'ru{/-\

t}_o,

N=r\

,Z\ Ho-{ )

\:-/

no{,

>\)

\

Figure3: Synthesis of DyeV First reaction coupling

Dyes VI - D( were prepared by diazotisation of an aromatic amine and coupling with 1-[-[(2-hydroxyethyl) sulfonyll phenyll-3-methyl-5-pyrazolone (PYRAZ).Attempts to accomplishthe esterification of the aliphatic hydroxyl group (-SOzCHzCHsOH) with sulfuric acid and oleum were unsuccessful. Thus, chlorosulfuric acid (HSOtCl) was used, whereupon the dehydration took place and vinylsulfonyl dye (chromophore-SOzCH=CHz) was prepared (Figure 4). The dye in this form is very reactive and can be used for wool dyeing directly [38].

|A+ffi

Y

X

T,*

?H TH,

Figure 4: Preparation of Dye Vl

no,sy'\'tr\l\so.u

a = so2cHzcHzoso3-

l lont f

N il N

v

..\

dye-SO;CH2CH;OH *

HSO3CI

HOsS

so3H dye-SO;CH-CH2

(1)

t

+ HCI + H2SO4 dye-SO;CH:CH2 + H.C-NH-CH;COOH

I

of DASA Bis-diazotisation

NH.

a\

l

t t l

N,'cl

YI

Y +2NaNO2-_ ?o,

+4Hcl

.\ i l l

NH

t'

toflu

dye-SO;CH;CH;Nr

* 2 NaCl

,cH,

-cH2cooH

io,

T"

+ 4H2O

t i l

\/

I NHt

)" I i l

>.

Q\

Dyes X - XII are based on the 2,3-dibromopropionamidyl reactive group (RG3) and on the 4-hydroxy-5-(4-aminocoupling component 7-disulfonic acid. benzoylamino)-naphthalene-2, Synthesis of synthetically pure secondary component (4-hydroxy-5-(4-amino-benzoylamino)naphthalene-2,7-disulfonic acid) is crucial for the successful synthesis of the reactive dye. The starting compound for the synthesis was H-acid, which was condensedwith 4-nitro-benzoylchloride [39] and then the nitro group reduced to the amino group (Figure 5).

N2 Cl

coupling reaction Second

( 1 )+ ( 2 ) cl

'r,-(

w \"*-so,',,-.. l - l

\./\N

I e'z I on f l

N tl N

HO3S (3)

so3H

L2

Advances in Colour Scienceand Technology Vol 7 No l Jan 2004

Figure5: Preparation of 4-hydroxy-5-(4-aminoino)-naphthalene-2, 7-d isulfonic benzoylam acid

,Z-1\

catalysis of FeCls (Figure 7). The product vvas purified by vacuum distillation. Figure 7: Preparation 2,3-dibromo-propionyl chloride

CH;CH-COOH * Br, .-----_

?' T",

l +

t i l nors,,,,^#sorx

cHr-cH-cooH Br Br C H - C H - f r - C I+ H c l + S o 2 Br BrO

+H SOC|2 + CH2-CH-COO Br Br

Prepared Dyes I - XII were salted out of the every dye reaction mixture, meaning that contained some amount of inorganic salt. Since Dyes I - XII were chromatographically pure, the content of dye was approximately determined by elemental analysis. Spectral properties of the dyes are summarised in Table 3.

?" 1*-8{f*",

HO35

mordant strength of synthesised Table3: Tinctorial reactive dyes(aqueous soluticin)

Dye Conc of dye / (mass %)

l^., I nm Grn., '/ dmt.g't.cm-t

so3H I ll lil IV V

4-hydroxy-5-(4-nitroof Bechamp reduction was benzoylamino)-naphthalene-2,7-disulfonic better than reduction with natrium sulfides (NaSH, NazS), where azoxy impurities were formed and the purification procedure was very difficult. The nitro compound can be also reduced by FeClz [40]. successfully Dyes X - XII were prepared by the classical diazotisation of o-aminophenols and consecutive 4-hydroxy-5-(4-aminocoupling reaction with acid benzoylamino)-naphthalene-2,7-disulfonic followed by the condensation of the dye (amrno group) with 2,3-dibromo-propionyl chloride (Figure 6) [29, 30, 41]. Figure 6: Synthesisof Dye X

