Professional Documents

Culture Documents

Bourdon Tube Installation

Uploaded by

Krushik DhadukOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bourdon Tube Installation

Uploaded by

Krushik DhadukCopyright:

Available Formats

DRUCK & TEMPERATUR Leitenberger GmbH

www.Leitenberger.com E-Mail: DT-Export@Leitenberger.de

INSTALLATION-USE-MAINTENANCE MANUAL FOR BOURDON TUBE DIAPHRAGMCAPSULE PRESSURE GAUGES (Brand: LR-GERMANY)

pressure gauge. Such pressures are generally indicated by LR instruments are designed and constructed to comply with the safety requirements prescribed by the international broad fluctuations of the pointer. It is necessary to minimise this type of pulsating pressure by fitting a snubber between regulations in force. Under the terms of directive 97/23/EC (P.E.D.), LEITEN- the source of the pressure and the instrument. Filling the BERGER pressure gauges are classified into 2 categories. case with a damper liquid can also reduce the harmful PS <=200 bar these instruments do not have to meet the effect of pulsations on the moving parts of the pressure essential safety requirements, but must only be designed gauge. Incorrect selection of the instrument may result in and constructed in accordance with "Sound Engineering fatigue failure. Practice" and are not required to bear the CE mark. A4271 - Fatigue Failure - This is caused by mechanical PS > 200 bar these instruments must comply with the stress resulting from the pressure and takes the form of a essential safety requirements prescribed by the PED, are small crack from the inside to the outside, generally along classified as Category 1 and certified according to Form A. an edge. Such failures are more dangerous when the They must bear the CE mark illustrated below. measured medium is a compressed gas rather than a liquid. Fatigue failures release the fluid gradually, and therefore the case pressure build-up is indicated by the opening of the relief valve. When measuring high pressures, the The recommendations are excerpts taken from the text of process operating pressure is close to the maximum the EN837-1/2/3 and ANSI B40.1 standards, which the user permissible stress limit, and can therefore result in an must be familiar with in order to safely put the instruments explosive failure. In this case a choke should be fitted on the into service. instrument's coupling, in order to limit the flow of liquid. Safety results from the careful selection and installation of the instrument in the pressurised system, as well as from E724 - Overpressure - Any overpressures subject the measuring element to stress, with a consequent reduction in compliance with the maintenance procedures set out by the manufacturer. The user is entirely responsible for ensuring its lifespan and accuracy. It is therefore always advisable to choose an instrument whose full scale pressure is greater correct installation and maintenance. The persons charged with the selection and installation of than the maximum operating pressure, so that it is better able to withstand overpressures and pressure surges. the instrument must be able to recognise the conditions that may negatively impact on the instrument's ability to Pressure surges can be handled in the same way as pulsating pressures. Overpressures of longer duration can perform its function and which may lead to premature be handled by installing a pressure-reducing valve on the failure. In order to correctly specify the functional and constructive pressure gauge line. The occurrence of even a single characteristics of the instruments, it is recommended to overpressure event can result in an overpressure failure. consult the most up-to-date version of the catalogue data A4272 Overpressure Failure - This is caused by sheets, available on-line at the website application of internal pressure greater than the rated limits of the measuring element, and can occur when a lowhttp://www.Leitenberger.com pressure gauge is installed on a high-pressure system. The SELECTION CRITERIA A431 Operating pressure range - The instrument effects of this type of failure, generally more serious in compressed gas applications, are unpredictable and may selected should have a full scale pressure range such that result in instrument fragments being projected in all the operating pressure occurs in the middle half (between directions. The opening of the safety device on the case 25% and 75%) of the scale. The full scale pressure of the does not always guarantee containment of the fragments. It gauge should be approximately two times the is generally accepted that using an instrument with a solid intended operating pressure. - A black front and blow-out back reduces the possibility of triangle symbol on the scale end of the dial fragments being projected toward the front of the indicates that the operating pressure may instrument, where the operator stops to take readings. The reach 90% for pulsating pressures and 100% for static clear front alone does not provide adequate protection, and pressures. in fact is the most dangerous component in such a case. A424 The following applications must be considered Overpressure pulses of short duration (spikes) can occur in potentially dangerous and carefully specified: pneumatic or hydraulic systems, especially when valves are opened or closed. The amplitude of such pulses can be Application Paragraph many times the operating pressure, and the great speed at NF20 Systems containing compressed gas which they occur prevents them from being read out on the