Professional Documents

Culture Documents

A Comparison of Deming, Juran, and Crosby

Uploaded by

Kashif AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Comparison of Deming, Juran, and Crosby

Uploaded by

Kashif AhmadCopyright:

Available Formats

Similarities and different between William Edward Deming, Joseph M. Juran and Philips P.

Crosby

Similarities o Quality requires a strong upper management commitment o Quality saves money o Responsibility is placed on managers, not workers o Quality is a never-ending process o Customer-orientation o Requires a shift in culture o Quality arises from reducing variance Nature of Organizations o Deming: Social Responsibility and moral conduct; the problems with industry are problems with society o Juran: Focused on parts of the organization, not whole o Crosby: Organization-wide, team building approach Implementation Processes o Deming: no roadmap is available; nowhere to start; no steps o Juran and Crosby: Very user friendly; prescriptive; obvious starting points Ability to do piecemeal o Crosby and Deming: approach is holistic. Deming requires a radical shift in values o Juran: can be done piecemeal in isolated parts of the organization Ability to handle resistance o Deming: very dogmatic and uncompromising; depends on facts, however, not gospel o Crosby and Juran: resistance is normal and need not be an obstacle. Depend on facts to unseat criticism. Initial acceptance by management o Deming: a threat to most managers. Requires an admission of incompetence. o Juran: since focus is largely on shop floor with support, managers are very comfortable o Crosby: requires very little shift in view of workers and managerial roles. View of Workers

o o

Deming: variance is largely unaffected by workers activities. Organization exists in large part to develop and provide for workers. Juran: workers are important because of being close to the activities impacting quality. Crosby: workers can be motivated to improve quality and not produce defects.

Final Comments

No one pathway is ideal for a company. Most companies create their own unique pathway Many companies evolve from Crosby to Juran to Deming

o

The reason: Crosby is not definitive about improvement methods; Juran is not sufficiently comprehensive

Each of the three hated each other.

o

Deming and Juran would hardly speak to one another, probably because of egos and who got credit for saving Japan. Deming and Juran agreed that Crosby was a superficial charlatan; referred to his organization as The University of Hot Air

Demings approach is very, very difficult for organizations to embrace; the changes required are immense. Demings approach is regarded as ideal by most quality experts, if ever instituted properly. No US company has yet to institute a Deming system completely.

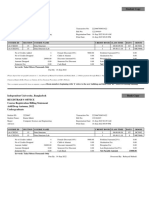

Basic orientation toward quality What is quality? Nonfaulty systems Fitness for use; freedom from trouble Who is Management Management responsible for quality? Importance of Very important Very important; customer customers at requirements each step of as standard product life cycle Goal of quality Meet/exceed Please customer needs; customer; continuous continuous improvement improvement Methods for Statistical; Cost of quality; achieving constancy of quality trilogy: quality purpose; continual planning, improvement; control, cooperation improvement between functions Chief elements 14-point program Breakthrough of projects; quality implementation council; quality teams

Table 1 - A comparison of Deming, Juran, and Crosby W. Deming J.M. Juran P. Crosby Technical Process Motivational

Conformance to requirements Management

Very important

Continuous improvement; zero defects 14-point framework;

14-step program; cost of quality; quality management "maturity grid" Role of training Very important for Very important Very important managers and for managers for managers workers and employees and employees For additional The W. Edwards Juran Institute Philip Crosby details, see Deming Institute Associates II web site:

Table 2 - A comparison of Garvin, Felgenbaum, and Taguchi D. Garvin Basic orientation toward quality What is quality? Strategic, academic Competitive opportunity A.V. G. Taguchi Felgenbaum Total, systemic Technical, proactive

Who is Management responsible for quality? Importance of Very important customer requirements as standard Goal of quality Pleasing customers; continuous improvement Methods for Identifying achieving quality niches quality

What customer Customer's says it is performance requirements Everyone Engineers

Very important Very important

Meet customer requirements; continuous improvement Statistical methods such as Loss Function; eliminating variations of design characteristics and "noise" through robust design and processes Chief elements Eight Statistical and Statistical design of of dimensions of engineering experiments; quality implementatio product quality: methods across teams n performance, the company features, reliability, conformance, durability, serviceability, aesthetics, perceived quality Role of training Important but Very important Important but not not clearly for managers defined defined and

