Professional Documents

Culture Documents

A2la C210

Uploaded by

Govind Shriram ChhawsariaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A2la C210

Uploaded by

Govind Shriram ChhawsariaCopyright:

Available Formats

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 1 of 17

ASTM Standard Practices for Laboratories Testing Concrete and Concrete Aggregates, Bituminous Materials, Soil, and Rock, Nondestructive Testing, and Masonry for Use in Construction and Criteria for Laboratory Evaluation

The following pages present the applicable criteria from ASTM C1077, D3740, D3666, E329, E543, and C1093 in a checklist format. The criteria contained on this checklist are unique to these ASTM Guides and are not required by ISO 17025, but are required by A2LA for accreditation to the respective guides. As an option, the laboratory may obtain accreditation for these Construction Materials Engineering Standards. The laboratory's policies and procedures must meet these requirements in order to obtain accreditation. Quality system documentation and supporting records must be available for the assessor's review. Before the assessment, the laboratory is asked to complete the document reference identifiers in the checklist's second column (labeled Reference") and place a tick mark in the yes (Y), no (N), or not applicable (NA) space for each checklist item. This serves to help both the laboratory and the assessors prepare for the assessment and may save a significant amount of assessment time and cost. The appropriate "reference" can include quality manual, laboratory manual, SOPs, records, etc. references. The noted references should specify procedure number, page number and section number, if possible, where each checklist item is addressed. Assessor Instructions: Review the laboratory's documented quality system to verify compliance with the appropriate ASTM Practice. Assess to verify that the documented quality system is indeed implemented as described. Assess the laboratory's technical competence to perform specific tests or specific types of tests. Record comments related to tests on separate sheets and/or on the draft scope(s) of accreditation. All deficiencies must be identified and explained in the assessor deficiency report. Notations can be recorded below the cited paragraph. Paragraphs which do not apply may be designated by N/A. Note to assessors and laboratory personnel: Redundant checklist entries need to be recorded only once, in the highest-level checklist in which it is found (i.e. ISO 17025specification checkliststest method checklists). Please circle ASTM assessed: C1077-11A D3740-10 D3666-09 E329-11b E543-09 C1093-11

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 2 of 17

To the best of my knowledge, all laboratory document references below as well as actual laboratory practice have been assessed for compliance with the relevant ASTM practices. I hereby attest that all Yes marked compliance clauses, whether initialed or not, meet the aforementioned requirements. Any areas of noncompliance have been fully described in the Assessor Deficiency Report.

CAB Name: Address: Contact: Phone:

Email:

Master Code: Certificate(s): Assessment Dates: Assessor(s):

Assessment ID: Conformity Standard: Assessment Type: Assessor Signature(s):

AcO:

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 3 of 17

CMT Practice Requirements

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

General ASTM E329 invokes requirements of C1077, D3740, D3666, E543, and C1093 for appropriate materials. Therefore, when one of these specifications is mentioned it is appropriate that the requirements also apply to E329 depending on material tested. E329, D3666 requires accreditation from third party i.e. A2LA, NVLAP etc. in field of operations. Site or temporary facilities must be on scope of accreditation. C1077 and D3740 require inspection only by a third party. Accreditation to D3740 requires that at least five tests are on the scope.

Organization and Management

Management All relevant testing services are provided under the full-time technical direction of a registered professional engineer with at least 5 years experience in construction materials testing. Employed by lab. May be responsible for more than one location. (Note: A QC laboratory used only for QC testing may be managed by a QC Manager). (Per E329; if a laboratory only serves as a Quality Control laboratory and produces no tests for acceptance, payment, or official record the requirement for a professional engineer is waived) or an equivalent science degree with related experience.

