Professional Documents

Culture Documents

Prep Meeting 22 00 00

Uploaded by

Hany Botros G. TadrosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prep Meeting 22 00 00

Uploaded by

Hany Botros G. TadrosCopyright:

Available Formats

FY 08 SOF PROGRAM FACILITIES AL UDEID AIR BASE Plumbing C. & H. Water and Comp.

Air Galvanize Iron pipes PREPARATORY MEETING MINUTES

Contract No.: W912ER-12-C-0011 Definable Feature: Spec Section: Galvanize pipe installation YES 22 00 00

Date: 01 / 04 / 2013

Gov. Rep Notified: 48 Hours in Advance: 1) Personnel Present: See attendance sheet 2) Submittal:

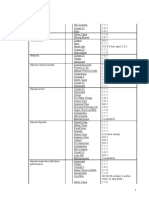

S. No

Tran. No

...X... NO...

Submittal No.

Description

Class.

Code

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

8 10.4 29 23 19 21 1 3.1 3.1 8 9 10.4 18 22 23 26 23 23 23 28

22 00 00 3.16 22 00 00 2.12 22 00 00 2.10 22 00 00 2.3 22 00 00 2.11 22 00 00 2.5 22 00 00 2.3 22 00 00 2.1 22 00 00 2.1 22 00 00 3.16 22 00 00 3.16 22 00 00 2.12 22 00 00 2.15.4 22 00 00 2.9.2 22 00 00 3.11.8 22 00 00 3.5 22 00 00 N/A 22 00 00 2.3 22 00 00 2.13 22 00 00 2.2

Galvanized Pipe & Fittings Compressed Air System Electric water heater Valves Hot water circulating Pump Backflow prevention Econosto Valves Eco Galvanized Pipes BIS Galvanized Fittings M.I. Galv. Pipe Fittings Mittal Galvanized Pipes Compressed Air Systems Pipe Hangers (Support Oil/Sand/Water Separator Water Hammer Arresters Water Heater Exp. Tanks Direct Vent Through Roof Vaccum Rel.Valve Fittings Domestic Water Meter Pipe Supports & Hangers

GA GA GA FIO GA GA FIO FIO FIO FIO FIO GA FIO GA FIO FIO FIO FIO FIO FIO

F A B F A A F F F F F A F B F F F F F F

21 22 23 24

28 28 31 32

22 00 00 2.3 22 00 00 N/A 22 00 00 3.12.1 22 00 00 3.12.1

Pressure Reducing Valve Strainer Plumbing Water Sup. G.F. Plumbing Water sup. 1st

FIO FIO GA GA

F F B B

3) Materials Needed: 1. Galvanized pipes and fittings 2. Approved workshop drawings Are all materials & drawings on hand? YES ...x.. NO.. 4) Equipment to be used: 1. Electric threading M/C 2. Electric Hilti drill M/C 3. Manual pipe clamp vice 4. Manual pipe rolling cutter 5. Alum. Ladders & Scaffolding 6. Hand tools for fittings assembly 5) Method statement for installation of G.I. pipes & fittings (Indoor): 1. Fix the G.I. pipe by using the manual pipe clamp vice. 2. Take the required length by using scale mark on the G.I. pipe 3. Cut the G.I. pipe by using the manual rolling cutter set. 4. Make pipe threading by the electric pipe threading M/C. 5. Fix the threaded pipe on the pipe clamp vice jacks then fix the pipe sealant on the pipe threaded 6. Join the pipe fitting on the pipe thread by proper hand tool key 7. Fix the pipe hanger supports by using the hilti for each (1.5 mt) .Adjust the pipe path and level by using manual water level and scale .8 : PIPING SYSYEM PRESSURE TEST

.Testing shall be performed in accordance with ICC, IPC requirements .1 All the pipe line will be water tightness tested at (1.5 times) the .2 operating water pressure. All outlets will be plugged :Two inlet and outlet valves will be installed .3 .a- One inlet at the line beginning to inlet water pressure test b- Second at the end of the line containing tee connection one of the Tee branch containing air valve to vent the air when the water inlet till removal all the air inside the pipe line then close that valve and open the .second Tee branch which contain the pressure gauge c- Starting to increase the water test pressure gradually till the required test pressure reach to its value then close the inlet pressure valve . completely d- Check the water gauge pressure reading that it is stable and reading the water pressure properly without any air bubbles error then register the pressure value Check the pressure reading after 2 hours and comparing it with last .4 pressure reading registration. Check that reading is the same reading to pass the test otherwise check for any leaking Any leaked joint will be disassembling and sealant again and .5 reassembling with fittings will be used to retest the pipes Testing will be redone till all pipes & joints are well tight .6