63 62 66

oo

420 420 412 490 600,392 411 396 445 417 530 516 520

44 34 40 62 34,10 92 82 55 21 28 25 25

vl

vll vilt

tx x

XI xll

69 41 42 43 43 85 87 88

' absorption forthedyeprecipitated wasmeasured coefficient (nonpurified) mixture from thereaction by electrospray confirmation Structure ionisation mass spectrometry The structures of some representative compounds were confirmed by ESI-MS spectrometry. Dye IV, MW (CztHzoOtzNtSa) = 652 MS: m/z 689, 2oo/o,[M-2H+K]-; nlz 673, 3l%, [M-2H+Na]-: mlz 651, 58%, [M-H]-; mlz 57I,98%, [M-H-HzSOr]-. lM-H-SO3l-;mlz 553, LOO%, MS/MS of 651 (collision amplitude, CA = 0.8 \D: mlz 593, 5%o,[M-2H+Na-SOe]-;mlz 571, 100%, [M-H-SOa]-. MS/MS of 571 (CA = I $: mlz 553, 45o/o, [M-H-HzSO.r]-; mlz 525, I8%, mlz 491,61%,M-H-25Orl-; [M-H-HzSOr-CHzCHz]-; mlz 186, mlz 462,3l%, [M-H-SOg-HSOa-CHzCHz]-; sSO.e]-. l0oo/o, [(NHXO)CoH The peaks of deprotonated molecule [M-H]- and the characteristic adducts for sulfonic aclds ([M-2H+Na]- and [M-zH+K]- ions) confirm unambiguously the expectedmolecular weight MW 652 Da. The neutral losses of SOe and HzSOa 13

OH

^!i l

l

?" y-E$*, -ffi

pH8 - HCI

Hors-\,\l^-sorH

cH2-cH-c-cl Br BrO

Dye X

2,S-Dibromo-propionylchloride was prepared by the procedure described in the patent literature [42], that is, the reaction of acrylic acid with bromine and treatment with thionylchioride under

Advances in Colour Scienceand Technology Vol 7 No 1 Jan2OO4

observedin both MS and MS/MS spectra show the presence of sulfonic and sulfate groups, respectively. The loss of CHzCHs can be also correlated with the structure, because this functionality is adjacent to the initially cleaved -OSOaHgroup. Dye VII, MW (CzrHzeOcNsSz)= 553 MS: mlz 552, IOO%, [M-H]-; mlz 508, 16%,

Dye IX, tuIW (CnHzaOcNrS) = 517 MS: mlz 516, 100%, [M-H]-; mlz 42i, [M-H-CHaNHCHzCOOH]-. MS/MS of 516 (CA = I $: mlz 458, 9%, [M-H-CHzCOO]-; mlz 42i, mlz 383, [M-H-CHNHCHzCOOH]-; [M-H-CHsNHCHzCOOH-COz]-;mlz 263, ICHz=CHSOzCaHTCsNzH(CHtO]-.

r2o/u.

100%. 52%, 71%.

lM-H-COd-.

MSA{S of 552 (CA = 0.9 \): mlz 472, 25%, [M-H-SOa]-: mlz 352, 3lo/o, 199, 5oo/o, lM-(OHXNz)CaHrSOsHl-; mlz mlz 186, l2o/o, [HOCoHz(Nz)SOa]-; mlz 17l, 100%,[HOCeHzSOs]-. [HOCcHz(NH)SOr]-; The deprotonated molecule at mlz 552 is the base peak of the spectrum, which is in accordancewith the expected molecular weight, MW 553 Da. The fragment ion at mlz 508 is a typical loss for carboxylic acids (Am/z = 44, QOz). The important fragment ions in MS/MS spectrum are again the products of the cleavage of azo bond and neighbourinCC-N bonds at mlz 171, 186 and 199. The presence of a sulfonic acid group is confirmed by the typrcal neutral loss of SOe. Dye VIII, MW (CzsHztOtrNtSz) = 648 MS: mlz 647, l0oo/o, [M-H]-; mlz 558, l5o/o, mlz 294, 5o/o, [M-H-CHeNHCHzCOOH]-; mlz 28r, 13%, t(NOr(OH)(Nz)CroHaSOel-; mlz 268, 4%, INOTXOH)(I9CroHrSOsl-; nlz 266, I5%, t(NOr(OH)CroHsSOel-; l(NOr(OH)CroHaSOal-. MS/MS of 647, collision amplitude (CA) = 0.6 V: llr.lz 619, 3%, [M-H-Nz]-; mlz 352, 3%, tM-(NOr(OH)(Nz)CroHaSOaHl-;mlz 294, 43o/o, 281, I3o/o, t(NOt(OH)(Nz)CroHsSOel-; mlz mlz 268, Looo/o, tNOt(OH)(l9CroHaSOal-; 266, 91%, tNOr(OH)CroHsSOrl-: mlz