A4274 Systems containing oxygen instrument, making them invisible to the operator. They Systems containing hydrogen or fluids A4274 can result in definitive breakage of the instrument or a diffused with hydrogen permanent zero error. A choke reduces the amplitude of the Systems containing corrosive fluids in a A4331, A4273 overpressure spike that reaches the measuring element. The liquid or gaseous state use of a pressure-limiting valve protects the instrument Pressurised systems containing A4274 from all pressures which exceed the calibration limit of the explosive or flammable fluids valve, thereby protecting the instrument form NF21 overpressures. Systems containing pressurised steam Systems subject to dynamic or cyclical E723, A4271 A4331 - The measuring element is generally characterised pressures by its thinness and therefore works under considerable mechanical stress. Chemical compatibility with the pressure Systems in which overpressures may E724, A4272 fluid must therefore be taken into account. None of the accidentally be applied or in which low commonly used materials can be considered immune to pressure gauges may be installed on chemical attack, and various factors can influence its extent: high pressure couplings Concentration, temperature and the type of mixture of the Systems in which interchangeable A4274 various chemical substances. Chemical attack can rapidly pressure gauges may give rise to lead to corrosion failure. dangerous contamination A4273 - Corrosion Failure - This occurs when the Systems containing toxic or radioactive A4274 material of the measuring element is weakened through fluids in a liquid or gaseous state Systems which produce mechanical A4275, A4276, attack by the corrosive chemicals present either in the E722, A4362, media inside or the environment around it. Failure may vibrations occur as a pinhole leakage or early fatigue failure due to A3352 stress cracking brought about by the chemical deterioration Systems with an operating temperature NF25 of the material. In such a case the use of a fluid separator that differs from the ambient made of suitable material must be considered. However the temperature addition of a separator may influence the sensitivity or NF20 In systems containing compressed gas, it is accuracy, or both. As an alternative to a fluid separator, it is advisable to select an instrument equipped with an possible to consider choosing a measuring element made adequate safety device. In the event of unexpected failure of from AISI316 or Monel 400, rather than phosphor bronze. the measuring element, the safety device allows the A4274 Explosive Failure - This occurs as a result of compressed gas to escape outside the case, thereby the violent release of thermal energy due to a chemical preventing the instrument from fracturing. The safety reaction, such as adiabatic compression of oxygen in the patterns employed on LEITENBERGER instruments are presence of hydrocarbons. It is generally accepted that the designated type S1 when they consist of a release valve effects of this type of failure cannot be anticipated. Even the which opens when the pressure inside the sealed case use of solid-front instruments does not esclude against the exceeds an established safety limit, putting it in projection of fragments toward the front of the instrument. communication with the outside, and are designated type Pressure gauges suitable for use with oxygen are marked S3 when the safety consists of an entire blow-out back and Oxygen - Use no Oil and/or with a crossed there is an added baffle wall separating the measuring out oil can symbol on the dial The instruments are supplied already washed element from the clear solid front, providing further protection to the operator. Select an instrument with an and degreased using appropriate products and packed in polyethylene bags. The user must take the adequate level of protection, consulting the following tables necessary precautions to ensure that the connection and the (Tab 1-2): elastic element are kept clean after the pressure gauge has TAB1 been unpacked. Pressurised LIQUID A4275 Vibration Failure - The most common mode fluid of vibration failure is that where the movement parts wear Case filling None Liquid filled because of high cyclic loading caused by vibration, DN <100 100 <100 100 Range (bar) 25 >25 25 >25 25 >25 25 >25 resulting in a gradual loss of accuracy and, ultimately, failure of the pointer to indicate a pressure change. Safety code 0 0 0 0 S1 S1 S1 S1 A4276 Vibration-Induced Fatigue Failure Tab 2 Large amplitude vibrations may in some instances cause Pressurised GAS OR STEAM fatigue cracks in the structure of the measuring element. In fluid this case the pressure build-up may be slow or fast, or even Case filling None Liquid filled explosive. ND <100 100 <100 100 E722 - Vibrations - When the pressure gauge support is Range (bar) 25 >25 25 >25 25 >25 25 >25 subject to vibrations, various solutions may be considered, Safety code. 0 S2 S1 S3 S1 S2 S1 S3 such as: E723 - Dynamic or cyclical pressures - These are generally a) the use of liquid-filled gauges; b) if the vibrations are encountered when the instruments are installed on pumps, strong or irregular, the instruments must be mounted at a and result in a significant reduction in the lifetime of the distance and connected using a flexible hose or tubing. measuring element and the amplifying mechanism of the The presence of vibrations is indicated by continuous, often irregular fluctuations of the pointer.

