Professional Documents

Culture Documents

2011 May

Uploaded by

prasaad08Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2011 May

Uploaded by

prasaad08Copyright:

Available Formats

www.jntuworld.

com

Code :R7320305

1

(Mechanical Engineering)

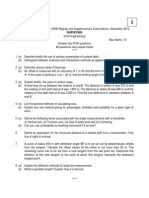

III B.Tech II Semester(R07) Regular & Supplementary Examinations, April/May 2011 DESIGN OF MACHINE MEMBERS-II Time: 3 hours Answer any FIVE questions All questions carry equal marks 1. (a) Dierentiate between Hydrostatic and Hydrodynamic bearings. (b) A full journal bearing of 100 mm diameter and 150 mm long, supports a radial load of 6 KN. The shaft rotates at 600 r.p.m. The radial clearance is 0.08 mm. The room temperature is 250 C, and the temperature of the bearing surface is limited to 550 C. The bearing is well ventilated and so no articial cooling is required. Suggest suitable oil to meet the requirements. 2. (a) Derive an equation for the Whipping stress in the connecting rod. (b) Explain the design procedure for Big end of the connecting rod. 3. (a) How do you reduce the distortion of the liners? Max Marks: 80

(b) What is the use of surface treatment of cylinder liners? Describe the various methods. 4. It is necessary to bend a link as shown in gure- in order to prevent interference with another part of the machine. The link is to suppose a load of 12.5 KN with a design factor of 2.5 on the yield strength of 250 MPa. Determine the thickness of the rectangular cross section of the link if the depth is to be 50 mm, neglecting stress concentration due to curvature and then nd the increase in stress in this section when curvature is taken into account.

5. Find the width of the belt necessary to transmit 10kW to a pulley 250mm diameter, if the pulley makes 1500 r.p.m. and the coecient of friction between the belt and the pulley is 0.22. Assume the angle of contact as 2100 and the maximum tension in the belt is not to exceed 8N/mm width. 6. The maximum thrust on a drill spindle is 15 kN. A 18 teeth pinion, driving a rack tted on the spindle is used to feed the drill into the work. Determine the module for the steel pinion. Take face width as 40 mm, and tooth prole as 14 1/2 0 full depth involute. 7. What advantages do the ball screws have over the usual translational screws? And What are the disadvantages? List applications for the recirculating the ball type of screw. 8. A 2m long, 1m high and 0.5 m wide lathe bed consists of two vertical walls strengthened by perpendicular or diagonal stieners. The thickness of the walls is 50mm, while that of the stiners is 25mm. calculate the reduced bending rigidity of the beds having perpendicular and diagonal stieners.

T N

W U

R O

D L

www.jntuworld.com

www.jntuworld.com

Code :R7320305

2

(Mechanical Engineering)

III B.Tech II Semester(R07) Regular & Supplementary Examinations, April/May 2011 DESIGN OF MACHINE MEMBERS-II Time: 3 hours Answer any FIVE questions All questions carry equal marks 1. (a) What are the dierent types of lubricants used in practice? (b) Layout the design procedure for Hydrodynamic journal bearing. 2. Explain the step-by-step design procedure for connecting rod of an I.C engine. 3. Determine the wall thickness of a 225 mm gas engine cylinder made of nickel cast iron. The maximum gas pressure is 2.2 Mpa. Also determine the thickness of the cylinder head and the number and size of the hold down bolts for the cylinder. 4. An oset tensile link is shaped to clear an obstruction with geometry as shown in the gure. The cross section at the critical location is elliptical, with a major axis of 100 mm and a minor axis of 50 mm. For a load of 90 KN, estimate the stresses at the inner and outer surfaces of the critical section. Max Marks: 80

5. A V belt dive system transmits 90kW at 475 r.p.m. the belt has a mass of 0.6kg/m. the maximum permissible tension in the belt is 900N. The groove angle is 380 and the angle of contact is 1600 nd the minimum number of belts and pulley diameter. The coecient of friction between belt and pulley is 0.2. 6. A reciprocating compressor is to be connected to an electric motor, through spur gearing. The distance between the shafts is 360 mm. The speed of the electric motor is 1000r.p.m.and the speed of the compressor shaft is 200 r.p.m. The torque to be resisted by the motor shaft is 3600 N-m. Determine (i) module and face width of the gears, using 200 stub teeth and (ii) number of teeth and pitch circle diameter of each gear. 7. (a) Dierentiate between dierential screw and compound screw. (b) Discuss the eect of eciency in power screw applications. List some examples where a high eciency is desirable. Also list applications where a lower eciency might be needed. 8. A hollow rectangular steel base of height 200mm, width 1000mm and wall thickness 25mm is loaded as shown in gure-5. Calculate the maximum angle of slope.