The molecular weight MW 517 Da can be easily confirmed by the presence of deprotonated molecule as the base peak of the MS spectrum. The neutral losses of CHaNHCHzCOOH and COz show the presence of these functionalities in the molecule and other structural subunits are confirmed by the fragment ions, for example m/z 263. Dye X, MW (CnHzoOnNtSzBrz) = 770 MS: m/z 689, 66%, [M-H-HBr]-; mlz 599, 100%, [M-H-2HBr]-. MS/MS of 689 (CA = r $: mlz 582, 87%, [M-H-HBr-HOCcHcI{j-; mlz 569, l0O%, [M-H-HBr-HOCoH.rN=NH)-; mlz 518, 94o/o, 489, 9%, [M-H-HBr-HOCoH4N-SOs]-; mlz [M-H-HBr-HOCoHaN=NH-SOg]-;mlz 438, ll%, lM-H-2HBr-HOCoH.rN-SO2l-. HBr is cleavedfrom the molecule so easily that the molecular ion is not apparent, but the identity is confirmed by the characteristic ions [M-H-HBr]and [M-H-ZHBr]- with appropriate isotopic ratios for one or zero bromine atoms. The MSIN,{S spectrum shows typical neutral losses for sulfonic acid group (SOr and SOz) and also the cleavageof HBr. Dye XI, MW (CzaHzoOteNtSrBrz) = 850 MS: mlz 851, 52%. [M-H]-; mlz 769, 100%, [M-H-HBr]-; mlz 679, 79%, [M-HBr-CHBr]-; m/z 637, 68%,[M-BrCH(Br)CCO]-. Surprisingly, the molecular ion [M-H]- is present with a relatively high intensity and some further neutral losses related to the bromine-containing part of the molecule are observed in accordance with the structure (mlz 769,679 and 637). Dye XII, MW (CzoHrsOtzNsSzBrz)= 815 MS: m/z 838, 2I%, [M-2H+Na]-; mlz 816, 560/o, [ M - H ] - ;m l z 7 5 2 , 3 1 % , [ M - H - S O z ] -m ; l z 7 3 6 ,7 2 % , [M-H-HBr]-; mlz 672, 28%, [M-H-HBr-SOz]-;m/z 644, 3S%, [M-H-HBr-CHBr]-; mlz 624, 38%, [M-H+Na-BrCHz(Br)CHCO]-; mlz 602, lO0%, m/z 366.5,16%,M-2H-HBrlr-' [M-BrCHz(Br)CHCO]-; m/z 300.5,11%,[M-H-BICHz(Br)CHCOIz-. The mass spectrum of this compound is more complex due to the presence of two sulfonic acid groups and two bromine atoms. The presence of more bromine atoms in a molecule usually causes

tNOTXOH)CroHrSOrl-; mlz

238,

4o/o,

mlz 220, 1%, [(OH)CroHeSOs] ; [(OXOH)CroHsSOs]-; ml z 204, 5%, [(NOz)(OH)CroHaO]-. The deprotonated molecule tM-Hl- is the base peak in the negative-ion ESI mass spectrum which makes it possible to confirm the expected molecular weight, MW 648 Da. Some fragment ions with relative abundances lower than 2O%o are also observed in the first stage mass spectrum such as [M-H-CHeNHCHzCOOH]- and ions resulting from the cleavage of the azo bond (m/z 281) and of neighbouring C-N bonds to azo bond (mlz 266 and 294). These ions are also apparent in the MSA4S spectrum of mlz 647, where the characteristic neutral losses confirm the presence of a sulfonic acid group (Lmlz = 64, SOz) and of a nitro group (Lmlz = 30, NO and Am/z = 46, NOz) yielding the fragment ions at mlz 238, 22O and 204.

L4

Advances in Colour Scienceand Technology Vol 7 No I Jan 2004

the consequent losses of HBr or Br, which can lead to decreasedrelative abundance or absenceof deprotonated molecule in the spectrum, as in the case of the sample studied. The special soft turung parameters (i.e. the compound stability value b0%) were set to reduce the molecular ion decomposition, hence the deprotonated molecule [M-H]- has 56%. Other fragment ions are related to the bromine-contairung part of the molecule (mlz 736,624 and 602) and confirm the presenceof -COCH@r)CHz(Br) functionality. Two sulfonic acid groups in a molecule are identified by means of characteristic doubly charged ions, as described in previous works [48,49]. Application of prepared dyes AII prepared Dyes I - XII were applied to wool. The dyeing of wool was carried out by a combination of reactive and mordant dyeing. The wool was first dyed under acid conditions (adsorption of dye on the fibre, formation of electrostatic bonds). Following this mordanting with a metal salt took place (formation of metal complex dye) and then in the new bath the coloured samples were treated with NaHCOa (at pH 7-8) (fixation of dye to the fibre by covalent bonds, Figure 1) and finally washed. Results of the dyeing and fastness properties are summarised in Tables4 - 6. The wool was also dyed with Mordant Black g (Diamant Schwarz PV, sample from Bayer BRD) and Mordant Black 11 (Alizarine Chrome Black PT, sample from Spolek pro chemickou a hutni vyrobu, Czech Republic) for the comparison of fastness properties. The application procedu.rewas classical mordant dyeing, that is, acid dyeing of the wool sample with the mordant black dye foliowed by oxidation and metallisation with dichromate (KzCrzOr). The obtained results are shown in Table 7.