Meet customer needs; continuous improvement Total quality control (TQC); excellencedriven rather than defectdriven

For additional details, see web site:

---

supervisors ---

---

You might also like

- Omct 1Document60 pagesOmct 1AkhilGovindNo ratings yet

- Mazda Fn4A-El 4 Speed Ford 4F27E 4 Speed Fnr5 5 SpeedDocument5 pagesMazda Fn4A-El 4 Speed Ford 4F27E 4 Speed Fnr5 5 SpeedAnderson LodiNo ratings yet

- Onan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750Document92 pagesOnan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750GreenMountainGenerators80% (10)

- Production & Operations ManagementDocument6 pagesProduction & Operations ManagementAjay LalwaniNo ratings yet

- Bank NIFTY Components and WeightageDocument2 pagesBank NIFTY Components and WeightageUptrend0% (2)

- Trading As A BusinessDocument169 pagesTrading As A Businesspetefader100% (1)

- Lecture 06 - Managing New Product Development TeamDocument20 pagesLecture 06 - Managing New Product Development TeamAli FaslNo ratings yet

- Ions ConsultingDocument2 pagesIons ConsultingVishwadeep DubeyNo ratings yet

- Competitor Analysis of Infosys, Accenture & TCSDocument2 pagesCompetitor Analysis of Infosys, Accenture & TCSabiNo ratings yet

- Operations Management Sample QuestionsDocument76 pagesOperations Management Sample Questionsluckiestmermaid0% (1)

- Case Study HRM AdobeDocument3 pagesCase Study HRM Adobeafifi50% (2)

- Taj Case-Organisation CultureDocument6 pagesTaj Case-Organisation CultureSoma Sundaram0% (1)

- Measuring Customers Perceptions-3080Document9 pagesMeasuring Customers Perceptions-3080Jagadish AppajiNo ratings yet

- OlistDocument19 pagesOlistAnkush PawarNo ratings yet

- Executive Summary: Operations Management Assignment Report Writing: Importance of Operations ManagementDocument12 pagesExecutive Summary: Operations Management Assignment Report Writing: Importance of Operations ManagementKunal GodboleNo ratings yet

- Total Quality Management For Flipkart: Submitted By: - Aditya Tyagi Mba 3 Semester ERP ID - 0191MBA150Document26 pagesTotal Quality Management For Flipkart: Submitted By: - Aditya Tyagi Mba 3 Semester ERP ID - 0191MBA150DullStar MOTONo ratings yet

- Summary The Coming of The New OrganizationDocument2 pagesSummary The Coming of The New OrganizationJc GereigeNo ratings yet

- Taj Hotel Group Culture Case AnalysisDocument6 pagesTaj Hotel Group Culture Case AnalysisSoma SundaramNo ratings yet

- Sunrise Case StudyDocument4 pagesSunrise Case StudyShubhajit Nandi0% (1)

- Prestige Case Study AnalysisDocument7 pagesPrestige Case Study AnalysisBo RaeNo ratings yet

- China StrategyDocument7 pagesChina StrategyHira Ahmed Khan50% (2)

- 9e Chapter 1 TestDocument17 pages9e Chapter 1 Testnivi_isNo ratings yet

- Session 3 Framework of Production ManagementDocument7 pagesSession 3 Framework of Production ManagementNarayana Reddy100% (1)

- Southwood School - Training and Development - PPT - FINAL2Document23 pagesSouthwood School - Training and Development - PPT - FINAL2Jody Gonzales100% (1)

- Pillars of TQM Implementation in Manufacturing Organizationan Empirical StudyDocument14 pagesPillars of TQM Implementation in Manufacturing Organizationan Empirical StudyIbrahimMustefaNo ratings yet

- Toyota Style ManagementDocument3 pagesToyota Style ManagementElzein Amir ElzeinNo ratings yet

- Operations Management CareerDocument5 pagesOperations Management Careerpravinepatil3426No ratings yet

- Competitive AdvantageDocument60 pagesCompetitive AdvantageFibin Haneefa100% (1)