A4362 - Liquid filled Cases - Liquid filling is

generally used to dampen the vibrations of moving parts due to vibrations and/or pulsations. Great care must be taken in choosing the damping liquid for instruments that will be used with oxidising media such as oxygen, chlorine, nitric acid, hydrogen peroxide, etc. In the presence of oxidising agents, there is the possible risk of chemical reaction, ignition and explosion of the instrument. In this case it is necessary to use fluorine or chlorine based filling liquids. In order to contain the damping liquid inside the case, the pressure gauges are built and supplied in a sealed construction. In some cases, during installation it is necessary to ventilate the case following the instructions on the label affixed to the instrument itself. Special care must be taken with the type of filling liquid used and its usage limitations as a function of ambient temperature (Tab.3). Filling liquids Ambient Temperature Glycerin 98% +15+65C (+60+150F) Silicone Oil -45+65C (-50+150F) Fluoridated Liquid -45+65C (-50+150F)

USE A432 - It is not advisable to use the instruments for measuring pressures near zero, as in that range the accuracy tolerance can represent a significant percentage of the applied pressure. For this reason, these instruments should not to be used for measuring residual pressures inside large volume containers such as tanks, surge tanks, and the like. In fact, such containers may retain pressures that are dangerous for the operator, even when the instrument indicates a zero pressure. It is recommended to install a ventilation device on tanks in order to achieve zero pressure before removing covers or connections, or performing similar tasks. E7251 - Ambient Temperature - It is difficult to insulate the instrument from ambient temperatures that are too high or too low. One solution is to position it further away from the source of cold or heat, when this is possible. If an instrument of accuracy class 0.6 or higher is used at an ambient temperature different from the reference value (20C 2C), it is necessary to make a correction. A44 - It is not advisable to successively install instruments on systems with different operating media, to avoid initiating chemical reactions that may cause explosions resulting from contamination of the wetted parts. NF45 If the instrument dial indicates a fixed pressure for a prolonged time, make sure this is not due to an obstruction of the pressure element supply pipe. Especially in the case of a zero pressure reading, make sure that there is effectively zero pressure inside the instrument before removing it, by isolating it using the shut-off valve. MAINTENANCE E9 - The general safety of an installation often depends on

the operating conditions of the instruments which it contains. It is essential that the measurements indicated by these instruments are reliable. Therefore, any instrument which appears to give an abnormal readout should be removed, checked and recalibrated if necessary. Maintenance of accuracy should be confirmed by routine checks. Checks and recalibrations must be carried out by competent personnel using suitable testing equipment. NF40 - Every 3/6 months after installation, check the accuracy and the wear on moving parts and the state of corrosion on the measuring element. For instruments used on plant subject to demanding conditions (vibrations, pulsating pressures, corrosive media, sediments, etc.) replace them after the time intervals indicated in the plant procedures A4332 - The calibration and testing fluid must be compatible with the measured media in the pressurised system. Fluids containing hydrocarbons must not be used when the measured medium is oxygen or any other oxidising substance. NF41 - Instruments kept in their original standard packing (cardboard box) must be stored in a closed area and protected from moisture: in this case no special attention is required. If the instruments are packed in special materials (wooden crates lined with tar paper or barrier bags) it is preferable to store them in a closed room if possible, or in any case in an area protected from the elements; the condition of the packed materials should be checked every 3-4 months, especially if the crates are exposed to the elements. The temperature of the storage area should be between 20 and +65C, except where otherwise specified on the catalogue data sheets.