Table 5: Wash fastness of dyed wool samples (60'C) (4% coloration, tSO 105 C03)

Dye Unmet.

4 (R)a, 1 - 2 b ,1 - 2 c 2 - 3 ,4 , 3 4 4(Y),4-5, 2-3

Mordant with FeCh 4,3,3 4 (R), 4, 34 4-5(Y), 4-5,3-4 4-5,5,4 4-5,4,4 4-5(Y), 4-5,4 4-5,4-5,4 4-s(R), 5, 2-3 3(Y)1 ,, 34 4(R), 5, 4 4-5,4-5,4 4-5,4-5,4

Mordant with CrFr 4-5,4,4

Mordant with FeCtr

4 - 5 ,4 , 3 4

4 - 5 , 4 - 5 , 4 3-4(Y),4Y,

4

4 - 5 , 4 - 5 , 4 4,3-4,3(R) 4-5,5, 5 4-5,4-5, 4-5 4-5(R), 4-5,4-5 4-s(R), 4-5,4-5 4-5,5, 4 4-5,2-3, 4-5 4 ( B )s , ,4 4-5,4-5, 3-4 4-5,4-5, 3-4

4-5,5,4 4-5,4-5,4-5 4-5(R), 4-5,4-5 4R,4-5,4-5 4R,4,3R 1(Y),2-3\23Y,4-5,4 34Y,4,4-5 4-5.4,4

tv V

VI

4-5,5,4 4-5, 4-5, 4-5

vll vill

tx

xl

xtl

4-5(Y), s, 4-5 4-5(Y), 5, 4-5 4(R), 4, 2-3 3 ( Y )1 ,, 34 3(B), 4, 34 4,34, 1-2 4,34,1-2

a colour change,b stainingon wool, c stainingon cotton

Table 6: Wash fastness of dyed wool samples (potting) (4% coloration, ISO 105 E09)

Dye Unmet. Mordant with FeCl: Mordant with CrFr 4-5, 3-4, 4-5 4-5, 3'4, 4_5 4-5, 5, 4-5 4-5,4-5, 4-5 4-5, 4(R), 4-5 4-5(R),5, 4-5(R),5, 5 4-5(R), 4-5,4-5 4-5,4-5,4 4(38), 5, 5 4,2-3,4 4.2-3. 4 Mordant with FeClz 4-5,34,4 3,4,4-5 4Y,3,4 4-5,3-4,4-5 4-5Y,34,4 4(R),3,4 3-4,4-5,4-5 4,3,4 2-3(Y),1,34 4,3,4 4,2-3,4-5 4 , 2 - 3 ,4

4-5(3R)a, 4 - 5 , 3 , 4 1b,3c 34,2-3, 4-5, 3, 4-5 4-5

ill

4 ( Y ) , 2 - 3 , 4 ( Y ) ,2 - 3 , 4 3-4 3,2-3,4 4,2-3,4 4, 3, 4-5

4-5,4,4-5 4-5,4,4-5 4-5,4,4-5 4-5(Y) 4, 4-5 2-3(Y),3, 2-3 4,34,4 4-5, 1-2, 4-5 4 - 5 ,1 - 2 , 4 5

Table 4: Light fastness of dyed wool samples (4% coloration, Xe-testISO 105-802)

Dye I ll ill IV Unmet.

4

3, 3-4,5 vtl vill 3, 3-4,5 2-3,3, 4 2-3(Y),3,

z-5

Mordant with FeClr

Mordant with CrFr

Mordant with FeGlz

2 3-4

4

6-7 3*4 3-4

4

4 34

4

6 3-4

4 4 4

lx

x

xl

xtl

4,2,34 4,1,3-4 4,1,3-4

v

VI vll vill

3-4 2

z

34 6-7 6-7 34 3 o

34

b b 4

tx x

xl xtl

4 3-4 3-4

2 6-7 6

4-5 3-4 4-5 3-4 6-7 4-5 6

a colourchange,b stainingon wool, c stainingon couon

Advances in Colour Scienceand Technology Vol 7 No 1 Jan 2OO4

15

HO\

/-\ N1h \-,f1 E O H O fso,ru'