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 4 of 17

CMT Practice Requirements

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

Supervising Field Technician 3 years experience and current technician certification: Relevant tests that must be covered by the certification program are: C31, C138, C143, C172, C173, C231, and C1064. Certification program shall include: 6.1.7.1. Written examination shall be of sufficient length and detail to cover the test method or practice, including, as applicable; the significance of the test or practice, sampling, specimen preparation, procedure, calculations, and reporting of results. 6.1.7.2. Performance evaluation shall include a demonstration of the test method or practice, to document the technicians ability to correctly perform the procedure in accordance with the standard 3 years experience. additionally D3666 Supervisor shall have certifications or qualifications through an agency or state DOT program or NICET Level II program. This person shall be able to demonstrate competency by performance evaluation and by oral and/or written examination, the ability to perform correctly the tests and duties in the manner stipulated by applicable procedures. 3 years experience is required. . Revaluation every three years of each test the person is authorized to perform is required. As a minimum the written exam shall include at least five tests. Current certification by a national, regional or state authority is also evidence of fulfilling written exam requirement.

For Concrete only

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 5 of 17

CMT Practice Requirements This person shall be able to demonstrate competency by performance evaluation and by oral and/or written examination, the ability to perform correctly the required duties. 5 years experience is required. (Current NICET Level III, ACI, or other qualified national, regional, or state authorities, is also evidence of competency.) (Also AWS-CWI, ASNT Level II) STEEL Supervision by AWS QC-1 Welding Inspector or by Licensed PE NDE (E543) Supervision by ASNT Level II for NDE methods on scope

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

Supervising Laboratory Technician 3 years experience and current technician certification: Relevant tests that must be covered by the certification program are: C31, C39, C40, C117, C127, C128, C136, C138, C143, C172, C173, C231, and C1064. Certification program shall include: 6.1.7.1. Written examination; shall be of sufficient length and detail to cover the test method or practice, including, as applicable; the significance of the test or practice, sampling, specimen preparation, procedure, calculations, and reporting of results. 6.1.7.2. Performance evaluation; shall include a demonstration of the test method or practice, to document the technicians ability to correctly perform the procedure in accordance with the standard This person shall demonstrate competency by performance evaluation and by oral and/or written examination, the ability to perform correctly the tests and duties in the manner stipulated by applicable procedures. 3 years experience is required. Revaluation every three years of each test the person is authorized to perform is required. As a minimum the written exam shall include at least five tests. Current certification by a national, regional or state authority is also evidence of fulfilling written exam requirement. This person shall demonstrate competency by performance evaluation and by oral and/or written examination, the ability to perform correctly

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

For Concrete only

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 6 of 17

CMT Practice Requirements the required duties. 5 years experience is required. Revaluation every three years of each test. (Current NICET Level III is also evidence of competency) This person shall demonstrate competency by performance evaluation and by oral and/or written examination, the ability to perform correctly the required duties. 5 years experience is required 3 years experience. additionally D3666 Supervisor shall have certifications or qualifications through an agency or state DOT program or NICET level II program. This person shall be able to demonstrate competency by performance evaluation and by oral and/or written examination, the ability to perform correctly the required duties. 5 years experience is required. (Current NICET Level III, ACI Grade II, or other qualified national, regional, or state authorities, is also evidence of competency.) (AWS-CWI, ASNT Level II) STEEL Supervision by AWS QC-1 Welding Inspector or by Licensed PE NDE(E543) Supervision by ASNT Level II for NDE methods on scope

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

Technician Laboratory and Field Technicians shall possess current technician certification. Certification program shall include: 6.1.7.1. Written examination; shall be of sufficient length and detail to cover the test method or practice, including, as applicable; the significance of the test or practice, sampling, specimen preparation, procedure, calculations, and reporting of results. 6.1.7.2. Performance evaluation; shall include a demonstration of the test method or practice, to document the technicians ability to correctly perform the procedure in accordance with the standard

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 7 of 17

CMT Practice Requirements

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

Laboratory tests include: ASTM C39, C617 or C1231; Aggregate Lab C40, C117, C127, C128, C136; Field C31, C138, C143, C172, C173, C231, and C1064. This person shall be able to demonstrate by written examination, the ability to perform correctly the required duties. (With high school diploma) Current certification shall be considered evidence of fulfilling written exam requirements. Five tests from ASTM Volumes 4.08 and 4.09 shall be included. Performance evaluation every 24 months. or Each person shall be reevaluated internally or externally, at least every three years for each test or inspection or both the person is authorized to perform. Demonstrate competence for the test being performed and work under the direct supervision of personnel meeting the above criteria given. Shall have qualifications/certifications thru a State DOT or NICET Level I - A trainee must achieve certification within two years. STEEL AWS QC-1 or as otherwise required by project specifications NDE (E543) ASNT Level I for NDE methods on scope

