Professional Documents

Culture Documents

Tires Stop The Car

Uploaded by

Kocic BalicevacOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tires Stop The Car

Uploaded by

Kocic BalicevacCopyright:

Available Formats

Tires Stop the Car

As you just learned in Chapter 1, brakes do not stop the carthey simply convert energy from one form into another. The responsibility of stopping the car falls solely on the tires, or more specifically the tire-to-road interface. Only these four palm-sized patches of rubber that are in contact with the road below (the contact patches) govern how quickly a car will stop. Of course, a poorly designed or malfunctioning brake system can certainly prevent a vehicle from achieving its maximum deceleration rate, but the best stopping performance each and every time is dictated by the tire-to-road interface. A few simple equations are used later in this chapter to illustrate this point, but for the next few pages sit back and hang tight. Its now time to talk about another law.

The brakes dont stop the tires job! For this r come in a wide variety sizes, and designs to o available brake force. T tread pattern on this tir poor choice for wet-we performance, but a gre racing when the track i Racing Tire)

The First Law of Motion

You may recognize Sir Isaac Newton as the guy who allegedly defined the concept of gravity when an apple fell on his head one afternoon. However, for a few paragraphs you should look past that rather major accomplishment and focus on the first of his three stated Laws of Motion. (Note that Newtons First Law of Motion is not to be confused with the First Law of Thermodynamics from Chapter 1. Apparently, every physicist wants to be known for discovering the first law of something or other.) Paraphrasing Newton with a reasonable degree of accuracy, the First Law of Motion states that an object at rest will stay at rest unless it is acted upon by an external force. Conversely, it also states that an object in motion will stay in motion unless it too is acted upon by an external force. In other words, things sitting still will just sit still until you push them and things that are moving continue to move until you do something to stop them.

Brake Forces

Applying Newtons First Law of Motion to vehicle brake systems is relatively straightforward. It goes something like this: Once in motion, a vehicle essentially will not slow down or stop unless it is acted upon by an external force, or what can now be called a brake force. So where do these brake forces come from? Essentially, they result from any mechanism that absorbs a vehicles kinetic energy (they are one and the same). Consequently, this merits a brief revisit of energy transformation factors from Chapter 1, now adding in the resulting brake force contributions for each mechanism: 1. Rolling resistance brake forces result from the body and tread of the tire resisting deformation at the contact patch. As the tire flattens out against the road, a force is generated that resists the motion of the vehicle. 2. Axle, differential, bearing, and engine brake forces result from rotating and reciprocating friction. As these components mesh and rub together, they resist any motion between themselves, which is then mechanically transferred to the tire-to-road interface. 3. Aerodynamic brake forces result from the vehicle simply traveling through the air. As the vehicle attempts to push the air out of its path, the air molecules react by resisting the motion. In other words, the air is not happy with the situation and it pushes back (the sensation you get from holding your hand out of the car window). 4. Mechanical deformation brake forces result from running the vehicle into a fixed object. Again, this is a highly undesirable, yet highly effective, way of stopping a vehicle. Turn 3 at Martinsville pushes back pretty hard, as do trees and telephone poles. So, while it is nice to be aware of these secondary brake force mechanisms, the whole point of this book is to understand the contribution of the brake system components. Consequently, the rest of this chapter leaves these factors behind and focuses on brake forces occurring at the tire-to-road interface as a result of brake system operation.

Brake forces can come of sources other than t system. For example, co-driver were to force at highway speeds into resulting driveline fricti be transmitted immedi driven wheels. Not tha experience here