NO,

z1

Cl Mordant Black 9

Cl Mordant Black11

properties Table7: Fastness of commercial samples = 0.25) (wool, 4% coloration, Cr-factor

Dye Potting Mordant Black 9 Mordant Black 11 Fastness data Wash test 60"c Xe-test 7- 8 7- 8

metalltsed) gives a complex with one or- rwo absorption bands in the visible region of the spectra bathochromically shifted in comparison with the unmetallised dye. The ongin of the bathochromic shift is usually explained b1' the ionisation of oxygen and nitrogen atoms in the complex (ionisation of the dye chromophore) [43461. Complexation with iron ions grves unfortunately two different absorption bands, one shifted bathochromically and one shifted hypsochromically. The origin of this "yellow band" is not expiained in any literature, and its presence means that all iron complex dves are in fact browns. Thirdly, the complexation of mordant dyes with a salicylic group in the molecule moiety (terminally metallised) does not change the colour (or the tight fastness) significantly. CONCLUSION A set of reactive mordant azo dyes (I - XII) has been prepared, where the mordant dyes contained the o,o'-dihydroxyazo moiety as a tridentate chelating ligand or the salicylic moiety as a bidentate ligand. The reactive group incorporated in the dye molecule was a derivative of either the vinyl sulfonyl group or the 2-bromoacryloamidyl group.

4-5,5, 5 4-5,5, 5

4-5,5, 5 4-5.5. 5

Reflection spectra Optical density (reflection) spectra of dyed wool samples were recorded in the visible region (380 to 740 nm). The representative spectra of Dyes III and VI are shown in Figure 8. Figure 8: Opticaldensityspectra

pye Ift salicylic moiety

1.6 t.4 - l'2

_;,

-Cr(llD -Fe(lll) -"_ft(ll)

E l o.s

E 0.6

E0.4 0 380 420 460 500 540 580 620 660 700 nm Dye Vl: o,o'-dihydroryazo moiety 1.2 I

o o.z

Dyes I - XII were applied to wool and the coloured samplestreated with Cr(III), Fe(III) or Fe(II) salts in the mordant dyebath under reactive dyeing conditions. The dyed samples were colorimetrically tested and wet fastness and light fastness were determined. Dyes III - VII and X - XII had good wet fastness independent of the type of reactive group. Complexation with the metal ion increasedthe wet fastnessslightly. Dyes I, II, IV, VI - VIII and X - XII with the o,o'dihydroxyazo moiety as tridentate chelating ligand showed good light fastness (Xe = 6-7) after mordanting with a metal salt, and the light fastness of the chromium complexes was comparable with that of the iron complexes. In contrast, mordanting of dyes III, V, and IX containing the sahcylic moiety did not change the light fastness of the coloured samples significantly (Xe = 4). Finally, the prepared dyes I - XII are not competitive with current commercial black mordant dyes such as Mordant Black 9 and Mordant Black 11. Nevertheless, syntheses of their reactive derivatives and their properties will be the aim ofour continuing research. ACKNOWLEDGEMENT This work was supported by research grant 253100001 MSMT CzechRepubiic.

.9 o.a

0.6

o.c E !r

5 0.2 0

380 420 460 500 s40 580 620 660 700 nm

g*-

R{tr}

From the spectra above it can be concluded, firstly, that complexation on the wool fibre with either Fe(II) or Fe(III) salt leads to the same result. This implies the idea, that due to the reductive properties of wool and oxidative properties of air oxygen a red/ox equilibrium is formed. Secondly, complexatron of mordant dyes with the o,o'-dihydroxyazo moiety by Cr(III) salt (medially

1C)

Advances in Colour Scienceand Technology Vol 7 No 1 Jan2004

M Holeapek acknowledges the support of grant project No. 253100002 sponsored by The Ministry of Education, Youth and Sports of the Czech RepubIic. REFERENCES l. 2. 3. 4. 5. 6. H Zollinger, Color Chernistry, Znd Edition, VCH Verlagsgesellschaft , Weinheim, 1991 PF Gordon and P Gregory, Organic Chemistry in Colour, Springer Verlag, Berlin, 1983 AC Welhelm, J.S.D.C., r02 (4), 1986, 126 H Thomas,J.S.D.C.,108 (4), 1992, 186 Z Gotzka, J Kraska and H Lawniczak. Dyes and Hgtnents,S, 1984,263 Colou.rIndex, 3th Edition, The Society of Dyers and Colourists, The American Associacion of Textile Chemists and Colorists, 2000 MM Moustafa, ME Moustafa, MK Sadek and RM Issa, Eglpt J. Chen.,36 (3), 1993,241 J Sokolowska-Gajda, HS Freeman and A Reife, T e x t .R e s J . .,64,1994, 388 HS Freeman, A Reife and J Sokolowska-Gajda,US P a t e n t5 3 7 6 1 5 1 , 1994