- Electrical Equipment Industry 2020Document2 pagesElectrical Equipment Industry 2020Ipsita Bhattacharjee100% (1)

- Notes On Session 1-10 - DRDocument32 pagesNotes On Session 1-10 - DRDeblina SaharoyNo ratings yet

- Thomas Green's Career in CrisisDocument6 pagesThomas Green's Career in CrisisGreggi RizkyNo ratings yet

- Operations ManagementDocument2 pagesOperations Managementedwinlcs100% (1)

- Monopoly Versus Perfect Compitition in PakistanDocument33 pagesMonopoly Versus Perfect Compitition in PakistanZahid Nazir83% (12)

- Quality assurance depends on design and delivery controlDocument12 pagesQuality assurance depends on design and delivery controlArmel AbarracosoNo ratings yet

- Annual Review Dilemma: Promote Growth or Risk Losing Top ClientDocument1 pageAnnual Review Dilemma: Promote Growth or Risk Losing Top Clientcallrecall911No ratings yet

- IMB 541 CASE Marketing Heads Conundrum R PDFDocument9 pagesIMB 541 CASE Marketing Heads Conundrum R PDFs4shivendra100% (1)

- Case Kimura KK MM1Document8 pagesCase Kimura KK MM1Anuj YadavNo ratings yet

- AbhiDocument4 pagesAbhivaibhavNo ratings yet

- Customer Driven QualityDocument7 pagesCustomer Driven QualityJason DeBoer-Moran100% (1)

- Ions ConsultantDocument15 pagesIons ConsultantAsep Kurnia0% (1)

- Manage occupational health & safety risksDocument3 pagesManage occupational health & safety risksAryan Singh100% (1)

- An AssignmentDocument6 pagesAn AssignmentasrajibNo ratings yet

- Case Study - The Case of The Un Balanced ScorecardDocument15 pagesCase Study - The Case of The Un Balanced ScorecardNadia HarsaniNo ratings yet

- Case StudyDocument3 pagesCase StudySawaira Khan0% (1)

- The Quality Improvement Customers Didn't WantDocument16 pagesThe Quality Improvement Customers Didn't Wantbbejasmine9541No ratings yet

- Report of The CaseDocument5 pagesReport of The CaseKumar GauravNo ratings yet

- Carol Tomé's Leadership SkillsDocument6 pagesCarol Tomé's Leadership SkillsAlisa BisopNo ratings yet

- Chapter 3 - Goals Gone Wild The Systematic Side Effects of Overprescribing Goal SettingDocument10 pagesChapter 3 - Goals Gone Wild The Systematic Side Effects of Overprescribing Goal SettingAhmed DahiNo ratings yet

- Case - Hi-Tech Incorporated (GP)Document2 pagesCase - Hi-Tech Incorporated (GP)Barbie JainNo ratings yet

- Best Buy Co-Case AnalysisDocument1 pageBest Buy Co-Case Analysisgane009No ratings yet

- Case 2 COO and Country Manager Job Selection Exercise KEEDocument1 pageCase 2 COO and Country Manager Job Selection Exercise KEEbamNo ratings yet

- Global Sourcing at Whirpool China - Case StudyDocument9 pagesGlobal Sourcing at Whirpool China - Case StudySacha AcocaNo ratings yet

- Case 1 ToyotaDocument5 pagesCase 1 Toyotapheeyona0% (1)

- BullWhip EffectDocument17 pagesBullWhip EffectSaurabh Krishna SinghNo ratings yet

- Similarities N Different Deming, Juran N CrosbyDocument4 pagesSimilarities N Different Deming, Juran N CrosbyNsa Syahida67% (15)

- Industry's Key Success Factors PDFDocument8 pagesIndustry's Key Success Factors PDFKaran UppalNo ratings yet

- Market Strategy of Volkswagen in IndiaDocument12 pagesMarket Strategy of Volkswagen in IndiaSathya K IyerNo ratings yet

- Ambrosia Catering ServicesDocument8 pagesAmbrosia Catering Servicessarathipatel0% (1)

- Strategic Management Quiz 2 PDFDocument4 pagesStrategic Management Quiz 2 PDFXainab AmirNo ratings yet