T N

W U

R O

D L

www.jntuworld.com

www.jntuworld.com

Code :R7320305

3

(Mechanical Engineering)

III B.Tech II Semester(R07) Regular & Supplementary Examinations, April/May 2011 DESIGN OF MACHINE MEMBERS-II Time: 3 hours Answer any FIVE questions All questions carry equal marks 1. (a) Name the commonly used bearing materials with their properties and limitations for sliding contact bearings. (b) Explain the design procedure for bearing cap and its holding down bots. 2. (a) What are the commonly used materials for the connecting rods? (b) The connecting rod of a slow speed Diesel engine is 3 m long and is made of alloy steel 55. Determine the suitable dimensions for a circular section of the rod. The bore and stroke of the cylinder are 900 mm and 1200 mm respectively. The maximum combustion pressure is 4.8 MPa. 3. Design the cylinder liner for a four-stroke water-cooled vertical diesel engine developing 4.476 KW power and running at 600 rpm. Assume the missing data reasonably. 4. Design a hook and its support for a 20 KN crane. The hook is of swiveling type and of trapezoidal section having a bed diameter of 80mm. The side members and the bridge are of forged steel. Design the hook for 50% overload. Assume suitable allowable stresses and draw a detailed drawing of the hook. 5. Determine the percentage increase in power capacity made possible in changing over from at belt drive to a V-belt drive. The diameter of the at pulley is same as the pitch diameter of the grooved pulley. The pulley rotates at the same speed as the grooved pulley. The coecient of friction for the grooved and at belt is same and is 0.3. The V- belt pulley groove angle is 600 . The belts are of the same material and have same cross sectional area. In each case, the angle of wrap is 1500 . 6. A cast steel 24 teeth spur pinion, operating at 1200 r.p.m, transmits 3 kW to a cast steel 56 teeth spur gear. The other particulars of the drive are: Module, m = 3 mm, Static strength = 100 MPa, Face width = 35 mm, Tooth prole = 14 1/2 0 full depth involute, Determine (i) induced stress in the weaker gear, (ii) dynamic load, (iii) wear load and (iv) allowable static load. Max Marks: 80

T N

W U

R O

D L

7. (a) Give examples of the use of buttress threads for the translation screws. (b) List-out the dierent types of stresses, to which a screwed fastener is generally subjected. 8. A hollow rectangular table is 2m long, 60cm wide and 9cm high. The 15mm thick horizontal walls of the table are joined by 10mm thick vertical stieners spaced at 400mm. Calculate the reduced stiness of the table.

www.jntuworld.com

www.jntuworld.com

Code :R7320305

4

(Mechanical Engineering)

III B.Tech II Semester(R07) Regular & Supplementary Examinations, April/May 2011 DESIGN OF MACHINE MEMBERS-II Time: 3 hours Answer any FIVE questions All questions carry equal marks 1. (a) How the sliding contact bearings are classied? (b) A ship traveling at 35 Kmph requires 2500 KW at the propeller. The diameter of the propeller shaft is 250 mm. Determine the number of collars required and collar thickness, if the bearing pressure is not to exceed 0.35 N/mm2 . The outer diameter of the thrust collar may be taken as 1.6 times the propeller shaft diameter. Also determine the heat developed at the bearing. 2. The high speed diesel engine has the following particulars: Bore of the cylinder 90 mm, stroke140 mm, speed 1500 rpm, compression ratio 16, maximum pressure 5.4 MPa up to 7% of the stroke, mass of the reciprocating parts is 3 kg, and the length of the connecting rod 350 mm. Design a suitable connecting rod for the given duty. 3. (a) List the various Liner materials. (b) How a piston is cooled and what are the advantages of cooling? (c) How will you x the size of the piston rings? Max Marks: 80