25. R Hrdina, L Burgert, S Lunrik Jr, P Kuthan and D Lu6tinec, Colorchetn 2000, 8th Intenwtiornl Conference on Dyes and Pigments, Spindleruv l{lyn. CzechRepublic, May 2000 26. J Heyna and W Schumacher, DBP 96b. 902. Hoechst, 1949

27. H Zollinger, Textilveredlung,6, Ig7 I, 5i 28. P

Wandrol, Reactiue dyes based otl 2-ftEo mirr.ophenyl )at lfony llethyl hy drogen sttlfate on d 2 [(3-aminophenyl)sulforyl]eth1,l 14'drogen sulfate, Diploma work, Faculty of Chemical Technology, University of Pardubice, CZ, 1998

29. DAS 1,127,016, BASF, 1957 30. BeP 693,749,CIBA, 1966 3 1 . Mdusezahl, Textilueredlung,5, 1970,839 32. P Ball, U Meyer and H Zollinger, Text. Res.J., 56,

L986,447 33. J Jarkovskf, F Macek and R Hulcov6, CS Patent 204071,1983 34. VI Ponomareva,VO Stepanenko,AL Poznyakevich, BA Ponomarev, AM Lobanov and LI Gorbenko, SU Patent1751176 A1, 1992 35. D Luitinec, R Hrdina, L Burgert and J Androvi, Colorchem 2000, 8th International Conferenceon Dtes and P|gntents, Spindler0v Mlj'n, Czech Republic, May 2000 36. M Szymczyk et al., Przeglad Wohientticzy + Technih Wohienniczl',10, 1996, 19 3?. HL Fierz-David and L Blangey, Grtntdlegende Operotionertder Forbertchemie,4th Edition, Wien, Julius Springer, 1938. 38. SM Burkinshaw, AS Zouny and MJ Bide, Dles ond Hgmetfis, 48,2OOl,245 39. F MuZik, CoIIect. Czech.Chem. Comrnun.,30, 1965, 559 40. IE Balaban and H King, J. Chem. Soc., 1927, 3068 (Abstracts 1928) 4f . KH Schundehutte, The Chentistry of Synthetic D1es, Ed. K. Venkataraman, VI, Academic Press, New York and London, 1972,26I 42. EU patent 457725, 1991 Ciba-Geigy, 43. Y Yagi, Bull. Chen. Soc. Jprt,37 (L2), 1964,1875 44. Y Yagi, BuIl. Chen. Soc. Jpn,37 (12),1964.1878 45. Y Yagi, BUII. Chem. Soc. Jprt,37 (12), 1964,1881 Jpn,36 (5), 1963,487 46. Y Yagi, Bull. Chen. Soc. 47. G Schetty and E Steiner, Heluetouo Chinica Acta, 57 (7), L974,2149 48. M Holdapek, P Jandera and P Zderadidka, J. A, 926, 2001, 175 Chromatogr. 49. M Holdapek, P Jandera and J Pfikryl, Dyes and Pigments, 43, L999, L27

7. 8. 9.

l 0 HS Freeman, J Sokolowska-Gajda and A Reile, Text. Chetn.Col.,27 (2), 1995, 13 1 1 . W Czajkowski, K Blush, J Sokolowska-Gajda, M Szymezyk and A Wojelechowska, Polish Patent 3 1 0 4 5 3 ,1 9 9 5 12. W Czajkowski, K Blush, J Sokolowska-Gajda, M Szymezyk and A Wojelechowska, PoU.sh Patent 311606,1995

1 3 . K Blush, Przegl W\ok,70,1996, 19 14. W

Czajkowski and M Hgrnents,37, 1998, 197 Szymezyk, Dyes and

1 5 . RM El-Shishtawy and MM Kamel, Chen. Eng. ol. 25 (8), 2002, 849 Techrt 1 6 . JH Xiu et al., Chittese Jou.rnal of Chetnical Engineeringfl (1), 2003, 68

1 t t

A Reife, E Weber and HS Freeman, Chentech October 1997: J. Am. Chem. Soc., 1997, 17

1 8 . N Sekar, Colottrage, August 1999,63 1 9 . N Sekar, Colou.roge, September 2001, 49 20. HS Freemann, Text. Clrcm. Col., 27, 1995, f 3 2 t . HA Bardole, HS Freeman and A Reife, Text. Res.J., 6 8 . 1 9 9 8 .1 4 1 22. L Burgert and R Hrdina, Zprauodaj Spolhu textilrr.tch chetnikfi a koloristfr, 2000, 34 23. S Morgan, J.S.D.C., )(LI (7), 1925,233 24. DM Lewis, C Hornett, P Smith and G Yan, Adu. C o l . S c i .T e c h . , 5( 1 ) ,2 0 0 2 , 1 3