CMT Practice Requirements The QAM (C1093 is QSM) shall contain a document describing the method(s) used to evaluate staff competency to ensure that each test covered by the scope of this standard is performed in accordance with standard procedures. This description shall include the frequency of evaluations for each technician, a description of the levels of training, the criteria for each level, and indicate what position(s) or employee(s) is responsible for evaluating staff competency and maintaining records. These procedures shall ensure that each technician performing the test method is evaluated. Note 13 Proficiency sample testing may be useful in evaluating staff

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 8 of 17

CMT Practice Requirements competency, however, it should be used in conjunction with observation of actual testing performed.

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

Test and Calibration Methods The testing laboratory shall be capable of performing the required ASTM test methods or practices and may request additional evaluation for optional methods to the extent that those services are provided by the laboratory. The laboratory shall use the latest version of each referenced method within one year of its publication unless an earlier version of the standard is required by the client. Laboratory Procedure Manual Shall maintain a procedure manual; citing ASTM method used, exceptions to ASTMs, or special criteria such as forms, QC, etc.

8.4.1 Verification of sieve accuracy shall be performed at least annually on each sieve used in the test for sieve analysis (Test Methods C117 and C136). Any one of the following three methods of verification is acceptable. Each method of sieve verification shall include an inspection of sieve cloth for punctures or obvious defects. (1) Verification of each sieve used according to the procedures prescribed in the Annex of Specification E11. (2) A comparison of the results of a split sample sieved on different sieve sets. Results shall be verified for single operator precision to the within the acceptable range of two results stated in the test method. (3) Participation in the sieve analysis test in an aggregate proficiency sample program, as described in the Quality System section. Results shall be verified for multilaboratory precision to be within the acceptable range of two results stated in the test method.

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 9 of 17

CMT Practice Requirements

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

8.4.2 When mechanical sieving devices are used, the period of mechanical agitation shall be checked at least annually for adequacy of sieving as described in Test Method C136. Mechanical agitation periods must be established for each different type of aggregate tested. 8.4.3 Specific Gravity and Absorption TestsWhen performing the procedures of Test Methods C127 and C128, duplicate tests shall be made at least once every 6 months. Results shall be verified for single operator precision within tolerance stated in the respective test method. Participation in a proficiency test program with satisfactory scores achieved in Test Methods C127 and C128 is an acceptable alternative.

Reports Test reports shall include the following information: Name of the registered professional engineer or his designee, and identification of tests performed by subcontractors. A record of each test report and related records shall be retained for at least 3 years. (3 years for D3740, C1077) (1 year for D3666 & C1093) (2 years min for A2LA which supersedes D3666) 11.4 Deficiencies noted in the final report provided to the testing agency by the evaluation authority shall be corrected within 30 days of receipt of the report. 11.4.1 If an inspection service is used, the agency shall supplement the final report with a statement of corrective actions taken, which is signed by the agencys professional engineer. 11.4.2 If an accreditation service is used, the agency shall report deficiency corrections to the Accreditation Body who will issue a certificate of accreditation when its requirements are satisfied

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 10 of 17

CMT Practice Requirements The laboratory shall (1) report deficiency corrections to AAP, A2LA, CMEC, NVLAP or other recognized accreditation body who will issue a certificate of accreditation when their requirements are satisfied, or (2) if an inspection service is used, supplement copies of the final report with a statement of corrective actions taken signed by the laboratorys professional engineer. Laboratory Procedure Manual- A laboratory procedure manual outlining the method or inspection procedure for each customary test or service performed by the laboratory shall exist. .procedure manual shall include reference to ASTMs etc., and if there are applicable exceptions and special instructions. The quality manual shall contain a list showing applicable dates of the qualifications, accreditations and recognition of the agency by others. The quality manual shall contain position descriptions for each technical operational position shown on the agencys organization chart in testing areas covered by the scope of this standard. These position descriptions shall identify the position and include a description of the duties associated with the position, required skills, education and experience, and supervision exercised and received. A reference to where the required position descriptions may be found is acceptable if they are not included in the quality manual. The quality manual shall contain typical test report forms, which illustrate the manner in which tests results and supporting information (See Section 8.1.11) are documented. Note 17 - A printout showing a typical test record is acceptable if the laboratory uses electronic media for report storage. The results of any on-the-job training performed including name of person, date of training, by whom and type of training

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 11 of 17

CMT Practice Requirements When the agency is responsible for collecting samples, the samples must be identified with the respective portions of the work in which the material represented was or will be used. Corrective actions reported by evaluating authority shall be corrected within 30 days. Test reports shall not be reproduced except in full without the permission of the laboratory.