Tire Slip

Tire slip, or simply slip, is the single most important concept in understanding any aspect of vehicle performance (at least in my humble opinion). Without slip, vehicles could neither accelerate, nor decelerate, nor turn, as a tire can only generate force when it is slipping. As youll learn in a few moments, a tire that is not slipping is free rolling, or coasting, and a free-rolling tire does not generate any force at all (except for the small amount of brake force due to its internal rolling resistance). Before going any further, lets clarify one important point: A tire does not need to be spinning wildly or skidding out of control to be slipping. Although these conditions are a result of a significant amount of slip, there are many other times where a slipping tire does not actually look like its slipping at all. Yet for all practical purposes, any time your vehicle is in motion, its tires are slipping, even though you cant see it with the naked eye. Applying this concept to brake system performance is relatively straightforward. In order for a tire to generate a brake force, it must be slipping relative to the road surface in the direction of travel (normally to a very small level, but it is slipping nonetheless). If a tire is not slipping, it is not generating any brake force (again, ignoring the brake force due to its internal rolling resistance). Although that may sound odd, it makes more sense by taking a moment to formally define slip. Tire slip can be quantified mathematically by the following equation: Tire slip (%) = (1 {speed of the tire (mph) speed of the vehicle (mph)}) x 100 What this implies is that in order for a tire to generate brake force, it must be spinning more slowly than the speed of the vehicle would suggest. However, looking at this relationship in tabular format is somewhat easier on the eyes. For this reason, make your way over the tire slip sidebar for a different look at this slightly perplexing situation.

Different surface textur environmental conditio levels can influence th contribution from the a deformation, and the m modes of friction. For e on the road surface pa the tire from the road, the available adhesive results in extended sto (Wayne Flynn/pdxspor

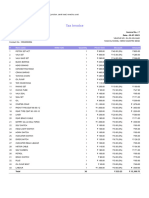

Tire Slip Calculations

The data in the table below illustrates how much tire slip would be present for given combinations of tire speed and vehicle speed. Tire speed Condition 1 Condition 2 Condition 3 50 mph 45 mph 0 mph 50 mph 50 mph 50 mph Vehicle speed 0% 10% 100% Tire slip

So, what do these numbers mean? Well, a few observations can quickly be made: 1. Condition 1 indicates that when the tire speed (50 mph) is the same as the vehicle speed (50 mph), there is zero slip present. Because this is a free-rolling condition, there is no brake force present between the tire and the road. The vehicle will be coasting. 2. Condition 2 indicates that when the tire slows down (45 mph) relative to the vehicle (50 mph), the slip level increases (10 percent in this case). This is the slip range where most normal braking occurs. 3. Condition 3 represents a tire that has stopped spinning (0 mph) although the vehicle continues to speed along (50 mph), resulting in 100-percent slip. This is the classic brakes locked up situation, which is usually accompanied by screeching sounds and billowing tire smoke. Note that this condition is also commonly referred to as sliding or skidding and is generally an undesirable way to slow down a vehicle.

100 percent tire slip, a wheel lock, occurs if a moving yet the tire is n rotating. This may be a spectators, but its not effective way to achiev possible stopping dista Flynn/pdxsports.com)

How Brake Forces are Generated

So now that you know that slip is required to generate force, how exactly does the slipping tire generate brake force? As the tire rolls along without slip, there is constant interaction between the tire and the road, yet with the exception of a small amount of rolling resistance, there are no brake forces generated. However, as soon as a torque is applied to the tire by the brake system (more to come in Chapter 3), it wants to slow down. Unfortunately for the tire, the car does not want to slow down, and consequently the tire is forced to stretch and distort. This is because there is resistance, or friction, at the tire-to-road interface that prevents the tire from decelerating as rapidly as it would like. Few things are more fun than getting a group of contact physicists together in a room and asking them why and how tires generate these forces, but for now it makes more sense to break it down into simple, bite-sized pieces.

Adhesive Effects

Any time two objects in nature come in contact with one another, there are momentary electrostatic bonds formed between them. In other words, to some extent they want to stick together. One of the best practical examples is that of garden-variety duct tape. The adhesive characteristics of the tape allow it to effectively stick temporarily wherever it is placed. This same mechanism is in effect as the tire rolls along the road. During braking, the contact patch is continuously forming adhesive bonds with the road surface below, which resist the tires desire to decelerateafter all, if the tire were hanging in mid-air, it would slow down much more quickly when the brakes were applied. While in this case the adhesive effect may not be as pronounced as it is with duct tape, the rubber tire will elastically deform, and consequently slip, when brake torque is applied. The force of the electrostatic bonds formed between the tire and the road is the first component of the total brake force.