Advances in Colour Scienceand Technology Vol 7 No I Jan 2004

t7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Car KotakDocument15 pagesCar Kotakkanji63No ratings yet

- DR ArchadDocument4 pagesDR Archadkanji63No ratings yet

- 4 Nitro N MethylphthalimideDocument1 page4 Nitro N Methylphthalimidekanji63No ratings yet

- Green 7Document7 pagesGreen 7kanji63No ratings yet

- RMC of Coal Tar 1.0 KG Rate Qty Cost Coal Tar Crude 6 1 6 After Water Remove 0.7 7Document1 pageRMC of Coal Tar 1.0 KG Rate Qty Cost Coal Tar Crude 6 1 6 After Water Remove 0.7 7kanji63No ratings yet

- Method for Producing Omeprazole IntermediateDocument4 pagesMethod for Producing Omeprazole Intermediatekanji63No ratings yet

- Technical Specifications For DIMETHYL ANTHRANILATEDocument1 pageTechnical Specifications For DIMETHYL ANTHRANILATEkanji63No ratings yet

- Listofdyes, Dye Intermediates, Agrochemicals and PharmaceuticalDocument11 pagesListofdyes, Dye Intermediates, Agrochemicals and Pharmaceuticalkanji63No ratings yet

- 1 3 DiiminoisoindolineDocument6 pages1 3 Diiminoisoindolinekanji63No ratings yet

- RMC of 3GKDocument1 pageRMC of 3GKkanji63No ratings yet

- Waste Water PatentDocument151 pagesWaste Water Patentkanji63No ratings yet

- Research On The Preparation of 2,5-Diaminotoluene With 2-Aminoazotoluene Catalytic HydrogenationDocument1 pageResearch On The Preparation of 2,5-Diaminotoluene With 2-Aminoazotoluene Catalytic Hydrogenationkanji63No ratings yet

- Basic Orange 2Document1 pageBasic Orange 2kanji63No ratings yet

- Acetyl Bronners Acid ChlorosulphonationDocument3 pagesAcetyl Bronners Acid Chlorosulphonationkanji63No ratings yet

- Acetamide From Urea FertiliserDocument5 pagesAcetamide From Urea Fertiliserkanji63No ratings yet

- Green - 7Document28 pagesGreen - 7kanji63No ratings yet

- Uses and Applications of AcetamideDocument2 pagesUses and Applications of Acetamidekanji6350% (2)

- Basic Blue 7Document1 pageBasic Blue 7kanji63No ratings yet

- EP0011048A1Document19 pagesEP0011048A1kanji63No ratings yet

- Flowdiagram of Disperse Blue 79Document4 pagesFlowdiagram of Disperse Blue 79kanji63No ratings yet

- Tax Certificate HomeDocument1 pageTax Certificate Homekanji63No ratings yet

- Disperse Blue79Document2 pagesDisperse Blue79kanji63No ratings yet

- Annexure-A Ambuja Intermediates LTD Raw Material SR No Name of R. M RemarkDocument2 pagesAnnexure-A Ambuja Intermediates LTD Raw Material SR No Name of R. M Remarkkanji63No ratings yet

- Disperse Blue79Document2 pagesDisperse Blue79kanji63No ratings yet

- Workplace Housekeeping - Checklist For General Inspection Floors and Other AreasDocument2 pagesWorkplace Housekeeping - Checklist For General Inspection Floors and Other Areaskanji63No ratings yet

- TFS Audit Program V2.0Document29 pagesTFS Audit Program V2.0kanji63No ratings yet

- Maintance Shift SchedualDocument2 pagesMaintance Shift Schedualkanji63No ratings yet

- Workplace Housekeeping - Checklist For General Inspection Floors and Other AreasDocument2 pagesWorkplace Housekeeping - Checklist For General Inspection Floors and Other Areaskanji63No ratings yet

- FC & GM Loan PolicyDocument4 pagesFC & GM Loan Policykanji63No ratings yet

- List of Licenses / Certificates: As Per List Attached Here WithDocument2 pagesList of Licenses / Certificates: As Per List Attached Here Withkanji63No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Understanding Mass SpectrometryDocument147 pagesUnderstanding Mass SpectrometryYee Kin WengNo ratings yet