A3352 - In case of radial mounting, especially if the case is filled with damping liquid and the vibrations are extensive, the possibility of failure resulting from the considerable vibrating mass of the pressure gauge must be taken into account. In such cases a threaded 1/2" coupling to the process line is an essential minimum requirement. E721 - Mechanical stress - Pressure gauges must not be subjected to mechanical stress. If the installation points are subject to mechanical stresses, the instrument must be installed at a distance and connected using flexible hoses. The instruments selected must be of the surface, wall or panel mount type. NF21 - Regardless of the material with which the unit has been made or welded (connection to the process, Bourdon tube, terminal) it is not advisable to use the pressure gauges at temperatures exceeding 65C (150F). It is recommended to use a trap in cases where the pressure gauge is used with steam or liquid media at high temperatures. A trap or similar device should always be fitted near the instrument and filled with condensed fluid before pressurising the system, so as to prevent the hot fluid from reaching the instrument during the initial pressure rise. The fluid should not be allowed to freeze or crystallise inside the measuring element. However, if the instrument is used for measuring points at high temperature, it is recommended to use a hose with inside diameter of at least 6 mm to connect it to the pressure coupling. A hose about 1.5-2 metres long reduces the effective operating temperature to approximately ambient level. If the type of fluid does not permit the use of a small section hose, it is often necessary to insert a separator between the process fluid and the instrument, provided that the transmission fluid is suitable for the temperature of the process fluid. NF22 - The characteristics of the instruments may be affected during transport, despite adequate packing, and must be checked before use. Correct calibration can be checked by excluding the instrument from the process by means of the shut-off valve and checking that the pointer returns to the zero mark (unless the temperature varies greatly from 20C). Failure of the pointer to return to zero indicates serious damage to the instrument. INSTALLATION E71 - To facilitate removal for maintenance purposes, a

shut-off valve can be installed between the pressure gauge and the plant. The pressure connection must be watertight. If the pressure connection has a cylindrical thread, the seal is achieved using an O-ring clamped between the two flat sealing surfaces, one on the pressure connection and the other on the instrument's process connection. If the pressure connection has a tapered thread, the seal is achieved by simply screwing the connection onto the coupling, through the mating of the threads. It is common practice to wrap PTFE tape around the male thread before coupling (see Fig2).

In both cases the torque must be applied using two hexagonal spanners, one on the flat faces of the instrument/process coupling and the other on the pressure connection.

Do not use the case as a means of tightening as this may cause damage to the instrument. When

pressurising the system for the first time, check the tightness of the connection seal. All instruments must be mounted in such a way that the dial is vertical, unless otherwise indicated on the dial itself. When the instrument includes a safety device, this must be at least 20 mm from any other object. - For wall or panel mount instruments, make sure that the pipe conveying the pressurised fluid is connected to the instrument coupling without exerting torsion or force. E727 - Effect of liquid columns - The installer must be aware that, if the instrument is subjected to the load of a liquid column, it must be calibrated to compensate for this effect. In this case, the compensation needs to be indicated on the dial, and should therefore be communicated to LEITENBERGER when placing the order. E8 Putting into service - The instrument must always be put into service with care, to avoid pressure surges or sudden changes in temperature. Shut-off

valves must therefore be opened slowly.

WARNING Improper use may damage the instrument, resulting in failure and possible injury to persons or damage to the plant. Carefully read the above instructions before using this product

You might also like

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- CP HS 12Document8 pagesCP HS 12aliNo ratings yet

- Ped StarterDocument19 pagesPed Starterjasons92No ratings yet

- Poettmann Carpenter BHPDocument5 pagesPoettmann Carpenter BHPcesar_d10% (1)

- Manual Compresores Ingersoll RandDocument186 pagesManual Compresores Ingersoll Randcristcc_877346100% (3)

- Design Requirements For Pressure Safety Relief Valves: Codes: Structure & ComparisonDocument5 pagesDesign Requirements For Pressure Safety Relief Valves: Codes: Structure & Comparisontss1372350% (2)