Reference

Yes

No

N/A

C1077

D3740

D3666

E329

E543

C1093

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 12 of 17

STEEL INSPECTION (Mill, Fabrication & Erection)

REQUIREMENTS REFERENCE YES NO NA E543

REFERENCE MATERIALS

Applicable Parts of ASTM Standards Applicable Parts of ASME Boiler & Pressure Code Applicable Building Codes AISC Manual of Steel Construction AWS D1.1 AWS D1.2 AWS D1.3 AWS D1.4 AWS D1.5 AWS D1.8 AWS B1.11 Steel Joist Institute (SJI) Recommended Code of Standard Practice for Steel Joists & Joist Girders.

FIELD EQUIPMENT

Steel Tape, Rule, Calipers, & other appropriate measuring Equipment Weld Dimension Gage Weld Viewing Shield Hammer for Weld Testing Battery operated Hand Light Paint Thickness Gage

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Thermometer or Temperature Measuring Crayons Inspectors identification Stamp or Tags Torque Wrench Tension Measuring Device (Skidmore-Wilhelm Device) Document Revised: June 22, 2012 Page 13 of 17

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 14 of 17

The tables included below are provided for reference and include Table 1 from D3740 for soils equipment calibration requirements with calibration intervals and Table 1 from D3666 for Bituminous Materials Test Equipment with calibration intervals.

TABLE 1 Test Equipment Calibration and Verification Requirements ASTM D3740

EquipmentTest Method Mechanical Shakers Gen. Purpose Balances, Scales & Weights Compression or Loading Device Mechanical Compactor CA Kneading Compactor Ovens Vacuum System Molds Manual Hammer Sieves Liquid Limit Device Grooving Tool Hydrometers Straightedge Weighted Foot Assembly CBR Annular and Slotted Weights CBR Penetration Piston Standard Metal Specimen Metal Follower Gen. Purpose Balances, Scales, Weights

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Requirement Ck. Sieving Thoroughness Verify Calibrate Calibrate Calibrate Verify Temperature Setting(s) Ck. Pressure Ck. Critical Dimensions Ck. Wt. & Critical Dimensions Ck. Physical Condition Ck. Wear & Critical Dimensions Ck. Critical Dimensions Ck. Critical Dimensions Ck. Planeness of Edge Ck. Weight Ck. Weight Ck. Diameter Ck. Outside Diameter Ck. Diameter Verify

Interval (Month) 12 12 12 12 24 4 24 12 12 6 12 12 24 6 12 12 12 12 12 12

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Compression or Loading Device Ovens Sieves Dial Gages, LVDTs, Micrometers Pressure Gages and Transducers Load Cells Flow Meters Thermal Meters and Transducers Sonic Transducers Verify Load Indications Verify Temperature Settings Check Physical Condition Verify Indications Calibrate Calibrate Calibrate Calibrate Verify Document Revised: June 22, 2012 Page 15 of 17 12 4 6 6 6 12 12 12 6

TABLE 1 Bituminous Materials Test Equipment ASTM D3666

EquipmentTest Method Saybolt ViscometersD 244 Mechanical Shakers General Purpose Balances, Scales and Weights Temperature Measuring Devices D5, D70, D113, D2041, D2170, D2171, D3142, D4402, D6648, D2872, D6521 Analytical Balances and Weights Compression Testing Machine D1074, D1075, D1559, D1560 CA Kneading CompactorD1561 TimersD2170, D2171 Ovens Penetrometer and Accessories D5 Calibrate Calibrate Calibrate Calibrate Calibrate Calibrate Temperature Settings Calibrate Dial and Ttimer Accuracy and Verify Needle Condition 6 12 12 24 6 12 12 6 Requirement Calibrate Verify Sieving Thoroughness Calibrate Interval (Month) 36 12 12