- Erzinger 2006Document9 pagesErzinger 2006Gilvandro CésarNo ratings yet

- Milovanovic 2017Document47 pagesMilovanovic 2017Ali AloNo ratings yet

- Jenke 2017Document10 pagesJenke 2017cute babyNo ratings yet

- IMA Questions PaperDocument17 pagesIMA Questions PaperAj ShindeNo ratings yet

- Planor Chrom ReviewDocument12 pagesPlanor Chrom ReviewIya GerzonNo ratings yet

- CAT - PerkinElmer HPLC ConsumablesDocument44 pagesCAT - PerkinElmer HPLC ConsumablesJosue Daniel MoralesNo ratings yet

- Geochronology, Methods and Case Studies (N.a. Morner, 2014)Document196 pagesGeochronology, Methods and Case Studies (N.a. Morner, 2014)EdilberAntonyChipanaPariNo ratings yet

- Phosphorylation Dependence and Stoichiometry of The Co - 2014 - Molecular - CellDocument14 pagesPhosphorylation Dependence and Stoichiometry of The Co - 2014 - Molecular - CellasdfweafsplashNo ratings yet

- Lubri Oil Additives PDFDocument47 pagesLubri Oil Additives PDFTejas PatelNo ratings yet

- A Critical Review of Drug Testing Policy in The Philippines: Carissa Paz Dioquino and Roy Roberto GeronaDocument7 pagesA Critical Review of Drug Testing Policy in The Philippines: Carissa Paz Dioquino and Roy Roberto GeronaSammy BallaNo ratings yet

- Ultrapure Water Essential For Direct Determination of Bisphenol A by HPLC - MS/MSDocument2 pagesUltrapure Water Essential For Direct Determination of Bisphenol A by HPLC - MS/MSSergio RodríguezNo ratings yet

- A Developed Process For The Synthesis of Tryptophol A Key Starting Material For Indoramin PDFDocument4 pagesA Developed Process For The Synthesis of Tryptophol A Key Starting Material For Indoramin PDFAntares1973No ratings yet

- 1 s2.0 S003194220600690X Main PDFDocument8 pages1 s2.0 S003194220600690X Main PDFMehboob AlamNo ratings yet

- Practical Techniques For LC - MS Analysis Shimadzu Scientific InstrumentsDocument94 pagesPractical Techniques For LC - MS Analysis Shimadzu Scientific InstrumentsМаратNo ratings yet

- LoratadinaDocument11 pagesLoratadinaSandraNo ratings yet

- Allergens in Perfumes - Gas Chromatography-Mass SpectrometryDocument8 pagesAllergens in Perfumes - Gas Chromatography-Mass SpectrometrymitsubisaNo ratings yet

- Importance of The Surface Oxide Layer in The Reduction of Outgassing From Stainless SteelsDocument7 pagesImportance of The Surface Oxide Layer in The Reduction of Outgassing From Stainless SteelsKay WhiteNo ratings yet

- A Vanitha - Antimicrobial Activity of Wild and Tissue Cultured Plant Extracts of Tylophora IndicaDocument12 pagesA Vanitha - Antimicrobial Activity of Wild and Tissue Cultured Plant Extracts of Tylophora IndicaRahul RanaNo ratings yet

- Analytical quality control and method validation procedures for pesticide residues analysisDocument46 pagesAnalytical quality control and method validation procedures for pesticide residues analysisAnonymous SiO8gwwRtoNo ratings yet

- Avances en Uroanalisis AutomatizadoDocument8 pagesAvances en Uroanalisis AutomatizadolaboratorioNo ratings yet

- 4 ChloromethcathinoneDocument15 pages4 ChloromethcathinoneMeilia SuhermanNo ratings yet

- Surface Analysis - The Principal TechniquesDocument680 pagesSurface Analysis - The Principal Techniqueskraven89100% (8)

- Analytical Method SummariesDocument41 pagesAnalytical Method SummariesLasny ManjithaNo ratings yet

- 1998-Molecular Characterization of Wax Isolated From A Variety of Crude OilsDocument11 pages1998-Molecular Characterization of Wax Isolated From A Variety of Crude Oilshaibo dingNo ratings yet

- Ms AnsDocument5 pagesMs AnsAhmed ZakyNo ratings yet

- TL 502 ScopeDocument21 pagesTL 502 Scopeca_rl_4No ratings yet

- TCH 30 Minute Guide To ICP MS 006355G 01Document8 pagesTCH 30 Minute Guide To ICP MS 006355G 01Anderson DavidNo ratings yet

- HKDSE Chemistry Exam Questions on Analytical MethodsDocument27 pagesHKDSE Chemistry Exam Questions on Analytical MethodsFrank Massiah100% (1)

- Data Sheet: Agilent 7000B Triple Quadrupole GC/MS SystemDocument2 pagesData Sheet: Agilent 7000B Triple Quadrupole GC/MS SystemMarine JolieNo ratings yet