Tires used for racing in optimized to take maxi of the deformation effe on the track greatly red adhesive effect. The ra here uses extremely so compounds to enhanc while large, open chan the tread face purge w contact patch in an atte adhesion. (Hoosier Ra

Although ABS is desig such theatrics, pulling stomping on the brake effective way to force t achieve 100-percent s technique wont genera possible stopping dista resulting skid marks pr that rubber is physicall the tire under these co Tire Rack)

You might also like

- Example 3 Chapter-8: Temperature Profile in A Water Injection WellDocument2 pagesExample 3 Chapter-8: Temperature Profile in A Water Injection WellKocic BalicevacNo ratings yet

- Introduction To Inventory Management: CTL - SC1x - Supply Chain & Logistics FundamentalsDocument13 pagesIntroduction To Inventory Management: CTL - SC1x - Supply Chain & Logistics FundamentalsKocic BalicevacNo ratings yet

- Time Series Analysis: CTL - SC1x - Supply Chain & Logistics FundamentalsDocument14 pagesTime Series Analysis: CTL - SC1x - Supply Chain & Logistics FundamentalsKocic BalicevacNo ratings yet

- Conservation of Linear MomentumDocument1 pageConservation of Linear MomentumKocic BalicevacNo ratings yet

- S+SIWP RFP App I (I) - MFS (Salalah)Document78 pagesS+SIWP RFP App I (I) - MFS (Salalah)Kocic Balicevac100% (1)

- Basic Measures and GraphsDocument11 pagesBasic Measures and GraphsKocic BalicevacNo ratings yet

- 1.4 - Measurement Systems AnalysisDocument45 pages1.4 - Measurement Systems AnalysisKocic BalicevacNo ratings yet

- SC0x W10R1 Final CleanDocument48 pagesSC0x W10R1 Final CleanKocic BalicevacNo ratings yet

- CH 09Document25 pagesCH 09Kocic BalicevacNo ratings yet

- Dire Wolf Industries Annual Costs by Category Total Annual Cost $ 5,001,800Document10 pagesDire Wolf Industries Annual Costs by Category Total Annual Cost $ 5,001,800Kocic BalicevacNo ratings yet

- OGSS AL C Index and ChecklistDocument134 pagesOGSS AL C Index and ChecklistKocic BalicevacNo ratings yet

- 2.1 - Normal DataDocument19 pages2.1 - Normal DataKocic BalicevacNo ratings yet

- W1L2 WorksheetDocument36 pagesW1L2 WorksheetKocic BalicevacNo ratings yet

- Galfar: Off Plot Delivery Contract - C-31/0603 Area Location Engineering & Contracting S.A.O.GDocument4 pagesGalfar: Off Plot Delivery Contract - C-31/0603 Area Location Engineering & Contracting S.A.O.GKocic BalicevacNo ratings yet

- SC0x W10R2 Final CleanDocument12 pagesSC0x W10R2 Final CleanKocic BalicevacNo ratings yet

- Oman Standard Specifications For Road and Bridge Construction 2010Document3 pagesOman Standard Specifications For Road and Bridge Construction 2010Kocic BalicevacNo ratings yet

- SU-40 Design Vehicle DimensionsDocument1 pageSU-40 Design Vehicle DimensionsKocic BalicevacNo ratings yet

- CH 13Document28 pagesCH 13Kocic BalicevacNo ratings yet

- WB-40 Design Vehicle DimensionsDocument1 pageWB-40 Design Vehicle DimensionsKocic BalicevacNo ratings yet

- Work Method Statement ToolkitDocument16 pagesWork Method Statement ToolkitKocic BalicevacNo ratings yet

- Raci ChartDocument2 pagesRaci ChartJuan Carlos Lekuona-Muñoz CarrilloNo ratings yet

- Project Earned Value Analysis1Document4 pagesProject Earned Value Analysis1Kocic BalicevacNo ratings yet

- Game TheoryDocument49 pagesGame TheoryKocic BalicevacNo ratings yet

- S CurveDocument4 pagesS CurveKocic BalicevacNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vehicle Identification Number Vin BaldwinDocument4 pagesVehicle Identification Number Vin BaldwinDRY12GS01No ratings yet

- Airworthiness Directives Final Rules: 79-10-14 R1Document3 pagesAirworthiness Directives Final Rules: 79-10-14 R1locoboeingNo ratings yet