4. Design a hook and its support along with a thrust bearing for a 5 KN load. The hook is of swiveling type and of triangular section. Choose your own materials and the probable values of permissible stresses, design and draw a detailed drawing of the hook for 50% overload. 5. Select a V- belt drive for 7 kW power to be transmitted from one shaft running at 1750 r.p.m. to other shaft at around 1200 r.p.m. The service factor may be taken as 1.3. The centre distance must not greater than 1.2m. Take larger pulley diameter as 300mm. 6. A pair of 5 mm module, 200 involute full depth spur gears, with a face width of 40 mm are made of steel having 350 BHN. The pinion has 28 teeth and runs at 1200 rp.m. The gear ratio is 4. What power can be transmitted as per Lewis strength design? Assuming that this much power is being transmitted, check the design for dynamic and wear loads. The static strength of the material of the gears is 210 MPa, and surface endurance limit is nearly 900 MPa.

T N

W U

R O

D L

7. The lead screw of a lathe has square threads of 24mm outside diameter and 5mm pitch. In order to drive the tool carriage, the screw exerts an axial pressure of 2.5 kN. Find the eciency of the screw and the power required to drive the screw, to rotate at 30 r.p.m. Neglect bearing friction. Assume coecient of friction of screw threads as 0.12. 8. A steel structure is studied by making its Perspex model on 1:10 scale. The natural frequency of the model in bending was found to be 150Hz. Determine the natural frequency of the steel structure, if density of Perspex =1.2g/m3 .

www.jntuworld.com

You might also like

- Connecting RodDocument29 pagesConnecting Rodprasaad08No ratings yet

- HMT Mod 5 NotesDocument66 pagesHMT Mod 5 Notesprasaad08No ratings yet

- Question Bank III B.Tech-II Sem Design of Machine Members-Ii Unit - I A Design of Curved Beams Short Answer QuestionsDocument11 pagesQuestion Bank III B.Tech-II Sem Design of Machine Members-Ii Unit - I A Design of Curved Beams Short Answer Questionsprasaad08No ratings yet

- Nanotechnology: Course: B.E & B.Tech Subject: APPLIED CHEMISTRY Unit: VDocument10 pagesNanotechnology: Course: B.E & B.Tech Subject: APPLIED CHEMISTRY Unit: Vprasaad08No ratings yet

- Aluminium: A Large Aluminium Billet From Which Wrought Products Will Be ProducedDocument38 pagesAluminium: A Large Aluminium Billet From Which Wrought Products Will Be Producedprasaad08No ratings yet

- 9A01303 SurveyingDocument4 pages9A01303 Surveyingprasaad08No ratings yet

- M.Tech - F Semester Regulor Exqminotions April 20t5: TimetobleDocument1 pageM.Tech - F Semester Regulor Exqminotions April 20t5: Timetobleprasaad08No ratings yet

- Jntua B.tech Eee r13 SyllabusDocument116 pagesJntua B.tech Eee r13 Syllabusprasaad08No ratings yet

- DV03PUB1 Study GuideDocument5 pagesDV03PUB1 Study Guideprasaad08No ratings yet

- 9A03504 Design of Machine Elements - IDocument1 page9A03504 Design of Machine Elements - Iprasaad08No ratings yet

- Previous Question Papers For Four Year B. Tech I Semester Regular Examinations February 2012Document20 pagesPrevious Question Papers For Four Year B. Tech I Semester Regular Examinations February 2012prasaad08No ratings yet

- YVC RaoDocument98 pagesYVC Raoprasaad08100% (1)

- 9A01101 Engineering MechanicsDocument2 pages9A01101 Engineering Mechanicsprasaad08No ratings yet

- 4-Distributed Forces FEDocument3 pages4-Distributed Forces FEprasaad08No ratings yet

- Dynamics of Machinery 4Document2 pagesDynamics of Machinery 4prasaad08No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 15 Day Detox ChallengeDocument84 pages15 Day Detox ChallengeDanii Supergirl Bailey100% (4)