:.N.T Safety activity hazard analysis ( A.H.A.) as attached report Q.C. inspection criteria daily monitoring and witness of testing 6) Comments

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- FPAL Product Code GuideDocument53 pagesFPAL Product Code GuideSRARNo ratings yet

- Notice: Environmental Statements Notice of Intent: Eldorado National Forest, CADocument2 pagesNotice: Environmental Statements Notice of Intent: Eldorado National Forest, CAJustia.comNo ratings yet

- Icpc11 - Thermodynamics and Fluid MechanicsDocument22 pagesIcpc11 - Thermodynamics and Fluid MechanicsAPARNANo ratings yet

- Chemistry NotesDocument11 pagesChemistry Notesraifaisal9267% (12)

- Output Process Input: Conceptual FrameworkDocument4 pagesOutput Process Input: Conceptual FrameworkCHRISTINE DIZON SALVADORNo ratings yet

- Modern Views Catalogue/Sotheby's BenefitDocument36 pagesModern Views Catalogue/Sotheby's BenefitStudio AdjayeNo ratings yet

- Epilepsy Lecture NoteDocument15 pagesEpilepsy Lecture Notetamuno7100% (2)

- Ieee 802Document3 pagesIeee 802M Zubair AslamNo ratings yet

- 173 EvidenceDocument6 pages173 EvidenceSantiago RubianoNo ratings yet

- Introduction To Reproduction PDFDocument8 pagesIntroduction To Reproduction PDFLmssvNo ratings yet

- Solomon On Sex - Avoiding Marital Disaster: February 12, 2012Document14 pagesSolomon On Sex - Avoiding Marital Disaster: February 12, 2012baimareanNo ratings yet

- Flash Memoir RevisedDocument3 pagesFlash Memoir Revisedapi-511179803No ratings yet

- The Explanation of The Fundamentals of Islamic BeliefDocument95 pagesThe Explanation of The Fundamentals of Islamic BeliefbooksofthesalafNo ratings yet

- ScilabDocument4 pagesScilabAngeloLorenzoSalvadorTamayoNo ratings yet

- Mwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToDocument7 pagesMwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToMateo AponteNo ratings yet

- Guide To Greyhawk PDFDocument108 pagesGuide To Greyhawk PDFAnonymous PtMxUHm9RoNo ratings yet

- Toptica AP 1012 Laser Locking 2009 05Document8 pagesToptica AP 1012 Laser Locking 2009 05Tushar GuptaNo ratings yet

- Homophones WorksheetDocument3 pagesHomophones WorksheetAmes100% (1)

- Volvo PDFDocument218 pagesVolvo PDFNelio Lara Ricaldi0% (1)

- Food - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonDocument9 pagesFood - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonRotten AnarchistNo ratings yet

- Vintage Tavern - PrintInspectionDocument4 pagesVintage Tavern - PrintInspectionBryce AirgoodNo ratings yet

- 1 Introduction To Microsoft VirtualizationDocument36 pages1 Introduction To Microsoft VirtualizationRavinder KantNo ratings yet

- Chapter 3 FinalizedDocument11 pagesChapter 3 Finalizedpeter vanderNo ratings yet

- Afectiuni Si SimptomeDocument22 pagesAfectiuni Si SimptomeIOANA_ROX_DRNo ratings yet

- Article Unleashing The Power of Your StoryDocument17 pagesArticle Unleashing The Power of Your StoryAnkit ChhabraNo ratings yet

- AVR Brosure Basler Decs 100Document2 pagesAVR Brosure Basler Decs 100NikolayNo ratings yet

- Science 10 Quarter 2 Module 4Document6 pagesScience 10 Quarter 2 Module 4Jess Anthony Efondo100% (4)

- CAT25256 EEPROM Serial 256-Kb SPI: DescriptionDocument22 pagesCAT25256 EEPROM Serial 256-Kb SPI: DescriptionPolinho DonacimentoNo ratings yet

- Mechanics of MaterialsDocument11 pagesMechanics of MaterialsPeter MwangiNo ratings yet

- Offsetting Macro-Shrinkage in Ductile IronDocument13 pagesOffsetting Macro-Shrinkage in Ductile IronmetkarthikNo ratings yet