- Dust Seals Pin Wipers Pages 36 - 37Document2 pagesDust Seals Pin Wipers Pages 36 - 37Andrey GyrychNo ratings yet

- Demontare-Montare Arc VariatorDocument5 pagesDemontare-Montare Arc VariatorcristianNo ratings yet

- Patel Motors (Indore) PVT LTDDocument1 pagePatel Motors (Indore) PVT LTDazharNo ratings yet

- Ministry of Defence: UnclassifiedDocument62 pagesMinistry of Defence: UnclassifiedAbdul AzizNo ratings yet

- 300-080-11 RSPC1 Instalation ManualDocument24 pages300-080-11 RSPC1 Instalation ManualLuis A DuarteNo ratings yet

- Workshop Laos - Gautam Patel EV PoliciesDocument25 pagesWorkshop Laos - Gautam Patel EV PoliciesDeepansha TyagiNo ratings yet

- RMI Hypercars Next Industrial Revolution 1996Document8 pagesRMI Hypercars Next Industrial Revolution 1996animemonster20No ratings yet

- AC Compressors & Filter DryersDocument172 pagesAC Compressors & Filter Dryersanyád baszomNo ratings yet

- 1nzfe Isc PDFDocument10 pages1nzfe Isc PDFMatt SholitNo ratings yet

- Yamaha FZ-S CatalogueDocument57 pagesYamaha FZ-S CatalogueAnonymous KoA00wXXD70% (80)

- Afm - A320 Aircraft FLGHT ManualDocument706 pagesAfm - A320 Aircraft FLGHT Manualduythienddt67% (3)

- Rimex Rim Catalogue PDFDocument39 pagesRimex Rim Catalogue PDFAbdul AzisNo ratings yet

- VBE Unit 2 Notes PDFDocument43 pagesVBE Unit 2 Notes PDFYash GargavNo ratings yet

- Spinny 2020 Toyota Glanza Inspection ReportDocument1 pageSpinny 2020 Toyota Glanza Inspection ReportsagarmohanNo ratings yet

- Theory Test Driving Abroad Info PN v012021Document6 pagesTheory Test Driving Abroad Info PN v012021Madster RobertsNo ratings yet

- The Automotive Landscape Set For A 180-Degree Overhaul: Says ZinnovDocument3 pagesThe Automotive Landscape Set For A 180-Degree Overhaul: Says ZinnovPR.comNo ratings yet

- Usa Super SHIFTER 175cc: (Max 176.6 CM )Document28 pagesUsa Super SHIFTER 175cc: (Max 176.6 CM )yasith madhukaNo ratings yet

- Neha Shelke - Tata MotorsDocument24 pagesNeha Shelke - Tata MotorsNeha ShelkeNo ratings yet

- Pulsar 220 Bsiv SPC 04012019Document81 pagesPulsar 220 Bsiv SPC 04012019Ankit Agarwal67% (3)

- Boletin Técnico Cta PDF Julio 2001Document8 pagesBoletin Técnico Cta PDF Julio 2001Fabian Carrasco NaulaNo ratings yet

- Mercury Bulletin Fuel ModuleDocument3 pagesMercury Bulletin Fuel ModulejimniiiNo ratings yet

- Honda Storm 125Document98 pagesHonda Storm 125Mario LopezNo ratings yet

- Characteristic Curves: Models: TX1.5Document2 pagesCharacteristic Curves: Models: TX1.5marco antonio ramos melendezNo ratings yet

- Mitesh PatelDocument2 pagesMitesh PatelTGCNo ratings yet

- Huracán Spyder - !! 4T90CE 1Document15 pagesHuracán Spyder - !! 4T90CE 1Kurniawan HammamiNo ratings yet

- GM Racing EcotecDocument1 pageGM Racing EcotecbienhopleikuNo ratings yet

- Segelflug (DFS) - The German Institute For The Study of Sailplane Flight. Their First Design Was ADocument2 pagesSegelflug (DFS) - The German Institute For The Study of Sailplane Flight. Their First Design Was AZeleaNo ratings yet

- ZHM HA250-1 Komatsu S6D125 (1993-1994) AbDocument2 pagesZHM HA250-1 Komatsu S6D125 (1993-1994) Absrabesh basnetNo ratings yet