- Submersible Pump Pre Commissioning ITPDocument12 pagesSubmersible Pump Pre Commissioning ITPTrungVuDinh100% (1)

- Comparison ASME and PEDDocument19 pagesComparison ASME and PEDManjadi MaverickNo ratings yet

- Hydrotest BlindDocument9 pagesHydrotest BlindAdrian RogersNo ratings yet

- OTECDocument6 pagesOTECibong tiriritNo ratings yet

- Manual Secador de Aire Wh-40Document56 pagesManual Secador de Aire Wh-40Marco Vargas100% (1)

- Esp SizingDocument17 pagesEsp SizingAmin ElfatihNo ratings yet

- LSR Cyclon Repair ManualDocument228 pagesLSR Cyclon Repair ManualMaura Paredes83% (6)

- Aircraft Maintenance Hangar: Hvac System (Air Side) VRV Airconditioning System 6. MaintenanceDocument7 pagesAircraft Maintenance Hangar: Hvac System (Air Side) VRV Airconditioning System 6. MaintenanceVagelis AntoniouNo ratings yet

- Pressure TestDocument9 pagesPressure Testwferry27100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Kerala BOE-2014 Paper-1 SolutionDocument10 pagesKerala BOE-2014 Paper-1 SolutionAlok DoshiNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Pressure System in IndustryDocument35 pagesPressure System in Industryhittu solankiNo ratings yet

- User Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi TubesDocument12 pagesUser Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi Tubesxaaabbb_550464353100% (1)

- Fundamentals of Valve Sizing For Liquids d350408x012Document10 pagesFundamentals of Valve Sizing For Liquids d350408x012twins19564839100% (1)

- Project Standards and Specifications Pneumatic Test Specification Rev01Document4 pagesProject Standards and Specifications Pneumatic Test Specification Rev01GabrielPantilicaNo ratings yet

- Rotary Screw ES - 6 Series Air Compressor: 5, 7.5 and 10HP 4, 5.5 and 7.5 KWDocument68 pagesRotary Screw ES - 6 Series Air Compressor: 5, 7.5 and 10HP 4, 5.5 and 7.5 KWAlexisAlejandroSandovalFloresNo ratings yet

- UP6 15, UP6 20, UP6 25, UP6 30 60Hz: Intellisys Option Dryer Option High Dust Option Outdoor Module Option PORO OptionDocument226 pagesUP6 15, UP6 20, UP6 25, UP6 30 60Hz: Intellisys Option Dryer Option High Dust Option Outdoor Module Option PORO Optionrfg21100% (1)

- Compressor Ingersool PDFDocument52 pagesCompressor Ingersool PDFFabripreta Santos100% (1)

- Process Plant Design - Training Course - 10 and 11 Jan 2018 - Process Line Sizing PDFDocument69 pagesProcess Plant Design - Training Course - 10 and 11 Jan 2018 - Process Line Sizing PDFNgàyMưaNo ratings yet

- 02250195-403 r00 - MAN - Regenerative-Heatless Dryer DHLDocument76 pages02250195-403 r00 - MAN - Regenerative-Heatless Dryer DHLJuan Ignacio Alvarez Claramunt100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- ACT 20 500 Manual 2012Document68 pagesACT 20 500 Manual 2012UbanAirlanggaNo ratings yet

- Compresor Ingersoll RandDocument48 pagesCompresor Ingersoll RandDanilo ContrerasNo ratings yet

- คู่มือการใช้งาน Pressure Gauge Nuova FimaDocument1 pageคู่มือการใช้งาน Pressure Gauge Nuova FimaParinpa KetarNo ratings yet

- Guidance On UseDocument7 pagesGuidance On UseLoveNo ratings yet

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 pagesUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- Operating Instructions: Pressure GaugesDocument1 pageOperating Instructions: Pressure GaugesTreeNo ratings yet

- RP10Document3 pagesRP10PireyiNo ratings yet

- MI-PRE - 340-2D2-ENG - 4 User Guide PRE ATEX@enDocument4 pagesMI-PRE - 340-2D2-ENG - 4 User Guide PRE ATEX@enUssamaNo ratings yet