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 16 of 17

TABLE 1 Bituminous Materials Test Equipment ASTM D3666

EquipmentTest Method Ductility MachineD113 TFO and RTFO OvenD1754, D2872 Sieves Molds, Followers, Calibration CylindersD1560, D1561 Molds, Manual Compaction Hammers, Breaking Heads D1559 Requirement Verify Molds and Speed of Travel Verify Shelf/Carriage Rotation Speed and Temperature Verify Physical Condition Verify Critical Dimensions Verify Critical Dimensions and Mass of Hammer Molds and PlungersD1074 Brass Rings and Assembly D36 PycnometersD70 Collars and FloatsD139 FlowmetersD1856, D2872 Molds and TampersC128 Flash Cups D92, D3143 Rotary TransducersD4402 Pressure and Vacuum GagesD6521 Stainless Steel BeamsD6648 Standard MassesD6648 Internal BalancesD6307 Verify Critical Dimensions Verify Critical Dimensions Calibrate Critical Dimensions Verify Critical Dimensions Calibrate Verify Critical Dimensions Verify Critical Dimensions Verify with a Reference Fluid Calibrate Verify Dimensions Verify Masses Calibrate 12 12 12 12 12 12 12 6 12 12 12 12 Interval (Month) 12 12 6 12 12

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

American Association for Laboratory Accreditation

C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

Document Revised: June 22, 2012 Page 17 of 17

Document Revision History

Date

12/21/2011 02/07/2012 06/22/2012

Description - Added CAB Information Block - Added requirement on Page 10 of 2 years min for A2LA which supersedes D3666 - Updated current versions of C1077-11, D3740-10, E329-11b - Added C1093-11 to checklist - Added most recent editions of C1077-11A, D3740-10, D3666-09, E329-11b, E543-09, - Added requirements of C1093-11

L:\Checklists\C210 Specific Checklist: Construction Materials Testing Laboratory Accreditation Program

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Appen E - Work in Progress Audit Checklist ExampDocument9 pagesAppen E - Work in Progress Audit Checklist ExampGovind Shriram ChhawsariaNo ratings yet

- 18 WDC 16 06 F1ConstEqptInspCklst 2Document2 pages18 WDC 16 06 F1ConstEqptInspCklst 2Govind Shriram ChhawsariaNo ratings yet

- AB-518b Quality Manual and Audit ChecklistDocument25 pagesAB-518b Quality Manual and Audit ChecklistAnousack KittilathNo ratings yet

- Ministry of The Environment Waste Form Report of A Waste Audit Large Construction and Demolition ProjectsDocument8 pagesMinistry of The Environment Waste Form Report of A Waste Audit Large Construction and Demolition ProjectsGovind Shriram ChhawsariaNo ratings yet

- Construction AuditDocument5 pagesConstruction AuditMohammed Mujahid100% (1)

- MEX 011 Contractor Management Audit ChecklistDocument22 pagesMEX 011 Contractor Management Audit ChecklistGovind Shriram ChhawsariaNo ratings yet

- Safety Audit Checklist For RoadworksDocument13 pagesSafety Audit Checklist For RoadworksGovind Shriram ChhawsariaNo ratings yet

- Force MajeureDocument13 pagesForce MajeureGovind Shriram ChhawsariaNo ratings yet

- Decision Self Audit Form: Administrative AppealsDocument3 pagesDecision Self Audit Form: Administrative AppealsGovind Shriram ChhawsariaNo ratings yet

- Property ProgramDocument18 pagesProperty ProgramGovind Shriram ChhawsariaNo ratings yet

- Structural Analysis - I PUDocument2 pagesStructural Analysis - I PUGovind Shriram ChhawsariaNo ratings yet

- Chapter 23Document7 pagesChapter 23Govind Shriram ChhawsariaNo ratings yet

- CV GovindDocument9 pagesCV GovindGovind Shriram ChhawsariaNo ratings yet

- Mapping Grid - Mechanics of Solids GTU FinalDocument3 pagesMapping Grid - Mechanics of Solids GTU FinalGovind Shriram ChhawsariaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Project Report On DMRCDocument22 pagesA Project Report On DMRCRahul Mehrotra100% (1)