- Value Chain Management Capability A Complete Guide - 2020 EditionFrom EverandValue Chain Management Capability A Complete Guide - 2020 EditionNo ratings yet

- Similarities: Similarities and Different Between William Edward Deming, Joseph M. Juran and Philips P.CrosbyDocument4 pagesSimilarities: Similarities and Different Between William Edward Deming, Joseph M. Juran and Philips P.CrosbyJuliaNo ratings yet

- SimilaritiesDocument2 pagesSimilaritiesJykyll PaulNo ratings yet

- TQM Philosophies and ContributionsDocument58 pagesTQM Philosophies and ContributionskavyashreembNo ratings yet

- 3 Expert On Quality MGMT PDFDocument41 pages3 Expert On Quality MGMT PDFKashif AhmadNo ratings yet

- 3 Expert On Quality MGMT PDFDocument41 pages3 Expert On Quality MGMT PDFKashif AhmadNo ratings yet

- 7 Ways To Cultivate A Positive Mental AttitudeDocument1 page7 Ways To Cultivate A Positive Mental AttitudeKashif AhmadNo ratings yet

- MpsalaryDocument67 pagesMpsalaryKashif AhmadNo ratings yet

- DNA Gel Electrophoresis Lab Solves MysteryDocument8 pagesDNA Gel Electrophoresis Lab Solves MysteryAmit KumarNo ratings yet

- Catalogoclevite PDFDocument6 pagesCatalogoclevite PDFDomingo YañezNo ratings yet

- Kami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Document3 pagesKami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Anna HattenNo ratings yet

- FSRH Ukmec Summary September 2019Document11 pagesFSRH Ukmec Summary September 2019Kiran JayaprakashNo ratings yet

- Rohit Patil Black BookDocument19 pagesRohit Patil Black BookNaresh KhutikarNo ratings yet

- Sentinel 2 Products Specification DocumentDocument510 pagesSentinel 2 Products Specification DocumentSherly BhengeNo ratings yet

- Movement and Position: Question Paper 4Document14 pagesMovement and Position: Question Paper 4SlaheddineNo ratings yet

- Service and Maintenance Manual: Models 600A 600AJDocument342 pagesService and Maintenance Manual: Models 600A 600AJHari Hara SuthanNo ratings yet

- C6030 BrochureDocument2 pagesC6030 Brochureibraheem aboyadakNo ratings yet

- Chapter 3 of David CrystalDocument3 pagesChapter 3 of David CrystalKritika RamchurnNo ratings yet

- Agricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsDocument84 pagesAgricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsRachel vNo ratings yet

- Table of Specification for Pig Farming SkillsDocument7 pagesTable of Specification for Pig Farming SkillsYeng YengNo ratings yet

- Why Genentech Is 1Document7 pagesWhy Genentech Is 1panmongolsNo ratings yet

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsDocument3 pagesAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CNo ratings yet

- Reg FeeDocument1 pageReg FeeSikder MizanNo ratings yet

- 2023 Test Series-1Document2 pages2023 Test Series-1Touheed AhmadNo ratings yet

- Cushman Wakefield - PDS India Capability Profile.Document37 pagesCushman Wakefield - PDS India Capability Profile.nafis haiderNo ratings yet

- Moor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsDocument4 pagesMoor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsIrene IturraldeNo ratings yet

- Break Even AnalysisDocument4 pagesBreak Even Analysiscyper zoonNo ratings yet

- Sharp Ar5731 BrochureDocument4 pagesSharp Ar5731 Brochureanakraja11No ratings yet

- Social Media Exposure and Its Perceived Impact On Students' Home-Based Tasks ProductivityDocument9 pagesSocial Media Exposure and Its Perceived Impact On Students' Home-Based Tasks ProductivityJewel PascuaNo ratings yet

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainNo ratings yet

- Customer Perceptions of Service: Mcgraw-Hill/IrwinDocument27 pagesCustomer Perceptions of Service: Mcgraw-Hill/IrwinKoshiha LalNo ratings yet

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument21 pagesCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroNo ratings yet

- 15142800Document16 pages15142800Sanjeev PradhanNo ratings yet

- Os PPT-1Document12 pagesOs PPT-1Dhanush MudigereNo ratings yet