- Self-Operated Pressure Regulators: Type 41-23 Universal Pressure Reducing ValveDocument20 pagesSelf-Operated Pressure Regulators: Type 41-23 Universal Pressure Reducing ValveDiego Martínez FernándezNo ratings yet

- Pressure Gauge SelectionDocument2 pagesPressure Gauge SelectiondjendraHeniNo ratings yet

- Instruction Manual KED150Document36 pagesInstruction Manual KED150Muhammad Asyraf100% (1)

- 2Document17 pages2WormInchNo ratings yet

- 1206 Dival507 MT235 ENGDocument30 pages1206 Dival507 MT235 ENGMisbachul ChoirNo ratings yet

- Measurement of Process Variables: Specification Preface SheetDocument13 pagesMeasurement of Process Variables: Specification Preface SheetRaj ChavanNo ratings yet

- DIVAL 500: Technical ManualDocument30 pagesDIVAL 500: Technical ManualchkzaNo ratings yet

- Operating Manual Pilot-Controlled Pressure Regulators: Sheet No. RP/4.1.161.1.1 Issue 11.02.2016 © 2016 Mankenberg GMBHDocument16 pagesOperating Manual Pilot-Controlled Pressure Regulators: Sheet No. RP/4.1.161.1.1 Issue 11.02.2016 © 2016 Mankenberg GMBHMunir KadernaniNo ratings yet

- Instruction and Maintenance Manual: Silenced Screw Rotary Compressor UnitsDocument34 pagesInstruction and Maintenance Manual: Silenced Screw Rotary Compressor UnitsJohnny Diaz VargasNo ratings yet

- FIKE RD Combo With Relief ValvesDocument11 pagesFIKE RD Combo With Relief ValvesAnkit GandhiNo ratings yet

- Series PS1000 PDFDocument9 pagesSeries PS1000 PDFMarlon Andres Morocho OñaNo ratings yet

- GAS Cut-Off DeviceDocument37 pagesGAS Cut-Off DeviceFRANCISCO JOSE GARCIA IBAÑEZNo ratings yet

- Heavy Duty ManualDocument26 pagesHeavy Duty ManualErnesto Andres Guevara MalaveNo ratings yet

- Abb Rotametro Que NecesitoDocument21 pagesAbb Rotametro Que Necesitomonyk_2442411No ratings yet

- Manuais - Autoclave 12L - 300051308 Rev 02Document24 pagesManuais - Autoclave 12L - 300051308 Rev 02Arif HidayatNo ratings yet

- Parr Hydrogenator 3900 SeriesDocument31 pagesParr Hydrogenator 3900 SeriesPedro MendoncaNo ratings yet

- Ldu 11 Eun 7696 en 25042005Document16 pagesLdu 11 Eun 7696 en 25042005Thiago FernandesNo ratings yet

- AVL 439 Opacimeter Operating ManualDocument196 pagesAVL 439 Opacimeter Operating ManualSasidharan100% (3)

- Spirax Sarco BVA300 ManualDocument20 pagesSpirax Sarco BVA300 ManualThomas神之领域No ratings yet

- Inherently Safe DesignsDocument4 pagesInherently Safe Designsjxd3261No ratings yet

- Betriebsanleitung Thermosyphon Fluiten EnglDocument11 pagesBetriebsanleitung Thermosyphon Fluiten Englyahya samiNo ratings yet

- Operating Instructions For ManometerDocument13 pagesOperating Instructions For ManometerPablo JesúsNo ratings yet

- Atlas Copco Impact Wrenches W2320XP-ATEXDocument16 pagesAtlas Copco Impact Wrenches W2320XP-ATEXexge2000No ratings yet

- Ped StarterDocument19 pagesPed Starterfeihung2012No ratings yet

- Operating Manual - FP3 - UK - Revision 1Document29 pagesOperating Manual - FP3 - UK - Revision 1benakiaNo ratings yet

- 30RB 21siDocument76 pages30RB 21sixavierxo50% (2)

- EVD SeriesDocument56 pagesEVD SeriesWan Fyzzul HabibonNo ratings yet

- Almig Pistons 'A' Range Operating ManualDocument22 pagesAlmig Pistons 'A' Range Operating ManualAndy MitchellNo ratings yet