- XZDD Asterms - and - Conditions PDFDocument1 pageXZDD Asterms - and - Conditions PDFTanmay Achal JonnadulaNo ratings yet

- ST 010 ISBT 128 Standard Product Description Code Database v6.0.0Document34 pagesST 010 ISBT 128 Standard Product Description Code Database v6.0.0Patrick Ramos100% (1)

- IHGStandards-IHG Technical SpecificationsDocument36 pagesIHGStandards-IHG Technical Specificationsatlcomputech100% (2)

- Chapter 3 - Bending MembersDocument41 pagesChapter 3 - Bending MembersSuhailah SuhaimiNo ratings yet

- G3616 Gas Engine Electrical System: Mids AdvisorDocument2 pagesG3616 Gas Engine Electrical System: Mids AdvisorDiego Ruben PalavecinoNo ratings yet

- IV-series-monitor Monitor Um 440gb GB WW 1027-3Document360 pagesIV-series-monitor Monitor Um 440gb GB WW 1027-3Quang DuyNo ratings yet

- Truwater - TCM SeriesDocument12 pagesTruwater - TCM SeriesnkhhhNo ratings yet

- Honda Fit Timing ChainDocument14 pagesHonda Fit Timing ChainJorge Rodríguez75% (4)

- 01-25 OB Bbs 3 Year Preboard 2076Document1 page01-25 OB Bbs 3 Year Preboard 2076Reestam SD100% (1)

- Six Tsakalis Pedal ManualDocument1 pageSix Tsakalis Pedal ManualAdedejinfoNo ratings yet

- KBC Nano in English PDFDocument57 pagesKBC Nano in English PDFBHUKKAD BOX100% (1)

- SSMT Solution ManualDocument12 pagesSSMT Solution ManualPraahas Amin0% (1)

- Click and Learn How To Get Free TikTok FansDocument4 pagesClick and Learn How To Get Free TikTok FansFreedmanMcFadden9No ratings yet

- Pharma MarketingDocument55 pagesPharma MarketingArpan KoradiyaNo ratings yet

- Sony NX Series PDFDocument62 pagesSony NX Series PDFMaya Tes0% (1)

- Swaroop (1) ResumeDocument4 pagesSwaroop (1) ResumeKrishna SwarupNo ratings yet

- List of RDSO Coaching DrawingsDocument21 pagesList of RDSO Coaching DrawingsShubhav Manav0% (2)

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokNo ratings yet

- Oracle9i Database Installation Guide Release 2 (9.2.0.1.0) For WindowsDocument274 pagesOracle9i Database Installation Guide Release 2 (9.2.0.1.0) For WindowsrameshkadamNo ratings yet

- G 342 Engine Part 1 PDFDocument26 pagesG 342 Engine Part 1 PDFharley florezNo ratings yet

- Cambridge Ordinary LevelDocument4 pagesCambridge Ordinary LevelHaziq AfzalNo ratings yet

- Aspect Oriented ArchitectureDocument43 pagesAspect Oriented ArchitectureerzhanbaiNo ratings yet

- Core Insights: Advances in 12G-SDIDocument3 pagesCore Insights: Advances in 12G-SDIHedsdasNo ratings yet

- Block Diagram: PowerDocument96 pagesBlock Diagram: PowerBrennan GriffinNo ratings yet

- LECTURE 6-Forming and Shaping of Plastics and CompositesDocument52 pagesLECTURE 6-Forming and Shaping of Plastics and CompositesM.k. VarmaNo ratings yet

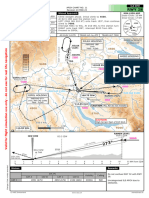

- LSZH Apch11 Rwy28 IlsDocument1 pageLSZH Apch11 Rwy28 Ilssamykarim2009No ratings yet

- ASME VIII Unfired Vessel Relief ValvesDocument53 pagesASME VIII Unfired Vessel Relief Valvessaid530No ratings yet

- SMA Inverter Catalogue PDFDocument290 pagesSMA Inverter Catalogue PDFxodewaNo ratings yet