- B I o G R A P H yDocument17 pagesB I o G R A P H yRizqia FitriNo ratings yet

- John L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDocument12 pagesJohn L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDivya AggarwalNo ratings yet

- How To Block HTTP DDoS Attack With Cisco ASA FirewallDocument4 pagesHow To Block HTTP DDoS Attack With Cisco ASA Firewallabdel taibNo ratings yet

- TriPac EVOLUTION Operators Manual 55711 19 OP Rev. 0-06-13Document68 pagesTriPac EVOLUTION Operators Manual 55711 19 OP Rev. 0-06-13Ariel Noya100% (1)

- Escaner Electromagnético de Faja Transportadora-Steel SPECTDocument85 pagesEscaner Electromagnético de Faja Transportadora-Steel SPECTEdwin Alfredo Eche QuirozNo ratings yet

- My Mother at 66Document6 pagesMy Mother at 66AnjanaNo ratings yet

- QSP 04bDocument35 pagesQSP 04bakrastogi94843No ratings yet

- Sample Monologues PDFDocument5 pagesSample Monologues PDFChristina Cannilla100% (1)

- Assignment of Chemistry For B.sc-B.ed First Semester Session 2019-2023-1Document2 pagesAssignment of Chemistry For B.sc-B.ed First Semester Session 2019-2023-1Payal sahaNo ratings yet

- Astm B19Document6 pagesAstm B19Davor IbarraNo ratings yet

- Illustrating An Experiment, Outcome, Sample Space and EventDocument9 pagesIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarNo ratings yet

- Oxford EAP B1 Pre-Intermediate Student - S Book 2Document167 pagesOxford EAP B1 Pre-Intermediate Student - S Book 2Thư Dương Thị AnhNo ratings yet

- PC Model Answer Paper Winter 2016Document27 pagesPC Model Answer Paper Winter 2016Deepak VermaNo ratings yet

- Subject Manual Tle 7-8Document11 pagesSubject Manual Tle 7-8Rhayan Dela Cruz DaquizNo ratings yet

- Configuring BGP On Cisco Routers Lab Guide 3.2Document106 pagesConfiguring BGP On Cisco Routers Lab Guide 3.2skuzurov67% (3)

- Microsmart GEODTU Eng 7Document335 pagesMicrosmart GEODTU Eng 7Jim JonesjrNo ratings yet

- Algoritm BackTracking EnglezaDocument6 pagesAlgoritm BackTracking Englezaionutz_67No ratings yet

- postedcontentadminuploadsFAQs20for20Organization PDFDocument10 pagespostedcontentadminuploadsFAQs20for20Organization PDFMohd Adil AliNo ratings yet

- BSC HTM - TourismDocument4 pagesBSC HTM - Tourismjaydaman08No ratings yet

- SASS Prelims 2017 4E5N ADocument9 pagesSASS Prelims 2017 4E5N ADamien SeowNo ratings yet

- MultiLoadII Mobile Quick Start PDFDocument10 pagesMultiLoadII Mobile Quick Start PDFAndrés ColmenaresNo ratings yet

- India TeenagersDocument3 pagesIndia TeenagersPaul Babu ThundathilNo ratings yet

- SLA in PEGA How To Configue Service Level Agreement - HKRDocument7 pagesSLA in PEGA How To Configue Service Level Agreement - HKRsridhar varmaNo ratings yet

- Quiz 140322224412 Phpapp02Document26 pagesQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriNo ratings yet

- Promotion-Mix (: Tools For IMC)Document11 pagesPromotion-Mix (: Tools For IMC)Mehul RasadiyaNo ratings yet

- WAQF Podium Design Presentation 16 April 2018Document23 pagesWAQF Podium Design Presentation 16 April 2018hoodqy99No ratings yet

- Quarter 1-Week 2 - Day 2.revisedDocument4 pagesQuarter 1-Week 2 - Day 2.revisedJigz FamulaganNo ratings yet

- Cable To Metal Surface, Cathodic - CAHAAW3Document2 pagesCable To Metal Surface, Cathodic - CAHAAW3lhanx2No ratings yet

- Eggermont 2019 ABRDocument15 pagesEggermont 2019 ABRSujeet PathakNo ratings yet