- Convertidor Neumatico Y695ADocument8 pagesConvertidor Neumatico Y695AALBERTONo ratings yet

- Flow Regulator SAMSON 42-36 ManualDocument28 pagesFlow Regulator SAMSON 42-36 Manualenjiniring sbklNo ratings yet

- The New Ansi Centrifufal PumpDocument7 pagesThe New Ansi Centrifufal PumpCésarRenatoCopacondoriCuaylaNo ratings yet

- Fire Pump Settings - NFPA 20 - Fire Protection SpecialistsDocument1 pageFire Pump Settings - NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- Bono-Energia FT WebDocument4 pagesBono-Energia FT WebMohamed Yassine LahianiNo ratings yet

- Experiment No. 6 7 8 Water TurbinesDocument69 pagesExperiment No. 6 7 8 Water TurbinesMilon MirdhaNo ratings yet

- Encana - Lara Conrad PresentationDocument47 pagesEncana - Lara Conrad PresentationСергей СтояновNo ratings yet

- Start-Up Sheet For CompressorsDocument1 pageStart-Up Sheet For CompressorsGreg LundyNo ratings yet

- Fluids Formula SheetDocument5 pagesFluids Formula SheetsjkwdfNo ratings yet

- Libretto Istruzioni Extreme - Extreme Ultra - CompressedDocument7 pagesLibretto Istruzioni Extreme - Extreme Ultra - CompressedagfranchiniNo ratings yet

- General Science & Ability - Mian Shafiq-1Document1 pageGeneral Science & Ability - Mian Shafiq-1Jahanzaib BrohiNo ratings yet

- ICE Quiz No. 1 (Mock Exam) : Name: Class: DateDocument20 pagesICE Quiz No. 1 (Mock Exam) : Name: Class: DateJoshua Ryan CanatuanNo ratings yet

- Class XI Assignment States of MatterDocument2 pagesClass XI Assignment States of MatterCheryl ChaudhariNo ratings yet

- Thermodynamics: Subject: Engineering Special Topics 1 Topic: Thermodyanmics Prepared By: Engr. Noel GatbontonDocument4 pagesThermodynamics: Subject: Engineering Special Topics 1 Topic: Thermodyanmics Prepared By: Engr. Noel GatbontonPaul Adriane TornerosNo ratings yet

- Deluge ValveDocument3 pagesDeluge Valvealdi sophianNo ratings yet

- Hs Hhs Ms Pump Performance SheetDocument1 pageHs Hhs Ms Pump Performance SheetsunbopumpNo ratings yet

- Answer - To - Subjective HydraulicsDocument3 pagesAnswer - To - Subjective Hydraulicsmellon3duwenNo ratings yet

- Experiments With Various Drag Reducing Additives in Turbulent Flow in Dense Phase Gas PipelinesDocument12 pagesExperiments With Various Drag Reducing Additives in Turbulent Flow in Dense Phase Gas PipelinesQaiser HafeezNo ratings yet

- Situational Problems (Nikko Barongan)Document3 pagesSituational Problems (Nikko Barongan)Jonnah Faye MojaresNo ratings yet

- BoilersDocument14 pagesBoilersSaddam Hussain AL HassaniNo ratings yet

- Subsystems of The EarthDocument10 pagesSubsystems of The Earthroderick dahilig100% (2)

- Spe 16242 Pa PDFDocument7 pagesSpe 16242 Pa PDFAndrei OrtegaNo ratings yet

- Airconditioning and Pressurization System: Malaysian Institute of Aviation TechnologyDocument160 pagesAirconditioning and Pressurization System: Malaysian Institute of Aviation Technologyronasso7No ratings yet

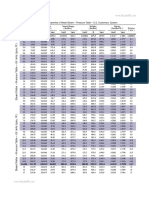

- Water-Steam Saturation Properties (By Pressure in US Units)Document5 pagesWater-Steam Saturation Properties (By Pressure in US Units)Juan Carlos Ramirez DariasNo ratings yet

- Hydraulic Diagram, With Option Components: Service InformationDocument4 pagesHydraulic Diagram, With Option Components: Service InformationPetrus Kanisius WiratnoNo ratings yet